Abstract

Spectroscopic ellipsometry is a potent method that is widely adopted for the measurement of thin film thickness and refractive index. Most conventional ellipsometers utilize mechanically rotating polarizers and grating-based spectrometers for spectropolarimetric detection. Here, we demonstrated a compact metasurface array-based spectroscopic ellipsometry system that allows single-shot spectropolarimetric detection and accurate determination of thin film properties without any mechanical movement. The silicon-based metasurface array with a highly anisotropic and diverse spectral response is combined with iterative optimization to reconstruct the full Stokes polarization spectrum of the light reflected by the thin film with high fidelity. Subsequently, the film thickness and refractive index can be determined by fitting the measurement results to a proper material model with high accuracy. Our approach opens up a new pathway towards a compact and robust spectroscopic ellipsometry system for the high throughput measurement of thin film properties.

Similar content being viewed by others

Introduction

For semiconductor processing, such as in the manufacturing of integrated circuits and flat display panels, to ensure processing quality and efficiency, it is crucial to accurately measure the thickness and optical constant of nanometer-scale thin films in a high throughput1,2,3,4. Instruments such as white-light interferometers, scanning electron microscopes, and atomic force microscopes may allow the measurement of film thickness with high accuracy, yet they have a relatively slow measurement speed and high system complexity. The measurement may also require direct contact with the sample under test. Spectroscopic ellipsometry is an alternative method that enables highly accurate and non-destructive measurements of thin film thickness as well as its optical constant, which has been widely implemented in semiconductor metrology and process monitoring5,6,7.

In a typical spectroscopic ellipsometry system, it first measures the change in the polarization state of light reflected from the thin film under test. The wavelength-dependent complex reflectance ratio \(\rho\) between p- and s-polarized light, or the ellipsometry parameters of the thin film is written as,

where tan(Ψ) and Δ represent the amplitude ratio and phase difference, respectively. After experimentally obtaining the ellipsometry parameters, it is fitted to a theoretical model to eventually determine the thin film thickness and optical constant.

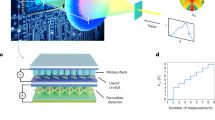

A conventional spectroscopic ellipsometer typically modulates the polarization state via mechanical rotation of the compensator or analyzer8,9,10, which may result in a large size and its sensitivity to mechanical vibration noise. To realize polarization modulation without moving parts, one may resort to photoelastic or electro-optic effects11. Single-shot Stokes ellipsometry12 has also been demonstrated based on the division-of-amplitude method using multiple beam splitters and polarizing prisms. For the spectral detection, an ellipsometer often uses a grating-based spectrometer13,14. The combination of fast polarization modulation and multichannel spectral detection have enabled real time ellipsometry measurements3,15,16 towards various applications17. Nonetheless, a typical spectroscopic ellipsometer, as shown in Fig. 1a, requires a cascade of polarization-modulation and spectral detection system. Recently, alternative methods, such as dual-comb spectroscopic ellipsometry18,19, have been proposed to partially address the abovementioned issues. However, dual-comb spectroscopic ellipsometry may have a limited spectral range for measurement, requires high-cost light sources, and also does not permit single-shot measurements.

a Schematics of a conventional spectroscopic ellipsometry system equipped with a compensator, a mechanically-rotating analyzer, and a grating-based multi-channel spectrometer. The thickness d and refractive index n of the thin film can be determined by fitting the measured ellipsometry parameters with a theoretical model. b Schematics of a metasurface array-based single-shot spectroscopic ellipsometry system. The metasurface array, with each unit cell designed to support anisotropic and spectrally-diverse response, is used to encode the full Stokes polarization spectrum of light reflected from the thin film onto a CMOS image sensor. The ellipsometry parameters can be computationally reconstructed and used to determine the thin film properties. CMOS complementary metal-oxide semiconductor

Metasurface20,21,22,23,24 is an emerging class of planar optical elements that allows extremely versatile manipulation of the amplitude25,26, phase27,28, polarization29,30,31, and spectrum32,33 of light at the subwavelength scale. Therefore, it may offer a new route toward constructing compact single-shot spectropolarimetric measurement systems. Recently, polarization-sensitive metalens arrays34,35,36,37 and metasurface-based polarization gratings38,39,40 have been utilized to build single-shot full Stokes polarization detection and imaging systems. On the other hand, to realize a compact spectrometer, one may design a metasurface-based narrowband filter array41,42, with each filter responsible for transmitting a specific wavelength. Yet, a narrowband filter array intrinsically has a low light throughput. More recently, there has been a growing interest to develop metasurface-based miniaturized spectrometers43,44,45,46,47 and hyperspectral imaging systems48,49,50,51 based on computational reconstruction. In this approach, a metasurface filter array with a random spectral response is coupled with an iterative optimization algorithm or deep learning to reconstruct the spectrum, thus offering a higher light throughput and less stringent metasurface design requirement. For metasurface-based computational spectrometers, one of the prerequisites of the robust reconstruction of the spectral information is the construction of a filter array with a low spectral correlation and the accurate calibration of the filter response. However, due to the angle- and polarization-dependent response of most metasurface-based filters, accurate spectral reconstruction may become rather challenging for generic applications that involve light with a wide range of incident angles and polarization states.

Some recent studies have also aimed at using metasurface for simultaneous spectropolarimetric detection52,53,54,55,56,57. For instance, a metasurface-based polarization grating has been utilized for splitting light with different spectral and polarization components in the spatial domain52,53. However, similar to a conventional grating-based spectrometer, spectropolarimetry based on polarization grating has a fundamental tradeoff between the optical path length (system form factor) and the spectral resolution. We recently demonstrated computational spectropolarimetry based on a tunable liquid crystal-integrated metasurface57, yet it requires active tuning elements and does not allow single-shot measurement. In addition, its spectral measurement range is limited to the near-infrared range.

In this work, we propose and experimentally demonstrate a single-shot spectroscopic ellipsometry system using a passive silicon-based metasurface array for spectropolarimetric encoding in the visible frequency regime, with the system schematically depicted in Fig. 1b. The metasurface unit cell is meticulously designed to exhibit rich and anisotropic spectral features. Combining a single-shot measurement taken by the CMOS sensor with a straightforward iterative optimization algorithm, the full Stokes polarization spectrum of light reflected by the thin film can be reconstructed in high fidelity. Subsequently, the thickness and refractive index of the thin film can be obtained by fitting the measured ellipsometry parameters with a theoretical model. For the proposed ellipsometry system, light impinges on the metasurface filter array at a near-normal incident angle, resulting in a well-calibrated filter response, thus allowing the robust reconstruction of the spectropolarimetric information.

Results

The detailed working principle of the metasurface array-based spectroscopic ellipsometry is schematically illustrated in Fig. 2. The full Stokes polarization spectrum of light impinging on the metasurface array can be expressed as \(\mathop{S}\limits^{ \rightharpoonup }\)(λ) = [s0(λ), s1(λ), s2(λ), s3(λ)]T. The metasurface array consists of N elements and its polarization-dependent transmittance spectrum can be described by a Mueller matrix M(λ), which is a function of the wavelength λ. The transmitted light with its intensity recorded by the CMOS sensor corresponds to the first element s0 in a Stokes vector, which can be expressed as,

where \({\mathop{I}\limits^{ \rightharpoonup }}_{{\rm{out}}}\) is an N × 1 vector; l is the number of spectral channels; M0 = [m00, m01, m02, m03] is the first row of M(λ) (Supplementary Section 1). By minimizing the cost function with regularization, the full Stokes polarization spectrum can be reconstructed as,

where k is the regularization coefficient. Subsequently, the ellipsometry parameters can be calculated from \(\mathop{S}\limits^{ \rightharpoonup }\) as (Supplementary Section 2),

The prototype consists of a single-layer metasurface array integrated on top of a CMOS image sensor. The Mueller matrix of the metasurface array (M0) is pre-calibrated. Together with the measured intensity on the imaging sensor (Iout), the full Stokes polarization spectrum of the incident light can be reconstructed by a convex optimizer with l2-regularization. In the following, the reconstructed full Stokes polarization spectrum can be converted to the ellipsometry parameters for the determination of thin film thickness d and refractive index n by fitting the measurement with a multi-beam interference model

After obtaining the ellipsometry parameters, the remaining steps for the determination of thin film properties are identical to that of a conventional ellipsometry system. We can first build a multi-beam interference model for the multilayer thin film stack under test and choose a proper material model to estimate the theoretical ellipsometry parameters (Supplementary Section 3). Thereafter, by minimizing the difference between the measurement and the theoretical estimation, one can determine the thickness d and refractive index n of the thin film.

In such a framework, the key to the accurate reconstruction of the ellipsometry parameters and thin film properties is to design a metasurface array with highly anisotropic and diverse spectral features58,59, such that the correlation coefficient of each row of the Mueller matrix can be minimized. In this work, each element of the 20 × 20 metasurface array is made of 300-nm-thick silicon nanopillars on a sapphire substrate. The geometry of each element is optimized by minimizing the correlation coefficient of M0 among different elements (Supplementary Section 4). Furthermore, we analyzed the system’s tolerance to fabrication errors, and confirmed that it is highly robust against fabrication errors, as long as the Mueller matrix of the fabricated metasurface array is carefully recalibrated. (Supplementary Section 5).

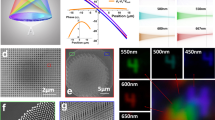

To experimentally demonstrate the metasurface array-based spectropolarimetric detection system, we assembled a prototype as shown in Fig. 3a. The metasurface array comprises 20 × 20 elements with a total size of 1.5 × 1.5 mm2. The metasurface array was fabricated via the standard electron-beam lithography and reactive-ion etching process on a silicon-on-sapphire substrate (see Methods). The metasurface array was integrated onto a CMOS image sensor (Sony IMX-183) with a 5-μm-thick optically clear adhesive tape. The photograph of the metasurface array and 4 representative scanning electron microscopy images of the metasurface elements are shown in Fig. 3b, c, respectively.

a Photograph of the metasurface array-based spectroscopic ellipsometer. Zoom-in photograph (b) and SEM images (c) of the fabricated metasurface array. d Full Stokes polarization spectra of narrowband light sources (with wavelength ranging from 520 nm to 680 nm in a 20-nm-interval, and with random polarization) measured with the metasurface array-based spectropolarimetric detection system (solid lines) compare with the ground truth measured with a quarter-waveplate, a rotating polarizer, and a conventional grating-based spectrometer (black dashed lines). e Reconstructed full Stokes polarization spectrum of linearly polarized light with dual spectral peaks separated by 8.7 nm measured with the metasurface array-based spectropolarimetric detection system (blue solid line) compare with the ground truth measured with a quarter-waveplate, a rotating polarizer, and a conventional grating-based spectrometer (red dashed line). The peak wavelengths are highlighted by the black dashed line. SEM scanning electron microscopy

To calibrate M0 of the metasurface array, we used a tunable monochromatic light source sampled at a 1-nm-interval across the spectral range from 500 nm to 700 nm (see Methods and Supplementary Figs. S14–S15). To evaluate the spectropolarimetric reconstruction performance of the system, we first reconstructed several spectra with simple narrowband features and with varying polarization states. As depicted in Fig. 3d, the reconstructed full Stokes polarization spectra agree very closely with the ground truth. The reconstruction error is quantitatively evaluated using the root mean square error \(({\rm{RMSE}})={{||}\frac{\mathop{S}\limits^{ \rightharpoonup }-\mathop{S{\prime} }\limits^{ \rightharpoonup }}{4\times v}{||}}_{2}\), where \(\mathop{S}\limits^{ \rightharpoonup }\) is the normalized ground truth, \(\stackrel{\rightharpoonup}{S^{\prime}}\) is the normalized reconstruction result, and v is the number of sampled spectral channels. The average peak-wavelength error, linewidth error, and RMSE, of the measured spectra are 0.17 nm, 0.33 nm, and 1.87%, respectively.

To further assess the system’s capability to resolve fine spectral features, we prepared a linearly-polarized incident light with a double-peak spectrum by combining a semiconductor laser emitting at a wavelength of 653.5 nm with a white-light source coupled to a monochromator. As shown in Fig. 3e, the metasurface array-based spectropolarimetric detection system can clearly distinguish double spectral peaks at 653.5 nm and 662.2 nm separated by 8.7 nm. With a smaller spectral separation, the reconstructed spectrum gradually deviates from the ground truth (Supplementary Fig. S16). The relatively low spectral resolution of the system, which is lower than the theoretical resolution (Supplementary Section 6), may be due to the inaccurate calibration of the Mueller matrix and the deterioration in the anisotropic spectral response of the experimentally realized metasurface array. This issue may be addressed via inverse design60,61,62 of freeform metasurface unit cells with further decreased correlation and by more accurate calibration of the Mueller matrix. Despite the moderate spectral resolution of our system, it is worth noticing that the complexity of the full Stokes polarization spectrum of a thin film is a function of the film thickness and refractive index. For most thin films with a moderate thickness (<1000 nm) and refractive index (<3), the ellipsometry parameters can still be reconstructed with high fidelity.

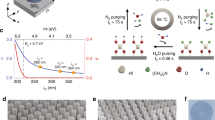

Finally, to experimentally demonstrate spectroscopic ellipsometry measurement, five SiO2 thin films with thicknesses ranging from 100 nm to 1000 nm deposited on a silicon substrate were selected as samples for testing, similar to the protocol in ref. 8. White light emitted from a halogen lamp, after passing through a 45° linear polarizer, impinged on the thin film samples at a 60° incident angle, close to the Brewster angle, to ensure significant polarization conversion. The reflected light from the thin film impinged on the metasurface array at normal incidence (Supplementary Fig. S17). The reconstructed full Stokes polarization spectra of two representative SiO2 thin films with thicknesses of 100 nm and 1000 nm are shown in Fig. 4a, b, respectively, which are compared to the ground truth measured with a quarter-waveplate, a rotating polarizer, and a conventional grating-based spectrometer, showing excellent agreement. Reconstructed spectra for thin films with other thicknesses can be found in Supplementary Fig. S18. A decent average RMSE of 4.5% was obtained for the five measured SiO2 thin films.

Comparison between the reconstructed full Stokes polarization spectra from the single-shot spectroscopic ellipsometer (blue solid line) and the ground truth (red dashed line) for SiO2 thin film with a thickness of 100 nm (a) and 1000 nm (b), respectively. The ground truth is measured with a quarter-waveplate, a rotating polarizer, and a conventional grating-based spectrometer. Comparison among the ellipsometry parameters Ψ and Δ from the single-shot spectroscopic ellipsometer (blue solid line), the ground truth (red dashed line), and the theoretical estimation (orange dots) for SiO2 thin film with a thickness of 100 nm (c) and 1000 nm (d), respectively. The ground truth is measured with a quarter-waveplate, a rotating polarizer, and a conventional grating-based spectrometer. e Comparison of the reconstructed thickness from the single-shot spectroscopic ellipsometer with the ground truth thickness from the commercial spectroscopic ellipsometer for five SiO2 thin films under testing. f Comparison of the reconstructed refractive index (red dots) from the single-shot spectroscopic ellipsometer with the ground truth (blue grids) from fused silica refractive index data in commercial spectroscopic ellipsometer for five SiO2 thin films under testing

Subsequently, the full Stokes polarization spectra can be converted to the ellipsometry parameters Ψ and Δ. The converted ellipsometry parameters of the SiO2 thin film with thicknesses of 100 nm and 1000 nm are shown in Fig. 4c, d, respectively, which are compared with the ground truth and the theoretical estimation calculated from a three-layer model consisting of air, SiO2, and a silicon substrate. Reconstructed ellipsometry parameters for films with other thicknesses can be found in Supplementary Fig. S18. By minimizing the squares error of the reconstruction and the theoretical estimation of Δ, the thickness and refractive index of the SiO2 thin films can be determined. The comparison between the film thickness reconstructed from our system and the measurement from a commercial spectroscopic ellipsometer (JA Woollam, V-VASE) is shown in Fig. 4e. Using the measured thickness from the commercial spectroscopic ellipsometer as the ground truth, the accuracy of the thickness measurement, defined as the relative error between the reconstructed film thickness and the ground truth, is only 2.16% on average for the five SiO2 thin films. The precision of the thickness measurement, defined as the standard deviation in the 10 measurements within a 10-minute timeframe, is only 1.28 nm on average for the five SiO2 thin films (Supplementary Fig. S19). In the fitting process, the refractive index of the SiO2 thin films was assumed to follow the Cauchy model as \(n=A+\frac{{B\lambda }^{2}}{{\lambda }^{2}-{C}^{2}}-{D\lambda }^{2}\), where A, B, C and D are the fitting parameters63. The reconstructed refractive index dispersions for the five SiO2 thin films are shown in Fig. 4f, with an average accuracy and precision of 0.84% and 0.0032, respectively (Supplementary Fig. S19). The entire computational reconstruction process was implemented in MATLAB, taking ~800 ms to reconstruct the full Stokes polarization spectrum and ~200 ms to reconstruct the thin film thickness and refractive index on a desktop computer equipped with an AMD Ryzen 7 3700x CPU and 32 GB RAM. To further enhance the speed and accuracy of the reconstruction, one may implement deep learning-based algorithms for both steps45,48,64,65.

Discussion

In conclusion, we have proposed and experimentally demonstrated a new type of metasurface array-based spectroscopic ellipsometry system for the single-shot measurement of thin film properties. Compared to conventional spectroscopic ellipsometers, our system has no mechanical moving parts or phase-modulating elements, Consequently, it may enable high-throughput, online measurement of thin film properties in semiconductor processing, such as in a thin film etching or deposition system. In the current prototype, we only reconstructed the thickness and refractive index of a single-layer lossless film. To allow the reconstruction of multi-layer films with losses, the design and fabrication of the metasurface array, as well as the ellipsometry fitting model, shall be further improved (Supplementary Section 7). For the prototype system, the spectral range of the ellipsometry measurement is mainly limited by the low quantum efficiency of the available CMOS image sensor above the wavelength of 700 nm and the high material loss of silicon below the wavelength of 500 nm. To further extend the range, one may select a CMOS image sensor with a higher quantum efficiency in the near-infrared range or design and fabricate metasurfaces using alternative materials with lower loss across a wider spectral range, such as SiN46. There is no fundamental limitation to extend its application to the UV, IR or THz range. It may also be possible to further simplify the spectroscopic ellipsometry system leveraging wavelength- and polarization-dependent speckle pattern of an inexpensive, commercial optical diffuser, despite that it would require a more careful calibration process and a broadband, spatially coherent light source for illumination. The metasurface array also holds promise for spectropolarimetric imaging, which may further allow the non-destructive characterization of spatially-inhomogeneous thin films.

Materials and methods

Metasurface fabrication

The fabrication of the metasurface was done via a commercial service offered by Tianjin H-Chip Technology Group. The fabrication process is schematically shown in Supplementary Fig. S12. The metasurface array was first patterned on a 300-nm-thick monocrystalline silicon film on a sapphire substrate by the electron beam lithography using a negative tone resist hydrogen silsesquioxane (HSQ). The next step involved transferring the pattern onto the silicon layer using HSQ as the mask via the reactive ion etching process. Finally, the HSQ resist is removed by buffered oxide etchant.

Metasurface characterization

The experiment setup for the calibration of the metasurface array response is schematically shown in Supplementary Fig. S13. A supercontinuum laser (YSL Photonics, SC-Pro-7) was coupled to a monochromator (Zolix, Omni-λ2007i) and a collimation lens to emit collimated light with a narrowband spectrum. To eliminate spatial coherence and the resulting speckles on the imaging sensor, the light passed through a rotating diffuser before reaching the metasurface array. To ensure uniform illumination on the metasurface array, we established a Köhler illumination condition using two lenses with focal lengths of 50 mm and 35 mm, respectively, along with two apertures.

To calibrate M0 of the metasurface array, its transmittance was measured with 0° linear polarization (Tx), 45° linear polarization (T45), 90° linear polarization (Ty), and left-handed circular polarization (Tlcp), respectively. The polarization state of the incident light was adjusted by a polarizer and a broadband quarter-waveplate. For each sampled spectral channel, the grayscale image of the metasurface array was captured by the CMOS sensor. The transmittance was subsequently calculated by dividing the light intensity underneath the metasurface array by the light intensity in a blank region after the subtraction of the background noise. M0 of the metasurface array was then calculated as,

References

McCrackin, F. L. et al. Measurement of the thickness and refractive index of very thin films and the optical properties of surfaces by ellipsometry. J. Res. Natl. Bur. Stand.- A. Phys. Chem. 67A, 363–377 (1963).

Azzam, R. M. A., Bashara, N. M. & Ballard, S. S. Ellipsometry and polarized light. Phys. Today 31, 72 (1978).

Vedam, K. Spectroscopic ellipsometry: a historical overview. Thin Solid Films 313-314, 1–9 (1998).

Kwak, H. et al. Non-destructive thickness characterisation of 3D multilayer semiconductor devices using optical spectral measurements and machine learning[J]. Light: Adv. Manufact. 2, 1 (2021).

Irene, E. A. Applications of spectroscopic ellipsometry to microelectronics. Thin Solid Films 233, 96–111 (1993).

Schubert, M. Infrared Ellipsometry on Semiconductor Layer Structures - Phonons, Plasmons, and Polaritons. (Berlin: Springer, 2004).

Fujiwara, H. & Kondo, M. Real-time monitoring and process control in amorphous/crystalline silicon heterojunction solar cells by spectroscopic ellipsometry and infrared spectroscopy. Appl. Phys. Lett. 86, 032112 (2005).

Collins, R. W. & Koh, J. Dual rotating-compensator multichannel ellipsometer: instrument design for real-time Mueller matrix spectroscopy of surfaces and films. J. Opt. Soc. Am. A 16, 1997–2006 (1999).

Shan, A. et al. High-speed imaging/mapping spectroscopic ellipsometry for in-line analysis of roll-to-roll thin-film photovoltaics. IEEE J. Photovolt. 4, 355–361 (2014).

Petrik, P. & Fried, M. Mapping and imaging of thin films on large surfaces. Phys. Status Solidi (A) 219, 2100800 (2022).

Jellison, G. E. & Modine, F. A. Two-modulator generalized ellipsometry: theory. Appl. Opt. 36, 8190–8198 (1997).

Azzam, R. M. A. Division-of-amplitude photopolarimeter (DOAP) for the simultaneous measurement of all four stokes parameters of light. Opt. Acta: Int. J. Opt. 29, 685–689 (1982).

Lee, J. et al. Rotating-compensator multichannel ellipsometry: applications for real time stokes vector spectroscopy of thin film growth. Rev. Sci. Instrum. 69, 1800–1810 (1998).

Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications. (Hoboken: Wiley, 2007).

Chen, C., An, I. & Collins, R. W. Multichannel mueller matrix ellipsometry for simultaneous real-time measurement of bulk isotropic and surface anisotropic complex dielectric functions of semiconductors. Phys. Rev. Lett. 90, 217402 (2003).

Collins, R. W. et al. Multichannel ellipsometry. in Handbook of Ellipsometry (eds Tompkins, H. G. & Irene, E. A.) (Norwich: William Andrew Publishing, 2005).

Mukherjee, D. & Petrik, P. Real-time ellipsometry at high and low temperatures. ACS Omega 8, 3684–3697 (2023).

Minamikawa, T. et al. Dual-comb spectroscopic ellipsometry. Nat. Commun. 8, 610 (2017).

Zhang, R. X. et al. Dynamic ellipsometry measurement based on a simplified phase-stable dual-comb system. Optics Express 30, 7806–7820 (2022).

Yu, N. F. et al. Light propagation with phase discontinuities: generalized laws of reflection and refraction. Science 334, 333–337 (2011).

Lin, D. M. et al. Dielectric gradient metasurface optical elements. Science 345, 298–302 (2014).

Yu, N. F. & Capasso, F. Flat optics with designer metasurfaces. Nat. Mater. 13, 139–150 (2014).

Yang, Y. M. et al. Dielectric meta-reflectarray for broadband linear polarization conversion and optical vortex generation. Nano Lett. 14, 1394–1399 (2014).

Zhu, Y. et al. Metasurfaces designed by a bidirectional deep neural network and iterative algorithm for generating quantitative field distributions[J]. Light: Adv. Manufact. 4, 9 (2023).

Lee, G. Y. et al. Complete amplitude and phase control of light using broadband holographic metasurfaces. Nanoscale 10, 4237–4245 (2018).

Overvig, A. C. et al. Dielectric metasurfaces for complete and independent control of the optical amplitude and phase. Light Sci. Appl. 8, 92 (2019).

Kwon, H. et al. Single-shot quantitative phase gradient microscopy using a system of multifunctional metasurfaces. Nat. Photonics 14, 109–114 (2020).

Wen, L. et al. Broad-band spatial light modulation with dual epsilon-near-zero modes. Opto-Electron. Adv. 5, 200093 (2022).

Wei, J. X. et al. Mid-infrared semimetal polarization detectors with configurable polarity transition. Nat. Photonics 15, 614–621 (2021).

Dorrah, A. H. et al. Structuring total angular momentum of light along the propagation direction with polarization-controlled meta-optics. Nat. Commun. 12, 6249 (2021).

Shen, Z. C. et al. Monocular metasurface camera for passive single-shot 4D imaging. Nat. Commun. 14, 1035 (2023).

Sautter, J. et al. Active tuning of all-dielectric metasurfaces. ACS Nano 9, 4308–4315 (2015).

Devlin, R. C. et al. Broadband high-efficiency dielectric metasurfaces for the visible spectrum. Proc. Natl. Acad. Sci. USA 113, 10473–10478 (2016).

Zhao, F. et al. Metalens-assisted system for underwater imaging. Laser Photonics Rev. 15, 2100097 (2021).

Ren, Y. Z. et al. Full-stokes polarimetry for visible light enabled by an all-dielectric metasurface. Adv. Photonics Res. 3, 2100373 (2022).

Arbabi, E. et al. Full-stokes imaging polarimetry using dielectric metasurfaces. ACS Photonics 5, 3132–3140 (2018).

Yang, Z. Y. et al. Generalized Hartmann-Shack array of dielectric metalens sub-arrays for polarimetric beam profiling. Nat. Commun. 9, 4607 (2018).

Rubin, N. A. et al. Matrix Fourier optics enables a compact full-Stokes polarization camera. Science 365, eaax1839 (2019).

Shaltout, A. et al. Photonic spin Hall effect in gap-plasmon metasurfaces for on-chip chiroptical spectroscopy. Optica 2, 860–863 (2015).

Pors, A., Nielsen, M. G. & Bozhevolnyi, S. I. Plasmonic metagratings for simultaneous determination of Stokes parameters. Optica 2, 716–723 (2015).

Tittl, A. et al. Imaging-based molecular barcoding with pixelated dielectric metasurfaces. Science 360, 1105–1109 (2018).

Yesilkoy, F. et al. Ultrasensitive hyperspectral imaging and biodetection enabled by dielectric metasurfaces. Nat. Photonics 13, 390–396 (2019).

Wang, Z. et al. Single-shot on-chip spectral sensors based on photonic crystal slabs. Nat. Commun. 10, 1020 (2019).

Yoon, H. H. et al. Miniaturized spectrometers with a tunable van der Waals junction. Science 378, 296–299 (2022).

Yang, Z. Y. et al. Miniaturization of optical spectrometers. Science 371, eabe0722 (2021).

Zhu, Y. B. et al. Compact CMOS spectral sensor for the visible spectrum.Photonics Res. 7, 961–966 (2019).

Cen, Q. et al. Microtaper leaky-mode spectrometer with picometer resolution. eLight 3, 9 (2023).

Zhang, W. Y. et al. Deeply learned broadband encoding stochastic hyperspectral imaging. Light Sci. Appl. 10, 108 (2021).

Xiong, J. et al. Dynamic brain spectrum acquired by a real-time ultraspectral imaging chip with reconfigurable metasurfaces. Optica 9, 461–468 (2022).

Yang, J. W. et al. Ultraspectral imaging based on metasurfaces with freeform shaped meta-atoms. Laser Photonics Rev. 16, 2100663 (2022).

Yako, M. et al. Video-rate hyperspectral camera based on a CMOS-compatible random array of Fabry-Pérot filters. Nat. Photonics 17, 218–223 (2023).

Chen, W. T. et al. Integrated plasmonic metasurfaces for spectropolarimetry. Nanotechnology 27, 224002 (2016).

Maguid, E. et al. Photonic spin-controlled multifunctional shared-aperture antenna array. Science 352, 1202–1206 (2016).

Ding, F. et al. Beam-size-invariant spectropolarimeters using gap-plasmon metasurfaces. ACS Photonics 4, 943–949 (2017).

Chen, Y. T. et al. On-chip spectropolarimetry by fingerprinting with random surface arrays of nanoparticles. ACS Photonics 5, 1703–1710 (2018).

Shinoda, K. & Ohtera, Y. Alignment-free filter array: snapshot multispectral polarization imaging based on a Voronoi-like random photonic crystal filter. Opt. Express 28, 38867–38882 (2020).

Ni, Y. B. et al. Computational spectropolarimetry with a tunable liquid crystal metasurface. eLight 2, 23 (2022).

Wu, C. et al. Spectrally selective chiral silicon metasurfaces based on infrared Fano resonances. Nat. Commun. 5, 3892 (2014).

Wang, S. et al. Arbitrary polarization conversion dichroism metasurfaces for all-in-one full Poincaré sphere polarizers. Light Sci. Appl. 10, 24 (2021).

Molesky, S. et al. Inverse design in nanophotonics. Nat. Photonics 12, 659–670 (2018).

Piggott, A. Y. et al. Inverse design and demonstration of a compact and broadband on-chip wavelength demultiplexer. Nat. Photonics 9, 374–377 (2015).

Wang, S. et al. Metasurface-based solid poincaré sphere polarizer. Phys. Rev. Lett. 130, 123801 (2023).

Herzinger, C. M. et al. Ellipsometric determination of optical constants for silicon and thermally grown silicon dioxide via a multi-sample, multi-wavelength, multi-angle investigation. J. Appl. Phys. 83, 3323–3336 (1998).

Tua, D. et al. Imaging-based intelligent spectrometer on a plasmonic rainbow chip. Nat. Commun. 14, 1902 (2023).

Liu, J. C. et al. Machine learning powered ellipsometry. Light Sci. Appl. 10, 55 (2021).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (62135008, 61975251) and by the Guoqiang Institute, Tsinghua University.

Author information

Authors and Affiliations

Contributions

Y.Y., S.W. and X.X. conceived this work. S.W. and X.X. designed and characterized the metasurface, developed the spectropolarimetric reconstruction algorithm, built the metasurface array-based spectroscopic ellipsometer system, and measured the thin film properties; S.W., X.X., L.S., S.W., Y.N., and Y.Y. analyzed the data; S.W., X.X., and Y.Y. wrote the manuscript. Y.Y. supervised the project.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wen, S., Xue, X., Wang, S. et al. Metasurface array for single-shot spectroscopic ellipsometry. Light Sci Appl 13, 88 (2024). https://doi.org/10.1038/s41377-024-01396-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41377-024-01396-3