Abstract

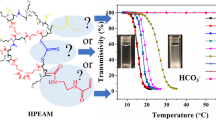

The phase behavior of a high-concentration solution of as-prepared sulfobetaine zwitterionic polymer solution, poly(3-dimethyl(methacryloyloxy-ethyl)ammonium propane sulfonate betaine (polySBMA) synthesized via radical solution polymerization was investigated utilizing ultraviolet–visible analytical techniques. The solution exhibited a stably reversible phase transition between transparency and opacity. The transition temperature decreased with increasing polymer concentration, in contrast to the phase behaviors of most water-soluble polymers reported in the literature. The equilibrium concentrations of the purified polySBMA with various molecular weights were further investigated. It was found that unlike most water-soluble polymers, which have low equilibrium concentrations, polySBMA had a high equilibrium concentration. In addition, the as-prepared polySBMA solution with high concentration presented an over-swelling behavior that exerted an important effect on the transition temperature of the solution. In addition, variations in the thermosensitivity of the as-prepared polySBMA hydrogels with various concentrations of crosslinking agent were investigated, confirming the conclusion stated above. Therefore, the temperature-dependent phase transition of the as-prepared polySBMA solution could be controlled by adjusting the concentration of the monomer SBMA or the crosslinking agent to make it suitable for biomedical uses or uses in other fields in the future.

Similar content being viewed by others

Introduction

Thermoresponsive polymers, a type of ‘smart material’, have attracted extensive interest in academia and in applied polymer science in the past several decades. For example, these materials have biomedical uses and are important in drug delivery systems, separation techniques and the construction of sensors.1, 2, 3, 4, 5, 6 Such polymers can be primarily classified into two categories: polymers with a lower critical solution temperature and polymers with an upper critical solution temperature. The best-characterized thermoresponsive lower critical solution temperature polymer is poly(N-isopropylacrylamide), and its aqueous solution undergoes a reversible phase separation induced by a hydration–dehydration transition when heated beyond 32 °C.7, 8 Compared with water-soluble lower critical solution temperature polymers, there are fewer studies on water-soluble polymers exhibiting upper critical solution temperature.9 Poly(acrylic acid) and polybetaines were reported to exhibit upper critical solution temperature, and these polymers commonly have a pair of interactive sites that cause the polymer to be insoluble at low temperatures because of intra-/intermolecular interactions such as hydrogen bonding and electrostatic attraction.10, 11, 12 Polybetaines are an important zwitterionic polymer with identical numbers of anionic and cationic species on the same monomer unit, and they are widely applied in the oil industry13, 14 and in the biotechnology and medical technology fields15, 16, 17 because of their unique physicochemical properties and anti-polyelectrolyte solution behaviors.18, 19 Poly(sulfobetaine methacrylate), that is, poly(3-dimethyl(methacryloyloxy-ethyl)ammonium propane sulfonate betaine (polySBMA), is a typical polybetaine that has a methacrylate main chain and a sulfobetaine analogue as the pendant group. In recent years, polySBMA has obtained considerably more attention because of its easy synthesis and good biocompatibility. For example, polySBMA is an effective and stable nonfouling material that could potentially provide a surface appropriate for use in human blood and biomedical implants.20, 21, 22

PolySBMA is usually insoluble in pure water and presents gel-like characteristics, but it is soluble in salt-containing solutions.18, 19, 23, 24, 25, 26 It was found that the solution properties of polySBMA are influenced by several factors such as polymer molecular weight, polymer concentration, electrolyte, pH and electric field. For example, the phase transition temperature (TT) of polySBMA in pure water increased with increasing molecular weight and decreased with increasing electrolyte concentration.27 With respect to the effect of the polySBMA concentration (cpolySBMA) on TT, the reports of Schulz et al.27 and Zhang et al.28 presented phase diagrams depicting the polymer solution behavior as a function of temperature versus polymer concentration. However, the reported phase diagrams of Schulz et al.27 were mainly at low concentrations (<10 wt%), and the data at high concentration (>10 wt%) were fewer in number and showed an increasing trend, whereas the phase diagram of Zhang et al.28 only showed a temperature increasing trend with increasing polymer concentration, but no detailed data were available. Therefore, it is difficult to determine the relationship between the polymer concentration and the temperature for the polySBMA solution at high concentrations. Furthermore, Zhang et al.28 noted that the mechanisms underlying the polySBMA phase transition from transparency to opacity can only be observed when the water content is sufficient to maintain phase separation. However, there has not been a reasonable explanation to describe this process until now.

Previously, most of the studies on polySBMA phase behaviors were at low concentration, and the polymer solutions used for transparency measurements were obtained from mixtures of the purified polySBMA (without unreacted monomer SBMA and residual initiator potassium persulfate) and water. However, when prepared via the mixing method, the polySBMA solutions at low concentrations were very unstable, resulting in a rapid precipitation of polySBMA. If the polySBMA solutions were made at high concentrations, it was difficult to obtain homogeneous polySBMA solutions via the mixing method. Therefore, we investigated the phase behavior of an as-prepared polymer solution, that is, the polySBMA solution with unreacted monomer SBMA and residual initiator potassium persulfate, at a high concentration. It was found that the TT of the as-prepared polySBMA solution decreased as the concentration increases, in contrast to the phase behaviors of most water-soluble polymers reported in the literature.29 The same result was obtained for another kind of as-prepared sulfobetaine polymer solution, poly(N,N-dimethyl(acrylamidopropyl)ammonium propane sulfonate) (polyDMAAPS).30 It was shown that the upper critical solution temperature of polyDMAAPS also decreased as the concentration increased (>10 wt%). The researchers attributed this behavior to the increase in the viscosity of the system that restricts the motion of the polymer chains and the arrangement of the polymer chains in the viscous solution. However, no detailed description of this process was given until now.

Therefore, in this paper, the relationships between the dynamic synthesis process and the mechanism underlying the behaviors of the as-prepared polySBMA solution at high concentration and its TT were investigated in detail. In addition, the effect of the chemical crosslinking agent N,N’-methylenebisacrylamide (BIS) on the TT of the as-prepared polySBMA solution is discussed.

Materials and methods

Materials

The monomer SBMA (97%) was purchased from Tianjin Heowns Biochem Technologies (LLC, Tianjin, China) and recrystallized with acetone purchased from Beijing Chemical Works. Potassium persulfate (KPS) was purchased from the Tianjin Fuchen Chemical Reagent Factory (Tianjin, China) and recrystallized with distilled water. BIS, a chemical crosslinking agent, was also purchased from the Tianjin Fuchen Chemical Reagent Factory.

PolySBMA solution synthesis and properties

PolySBMA solutions (physical crosslinking gel) were synthesized using radical polymerization as described in the literature.27 Aqueous solutions of SBMA at various concentrations (cSBMA) were prepared in 10 ml glass tubes. First, the glass tubes were purged with nitrogen for 5 min, and then KPS initiator (0.2 wt% SBMA) was injected into the solutions. Purging of the solutions with nitrogen was continued for 5 min, after which 4 ml of each solution was removed into glass cells (bottom area of 1 cm2), sealed with covers, heated to 53.0 °C and allowed to react for 10 h. After the polymerization, the as-prepared polySBMA solutions at various concentrations were synthesized in the glass cells and directly used for transparency measurements.

The various molecular weights of the as-prepared polySBMA solutions synthesized at a cSBMA of 35 wt% were adjusted by changing the reaction temperature (TR). The polySBMA products were purified as described previously.31 The viscosity-average molecular weight (MV) of polySBMA was measured with an Ubbelohde viscometer, as described in other references.32 The values of conversion were obtained from the ratio of the weight of polySBMA obtained to the weight of SBMA used. All the molecular weights and conversions of the polySBMA solutions were obtained after the transparency measurements were completed.

The preparations of the chemical crosslinking polySBMA gels with various concentrations of BIS were consistent with the above method. The concentrations of BIS (cBIS) were calculated based on the weight ratio percentage of SBMA concentration (cSBMA), and the range of cBIS was between 0 and 6%. Herein, cSBMA was 20 wt%.

Transparency measurements

The phase behavior of the as-prepared polySBMA solution was characterized by the measurement of the transmittance at a wavelength of 600 nm with a ultraviolet–visible spectrophotometer (Shimadzu UV-2450, Kyoto, Japan) with temperature control. The temperature was varied from 80 to 1 °C, and the transmittance value was recorded at every 0.5 °C decrease. The time interval between each temperature decrease was 15 min. To examine the reversibility of the phase transition between opacity and transparency of the as-prepared polySBMA solution, the temperature of the as-prepared polySBMA solution polymerized at a cSBMA of 25 wt% (TT=36.24 °C) was alternated between 5 and 50 °C for several cycles.

Tracking transparency measurements of the as-prepared polySBMA solutions

The as-prepared polySBMA solution separated into two phases after standing for a period of time: the upper layer was water and the lower layer was the concentrated polySBMA solution. As the standing time increased, the concentration of the lower layer polySBMA solution increased, and the volume of the lower layer polySBMA solution decreased. Herein, the as-prepared polySBMA solutions synthesized at cSBMA ⩾17.5 wt% were chosen for testing because the volumes of the as-prepared polySBMA solutions synthesized at low concentrations (cSBMA <17.5 wt%) were too low to be tested after standing for a period of time.

Measurement of the equilibrium concentrations of polySBMA solutions

PolySBMA (Wd g) samples with various molecular weights, after being purified and dried, were mixed with excess water in glass tubes and sealed with covers, then left standing for 3 months at 23 or 56 °C to become fully swelled. After that period, the mixtures separated into two phases: the upper layer was water, whereas the lower layer was the concentrated polySBMA solution. The water was then poured out, and the concentration of the lower layer of polySBMA solution (Wc g) was its equilibrium concentration (c*polySBMA) that can be calculated from the following equation:

The results are shown in Table 3.

Results and discussion

Phase behaviors of the as-prepared polySBMA solutions

The phase behaviors of the as-prepared polySBMA solutions could be investigated by measuring the solution transmittance at 600 nm with a ultraviolet–visible spectrophotometer, as described in our earlier study.29

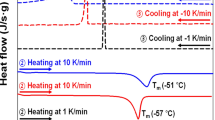

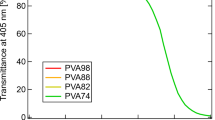

Figure 1 shows the temperature dependence of the transmittance for the as-prepared polySBMA solutions synthesized at various cSBMA values, tested directly after polymerization. As shown in this figure, the transmittance of the as-prepared polySBMA solutions is 100% at high temperatures, and the solutions are transparent. However, as the temperature decreases, the solutions become cloudy, and the transmittance rapidly decreases. The change in transmittance with temperature is completely reversible and stable. Herein, to demonstrate the reversibility of the transparency as the temperature changes, the transmittance change for the as-prepared polySBMA solution synthesized at a cSBMA of 25 wt% was examined between 5 and 50 °C, as these temperatures covered the sample’s phase transition temperature (36.24 °C). Figure 2 shows the transmittance changes of the as-prepared polySBMA solution synthesized at a cSBMA of 25 wt% between 5 and 50 °C. The highest transmittance was observed at 50 °C, and the transmittance decreased when the temperature was changed to 5 °C, and vice versa. The transmittance response to temperature occurs very rapidly, within ∼2 min, and was not weakened by multiple temperature changes.

Temperature dependence of transmittance at 600 nm for the as-prepared poly(3-dimethyl(methacryloyloxy-ethyl)ammonium propane sulfonate betaine (polySBMA) solutions synthesized at various cSBMA values and tested directly after polymerization at a heating rate of 0.5 °C min−1. A full color version of this figure is available at Polymer Journal online.

It is interesting to observe that the temperature at a transmittance of 50%, which is considered to be the phase transition temperature (TT), decreases linearly with increasing cpolySBMA (Figure 3, the cSBMA is almost equal to the cpolySBMA because of the high conversion of polySBMA synthesized at various cSBMA values that will be discussed below). The function of the fitting curve was constructed as follows:

Transition temperature of the as-prepared poly(3-dimethyl(methacryloyloxy-ethyl)ammonium propane sulfonate betaine (polySBMA) solution as a function of cpolySBMA (the transition temperature was defined as a transmittance of 50%). A full color version of this figure is available at Polymer Journal online.

The correlation coefficient is 0.998.

The results stand in opposition to the findings of Schulz et al.27 and Zhang et al.28 They studied the phase behaviors of polySBMA solutions obtained by mixing the purified polySBMA with water. Their results showed that TT increased with increasing cpolySBMA for polySBMA solutions at high concentrations (>10 wt%). However, in this work, the analysis of the phase behaviors of the as-prepared polySBMA solutions showed that TT decreased with increasing cpolySBMA. This difference may be because the data are insufficient to provide detailed information about the changes in the TT of polySBMA solutions at high concentrations. Therefore, in this paper, studies on the factors influencing the TT of the as-prepared polySBMA solutions at high concentrations were carried out.

Factors influencing the TT of the as-prepared polySBMA solutions

The residual monomer SBMA remaining in the as-prepared polySBMA solutions obtained after polymerization for 10 h had a very small effect on the TT of the solutions because of the high conversion of polySBMA (conversions >92 wt%, as shown in Tables 1 and 2). In addition, the effect of the initiator KPS remaining in the polymer solutions on the TT of the as-prepared polySBMA solutions could be considered negligible because the amount is very low. Therefore, there are two predominant factors influencing the TT of the as-prepared polySBMA solutions: one is the molecular weight of polySBMA and its polydispersity, and the other is the concentration of the as-prepared polySBMA solution.

Table 1 shows the molecular weights of polySBMA synthesized at various cSBMA values. As the conversion of polySBMA synthesized at various cSBMA values is very high (>92 wt%), cpolySBMA can be considered to be equivalent to cSBMA. Thus, from Table 1, we can see that MV increased with increasing cpolySBMA, whereas TT decreased with increasing cpolySBMA, contrary to the finding in previous studies27, 33 that TT increased with increasing MV. Thus, the molecular weight is not the factor contributing to the TT reduction of as-prepared polySBMA solution as cpolySBMA increases. We also investigated the change in TT of the as-prepared polySBMA solutions with various molecular weights obtained by adjusting the reaction temperatures (TR) (Table 2). From Table 2, we can see that MV decreased as the reaction temperature increased because of the increase in the decomposition rate constant of the initiator KPS that resulted in increased polymerization. In addition, from the results in Table 2, we can see that when MV increased from 4.77 × 105 to 8.13 × 105, TT increased from 13.18 to 15.55 °C, which is consistent with the results of previous studies,27, 33 but it can be seen that there was only a 2 °C increase in TT. The small increase in TT may be because of the higher molecular weight distribution of the polySBMA synthesized by radical solution polymerization, the polydispersity of which is in the range of 2.0–3.0.34 However, the report of Huglin and Radwan33 on polySBMA samples obtained from isothermal fractionation showed that when Mw increased from 2.15 × 105 to 2.07 × 106, TT increased from 22 to 32 °C. That is, the molecular weight of polySBMA increased by nearly 10 times; however, the increase in TT was <10 °C. In addition, from the results in Table 1, we can see that when cpolySBMA increased from 10 to 40 wt%, MV increased from 5.16 × 105 to 8.78 × 105, but TT decreased from 65.04 to 7.44 °C, and this was an ∼58 °C reduction in TT. Therefore, although the higher molecular weight distribution of polySBMA may result in a decrease in TT, it could not result in as great a reduction in TT (58 °C) as increasing cpolySBMA. In addition, this result was also observed in another kind of as-prepared sulfobetaine polymer solution, polyDMAAPS.30 It was shown that when the polyDMAAPS solutions were at high concentrations (>10 wt%), the TT of the polyDMAAPS solutions obtained from the mixture of the purified polymer ([η]=1.02 dl g−1) and water was almost identical to the TT of the as-prepared polyDMAAPS solutions. (Compared with the structure of polySBMA, the presence of an amide group in polyDMAAPS instead of the ester group of polySBMA increases the solubility of polyDMAAPS in water because of the hydrogen bond formed between the amine group and the water. Therefore, it is easier to prepare a mixture of polyDMAAPS and water than a mixture of polySBMA and water.) Therefore, the decrease in the TT of the as-prepared polySBMA solution can be considered to be mainly influenced by cpolySBMA.

Over-swelling phase behaviors of the as-prepared polySBMA solutions

It was found that the as-prepared polySBMA solutions synthesized at low cSBMA underwent macro-phase separation, whereas the polySBMA solutions synthesized at high cSBMA did not undergo macro-phase separation. This difference indicates that there is a critical SBMA concentration (c*SBMA) at which the as-prepared polySBMA solution (c*polySBMA) synthesized does not undergo macro-phase separation and reaches equilibrium. Therefore, c*polySBMA is the equilibrium concentration of polySBMA because of its high conversion (⩾92%).

Table 3 shows the c*polySBMA of polySBMA with various MV at 23 and 56 °C via the method of mixing the purified polymer with water. It can be seen from Table 3 that c*polySBMA increased as the MV increased or the temperature decreased. Therefore, combining the data in Tables 2 and 3, the c*polySBMA values of the polySBMA synthesized at various cSBMA were more than 39.2 wt% (23 °C). Herein, a higher c*polySBMA of 40.1 wt% was chosen as the average c*polySBMA of polySBMA solutions because the magnitude of the change in c*polySBMA is small. Therefore, when cpolySBMA is lower than c*polySBMA, the as-prepared polySBMA solution is unstable and undergoes macro-phase separation. For example, the as-prepared polySBMA solution synthesized at a cSBMA of 5 wt% underwent macro-phase separation after 10 h of polymerization (Figure 4, cSBMA=5 wt%).

It was found that the as-prepared polySBMA solutions polymerized in the range of 10.0 wt%<cSBMA<c*SBMA in glass cuvettes of a certain size (1 cm2 × 4 cm) did not undergo obvious macro-phase separation because of space hindrance and the high viscosity of the as-prepared polySBMA solutions (see, for example, Figure 4 cSBMA=15 wt%), but after standing for 7 months, macro-phase separation occurred, and the solutions separated into two phases. As the solutions of polySBMA with higher molecular weights at high concentrations present the characteristics of gels,28, 35 the state of the as-prepared polySBMA solution (10.0 wt%<cpolySBMA<c*polySBMA) without macro-phase separation in a certain period of time is called an over-swelling state. The over-swelling state is a metastable state that is unstable and will undergo macro-phase separation if the solution is given sufficient standing time.

The formation of the over-swelling state of as-prepared polySBMA solution in glass cuvettes of a certain size (1 cm2 × 4 cm) is closely related to the anti-polyelectrolyte properties of polySBMA and the nature of free radical polymerization. In addition to containing a small amount of initiator KPS, the as-prepared polySBMA solution system mainly consists of SBMA, polySBMA and water. The intra-/intermolecular chains of polySBMA are associated with each other via the coulombic interactions between the oppositely charged groups and form a physical crosslinking network that cannot be dissolved in water. The physical crosslinking points in the network could be affected by changes in the environment, for example, it could be broken by adding electrolytes or increasing the temperature. Therefore, the oppositely charged group associations of polySBMA could be disassociated by the monomer SBMA because of the electrolytic properties of SBMA that induces an increase in the solubility of polySBMA in water (see Supplementary Figure S1). This phenomenon is called the shielding effect of SBMA. At the initial stage of polymerization, the polymerization rate of polySBMA was rapid and resulted in a physically crosslinked gel. At this stage, the concentration of unreacted SBMA monomer was very high that led to a large amount of water retention in the polySBMA network because of the shielding effect of SBMA. Then, the molecular weight of polySBMA increased as SBMA was continually involved in the polymerization that decreased the shielding effect of SBMA, although a large number of solvent water molecules were retained in the polySBMA network. Therefore, when the concentration of monomer SBMA was lower than the critical SBMA concentration, such as 10.0 wt%<cSBMA<37.5 wt%, the resulting as-prepared polySBMA solution was in an over-swelling state. However, if the cSBMA was too low, such as cSBMA<10.0 wt%, the viscosity of the resulting as-prepared polySBMA solutions was too low to maintain the over-swelling state in the glass cuvette, leading to the macro-phase separation that occurred during the process of the polymerization (Figure 4, cSBMA=5 wt%).

Therefore, this work mainly addresses the phase transition behaviors of as-prepared polySBMA solutions in over-swelling states.

Influence of the stability of the as-prepared polySBMA solutions on their TT

In the over-swelling state, the as-prepared polySBMA solutions underwent macro-phase separation and separated into two phases: the upper layer was water, whereas the lower was the concentrated polySBMA solution. Therefore, the cpolySBMA of the as-prepared polySBMA solutions at the lower layer increased as the standing time increased. Thus, the stability and the phase separation process of the as-prepared polySBMA solutions can be tracked to the change in TT of the lower layer of the as-prepared polySBMA solution at different standing times (for methods, please see the Material and methods section). Figure 5 shows the variation in the TT of the as-prepared polySBMA solutions with various cpolySBMA. After standing for different periods of time (the temperature dependence of the transmittance of as-prepared polySBMA solutions with various cpolySBMA values at different standing periods of time is shown in Supplementary Figure S2). From Figure 5, it can be seen that TT decreased with increasing standing time, that is, TT decreased as cpolySBMA increased, consistent with the result shown in Figure 3. In addition, from curve ‘c’ in Figure 5, we can see that the TT values of all the as-prepared polySBMA solutions were ∼12.0 °C after standing for 7 months at 25 °C, and this was exactly the TT of as-prepared polySBMA solution at the cpolySBMA of 37.5 wt% (25 °C). This sameness indicates that the c*polySBMA of the as-prepared polySBMA solutions is ∼37.5 wt% at 25 °C that is slightly lower than that of the c*polySBMA (∼39.2 wt% shown in Table 3) obtained from the mixing method because of the shielding effect of SBMA that increased the solubility of polySBMA in water. Therefore, the TT of the as-prepared polySBMA solution is closely related to the stability of the as-prepared polySBMA solution: the lower the cpolySBMA, the worse is the stability of the as-prepared polySBMA solution, and the higher the TT of the as-prepared polySBMA solution.

Variation in the transition temperature of the as-prepared poly(3-dimethyl(methacryloyloxy-ethyl)ammonium propane sulfonate betaine (polySBMA) solutions with various cpolySBMA values after standing for different periods of time; a, after reaction; b, standing for 1 month; and c, standing for 7 months. A full color version of this figure is available at Polymer Journal online.

Influence mechanism of the concentration on the transparency–opacity phase transition of the as-prepared polySBMA solution.

It is well known that TT usually increases with increasing polymer concentration for most water-soluble polymers. For example, the TT of poly(acrylic acid-co-acrylamide) copolymer increased with increasing the polymer concentration because of the increase in the amount of hydrogen bonds between carboxyl and amide group per unit volume.29 However, for polySBMA, TT decreased with increasing cpolySBMA (Figure 3). Based on the above results, a mechanism for the unique effect of concentration on the transparency–opacity phase transition in the as-prepared polySBMA solutions was proposed.

According to the theory of thermodynamic equilibrium, thermodynamic equilibrium is achieved when the free energy change of the polymer solution is zero. For the as-prepared polySBMA solution (physical gel), the free energy (G) results from three different contributions.36

The first is the mixing of polymer and water (Gmix) that is dependent on the local polymer concentration and the interaction between the polymer segments and water. The second is the elasticity of the polymer network (Gelastic) that is dependent on the crosslinking degree. The third is the coulombic interaction (Gcoulombic) between the oppositely charged groups of the polySBMA that is dependent on the dielectric permittivity of the solvent, the distance between the oppositely charged groups and the total number of positive and negative fixed charged groups.36, 37 For polySBMA solutions at high concentrations, there are two main aspects to the phase behaviors. One is the macro-phase separation: the solution exhibits two phases under the actions of the network swelling effect and the network retraction effect. The other is the micro-phase separation, in which the solution exhibits a transparency–opacity transition influenced by temperature.

As the as-prepared polySBMA solution at a high concentration presents a crosslinked network structure in the gel,28, 35 the network of the gel acts as if it provides its own semipermeable membrane that passes solvent molecules freely, but not polymer chains.38 Therefore, the macro-phase behavior of the as-prepared polySBMA solution at high concentration can be reflected by the osmotic pressure of the solvent (π) in the solution. The water osmotic pressure of as-prepared polySBMA solutions comes from two effects: one is the swelling effect of the polySBMA network under the contribution of Gmix, and the other is the retraction effect of the polySBMA network under the contributions of Gelastic and Gcoulombic. In the over-swelling state, Gmix decreased (ΔGmix<0) because the excess water resulting from the shielding effect of SBMA was excluded from the network. In addition, this situation increased the retraction effect of the network because of the increase in oppositely charged group interactions (the increase in the physical crosslinking points (ΔGelastic>0) and the coulombic interactions (ΔGcoulombic>0) between the oppositely charged groups) that in turn resulted in the excess water stored in the network once again. Therefore, the polymer network continued to shrink and resulted in the macro-phase separation of the as-prepared polySBMA solution (ΔG=ΔGmix+ΔGelastic+Gcoulombic<0). When the polymer network shrank to the point that the two effects were equal (ΔG=0), the as-prepared polySBMA solution reached macro-phase equilibrium, and the water osmotic pressure was zero. Therefore, for the as-prepared polySBMA solutions, the lower cpolySBMA is, the worse the stability, and the higher the free energy of the solution system. A schematic illustration of the macro-phase separation of the as-prepared polySBMA solution is shown in Figure 6.

The main reason underlying the transparency–opacity phase transition of the as-prepared polySBMA solution is that micro-phase separation occurs in the solution (Figure 7). For example, when the temperature was lower (<TT), the as-prepared polySBMA solution underwent micro-phase separation because of the association between the intra-/intermolecular chains, and the solution appeared opaque. Correspondingly, when the temperature increased (>TT), the intra-/intermolecular association was broken, and the solution appeared transparent. For the as-prepared polySBMA solutions in an over-swelling state, the lower the concentration, the higher the free energy of the solution system. In addition, the intra-/intermolecular chains of a polySBMA solution at a lower concentration are more easily associated because of the lower viscosity of the solution. Thus, given the above effects, when the temperature decreased, the polySBMA solution at lower concentration was associated first, resulting in a solution with a higher transition temperature.

Influence of chemical crosslinking agent on the TT of the as-prepared polySBMA solution.

Based on the above results, the TT of the as-prepared polySBMA solution is closely related to its over-swelling characteristic caused by the continuous collapse of the polySBMA network because of the increase in physical crosslinking points through oppositely charged groups between the inter-/intra chains. The physical crosslinking points are not permanent and can be altered by different environmental conditions, such as temperature, ionic strength and pH. However, the chemical crosslinking points introduced by the addition of a crosslinking agent (BIS) are fixed. Thus, the over-swelling characteristic of the as-prepared polySBMA solution could be controlled by the addition of BIS by confining the movement of the chains. Figure 8 shows the effect of the crosslinking agent BIS on the phase behavior of the as-prepared polySBMA solution. As shown in Figure 8, the transmittance of the solutions decreased as the content of the crosslinking agent BIS increased. This was because the over-swelling behavior of the as-prepared polySBMA solution was confined by the BIS. In addition, the slope of the curve of transmittance versus temperature also decreased with the increasing crosslinking agent BIS content. This result indicates that the thermosensitivity of the as-prepared polySBMA solution decreases with the increase in the crosslinking agent BIS content. It can be observed that the transmittance of the as-prepared polySBMA solution at a BIS content of 6.0% increased almost linearly with increasing temperature, and the max transmittance was only 45% at high temperature.

Temperature dependence of the transmittance at 600 nm for the as-prepared poly(3-dimethyl(methacryloyloxy-ethyl)ammonium propane sulfonate betaine (polySBMA) gels synthesized at various concentrations of N,N’-methylenebisacrylamide (BIS) measured at a heating rate of 0.5 °C min−1 (PolySBMA was synthesized at 20 wt% cSBMA.) A full color version of this figure is available at Polymer Journal online.

Conclusions

In this work, the transparency–opacity phase transitions of as-prepared sulfobetaine zwitterionic polymer (polySBMA) solutions synthesized at various cSBMA values via radical polymerization were investigated by measuring the transparency with a ultraviolet–visible spectrophotometer. The solution exhibited a stably reversible phase transition between transparency and opacity. In addition, the results showed that the transition temperature (TT) of as-prepared polySBMA solutions decreased with the increase in cpolySBMA, in contrast to the behavior of the most important water-soluble polymer. It was found that unlike most water-soluble polymers with low equilibrium concentrations, polySBMA has a high equilibrium concentration (40.1 wt%) that led to the as-prepared solution presented an over-swelling state. In addition, the results of the influence of the stability of the as-prepared polySBMA solution on TT showed that the TT of the as-prepared polySBMA solution was closely related to its over-swelling characteristic. The addition of the chemical crosslinking agent BIS to the as-prepared polySBMA solution could confine its over-swelling behavior to a certain degree that decreased both the TT and the thermosensitivity of the as-prepared polySBMA solution.

References

Chang, Y., Yandi, W., Chen, W. Y., Shih, Y. J., Yang, C. C., Chang, Y., Ling, Q. D. & Higuchi, A. Tunable bioadhesive copolymer hydrogels of thermoresponsive poly(N-isopropyl acrylamide) containing zwitterionic polysulfobetaine. Biomacromolecules 11, 1101–1110 (2010).

Wang, F., Klaikherd, A. & Thayumanavan, S. Temperature sensitivity trends and multi-stimuli sensitive behavior in amphiphilic oligomers. J. Am. Chem. Soc. 133, 13496–13503 (2011).

Tang, L., Liu, W. & Liu, G. High-strength hydrogels with integrated functions of H-bonding and thermoresponsive surface-mediated reverse transfection and cell detachment. Adv. Mater. 22, 2652–2656 (2010).

Su, Y., Zheng, L., Li, C. & Jiang, Z. Y. Smart zwitterionic membranes with on/off behavior for protein transport. J. Phys. Chem. B 112, 11923–11928 (2008).

Polzer, F., Heigl, J., Schneider, C., Ballauff, M. & Borisov, O. V. Synthesis and analysis of zwitterionic spherical polyelectrolyte brushes in aqueous solution. Macromolecules 44, 1654–1660 (2011).

Yang, W., Xue, H., Carr, L. R., Wang, J. & Jiang, S. Zwitterionic poly(carboxybetaine) hydrogels for glucose biosensors in complex media. Biosens. Bioelectron. 26, 2454–2459 (2011).

Rice, C. V. Phase-transition thermodynamics of N-isopropylacrylamide hydrogels. Biomacromolecules 7, 2923–2925 (2006).

Ono, Y. & Shikata, T. Hydration and dynamic behavior of poly(N-isopropylacrylamide)s in aqueous solution: a sharp phase transition at the lower critical solution temperature. J. Am. Chem. Soc. 128, 10030–10031 (2006).

Seuring, J. & Agarwal, S. Polymers with upper critical solution temperature in aqueous solution. Macromol. Rapid Commun. 33, 1898–1920 (2012).

Buscall, R. & Corner, T. The phase-separation behaviour of aqueous solutions of polyacrylic acid and its partial sodium salts in the presence of sodium chloride. Eur. Polym. J. 18, 967–974 (1982).

Huglin, M. B. & Radwan, M. A. Unperturbed dimensions of a zwitterionic polymethacrylate. Polym. Int. 26, 97–104 (1991).

Arotçaréna, M., Heise, B., Ishaya, S. & Laschewsky, A. Switching the inside and the outside of aggregates of water-soluble block copolymers with double thermoresponsivity. J. Am. Chem. Soc. 124, 3787–3793 (2002).

Sabhapondit, A., Borthakur, A. & Haque, I. Characterization of acrylamide polymers for enhanced oil recovery. J. App. Poly. Sci. 87, 1869–1878 (2003).

Zhang, L. M., Tan, Y. B. & Li, Z. M. New water-soluble ampholytic polysaccharides for oilfield drilling treatment: a preliminary study. Carbohydr. Polym. 44, 255–260 (2001).

Zhang, Z., Chen, S. & Jiang, S. Dual-functional biomimetic materials: nonfouling poly(carboxybetaine) with active functional groups for protein immobilization. Biomacromolecules 7, 3311–3315 (2006).

Mumick, P. S., Welch, P. M., Salazar, L. C. & McCormick, C. L. Water-soluble copolymers. 56. Structure and solvation effects of polyampholytes in drag reduction. Macromolecules 27, 323–331 (1994).

Jiang, S. Y. & Cao, Z. Q. Ultralow-fouling, functionalizable, and hydrolyzable zwitterionic materials and their derivatives for biological applications. Adv. Mater. 22, 920–932 (2010).

Salamone, J. C., Volksen, W., Olson, A. P. & Israel, S.C. Aqueous solution properties of a poly(vinyl imidazolium sulphobetaine). Polymer 19, 1157–1162 (1978).

Soto, V. M. M. & Galin, J. C. Poly(sulphopropylbetaines): 2. Dilute solution properties. Polymer 25, 254–262 (1984).

Carr, L., Cheng, G., Xue, H. & Jiang, S. Engineering the polymer backbone to strengthen nonfouling sulfobetaine hydrogels. Langmuir 26, 14793–14798 (2010).

Ladd, J., Zhang, Z., Chen, S., Hower, J. C. & Jiang, S. Zwitterionic polymers exhibiting high resistance to nonspecific protein adsorption from human serum and plasma. Biomacromolecules 9, 1357–1360 (2008).

Chang, Y., Chen, W. Y., Yandi, W., Shih, Y. J., Chu, W. L., Liu, Y. L., Chu, C.W., Ruaan, R. C. & Higuchi, A. Dual-thermoresponsive phase behavior of blood compatible zwitterionic copolymers containing nonionic poly(N-isopropylacrylamide). Biomacromolecules 10, 2092–2100 (2009).

Liaw, D. J., Lee, W. F., Whung, Y. C. & Lin, M. C. Aqueous solution properties of poly[3-dimethyl(methacryloyloxyethyl)ammonium propane sulfonate. J. Appl. Polym. Sci. 34, 999–1011 (1987).

Berlinova, I. V., Dimitrov, I. V., Kalinova, R. G. & Vladimirov, N. G. Synthesis and aqueous solution behavior of copolymers containing sulfobetaine moieties in side chains. Polymer 41, 831–837 (2000).

Lee, W. F. & Lee, C. H. Poly(sulfobetaine)s and corresponding cationic polymers: 3. Synthesis and dilute aqueous solution properties of poly(sulfobetaine)s derived from styrene-maleic anhydride. Polymer 38, 971–979 (1997).

Lee, W. F. & Tsai, C. C. Synthesis and solubility of the poly(sulfobetaine)s and the corresponding cationic polymers: 2. Aqueous solution properties of poly[N,N’-dimethyl-(acrylamide propyl) ammonium propane sulfonate]. Polymer 36, 357–364 (1995).

Schulz, D. N., Peiffer, D. G., Agarwal, P. K., Larabee, J., Kaladas, J. J, Handwerker, L. S. B. & Garner, R. T. G. Phase behavior and solution properties of sulphobetaine polymers. Polymer 27, 1734–1742 (1986).

Zhang, Z., Chao, T. & Jiang, S. Y. Physical, chemical, and chemical-physical double network of zwitterionic hydrogels. J. Phys. Chem. B 112, 5327–5332 (2008).

Yang, M., Liu, C., Li, Z. Y., Gao, G. & Liu, F. Q. Temperature-responsive properties of poly(acrylic acid-co-acrylamide) hydrophobic association hydrogels with high mechanical strength. Macromolecules 43, 10645–10651 (2010).

Ning, J. Y., Kubota, K., Li, G. & Haraguchi, K. Characteristics of zwitterionic sulfobetaine acrylamide polymer and the hydrogels prepared by free-radical polymerization and effects of physical and chemical crosslinks on the UCST. React. Funct. Polym. 73, 969–978 (2013).

Yu, J. F., Li, Z. Y., Liu, X. L., Song, S. N., Gao, G. & Liu, F. Q. Molecular size and morphology of single chains of poly(sulfobetaine methacrylate). Chem. Res. Chin. Univ. 32, 499–504 (2016).

Huglin, M. B. & Radwan, M. A. Properties of poly[N-2-(methyacryloyloxy)ethyl-N,N-dimethyl-N-3-sulfopropylammoniumbetaine] in dilute solution. Makromol. Chem. 192, 2433–2445 (1991).

Huglin, M. B. & Radwan, M. A. Unperturbed dimensions of a zwitterionic polymethacrylate. Polym. Int. 26, 97–104 (1991).

Mary, P., Bendejacq, D. D., Labeau, M. P. & Dupuis, P. Reconciling low- and high-salt solution behavior of sulfobetaine polyzwitterions. J. Phys. Chem. B. 111, 7767–7777 (2007).

Kamenova, I., Harrass, M., Lehmann, B., Friedrich, K., Ivanov, I. & Georigiev, G. Swelling of the zwitterionic copolymer networks and dehydration of their hydrogels. Macromol. Symp. 254, 122–127 (2007).

Georgiev, G. S., Mincheva, Z. P. & Georgieva, V. T. Temperature-sensitive polyzwitterionic gels. Macromol. Symp. 164, 301–311 (2001).

English, A. E., Mafé, S., Manzanares, J. A., Yu, X., Grosberg, A. Y. & Tanaka, T. Equilibrium swelling properties of polyampholytic hydrogels. J. Chem. Phys. 104, 8713–8720 (1996).

Hirotsu, S. Static and time-dependent properties of polymer gels around the volume phase transition. Phase Trans. 47, 183–240 (1994).

Acknowledgements

We acknowledge financial support from the National Natural Science Foundation of China (No. 21174053).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Yu, J., Liu, Y., Song, S. et al. Phase behavior of a high-concentration sulfobetaine zwitterionic polymer solution. Polym J 49, 767–774 (2017). https://doi.org/10.1038/pj.2017.51

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.51