Abstract

The global energy crisis is increasing the demand for innovative materials with high purity and functionality for the development of clean energy production and storage. The development of novel photo- and electrocatalysts significantly depends on synthetic techniques that facilitate the production of tailored advanced nanomaterials. The emerging use of pulsed laser in liquid synthesis has attracted immense interest as an effective synthetic technology with several advantages over conventional chemical and physical synthetic routes, including the fine-tuning of size, composition, surface, and crystalline structures, and defect densities and is associated with the catalytic, electronic, thermal, optical, and mechanical properties of the produced nanomaterials. Herein, we present an overview of the fundamental understanding and importance of the pulsed laser process, namely various roles and mechanisms involved in the production of various types of nanomaterials, such as metal nanoparticles, oxides, non-oxides, and carbon-based materials. We mainly cover the advancement of photo- and electrocatalytic nanomaterials via pulsed laser-assisted technologies with detailed mechanistic insights and structural optimization along with effective catalytic performances in various energy and environmental remediation processes. Finally, the future directions and challenges of pulsed laser techniques are briefly underlined. This review can exert practical guidance for the future design and fabrication of innovative pulsed laser-induced nanomaterials with fascinating properties for advanced catalysis applications.

Similar content being viewed by others

Introduction

The rapid growth of population and the development of civilization has led to increased energy consumption along with environmental pollution and energy crisis, which has become a global challenge. Subsequently, the exploration of renewable energy has been significantly accelerated to achieve sustainable development. The development of efficient energy conversion and storage devices and environmental remediation technologies based on electro- and photochemistry is of paramount importance to tackle these challenges1,2,3,4,5,6. However, the abovementioned devices function with different working mechanisms, and their reliability and photo- or electrochemical performances are mainly controlled by the involved active catalytic materials. Thus, the design and synthesis of advanced materials and their implications have been exhaustively investigated.

The earlier decade has identified the prompt expansion of nanoscience and nanotechnology, which emerged as a key discipline due to various applications in practically all fields associated with energy and the environment. Nanomaterials are well defined as material configurations with a size scale in the range of 1–100 nm. The concept of nanotechnology was first introduced by Nobel laureate and American physicist Richard Feynman during the annual meeting of the American Physical Society in 1959. The Japanese scientist Norio Taniguchi first coined the term “nanotechnology” in 1974 to depict the specific production method of materials7,8. The area of nanotechnology was only briefly discussed until the 1980s, and the concept of nanotechnology has taken ground afterward with the prospective for technological advancements.

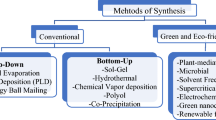

Nanomaterials possess unique properties with specific structures, size, surface-area-to-volume ratio, purity, and composition of the materials. Particularly, photo- and electrocatalytic properties can be advanced by controlling the compositions and structures of the nanomaterials. These unique properties make them efficient and flexible to be used for global needs in diverse energy and environmental applications9,10,11,12,13. Thus, the uniqueness of nanomaterials originates from their synthesis because even a small modification in the synthetic process can lead to a tremendous change in their intrinsic properties. Numerous methods have focused on the fine-tuned synthesis of nanomaterials using new techniques to accomplish distinct architectures, surface structures, size, stability, and chemical composition. However, nanomaterial production development faces several difficulties. Each synthetic method has its merits and demerits. The traditional synthetic methods are often energy- and time-consuming. Conventional chemical (thermal decomposition, chemical reduction, hydrolysis, solvothermal, hydrothermal, and electrochemical methods) and physical (microwave, sonochemical, chemical vapor deposition (CVD), and physical vapor deposition) methods require expensive precursor materials, involve ligand exchange reactions, and generate toxic byproducts or use stabilizing agents/surfactants1,8,14,15. Consequently, the advancement of rapid and facile synthetic techniques for producing highly efficient nanomaterials is expected to overcome the abovementioned issues in conventional synthetic methods and improve the functionality and purity of the products.

In recent decades, pulsed laser-assisted synthesis, which integrates the use of light with nanomaterial synthesis, has drawn numerous attention as an efficient method for the production of several compositions of nano- and submicron-sized materials and holds huge promise for fine-tuning the surface, electronic, and/or crystal structure of nanomaterials. The pulsed laser method uses a laser as an energy source for the reaction of targeted source materials. The interaction of the laser and source materials can be designed in various environments to produce diverse materials2,16,17. The pulsed laser-assisted synthetic route offers many degrees of parameter control (i.e., pulsed laser wavelength, power, reaction time duration, laser pulse repetition rate, and solvent) and possesses several advantages over conventional chemical and physical synthetic routes to control the fine-tuning of size, composition, surface, and crystalline structures associated with catalytic, electronic, thermal, optical, and mechanical properties1,18,19.

In this review article, we mainly focus on recent advances in photo- and electrocatalytic nanomaterials via pulsed laser-assisted synthesis technologies with detailed mechanistic insights and chemical, physical, and structural properties along with effective catalytic performances in various energy and environmental remediation processes. After a concise research overview, we present the importance of pulsed laser-assisted synthesis methods and fundamental concepts in the pulsed laser process, i.e., various roles and mechanisms involved in the production of various categories of nanomaterials, such as metal nanoparticles (MNPs), oxides, non-oxides, chalcogenides, and carbon-based materials. Consequently, the structural optimization/regulation and versatile applications of laser-assisted catalytic nanomaterials for energy conversion, storage, and environmental remediation applications are comprehensively summarized. Finally, the future directions and challenges in pulsed laser techniques are briefly proposed.

Advantages of laser-assisted methodologies

-

1.

The pulsed laser-assisted synthesis is a “green chemistry” process. No surfactants or capping agents are required during the synthesis of nanomaterials, whereas most wet chemical synthetic routes involve surfactants and are often incomplete or poorly reproducible.

-

2.

The absence of surfactants and capping agents is advantageous as these molecules can ligate the surface of atoms and block the catalytically surface-active sites of the particles.

-

3.

No byproducts and toxic reducing agents are needed for the reaction. Hence, the pulsed laser synthesis techniques are environmentally friendly.

-

4.

The experimental setup is simple and minimal, offering a low-cost method.

-

5.

Pulsed laser-assisted synthesis of nanomaterials (<100 nm) with uniform size distribution is exceptionally rapid. The production of the nanomaterials in bulk quantities can take approximately 1 h or less, depending on the laser repetition rate. Scale-up production to grams per hour has been demonstrated, making it appropriate for industrial applications20,21,22.

-

6.

The pulsed laser process can also be used for fabricating inorganic metal complexes and metal-organic frameworks (MOF) or the surface modification of nanomaterials, such as nanoparticles coated with organic molecules, which can be rapidly obtained using a single-step process.

Owing to the above advantages, research on the production of nanomaterials using pulsed laser-assisted technologies has been increasing. Conducting a literature search on the topic based on the Scopus database using the search term “pulsed laser synthesis,” we found 4074 publications with an increasing publication frequency from 1973 to 2021 (Source: Scopus database, searched on August 31, 2021), as shown in Fig. 1a. Notably, the nanomaterials synthesized by pulsed laser methods are mostly concentrated in the “materials science” subject (Fig. 1b), proposing diverse photo- and electrocatalytic applications.

Fundamentals of the pulsed laser process

In 1960, Theodore Harold Maiman designed the first functional laser at Hughes Research Laboratories by focusing a high-power flash lamp on the surface of a silver-coated ruby rod23. Since then, lasers have been broadly utilized in scientific and technological applications. Through scientific advancements, the interaction of the laser and targeted source materials can be constructed in different environments to produce various functional materials. At the beginning of 1965, the ruby laser was applied in vacuum chambers to produce dielectric thin films, which is called pulsed laser deposition (PLD). In the PLD process, the desired material is vaporized from the source of the target in ultrahigh vacuum conditions to create a plasma plume and then deposited on a substrate as a film. The PLD technique is used to fabricate a variety of thin films, including metallic multilayers, ceramic oxides, nitrides, and various superlattices with fine crystalline quality and different textures. Also, PLD validates relatively less costs compared to other thin film deposition techniques such as CVD and molecular beam epitaxy2,16.

Especially, in the last two decades, pulsed laser ablation (PLA) and pulsed laser irradiation (PLI) have been widely applied for the production of various nanostructures. PLA and PLI differ in terms of the interaction of the incident laser beam on the surface of the target source. PLA applies a focus lens at various distances to assemble the laser beam in one spot with ~1 mm size. It can deliver high energy on the designated small spot and leads to target substance evaporation into the solvent to form desired nanostructures. Conversely, the PLI process utilizes no focus lenses and is applied to colloidal solutions rather than solid targets11. In general, the formation of NPs in the PLA in the liquid (PLAL) process occurs via two mechanisms: thermal evaporation and explosive ejection process24. In the thermal evaporation process, the plasma plume and vapor are produced when a focused laser beam is allowed to interact on the surface of the target metal immersed in a liquid (solvent). The element of the target component can be either a single or mixed metal element, or a compound, based on the desired product. Then, the stronger confinement of the plasma plume including ablated materials expands into the liquid environment, which is associated with shockwave emission. Later, the plasma plume cools down during the expansion, and fast energy transfer to the surrounding liquid. This phenomenon produces a cavitation bubble, which then expands and collapses as the bubble extends its maximum radius within a hundred microseconds. During bubble collapse, NPs are released into the liquid environment to form a stable colloidal solution18,25. In the explosive ejection process, where solid fragments and nano- or microsized hot droplets are ejected directly from the target to form NPs. The laser parameters are mainly influenced by the dominating mechanism, i.e., plasma and vapor are generated (thermal evaporation process) when the high energy density of short-pulse lasers is used (nanosecond (ns) pulsed laser with several ns pulse width and power density of 108–1010 W cm−2). Moreover, with the use of low-power density lasers (picoseconds (ps) or femtoseconds (fs) lasers), the fragments/nanodroplets (explosive ejection process) are obtained as the major product24. In the meantime, the nature of the solvent (type of solvent, temperature, and pH) can also affect NP formation.

During the PLI process, the formation of metal or alloy NPs via irradiation of nonfocused laser beams on the concerning metal salts as the precursor solution is ascribed to the optically induced decomposition of solvents without utilizing any other chemical reducing agents, which is called photoreduction. Upon laser irradiation in liquid (solvents: water or organic solvents), solvated electrons (e−liquid) and free radicals such as H•, and OH• are generated (Eq. (1)), where e−liquid and H• act as reducing agents for the reduction of metal salts into corresponding metal NPs, as shown in Eq. (2)1,11.

In the case of organic solvents such as methanol and ethanol, CH3• and CH3CH2• radicals are generated.

If the experimental conditions are appropriately optimized, the PLAL and PLIL processes can produce uniformly distributed and highly stable NPs in a suitable solvent without adding any stabilizing/reducing agents, making them exceptionally advantageous for photo- and electrocatalytic applications. In general, the catalytic performance of nanomaterials strongly depends on their surface chemistry. Even though numerous nanostructured catalysts are attainable using conventional chemical synthesis routes, the catalyst surface is not optimal to enhance photo- and/or electrocatalytic performance or both because of the adsorbed reaction residues or stabilizing molecules, causing “barrier effect.” The ligand-free catalyst surface with high purity is highly advantageous for the interaction/reaction with adsorbents. The catalytic materials produced using the PLAL process are expected to show higher surface coverage than those produced using chemical routes, suggesting that materials with “clean and bare” surfaces are highly preferred for catalytic applications3,24,26. The schematic illustrations of the laser-induced plasma plume and PLD, PLAL, and PLIL processes are depicted in Fig. 2.

The selection of the appropriate laser system is crucial for the production of desired nanomaterials with controlled size and structure. The plasma plume and vaporization rate of the target source material are usually controlled by laser parameters (laser source/wavelength, fluence, pulse width, and pulse repetition rate/frequency), the condition of the liquid environment, and the efficiency of the light absorption behavior of target material.

Laser source/wavelength

The laser wavelength is the main parameter that regulates the absorption efficiency of the fixed target, which can also influence the absorption depth and area of the focusing spot. In the early stage of the PLA synthesis of nanomaterials, an excimer laser in the UV region (ArF for 193 nm, and KrF for 248 nm) is used as a light source, which mostly employs gas as its active medium. With scientific advancements, the process utilized upgraded computer control, a sensor for monitoring the process, and scanning stage technology. Recently, Q-switch pumped pulsed Neodymium-doped yttrium aluminum garnet (Nd:YAG) laser, a solid-state crystal laser, has been commonly utilized for laser ablation since they do not involve hazardous gases. Nd:YAG lasers produce light at a λ of 1064 nm for the first harmonic wave (IR region), which can be altered by utilizing nonlinear optical crystals (e.g., second-harmonic laser λ at 532 nm and third harmonic laser λ at 355 nm).

The laser wavelength determines the penetration depth (skin depth), and subsequently, the depth of ablation on the target. The penetration depth is higher for a higher wavelength of a pulsed laser, i.e., the penetration depth of a 1064-nm pulsed laser in the target is higher than that of the 532-nm pulsed laser (order of penetration depth can be followed as 355 nm < 532 nm < 1064 nm), which suggests that the ablated mass per pulse can increase with the increased pulsed laser wavelength. Furthermore, the laser wavelength strongly influences the produced amount and size of NPs in the PLAL process. In general, the amount (mass) of NPs is higher using a higher pulsed laser wavelength and subsequently, the NP size also increases at a higher wavelength27. Kim et al.28 studied the effect of various pulsed laser wavelengths (355, 532, and 1064 nm) and fluences (8.92 and 19.90 J cm−2) on the size and produced amount of Pd-NPs obtained by the PLA of a Pd target in water. As a result, the average particle size of Pd-NPs was increased with the wavelength at a fixed fluence: 3.56, 4.70, and 6.98 nm Pd-NPs were obtained by 355, 532, and 1064 nm laser wavelength at 19.90 J cm−2 fluence. The particle size increased along with the amount when the fluence increased at a fixed laser wavelength, as shown in Fig. 328. At a lower fluence, the surface atom from the target is removed by evaporation, which leads to NP formation owing to the nucleation of evaporated atoms with uniform size distribution. Conversely, as the fluence increases, high energy is released to the target, which removes the material by melting. The interactions of metal droplets are fragmented by the laser beam and rapid quenching, causing the production of larger NPs with broader size distribution. Thus, the production of a large amount of Pd-NPs upon increasing the laser fluence occurred due to the ablation of the Pd target at high energy28.

a–c At fixed 8.92 J/cm2 fluence with various wavelengths, 355, 532, and 1064 nm, respectively, d–f at fixed 19.90 J/cm2 fluence with various wavelengths, 355, 532, and 1064 nm, respectively28. Copyright (2021) Elsevier

Pulse duration or pulse width

The laser pulse width, which is also called pulse duration, is also an important parameter in material synthesis. Varying it from ns to ps and fs changes the ablation mechanism from thermal evaporation to the explosive ejection process of chemical bond breaking at the target surface. A shorter pulse width results in the efficient ablation process, ensuring rapid evaporation and the smallest heat-affected region29.

Fluence/energy density

The power of a laser is estimated in watts (W), which expresses either the average power of a pulsed laser or the optical output power of a continuous laser wave. Pulsed lasers are also considered by their pulse energy, which is inversely proportional to the laser’s repetition rate or directly proportional to the average power. Energy is estimated in joules (J).

Fluence (F) is defined as the laser energy per unit area (J cm−2) on the target source materials, expressed as F = I/A, where I refers to the laser power in J pulse−1, and A refers to the area of the laser spot on the target source in cm2. The PLAL process expanded to NP synthesis at various energy densities suggesting that the produced amount of materials increases with a higher energy density. Regarding particle size, the growth and nucleation theory can be employed to describe particle size variances based on energy density. The nucleation is challenging at a lower energy density, which leads to a small number of nuclei and bigger particle sizes, whereas nucleation takes place instantaneously in the case of higher energy densities, which leads to a large number of nuclei with smaller particle sizes29.

Pulse repetition rate

The pulsed laser repetition rate is also known as pulsed repetition frequency, which is described as the number of output pulses emitted per second. The repetition rate is inversely proportional to the pulse energy. The impact of the repetition rate can be exactly determined only at fixed pulse energy. The cavitation bubble produced by the first pulse can shield the incident laser beam; in addition, the occurrence of an ablated particle in the path of the successive incident laser pulse reduces the maximum effectiveness of the repetition rate. Hence, some temporal repetition delay is required to permit the transmission of a consequent pulse to the surface of the target source without attenuation of an excessive intensity. Therefore, the optimization of the repetition rate is required at each intensity of the liquid–target source material system27.

Note that the shielding of ablation occurs when the second pulse attains during the first pulse cavitation produced; thus, the second bubble lifetime shortens due to the lower pulse energy in the reduced size of the cavitation bubble. The fluctuation in the cavitation bubble induced by the repetition rate remains there until it reaches the maximum steady state for several pulses27. At the point when the repetition rate is about ≤1 kHz, the produced NP amount increases with the increased repetition rate, even at high pulse energies. However, more sophisticated laser scanners are needed for higher repetition rates27.

Laser-focusing parameters

The condition of the laser focusing point (target position) is a crucial parameter, which influences the size distribution and shape of the NPs. The ablation of the target position can be changed by altering the position of the lens using a micrometer screw, which is attached to the mount of the lens. At a fixed target, the ablation can be performed at three positions (above-focus or defocus, at-focus or focal point, and below focus), as illustrated in Fig. 4.

The average particle size is larger when the target is ablated at the focal point compared to the above-focus and below-focus conditions, while smaller particle size is obtained at the below-focus condition30,31. A detailed study about the effect of target position on the particle size of Au-NPs via PLA was reported by Imam et al.30. During the PLA of the Au plate in water at the above-focus point, an average particle size of around 8.6 nm was obtained with a low yield, which might be due to the low fluence, and breakdown of water (or any solvent) medium does not occur at the above-focus point. When the target is heated at this fluence, the vaporization rate is limited owing to the strong liquid confinement on the target surface. The resulting TEM image and histogram of Au-NPs synthesized by ablation at the above-focus point are shown in Fig. 5a, b. The Au-NPs obtained at the focus condition show an average size of about 8.9 nm with a spherical shape, as depicted in Fig. 5c, d, which is larger than the Au-NPs obtained at the above-focus (defocus) condition. The PLA at the focus point follows the thermal evaporation mechanism, as explained in the section “Fundamentals of the pulsed laser process”. When the target was ablated at the focus point, the temperature, plasma pressure, and density increased compared to those at the defocus condition. The high plasma temperature excites, ionizes, and the surrounding water medium dissociates, initiating the nucleation directly. The increased particle size might be due to the enhanced particle growth and molecular integration by the high plasma density. On the contrary, Au-NPs obtained by below-focus ablation shows a smaller average particle size (~7.2 nm) than those produced at the defocus and focus conditions, as shown in Fig. 5e, f, likely because when the target was ablated at the below-focus condition, the maximum amount of energy was absorbed by the liquid (water) medium, reducing the energy that reaches the target. Another investigation by Nath et al.31 also confirmed this explanation, wherein, TiO2 NPs were prepared via the PLA of the titanium target plate in water at various target positions, and the average size of TiO2 NPs prepared at the focus point was higher than those produced at the defocus (above-focus) and below-focus conditions. The additional information about spot size was also provided, which mainly depends on the target position. The minimum spot size is preferred for effective NP production. The spot size is smaller when the target is ablated at the focus point, while it is larger at the above-focus condition, as shown in Table 1.

a, b above-focus, c, d at-focus, and e, f below-focus conditions30. Copyright (2021) Scientific Research Publishing

Solvent medium

The solvent medium is another important source in PLAL, which can control not only the shape and size of NPs but also the structure and composition of the final product. A detailed explanation of the solvent effect is provided in this section.

Effect on crystal structure

Our research group investigated the effect of various solvents [DI water, methanol, hexane, and acetonitrile (ACN)] on the production of Ni NPs by PLA using a 1064-nm Nd:YAG laser with a focal length of 30 mm, and the PLA reaction was performed for 20 min32. Interestingly, it was identified that the specific solvents resulted in specific Ni NP phases; fcc Ni/NiO and pure fcc Ni NPs were obtained in DI water and methanol medium, respectively, while a mixture of fcc/hcp Ni phases was obtained in both hexane and ACN. The observed results indicated that NP formation during the PLA process is strongly dependent on the solvent medium; as a result, the specific heats of different solvents produce the distinct phases of Ni NPs. We further performed secondary laser irradiation for the obtained colloidal solution for another 20 min and noticed that there were no changes in DI water and methanol samples; however, pure fcc Ni and hcp Ni phases were obtained in hexane and ACN, respectively, and the resulting XRD pattern is shown in Fig. 6. This result can be explained as the phenomena of plasma plume cooling experienced by Ni NPs, which differ significantly for various solvents, leading to different Ni NP phases. During adiabatic expansion and plasma plume cooling, specific heats of the solvents can contribute to nuclei growth and nanocrystal coalescence. Particularly, the high pressure and temperature of the plasma plume induced by the laser are uniquely produced at the interface of the liquid–solid target. Then, the plasma plume condensates at various cooling rates in different confining solvents due to the liquid confinement effect to produce Ni NPs with various phases. Considering the high-temperature and high-pressure region on their thermodynamic phase equilibrium diagram, a high temperature of ~6000 K and high pressure of ~10 GPa are favorable for the production of the metastable phases. In this case, the high cooling rate of the plasma plume in the confined liquid enhances the metastable NPs. Thus, the cooling rate mainly depends on the specific heats of solvents; those with lower specific heat cool the plasma plume efficiently and produce the metastable phase of hcp Ni NPs (specific heats: ACN (2.2 J kg−1) < hexane (2.3 J kg−1) < methanol (2.5 J kg−1) < DI water (4.2 J kg−1)). Furthermore, the NP size is reduced upon second irradiation, resulting in the fragmentation of the formed NPs in the primary ablation and renucleation into smaller sizes. Thus, the additional laser irradiation selectively heats and vaporizes bigger particles, and the consequent rapid cooling of the vaporized particles initiates the production of smaller NPs.

a DI water, b methanol, c hexane, and d acetonitrile32. Copyright (2021) American Chemical Society

The above investigation was further confirmed by our research group with time-resolved dynamics studies of laser-induced cavitation bubbles (LICBs) during Ni NP formation via PLA in various solvents25. Herein, the time-resolved formation of LICBs was measured using an intensified charge-coupled device camera, and it was found that the lifetime of LICBs is dependent on the solvent medium and that the phase of Ni NPs is defined by the LICB lifetime during the PLA process. Especially, the short lifetime of LICBs in ACN leads to the formation of metastable hcp phase Ni NPs, while the long LICB lifetime produced a stable fcc Ni phase in methanol. In detail, the formation of Ni NPs takes place via the plasma plume at high pressure and temperature during PLAL. The phase of Ni NPs is altered according to the plasma plume cooling rate. When the cooling rate is slow, the lifetime of LICBs is long; thus, Ni NPs have enough time to produce thermodynamically stable fcc structures. On the contrary, when the cooling rate of the plasma plume is rapid, the lifetime of LICBs is short, and Ni NPs have a metastable hcp phase. The study of the dynamics of LICBs showed the mainly solvent-dependent lifetime and size of LICBs. The time-resolved images of the LICBs taken during the PLA of the Ni plate for 30 min at various solvents are shown in Fig. 7a; the maximum size of LICBs (2.28, 2.70, 3.36, and 4.0 mm) reached at 201 μs (methanol), 251 μs (DI water), 276 μs (hexane), and 351 μs (ACN), respectively. Consequently, the LICBs began to collapse and disappeared completely at 426, 501, 551, and 651 μs, respectively (Fig. 7a, c), as presented in Table 2. Figure 7b represents the theoretical lifetime value of LICBs based on the Rayleigh–Plesset theory. If they had collapsed before the theoretical lifetime value, the LICBs would have revealed a shorter lifetime, but they disappeared after the theoretical lifetime value, exhibiting a longer lifetime. Herein, the LICBs produced in the ACN medium showed a shorter lifetime, while the LICBs produced in methanol exhibited a larger longer lifetime. As a result, it is confirmed that the lifetime and size of the LICBs highly depend on the solvents used in the PLA process25.

a Time-resolved images of LICBs taken during the PLA of the Ni plate for 30 min in (a) methanol, (b) DI water, (c) hexane, and (d) ACN medium; b theoretical lifetime values of LICBs obtained based on the Rayleigh–Plesset theory; c time-resolved LICB radius evolved during the PLA of the Ni plate in (a) methanol, (b) DI water, (c) hexane, and (d) ACN medium25. Copyright (2021) Elsevier

Effect on composition and morphology

Recently, our research group has investigated the effects of various solvents (DI water, methanol, ethanol, 1-propanol, butanol, ethylene glycol, hexane, and ACN) on the final composition and surface morphologies of Cu-NPs synthesized via the PLA of the Cu target using 1064-nm Nd:YAG (laser energy: 80 mJ pulse−1) for 10 min10. Interestingly, the PLA of the Cu-plate in ethanol, 1-propanol, butanol, and ethylene glycol provided fcc Cu-NPs with a spherical shape, whereas ACN leads to CuCN cubes. The ablation of the Cu-plate in DI water and methanol leads to the formation of Cu2O and CuO with spherical and rod-like structures, respectively, and corresponding high-resolution transmission electron microscopy (HR-TEM) images with lattice distances are depicted in Fig. 8. During the ablation of the Cu target, the high temperature and pressure of the plasma plume lead to the decomposition of solvent molecules, producing O2, H2, free radicals, and carbon-based fragments. Subsequently, the vaporized metal ions condensed and reacted with these species to produce the resulting materials. Thus, the formation of different compositions and morphologies of Cu-based NPs is due to the bond energy differences in various solvents, which play a vital role in solvent decomposition and affects the final products10.

a DI water, b methanol, c ethanol, d hexane, and e ACN. The insets show the TEM images of the resulting products10. Copyright (2021) Elsevier

Methanol can release the OH group by bond breaking between C and O atoms and thus lead to the formation of Cu(OH)2. Then, the decomposition can occur during the PLAL process and form CuO rods. In the case of carbon-rich solvents (ethanol, 1-propanol, butanol, hexane, and ethylene glycol), the binding energy of C1–C2 is lower, which is more favorable to dissociate than that of the C–O bond. As a result, carbon atoms decomposed from the carbon-rich solvents are deposited as the GC layer on the Cu NP surfaces (a more detailed mechanism about carbon layer formation is provided in the section “Solvent as an element source”). The bond length of these solvents is also consistent with the bond breakage orders, where the C–C bond length is longer than that of C–O; hence, the dissociation of the C–C bond can occur earlier than that of the C–O bond. Therefore, the formation of CuO is less favorable in the case of long-carbon-chain solvents. On the other hand, a new phenomenon was observed during the PLA of the Cu-plate in ACN, which led to the formation of CuCN as the predominant product. Thus, the formation of CuCN is due to the generation of the cyano group by the decomposition of ACN solvents, which can form strong complexation with metal ions to form CuCN10.

Further investigation on the formation mechanism of CuCN was conducted by the ablation of the Cu-plate in various nitrile solvents with different binding energies (acetonitrile, propionitrile, and butyronitrile)33. The cube-like CuCN was formed by the reaction of oxidized Cu ions with CN− groups obtained by the dissociation of ACN, whereas other nitriles (propionitrile and butyronitrile) produced spherical graphitic-carbon-covered Cu-NPs (Cu@GC NPs). Thus, the formation of CuCN occurs in ACN only due to the easy accessibility of the CN− group after the dissociation of ACN into CH3+ and CN− by PLA, whereas propionitrile and butyronitrile solvents generate hydrocarbons in large amounts, which can be deposited as GC layers on the surface of Cu-NPs and hinder the interaction of the CN− group with Cu-NPs. The formation mechanism was also confirmed by the theoretical quantum chemical calculations on the binding energy of various nitrile solvents, as presented in Fig. 933.

Solvent as an element source

Its commonly known that the free radicals are produced by the decomposition of solvents during the laser irradiation/ablation process, which can act as reducing agents. Also, carbon-rich solvents can be decomposed during laser ablation and condensed as a carbon layer on the NPs. More recently, our group utilized a solvent (DMSO) as a sulfur source for the preparation of ZnS34. In detail, ZnS nanospheres were synthesized by the PLA of the Zn plate in DMSO without using any additional sulfur source, reducing agents, or surfactants. DMSO acted as both a solvent and sulfur source. During the ablation of the Zn plate, Zn2+ ions are generated and vaporized along with the plasma plume and subsequently reacted with the sulfur source obtained by the decomposition of DMSO to form ZnS. Similarly, others have reported the utilization of DMSO as a sulfur source for the one-spot production of various metal sulfides, including cadmium sulfide (CdS), CuS, and tin sulfide (SnS)35,36.

Another report by our research group utilized ACN as a carbon and nitrogen source for the production of N-doped GC-covered Ni NPs (Ni@NGC NPs)37. The Ni target was ablated in various solvents, such as DI water, methanol, hexane, and ACN. As a result, Ni@NiO and Ni NPs were produced in DI water and methanol medium, respectively, whereas GC and Ni@NGC NPs were produced by hexane and ACN, and the corresponding TEM and elemental mapping images are shown in Fig. 10.

a methanol, b DI water, c hexane, and d ACN. The insets show the images of the i overall, ii Ni, iii O, iv C, v N, and vi resulting TEM images37. Copyright (2021) Elsevier

During the adiabatic cooling of Ni NPs, the H, C, and N atoms or ions, and CH3+ and CN− ions obtained by the decomposition of the solvents (hexane and ACN) are condensed on the surface of Ni NPs and produce the GC- and NGC-covered Ni NPs37. However, the doping of N is not favorable in all metal NPs, which is strongly based on the solubility of N on the metal. For example, a similar investigation was conducted using Au-NPs, and both hexane and ACN produced the GC layer on the Au-NPs. Thus, the formation of Au@GC NPs rather than Au@NGC NPs in ACN may be ascribed to the fact that the energy formation among the Au atomic lattice is ~5 times higher than that of Ni. The formation energy of N in Au lowers the solubility of N in Au-NPs, making N doping in the GC layer difficult38. It can be suggested that alloy or bimetallic NPs with appropriate solvents such as N or C sources can be obtained by tailoring Metal@NGC or Metal@GC NPs.

The next section describes the key works related to material production via pulsed laser-assisted techniques, especially PLA and PLI processes in liquid media. The effects of laser parameters, such as laser fluency (time duration, pulse width, wavelength, and repetition rate), focusing parameters (target position and focal length), and the liquid medium (type of solvent, plasma plume) on the formation of diverse functionalized nanostructures are discussed.

Photo- and electrocatalytic materials: an overview

PLAL process

In the past decades, the progress of human civilization has been completely centered on fossil fuel exploitation, which has generated substantial crises, such as environmental pollution and global warming39,40. Owing to the sudden growth of the human population, there was an increasing shortage of fossil fuels. To resolve this, scientific community has proposed to upgrade the energy sectors with wide plausible technologies; however, only moderate progress has been made owing to economic deliberations. Therefore, developing inexpensive, clean, green, and renewable energy sources, although challenging, is crucial. In the meantime, the evolution of energy materials equals pivotal, which helps the conversion, storage, and harvest of clean sources. Pulsed laser technology has been vastly used in time-resolved characterization techniques, including fluorescence or transient-absorption spectra, which simplify the progress of basic science. Moreover, in nanomaterial synthesis, the pulsed laser process has been espoused largely in a technology labeled as the PLA. Recently, PLAL has received great interest in photo/electrocatalytic process owing to its several advantages, such as facile experimental setup, ecofriendliness, long-term nanoparticle stability, and lack of undesired impurities or toxic precursors. PLAL is used to fabricate numerous nano- and submicron-sized materials with unique topographies, phases, and structures via a single-step process, realizing their applications in sensors, displays, catalysts, optics, and biological fields. Though numerous works were reported in PLA, the acceptance of this technique in catalysis-oriented applications is relatively undervalued.

Generally, the surface chemistry of the NPs is one of the decisive factors to determine their catalytic activity. Though chemical synthesis was largely applied to achieve metal nanostructures, the NP’s surface is not ideal for the catalytic process owing to firmly adsorbed reaction residues or surface-stabilizing compounds, hindering the catalysis and poisoning the NP catalysts. For such requirements, catalysts with ligand-free surfaces and high purity are highly essential to interact with their adsorbents. In this regard, catalytic NPs obtained using PLAL are shown to retain a five-fold higher surface area coverage than their chemical process counterparts suggesting improved efficiency for the surface interaction with the adsorbents. Thus, metal nanostructures derived using PLAL with clean and bare surfaces are highly desired for catalysis, including photo- and electrocatalytic methods. In this section, the key properties and functions of PLAL-based fabrication of photo- and electrocatalytic nanomaterials, including MNPs, core-shell NPs, oxides, and nonoxide nanomaterials with unique structures, and their salient features are discussed.

Metal nanoparticles

In general, MNPs possess a wide range of specific (optical, electrical, and magnetic) properties compared to their bulk counterparts. These specific properties largely depend on their particle size, distribution, surface structure, and composition. For instance, Si-NPs are highly active in the visible region and photoluminescent at room temperature due to their particle size, which could be used to control the wavelength of emitted light. Interestingly, when their particle size is at the nanometer scale, MNPs possessed unique characteristics, including fluorescence, paramagnetism, ferromagnetism, and spin quantum effect. As mentioned earlier, bottom-up liquid-phase methods (chemical reduction and sol–gel) are used to produce MNPs with well-defined specific nanostructures, whereas bottom-up vapor phase (CVD, PVD) approaches yield high-purity MNPs. Both bottom-up approaches (liquid and gas phases) provide powder MNPs derived from the nucleation of super-saturated species as the end products, and both processes have their own advantages and disadvantages. Henceforth, to fabricate high-purity MNPs with well-defined nanostructure using a cost-effective method, Neddersen et al. introduced the PLA method by ablating the solid-target material by means of a laser energy source41.

Based on the PLA process, numerous works have been devoted to fabricating MNPs in the early 90s. The Au and permalloy (80% Ni–20% Fe) microspheres with diameters of 2 and 1–10 μm, respectively, under ambient conditions, have been generated by Cai et al., which provided a very small mean diameter and good dispersion compared to other conventional flat-surface methods42.

In the upcoming subsections, we focus on the properties, function, and recent advancement of PLAL (ablation in liquids)/PLIL (irradiation in liquid) related metallic NPs in photo- and electrocatalytic processes. We start with the representative examples of the PLAL-based metallic NPs, oxides, and their composites for photo/electrocatalytic processes and then move out to deliver the salient features of PLIL for various catalytic processes. Furthermore, recent developments about using PLAL- and PLIL-driven metal NPs are briefly summarized.

Noble metals

Colloidal noble MNPs are of huge importance for applications in a broad range of disciplines because of their unique optical and electrical properties. Different laser sources and solvents have been reported to synthesize various morphologies of Ag and Au-based nanostructures43,44. For example, Simakin et al. developed nanodisk-shaped Au and Ag with an average diameter of 20–60 nm through the PLAL process without including any counter ions and surface-active agents45. For this process, a Cu-vapor laser was used as an energy source, which ablated Ag and Au targets in water and produced their respective colloidal sols. These Ag and Au-based aqueous sols were further confirmed by the presence of plasmon bands at 400 and 520 nm through UV-vis spectroscopy. Using an Nd:YAG laser source with λ = 1064 nm, a similar type of Ag-NPs was generated by PLAL in different concentrations of NaCl and clear water solutions by Bae et al.46. Compared to other concentrations, 5 mM NaCl led to a particle size between 5 and 50 nm with an average particle diameter of 26 nm. Thus, the presence of Cl− ions in H2O reduced the particle size of NPs, which resulted in improved NP formation during the PLAL process. Ag-NPs fragmented by the absorption of the laser light at 355 nm in 5 mM NaCl solution have been observed to be highly effective. Interestingly, when Ag-NPs were fabricated in acetone at different irradiation times and laser wavelengths (266, 400, 532, and 800 nm), they demonstrated different morphologies ranging from spherical to nanowire. The mechanism for Ag nanowire formation depends on the type of laser light used and the irradiation time. The achieved nanowires had an average size and length of 100 and 600 nm, respectively47. Based on these findings, Fazio et al. developed both solid and colloidal Ag and Au-NPs through the PLA process in water to improve the surface-enhanced Raman scattering (SERS) of conventionally available red organic dyes, such as carmine, bazilwood, madder lake, and dragon’s blood, using an Nd:YAG laser at 532 nm under inert atmosphere48. Using different laser times such as 6 ns, 200 ps, and 60 fs, Ag-NPs with 8 nm have been generated by Boltaev et al. in water and air media49. Their optical properties were studied at two wavelengths and observed the nonlinear absorption coefficient of 3 × 10−5 W cm−1. Vinod et al. synthesized monodispersed Au:Ag-NPs by PLAL for the improved SERS activity. They used an Nd:YAG energy source at two wavelengths (355 and 1064 nm) for ablating target materials50. The highest SERS activity with an enhancement order of about 105 has been achieved for <Au80:Ag20>1064.

Moreover, Pd and Pt are widely employed as automotive and industrial catalysts due to their potential advantages, including selectivity, lifetime, reusability, and activity, especially in energy and environmental areas. When these metals are in colloidal NP form, they can adsorb a huge quantity of ligands because of their large surface area. Like other MNPs, the formation of colloidal Pd-NPs with unique nanostructures depends on various parameters, such as solvents, laser fluence, laser wavelength, surfactants, and irradiation time28. Cristoforetti et al. investigated the effect of surfactant (sodium dodecylsulfate) on the production of Pd-NPs by PLAL using various solvents (ethanol, 2-propanol, acetone, toluene, and n-hexane)51. As a result, Pd-NPs possessed appreciable SERS activity and adsorbed large organic molecules. Nishi et al. testified the behaviors of Pd-NPs obtained by the ablation of the Pd target in the light and heavy water samples52. The average diameter of Pd-NPs produced in the heavy water was much smaller than that of Pd-NPs produced in the light water. Based on the M–H curves, they concluded that the magnetic susceptibility of Pd-NPs produced in the heavy water was larger than that produced in the light water and commercial Pd-NPs. Bonis et al. investigated the dynamics of multiple cavitation bubbles created by femtosecond PLAL of Pd in acetone through a rapid time-resolved shadow-graph process and observed that the size distribution of the laser-induced Pd-NPs is highly related to cavitation bubble dynamics53. The solvent effect using the Pd target in water and methanol/water mixtures using SDS as a surfactant has recently been identified through the PLAL process54. In this process, the spherical Pd-NPs with an average diameter of 27–13 nm have been generated using the Nd:YAG laser with a wavelength of 1032 nm and energy fluence of 40.5–8 J cm−2. Based on the TEM results as shown in Fig. 11, it was observed that the NPs aggregated more in water than in the methanol/water mixture. Also, SDS facilitated the particle size and agglomeration control (Fig. 11). In addition, laser post-irradiation and ultrasonication processes have been employed to redisperse Pd NP precipitates, which greatly enhanced the optical properties. Recently, Au, Pt, and Pd-NPs have been synthesized through the PLAL process in water, demonstrating excellent catalytic behavior under ambient conditions24.

a–f DI water, g–l methanol–DI water mixture, m–o 1 mM SDS. The insets represent their corresponding particle size distributions54. Copyright (2021) Elsevier

Pt and its alloy nanostructures are gaining interest owing to their plausible applications in many catalysis reactions. Between various synthesis routes including hydrogen reduction, radiolysis, and citrate reduction, PLA is one of the cost-effective, rapid, versatile, and green routes to generate Pt and Pt-based compounds at the nanometer scale. Recently, the PLAL syntheses of Pt-NPs with different shapes, sizes, and properties have been reported by different research groups55,56. For instance, Mafune et al. developed stable Pt-NPs with the range of 1–7 nm in size distribution through PLA in water using SDS as a surfactant57. In this process, the formation of Pt-NPs in SDS was related to the dynamic formation mechanism58,59. In brief, the laser ablation of the Pt-target in SDS generates the clouds of Pt atoms over the laser spot of the Pt plate surface, which aggregate quickly into small particles of Pt. This process occurs until available Pt atoms are present in the closest vicinity and create more embryonic particles with a diameter of ~2 nm. These embryonic Pt-NPs grow by the addition of Pt atoms and diffuse into the void region after the rapid-growth process stops. Similarly, Yan et al. produced hollow micro/nano-Pt particles by the ablation of the Pt-target in water using different laser fluences (2.3–6.8 J cm−2)60. Other colloidal transition MNPs of inexpensive noble metal Ru have also been fabricated by the PLAL method61. Non-noble colloidal MNPs such as Si, Ni, Al, and Zn have also been synthesized through the PLAL process in liquid, as presented in Table 362,63,64,65.

The noble metals, such as Pd, Pt, Ag, and Au, derived from PLA have distinct shape, size, surface plasmon resonance (SPR), zeta potential, and enhanced optical properties, which allow them to be widely used in optics, materials science, and drug delivery.

Alloy and core-shell nanoparticles

Bimetallic or alloy NPs show remarkable performances compared to their monometallic counterparts and have received increasing interest in the scientific community66. For example, Yang et al. correlated the catalytic behavior of NiPt alloy NPs with pristine Ni and Pt-NPs for borazane hydrolysis and demonstrated the high catalytic performance of NiPt-NPs67. Likewise, NiPt and NiRu NPs exhibited improved electrocatalytic performance toward the dehydrogenation of ammonia compared to their individual counterparts68. In addition, the alloy NPs act as multifunctional materials as they comprise the combined properties of the respective individual metals. A typical example of FeAu alloy NPs involves the combined unique properties of Au-NPs, such as SPR and magnetic behavior of Fe NPs, and henceforth finds applications in the magneto-optical and catalysis fields69,70. Furthermore, the added advantage of the bimetallic NPs is that alloying utilizes inexpensive, earth-abundant transition metal ions, which reduce the potential use of noble metals, including Pt and Pd, leading to cost-effective materials.

Among the various alloyed NPs produced by PLAL, Ag-Au is one of the classical examples owing to the similar lattice constants of Ag and Au, which made them completely miscible in the whole concentration range71,72. Furthermore, both Ag and Au-NPs provide strong SPR bands in the visible region, and the SPR of Ag-Au alloy could be altered by changing the ratio of Au/Ag. A series of colloidal Ag-Au alloy NPs with various concentrations have been prepared through the ablation of Ag-Au targets (different concentrations) in water by Barcikowski et al.73. The formation of alloy NPs of certain elements is highly challenging via conventional synthetic routes. For example, it is impossible to form alloys such as Au–Fe and Pt-Fe under ordinary ambient conditions due to their wide miscibility gap. Conversely, the hydrothermal method and wet chemical strategies generally occur near the thermodynamic equilibrium that could provide a hybrid structure of aggregated phases instead of alloy NPs.

As compared to conventional chemical strategies, PLAL is an apt metastable process to conduct alloy formation at extreme conditions, including high-pressure and high-temperature laser plume, and generally, the reaction happens above the thermodynamic equilibrium. Au–Fe-alloy NPs constructed by the PLAL of the Au73Fe27 target in ethanol were investigated for multimodal imaging and diagnostic applications by Amendola et al.74. The formation mechanism of the Fe–Au alloy involves the ejection of melted drops from the target. Further evidence from UV-vis absorption spectra showed that after alloying with Fe, Au-NPs tend to provide SPR peaks with reduced intensity. In the meantime, magnetic study results revealed the strong magnetic responsive nature of the Fe–Au alloy even after introducing a minor amount of Fe in the Au lattice. From the observed data, they firmly concluded that the PLAL method can overcome the thermodynamic limitations and make it more feasible to obtain Au–Fe alloys at ambient conditions. A similar study on the production of spherical Fe–Au alloy NPs using the PLAL process has been reported by Fuse et al.75. In recent years, the colloidal solutions of Pt-NPs–graphene nanosheets, Pt–Ir alloy, and Pt–Au in acetone have been fabricated through femtosecond laser ablation, which can find applications in electrocatalysis, sensors, and energy storage76,77,78. Based on the concepts introduced by Amendola, various alloy NPs including Ni–Fe, Ni–Ti, Sm–Co, Al–Cu–Fe, and Au–Ge have been successfully constructed from their respective targets in liquid media77,79,80. For instance, the fs-laser ablated Pt–Ir alloy NPs formed without stabilizing or chemical agents show an average particle size of ~26 nm. The high stability of the Pt-Ir colloid was revealed by its zeta potential value of ~45 mV and hydrodynamic diameter of ~63 nm, respectively77. Interestingly, the fs-laser ablated NiTi NPs show a large particle size distribution of ~10–200 nm. Furthermore, it showed interesting effects that include the phase transitions of austenite and weak martensite in the generated NiTi NPs. Moreover, the phase transition temperature was much lowered (40 K) than the bulk target79.

Solvents employed in the PLAL process also play a huge role in determining the internal structural constituents of bimetallic NPs. For instance, when water or aqueous media was employed as solvents in the construction of the Au–Fe alloy, it could form Fe3O4 shell over the surface of the Au particle, whereas the introduction of organic media including methacrylate, acetonitrile, or acetone solvents produces Fe@Au core-shell structure without further oxidation of iron. Also, in such a case, no alloy NP formation occurs despite the use of the Au–Fe-target. While combining various compositions of elements in both aqueous and organic media, the core-shell morphology is more predominant, which may be attributed to the solvent–metal and solvent–metal-oxide interactions. It is anticipated that NP formation is more favored during the PLAL process owing to the kinetically controlled process at the initial stage. Then, the internal phase transformation of NPs occurs owing to metal-solvent interaction. While at high temperature and pressure, the cavitation bubbles finally collapse, which leads to NP formation in unstable thermodynamic conditions, favoring the aggregation of phases and core-shell structure. Based on this mechanism, plenty of core-shell NP structures including Zn@ZnO, Au@Al2O3, Ag@SiO2, Fe@FeOx, Fe@C, Au@GC, and Au@CdO have been successfully fabricated through the PLAL process38,81,82,83,84,85. The different physicochemical, morphological, and laser parameters, including the laser sources, solvents, fluences, and irradiation times of PLA-processed metals and alloy materials are provided in Table 3.

In summary, we have discussed the various plausible formations of alloy and core-shell NPs, such as Ag-Au, Au-Pt, Au-Fe, Pt-Fe, Ag@SiO2, and Fe@FeOx from bulk alloy using PLA process in various solvent media. During alloy formation, the PLAL occurs either directly inside the cavitation bubble or plasma plume through the amalgamation and evolution of the NPs. The facile preparation process and controlling NPs size by changing the laser pulses are the major advantages of this versatile PLAL preparation of alloys. In addition, the absence of any unwanted ions/impurities in the final alloy and core-shell product makes this preparation more feasible for making several other metal alloy nanostructures.

Oxide materials

In general, the prime and most common products of the ablation process in liquid media are the metal-oxide NPs obtained through the reaction of ablated target metals with solvent media. As mentioned earlier, during the ablation process in the presence of laser-produced plasma, if the target material is a noble metal (Pt, Pd, Au, or Ag) or materials such as silicon or carbon, pure metal NPs were formed as the end product. This, in turn, means that the chemical reaction of target metals with a liquid medium is highly restricted in such cases. When surfactant or additive agents are introduced in liquid media to stabilize NP formation in such circumstances, metal-oxide or hydroxide NPs are formed as the ablated products. To avoid the aggregation effect and improve the stability of NPs, the use of co-ligand or surfactant is also beneficial in the PLAL process. For instance, Zeng et al. generated ZnO and TiO2 NPs using a 1064-nm Nd:YAG laser to irradiate Zn and Ti-metal targets in an aqueous solution using SDS as a surfactant86,87 and employed them as promising candidates for photocatalytic and photovoltaic applications. A spindle-link β-Ga2O3 NPs could be developed by the PLAL process of the Ga target in water using CTAB as a surfactant by Huang et al.88. Interestingly, using a similar Nd:YAG laser source, metal targets like Ni, Co, and Al in the water itself produce their respective NiO, Co3O4, Al2O3 NPs without the addition of any surfactants through the PLAL process89,90,91.

In certain cases, during the ablation process, the liquid media could also act as targets to absorb laser energy sources and generate colloidal metal-oxide NPs. As an example, Fauteux et al. developed a series of ZnO nanostructures using a new type of CO2 laser source for ablating the zinc acetylacetonate (Zn(AcAc)2, a hydrated metal complex) in water and alcohol solvents, as shown in Fig. 12a, b92. After irradiating with a CO2 laser of λ = 10.6 μm for a few seconds in Zn(AcAc)2 of a water-ethanol solution, it produces ZnO nanorods and nanowires, respectively, along with ZnO NPs near the irradiated place, as shown in Fig. 12b. The formation mechanism for ZnO involves the oriented attachment in which small particles are aggregated to form rod-shaped bigger solid particles through the self-assembly process. Interestingly, the length and width of the formed nanowires change with the irradiation time, as shown in Fig. 12c–f. Especially, the growth of ZnO nanowires was uniform during longer irradiation times and less uniform in the case of shorter irradiation times. Meanwhile, ZnO nanocrystals have been constructed by Henley and his group by means of introducing a novel approach that included the PLAL process in a hydrothermal configuration93. They employed a KrF excimer laser source with a λ of 248 nm to irradiate precursor solutions, zinc nitrate hexahydrate, and hexamethylenetetramine, in DI water to generate the nanocrystals. Furthermore, they observed the growth process of NPs in the presence of laser-induced plasma controlled by Ostwald ripening, which led to bi, tri, or tetrapod-like nanostructures. Based on these concepts, different metal oxides (MOs) and hydroxides NPs, such as CuO, FeOOH, CoO, MgO, and FeO, have been developed94,95,96. A series of MOs and sulfides have been prepared via laser ablation of metal targets in the suitably selected media96. The corresponding MOs, such as CuO, CoO, FeO, ZnO, and MgO with a hollow nanospherical morphology are readily formed in water/ethanol medium through the Kirkendall mechanism. The metal sulfides, including PbS and ZnS, formed by ablating the metal targets (Zn and Pb) in mercaptoethanol provide hollow NPs that confirms that the PLAL is a versatile technique to achieve various nanostructures.

a, b Schematic illustration of the synthesis (laser-induced decomposition) and reaction zone of various ZnO nanostructures, c, d SEM images of ZnO nanowires after laser irradiation with a pulse energy of 20 W for 5 s, and e, f SEM images ZnO nanonails after laser irradiation with a pulse energy of 20 W for 2 s92. Copyright (2021) American Chemical Society

The PLA process of titania (TiO2) NPs is crucial since it is one of the prime candidates for photovoltaic and photocatalytic applications. Seto et al. synthesized TiO2 NPs by irradiating the Ti-metal target using a nanosecond PLA process in an inert He atmosphere97. Tsuji et al. introduced the laser oven process to prepare TiO2 NPs by means of ablating the Ti target in a tubular furnace (O2 atmosphere)98. Furthermore, they controlled the shape and size of the TiO2 NPs by varying the temperature of the tubular furnace, which provided an average particle diameter in the range from 11 to 24 nm at 800–1200 °C. Using Nd:YAG at 1034 nm over the Ti target in water produced TiO2 NPs, which showed excellent photocatalytic and antibacterial activities99. The improved photocatalytic behavior of Ag/TiO2 NPs has been observed by Zhou et al. by means of ablating the Ag and Ti plates in ethanol–water mixture through an Nd:YAG laser (1034 nm)100. Recently, the conversion of anatase TiO2 to rutile TiO2 NPs by varying the surfactant concentration and ablation time in a PLAL process has been reported by Chaturvedi et al.101.

Magnetic NPs comprised of iron-related compounds, especially iron oxide, have received huge consideration for their extensive applications in biomedical, material science, biotechnology, environmental, and engineering fields because of their excellent catalytic, biocompatible, and magnetic behaviors102. Henceforth, the extraction and synthesis techniques of iron-related compounds have become popular in the late 90s. The synthesis of Fe NPs through PLAL is free from toxic starting materials, and they possess outstanding chemical reactivity. Among the different synthesis methods employed, PLAL is one of the finest processes to obtain high-purity iron oxide-based NPs. The preparation of Fe NPs through PLAL has been extensively investigated using different laser fluences, solvents, and irradiation time. Due to the high reactivity of Fe vapors, which react with surrounding liquids during the PLAL process, it can afford various carbonization and oxidation states in a nanosecond. Henceforth, choosing the right liquid medium and laser energy source is highly essential for the formation of Fe NPs via the PLAL process. Amendola et al. derived multifunctional iron oxide NPs from the Fe metal target in a water medium through PLAL103. The magnetic Fe3O4 and Fe3C NPs have been derived from the PLA of the Fe foil in ethanol by Franzel et al.104. The prepared Fe NPs in water and ethanol have possessed the maximum super magnetization values of 80 and 124 emu.g−1, respectively. In this process, the NP formation mechanism comprises small embryonic particle growth followed by their coalescence into macro particles. Following Franzel et al., several research groups have investigated the effects of solvents on the formation of FeOx nanostructures by ablating the bulk targets such as Fe3O4, Fe2O3, and Fe in water which produces their corresponding iron-oxide (FeO, Fe3O4) NPs. Two small particle diameters were achieved through this process including 1 and 5 nm using Nd:YAG laser. The small diameter particles were evenly distributed, whereas large diameter (5 nm) particles were agglomerated, which could disperse uniformly using the protective agent poly(N-vinyl-2-pyrrolidone) (PVP). The dispersity of large particles depends on the PVP concentration. A similar observation has been found for fabricating FeO NPs from the pure Fe target in PVP solution. The particle size of FeO can be controlled by PVP concentration. The optical absorption analysis confirmed the redshift for FeO NPs with improved optical features. They concluded that PLAL is an appropriate technique for the fabrication of dome NPs with special features that conventional techniques could not easily obtain105,106. Recently, Svetlichnyi et al., fabricated a series of iron oxide nanostructures including Fe3O4, Fe2O3, and FeOx via PLA using an Fe-target in water102. Kanitz et al. investigated the ultrashort PLA of the Fe-target in different solvents, including acetone, water, methanol, ethanol, and toluene, and studied the relationship between the liquid properties and the ablation rate on the formation of Fe NPs107. The NPs generated by the ultrashort PLA possessed better polycrystallinity than the short PLA-produced NPs. The significant parameters for the PLAL process that derived FeOx and other metal-oxide nanostructures are tabulated in Table 4.

Similar to Fe, Cu has gained huge attention in the fields of metallurgy, nanoelectronics, optoelectronics, and catalysis owing to its abundance and electrical, mechanical, optical, and catalytic properties. In the late 90s, Jordan et al. studied the laser ablation of the Cu target in water using an Nd:YAG laser operating at a pulse length of 6 ns and wavelength of 532 nm to generate Cu-NPs108. The aging effect of Cu@Cu2O NPs fabricated by the PLA of the Cu-plate in water was systematically investigated by Swarnkar et al.109. The formed cactus-like Cu@Cu2O NPs had a 7-nm diameter with a bandgap energy of 2.24 eV. The same group developed Cu@Cu2O nanowires through PLA in water, which showed improved antibacterial activity110. Few other reports showed the unique morphology of Cu-NPs through the PLA of the Cu target in aqueous solutions111,112,113, which are discussed in detail as follows: The PLA of Cu/Cu2O NPs in ethanol was prepared and studied for the effect of low quantity of acid-base and oxidizing species on the structure, composition, and morphology of the formed NPs. While using water as a solvent in PLA, owing to NaOH and H2O2 species, a cubic Cu2O was formed rather than Cu NPs. The morphologies of the Cu2O could be changed with respect to NaOH and H2O2 in water, such as leaf-like CuO and sheet-like CuO formed during the PLA process on Cu target. These observations undoubtedly confirm that PLA is a major technique to generate different shapes of Cu NPs. However, the ablation efficiency analysis was performed under different numbers of pulses per burst in the range between 1 and 40. It was observed that the ablation efficiency (4.84 µm3 µJ−1) increased by 20% for 3 pulse/burst compared to the nonburst regime. This study provides the advantages of the burst regime for forming PLA-based Cu NPs. Fascinatingly, cube- and nanorod-shaped copper cyanide and Cu2O@graphitic carbon NPs have been developed by the PLA of the Cu-plate in acetonitrile and water by Begildayeva et al.10. Especially, the PLAL-produced Cu2O@graphitic carbon layer showed a superior catalytic reduction of nitrophenol and nitrobenzene.

Based on the discussions mentioned earlier, it is concluded that the nature and properties of stable colloidal MO NPs, such as ZnO, TiO2, Fe3O4, Cu2O, and ZrO2 produced via PLAL depend on the laser fluence, energy, and the number of laser pulses in liquid. The prepared colloidal oxide NPs comprise high absorption and relatively low bandgap values, confirming their better optical properties. For large-scale commercial production, the reusability and stability of these MO NPs should be checked under various laser conditions and solvent media.

Nonoxide materials

Nanometer-sized metal sulfides can be applied to a wide range of applications in several fields, including photocatalysis, antimicrobial activity, energy conversion/storage devices, and optoelectronics, due to their specific physicochemical behaviors. Between various synthesis approaches, the PLAL of metal sulfides is of great interest due to their high quality, simplicity, and product purity. In the beginning, Niu et al. prepared various metal sulfide NPs, such as ZnS, PbS, and CuS, through the ablation process of metal targets in sulfur precursor liquid media, including β-mercaptoethanol, 1-dodecanethiol, and dodecyl mercaptane96,114. The effect of laser fluence on the formation of CuS NPs has been studied by Khademian et al.35. For this process, they used an Nd:YAG laser with 1064 nm at 7 ns pulse to irradiate the Cu target in DMSO, and the prepared CuS exhibited a bandgap between 3.77 and 3.94 eV. Very few reports on the generation of antimony sulfide (SbS), copper-antimony sulfide (CuSbS2), arsenic sulfides (As2S2 and As2S3), and SnS NPs through the PLAL process have recently been reported115,116,117,118. More recently, our group has fabricated ZnS nanospheres using the PLA of the Zn target in DMSO without using any additional sulfur source and reducing agents. DMSO was employed both as a solvent as well as a sulfur source for the production of ZnS34.

Meanwhile, the PLAL process of CdS, a semiconducting material with various nanostructures, including quantum dots, thin films, and nanowires, has been vastly studied. Vitukhnocsky et al. successfully prepared quantum dots of CdS and ZnSe in liquid media (diethylene glycol and ethanol) and achieved average particle sizes between 10 and 20 nm119. Likewise, CdS NPs with outstanding colloidal stability even at high laser fluences have been developed by Gong et al.120. The effect of various laser parameters such as pulse width, wavelength, fluence, and surfactant in liquid, on the formation of CdS NPs has been investigated by Darwish et al.121. Recently, a series of colloidal NPs of CdS, SnS, and CuS have been prepared efficiently by ablating their respective metal targets in sulfur precursors containing DMSO, and their antimicrobial activity against various microorganisms has been studied36.

Owing to their excellent chemical and physical properties, 2D graphene-like MoS2 metal chalcogenides are considered candidate materials for numerous applications. The bonds S–Mo–S appear as a sandwich structure held together by weak van der Waals forces, which can be broken easily. Furthermore, it comprises a sizable intrinsic bandgap for various energy applications. Similar to CdS, MoS2 has also been prepared in different nanoforms through the PLAL process. As an example, the thin films of MoS2 over an alumina substrate have been prepared through the KrF excimer laser ablation process in the early 90s122. A colloidal MoS2 fullerene-like NPs with an average diameter of 10–15 nm has been prepared through the ablation process of the MoS2 target in water by Compagnini et al.123. Also, Li et al. constructed MoS2 quantum dots through the femtosecond PLA process of MoS2 targets in water124. Due to the excellent purity of the prepared single-layered MoS2 quantum dots, it finds plausible electrocatalytic application toward hydrogen evolution reaction. The different physicochemical, morphological, and laser parameters, including laser source, solvents, fluences, and irradiation time of PLA-processed oxides and nonoxide materials are provided in Table 4.

The preparation of metal selenides through the PLAL process is highly complicated due to the high reactivity of selenium and tellurium precursors in liquid media, readily forming their respective oxides. Henceforth, reports on the PLAL process of metal selenide formation have been limited. The type II–IV semiconducting materials such as CdSe, ZnTe, and CdTe NPs with an average radius of 5–6 nm have been produced through the PLAL process in various liquid media by Semaltianos et al.125. Likewise, the spherical NPs of CdSe and CdTe with an average radius of 3–7 nm have been reported by Ruiz et al.126. CdSe quantum dots have been prepared through PLA in superfluid helium by Minowa et al.; they reported the improved luminescence property of the CdSe quantum dots127. The effects of laser parameters on the formation of Ag2Se, PbTe, and AgInSe2 in PLA have also been investigated and reported elsewhere128,129,130. For instance, an innovative laser-based solid-liquid ablation method was used for fabricating silver selenide (Ag2Se) NPs from Se powder and AgNO3 using ethylenediamine and 2-propanol. Homogeneous spherical particles with an average size of 30 nm were formed via this process128. Similarly, well-crystallized PbTe NPs with an average size of 4–6 nm were produced through the PL fragmentation of PbTe bulk powder129. The effects of various experimental parameters, such as treatment duration, wavelength, and output energy have been studied. Though uniformly grown homogeneous particles with specific shapes are formed, their production efficiency is very low.

Here, we summarize the fabrication, laser parameters, and properties of various sulfide, selenide, and telluride NPs by PLAL and discuss their feasibility in various electro and photocatalytic processes. Effects of various laser times (fs and ns), liquid media, and laser wavelengths (532 and 1064 nm) on the shape, optical, and structural properties of the metal halide NPs are summarized in more detail. A few works on the production of metal sulfides and carbon composites without any additional external source for sulfur and carbon because the solvents used in the PLAL act as sulfur (e.g., DMSO) and carbon sources (e.g., carbon-rich solvents like hexane) are discussed. This should be extended to fabricate a wide range of metal sulfides and other nonoxide materials such as carbides and nitrides.

There are some minor disadvantages to the fabrication of metallic nanostructures using PLA. For example, long exposure to laser ablation leads to large quantities of NPs in the colloidal suspension, leading to blocking the laser energy and laser path, which is adsorbed by generated NPs instead of the surface of the metal target. This leads to hinder the rate of PLA process.

PLIL process

Usually, the bottom-up and top-down approaches involve the interactions between electrons, photons, and ions with materials for the construction of metal/metal-oxide nanostructures. Owing to these interactions, there is an energy transfer between the molecules and irradiated material atoms. This section of the review article focuses on using laser–material interactions to control the structure at the nanometer scale. Recently, fast and ultrafast pulsed lasers (ns, ps, and fs) have received considerable attention to draw a new perspective for fabricating NPs. While irradiating with the pulsed lasers, plasmonic NPs could be rapidly heated to high temperatures. Henceforth, the thermal effects as functions of laser wavelength, pulse width, and pulse energy are responsible for melting, fragmentation, and reshaping processes. Various nanostructures, including metal NPs, MOs, metal nanocomposites, carbon, and metal halides, have been assessed for their stability to the PLIL process; however, identifying the particle size and distribution of the resulting nanostructures remains challenging because identifying the structure–stability relationship requires extreme experimentation131. Moreover, the structure–stability phenomenon is a critical tool for understanding the purity, particle compatibility, and firm role in photo- and electrocatalytic applications. Moreover, the structure–stability relationship in the PLIL process is further advantageous for fabricating innovative metal and metal composite nanostructures.

As described earlier in the PLAL process, the laser source is focused on the solid metal target immersed in a solvent, which leads to the evaporation of the materials that are converted into an intensifying plasma plume surrounded by the solvent. On the other hand, PLIL is firmly related to the irradiation of colloidal suspended particles in a solvent medium in which the laser energy is cautiously absorbed by the NPs, which leads to their heating without transferring their thermal energy to the solvent medium. The phase changes and temperatures acquired by the formed NPs strongly depend on the laser fluence, refraction index, optical, and thermodynamic properties of the solvent. During the reaction, the heat energy of NPs reduces to room temperature and recrystallize. Apart from NP reshaping, this process is also used to form alloy and composite NPs by irradiating mixed colloidal suspensions.

Metallic nanoparticles

Recently, metallic nanostructures fabricated by PLI have received great interest owing to their widespread applications in the fields of electronic, sensing, catalytic, and optophotonic devices. By means of nanosecond, picosecond, or femtosecond laser irradiation, the shape can be varied, and the size of the desired metal particles can be reduced either in an aqueous medium or supported substrates. In particular, the size reduction of the NPs can be explained by melting/heating and the excitation of robust surface plasmon transition through the laser energy. To date, numerous reports were available on the feasibility of particle size modification through PLI.

The fabrication of metal NPs mainly depends on the types of laser energy source, solvent, and irradiation time employed. In the later 90s, Kurita et al. formulated the size reduction of Au-NPs with <20 nm diameter through the second-harmonic PLI process using an Nd:YAG laser (532 nm) source in water132. The prepared Au-NPs are spherical and formed by heating the colloidal suspension within a short time of laser irradiation. The formation mechanism of Au-NPs by the Nd:YAG laser is realized by the initial surface plasmon absorption of Au-NPs followed by poor energy loss of the heated Au-NPs in water. The same group proposed the formation of Ag-NPs through PLI in which the formation mechanism remained unclear133. Interestingly, Prevo et al. proposed a way to form Au nanoshells with the desired size through PLI in aqueous media134. In this process, a femtosecond laser pulse was applied to a colloidal sol, which allowed the smallest nanoshells to reach the highest temperature and produce spherical NPs quickly. The ultrashort-pulse irradiation of Au-NPs in polyvinyl alcohol solution has produced Au nanorods that possessed excellent chromaticity135. Very recently, the PLI production of functionalized Au-NPs with the aid of lignin matrix in water has been proposed by Yu et al.14. In this study, a nanosecond (10 ns) pulsed 532 nm laser was utilized to irradiate various concentrations of HAuCl4 and lignin solution to obtain the desired lignin-functionalized Au-NPs (Fig. 13). The desired functionalized Au-NPs were subjected to the calorimetric sensing of various heavy metal ions, including Pb2+, Cu2+, Fe3+, Co2+, Ba2+, Cd2+, and Hg2+, and they effectively detected Pb2+ from various ions.