Abstract

Photo-crosslinkable groups were introduced to β-cyclodextrin (β-CyD) by the reaction of β-cyclodextrins with isophorone diisocyanate and 2-hydroxyethyl acrylate to produce polysubstituted photo-crosslinkable β-CyD (PSβCyD). To yield PSβCyD of a spherical shape, a suspension consisting of PSβCyD and aqueous sodium alginate solution was added dropwise into an aqueous calcium chloride solution. Then, the PSβCyD macromonomer was photo-crosslinked with ultraviolet radiation to obtain β-CyD polymer beads. The physical properties of the highest quality polymer beads prepared were as follows: diameter (φ) 2.7 mm and compressive strength 6.5 MPa that showed 69% separation efficiency of phenol from the raw industrial 8.9 wt% phenolic waste water.

Similar content being viewed by others

Introduction

Cyclodextrins (CyDs) are a family of torus-shaped cyclic oligomers composed of glucopyranose units linked by α-1,4 glycosidic bonds. They have a hydrophobic interior cavity that can accommodate a wide range of guest molecules owing to their inclusion ability.1 Thus, CyD polymers can be prepared to utilize their inclusion abilities as an industrial adsorbent. CyD-containing polymers can be obtained by either polymer modification with CyD-derivatives or polymerization of CyD-containing monomers. To date, a large number of papers have reported the latter method, by synthesis of vinyl CyD-monomers and their homo- or co-polymerization with other vinyl monomers. Synthesis of the mono-vinyl CyD monomer is complicated because of the parent CyD molecule having many hydroxyl groups; therefore, it has been carried out by introducing p-toluenesulfonyl as a leaving group to obtain the CyD monomer carrying an unsaturated mono-vinyl group, glycidyl methacrylate-ethane diamine-β-CyD2, 3 and mono-6-(allyl-amino)-β-CyD.4 The preparation of linear, water-soluble, CyD-containing polymers may require the use of mono-vinyl CyD monomers, whereas water-insoluble polymeric CyDs are prepared simply by polymerizing multi-vinyl CyD monomers. Multi-vinyl CyD monomers bearing functional vinyl groups such as an allyl,5, 6 methacrylate,7 itaconate8 or vinyl carboxylic group9 have been reported.

In this study, we prepared a β-CyD carrying multiple vinyl groups, 2-hydroxyethyl acrylate-isophorone diisocyanate-β-CyD. We characterized 2-((((5-isocyanato-1,3,3-trimethylcyclohexyl)methyl)carbamoyl)oxy)ethyl acrylate (IEA) and photo-crosslinkable β-CyD (PSβCyD) using proton nuclear magnetic resonance, Fourier transform infrared, X-ray diffraction and MALDI TOF/MS (matrix-assisted laser desorption/ionization time-of-flight mass spectrometry), and further used the spherical PSβCyD photo-crosslinkable macromonomer for the synthesis of the PSβCyD polymer beads that were novel photo-crosslinked polymers. This study offers a new approach to prepare CyD polymer beads with potential application as an adsorbent in the future, and expands the scope of cyclodextrin chemistry. Moreover, to the best of our knowledge, this is the first report on the synthesis and characterization of photo-crosslinked CyD polymers.

Experimental procedures

Materials

β-CyD was kindly supplied by Mercian Co., Ltd (Tokyo, Japan), and used after drying overnight at 60 °C in vacuo. Isophorone diisocyanate, 2-hydroxyethyl acrylate, di-n-butyltin dilaurate and 2-hydroxy-2-methylpropiophenone were purchased from Tokyo Kasei Kogyo (Tokyo, Japan). 2-Hydroxyethyl acrylate was dried over sodium sulfate anhydride before use. Sodium alginate (NaAlg, 500 cps) was purchased from Sigma-Aldrich Japan (Tokyo, Japan). Dimethyl sulfoxide (DMSO) was used after distillation in vacuo and drying over a molecular sieve. All other organic and inorganic reagents were of the purest grade available from commercial sources.

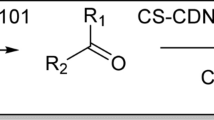

Synthesis of IEA

The precursor IEA, used for introducing the photo-crosslinkable functional groups into β-CyD, was synthesized by the reaction of 2-hydroxyethyl acrylate and isophorone diisocyanate at an equivalent molar ratio in the presence of di-n-butyltin dilaurate as a catalyst and hydroquinone as a polymerization inhibitor, as described in previous works10,11,12,13 (Scheme 1, (1)). Briefly, a typical run involves dropping isophorone diisocyanate (6.1 g, 28 mmol) in DMSO (4 ml) into 2-hydroxyethyl acrylate (3.2 g, 28 mmol), hydroquinone (0.2 g, 1.6 mmol) and a few drops of di-n-butyltin dilaurate in DMSO (10 ml) with stirring under a nitrogen atmosphere at 70 °C for 2 h. The resultant liquid was used in the next reaction without isolation.

Synthesis of β-CyD derivatives bearing polysubstituted photo-crosslinkable groups: PSβCyD

The β-CyD derivatives bearing polysubstituted photo-crosslinkable groups (PSβCyD) were synthesized by the reaction of the hydroxyl group in the β-CyD unit with the isocyanate group of IEA, as shown in Scheme 1, (2). A series of PSβCyDs were synthesized by varying the molar ratio of β-CyD to IEA in the reaction mixture. Powder-dried β-CyD (9.0 g, 8 mmol) and catalytic amounts of di-n-butyltin dilaurate were added to the IEA reaction solution (Table 1). To obtain a suspension of the resulting PSβCyD macromonomer, the reaction mixture was stirred for 48 h at 70 °C.

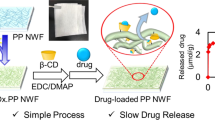

Preparation of spherical PSβCyD macromonomer

Preparation of spherical PSβCyD macromonomer was carried out from the resultant PSβCyD DMSO solution, as shown in the Scheme 2.14 After the addition of 1 wt% of aqueous NaAlg solution (quarter amounts for the PSβCyD DMSO solution) and a small amount of 2-hydroxy-2-methylpropiophenone as a photo-crosslinking initiator, the resulted suspension was added dropwise throughout the 2 mm φ cylinder tip from the height of 2 to 4 cm into an aqueous calcium chloride solution (3 wt%, CaCl2(aq.)) in a petri plate at 20 to 25 °C to precipitate the spherical PSβCyD macromonomer.

Preparation of PSβCyD polymer beads

The spherical PSβCyD macromonomer in the petri plate was ultraviolet irradiated for 10 min at room temperature. After filtration, the PSβCyD polymer beads were lyophilizated in a freezer at −20 °C (Scheme 1, (3)).

Measurements

The chemical structure of the PSβCyD macromonomer was determined by the proton nuclear magnetic resonance spectra with a JNM-AL400 apparatus (JEOL Co., Ltd, Tokyo, Japan) using CDCl3 as a solvent. Fourier transform infrared spectra were obtained using a JASCO FT/IR-4100 (JASCO Co., Tokyo, Japan) spectrophotometer. MALDI-TOF/MS Voyager-DE PRO (Applied Biosystems Japan, Tokyo, Japan) was used for measurement of the molecular weight of PSβCyD. 2,5-Dihydroxybenzoic acid (Fluka - Sigma-Aldrich Japan K. K., Tokyo, Japan) was used for the matrix, and sodium trifluoroacetate was used as a cationization agent. The composition of the PSβCyD macromonomer and polymer was determined by elemental analysis using a Micro Corder JM10 (J-Science Lab Co., Ltd, Kyoto, Japan). X-ray diffraction patterns were obtained with an X-ray diffractometer RINT2200 (Rigaku Co., Tokyo, Japan). The compressive strength of the PSβCyD polymer beads was determined by the use of a tensile and compressive testing machine, STA-1150 (A&D Co. Ltd, Tokyo, Japan). The surface properties of the adsorbents were studied by scanning electron microscopy with a FE-SEM S-4300 (Hitachi High-Technologies Co., Tokyo, Japan) using an accelerating voltage of 6 keV after coating with Pt, as well as optical microscopy with a VH-8000 digital microscope (Keyence Co., Osaka, Japan). The batchwise adsorption experiments by using β-CyD polymer beads as a sorbent were carried out according to the previous paper.14, 15 Aqueous industrial waste water discharged from phenolic resin processing by Meiwa Plastic Industries, Ltd (Ube, Japan), the components of which were phenol (8.9 wt%), m- and p-cresols (0.33 wt%), xylenols (0.044 wt%) and methanol (9.95 wt%) at pH=3.0, was used in adsorption experiments.

Results and discussion

Synthesis of PSβCyD macromonomer and PSβCyD polymer

The proton nuclear magnetic resonance spectrum of the PSβCyD macromonomer (Table 1, run 6), measured in CDCl3 after precipitation in excess acetone to pick up purified PSβCyD and then dried at RT in vacuo, is shown in Figure 1. The spectrum is consistent with that expected from the synthesis of PSβCyD by the route shown in Scheme 2; all peaks of the PSβCyD macromonomer were assigned to the glucose ring (a and a’), the isophorone ring (b) and the vinyl groups (c), corresponding to the residue for raw materials.

Proton nuclear magnetic resonance (1H-NMR) spectrum of the photo-crosslinkable β-cyclodextrin (PSβCyD) macromonomer (Table 1, run 6) for the acetone-soluble part in CDCl3. A full color version of this figure is available at Polymer Journal online.

The IEA residue, with optically polymerizable functional groups, can be used to introduce a maximum of 21 units into β-CyD, because β-CyD had 21 hydroxide groups per molecule when the PSβCyD macromonomer was synthesized. Seven kinds of PSβCyDs were prepared by reacting with 1–4 times molar ratio of IEA to β-CyD in the feed, and the corresponding PSβCyD polymer beads were obtained. The degree of substitution (DS) of IEA for β-CyD in the PSβCyD macromonomer and PSβCyD polymers and β-CyD content in the resins were determined by TOF/MS measurement and carbon hydrogen nitrogen (CHN) elemental analysis, respectively, and are shown in Table 2.

TOF/MS experiments helped to clarify the molecular sequence of PSβCyD (Table 1, run 6). The result is illustrated in Figure 2. The peak of PSβCyD at a molecular weight of ∼1494 was confirmed as a β-CyD unit (∼1157 when sodium trifluoroacetate was present in the matrix) condensed with an IEA unit (∼338). With increasing degree of substitution for IEA from 2 to 9, this peak appeared at increasing intervals of 338. The average values of DS were determined to be from 1.2 to 2.4 based on the peak area of each PSβCyD macromonomer.

Time-of-flight mass spectrometry (TOF/MS) spectrum of the photo-crosslinkable β-cyclodextrin (PSβCyD) macromonomer (Table 1, run 6). A full color version of this figure is available at Polymer Journal online.

The DS values of PSβCyD polymers were calculated from CHN data and determined to be between 1.1 and 6.4. Expectedly, the values increased with increasing IEA molar ratio in the feed. The DS values of the PSβCyD polymers were larger than those of the PSβCyD macromonomers, because the photo-crosslink reaction occurred predominantly between higher DS photo-crosslinkable PSβCyDs than the others. Therefore, the PSβCyD macromonomers with a lower than 2.0 DS and unreacted β-CyD were removed in the purification process.

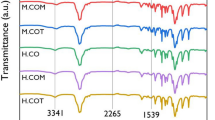

The chemical structure was confirmed with Fourier transform infrared analysis (Figure 3). The specific absorption because of amide groups and vinyl groups appeared at 1700 cm−1 and 1650 cm−1, respectively, in the PSβCyD macromonomer (Table 1, run 6), as compared with raw β-CyD. The specific absorption of vinyl groups disappeared in the PSβCyD polymer.

X-ray diffraction patterns of β-CyD, the PSβCyD macromonomer and the PSβCyD polymer are shown in Figure 4. Though crystalline sharp peaks appeared in β-CyD, these peaks were not present in the PSβCyD macromonomer and polymer. Therefore, it is suggested that the introduction of the photo-crosslinkable unit into β-CyD changed the crystallinity of β-CyD.

Preparation and properties of PSβCyD polymer beads

The polysubstituted β-CyD macromonomer formed networked polymer gels by photo-crosslinking reactions that then become insoluble in water. Thus, they can be used as a sorbent for the recovery of organic compounds from water. Therefore, the properties of PSβCyD polymer gels should be improved by fabricating polymer gels with 3 mm diameter globular particles, for optimum handling performance, an excellent porous structure for good material permeability and the mechanical strength that would enable repeated use.

The properties of PSβCyD polymer beads, obtained from different molar ratios of IEA/β-CyD in the feed as described in the Scheme 2, the diameter, compressive strength and shape judgment as general properties and separation efficiency and molar ratio of adsorbed phenol vs βCyD unit in PSβCyD polymer beads as a performance of phenol adsorption are shown in Table 3. The polymer beads were obtained in an overall yield of 33 to 69%, corresponding to the feed composition (Table 2). Diameters were in the range 2.3 to 2.9 mm. The compressive strengths were between 0.6 and 6.5 MPa; it is likely the large range of values resulted from the different components. The polymer beads of runs 3 to 6 had higher compressive strengths; especially, the polymer beads of run 6, which has the highest DS of PSβCyD polymer 6.4, obtained from a reaction with a molar ratio of β-CyD/IEA=1:3.5 (mol mol−1), showed the highest compressive strength of 6.5 MPa. The bead shapes were analyzed from enlarged pictures of the polymer beads shown in Figure 5 (⊚: excellent spherical, ○: spherical, × : lumpish). As can be seen, polymer beads obtained from runs 1, 2 and 7 did not have a regular shape; in contrast, polymer beads obtained in runs 3 to 6 exhibited a regular shape, with the polymer bead obtain in run 6 being perfectly spherical in shape.

Optical microscope photograph of photo-crosslinkable β-cyclodextrin (PSβCyD) polymer beads of runs (a) 1, (b) 2, (c) 3, (d) 4, (e) 5, (f) 6 and (g) 7 (in Table 1, × 50).

Figure 6 shows scanning electron microscopy images of the polymer beads surface (× 10 000 magnification). Though the polymer beads in run 1 are observed mainly as an aggregated structure, those obtained in runs 2 and 3 have a micro-porous thicker inner structure and slight network structure. The polymer beads in runs 4–6 were observed to have a continuous pellicular structure over a networked structure. The network has pore sizes between 0.5 and 1.0 μ φ, suggesting that the polymer beads had good material permeation properties. The bead in run 7 showed an allover continuous pellicular structure, but the network structure was poor. It was indicated that the continuous structure of each type of polymer beads appeared to be connected with the compressive strength of the polymer beads.

Scanning electron microscopy (SEM) pictures of the surface of the photo-crosslinkable β-cyclodextrin (PSβCyD) polymer beads of runs (a) 1, (b) 2, (c) 3, (d) 4, (e) 5, (f) 6 and (g) 7 (in Table 1, × 10 000).

In the case of runs 1 and 2 where the molar ratios of IEA units were lower in the feed, resulting in lower DS than 2.0 of β-CyD macromonomer, the viscosity of the PSβCyD suspension containing IEA, β-CyD and aqueous NaAlg solution became low. Therefore, the preparation of the beaded polymer was difficult, and resulted in a compressive strength below 1 MPa. In the case of run 7, when the molar ratio of IEA unit was the highest, the preparation of the beaded polymer was also difficult, resulting in a lumpish shape with a compressive strength of 3.9 MPa.

The capacity of each PSβCyD polymer bead was determined by its removal efficiency per 1 g of beads for the uptake of phenol from 5 cm3 of wastewater solution for 24 h in the batchwise case. By increasing PSβCyD components in beads, the separation efficiency of phenol rose from 46 to 69%. Runs 6 and 7 showed almost same excellent performance of the uptake of phenol. The molar ratios of (adsorbed phenol)/(β-CyD components in polymer beads) were higher by increasing PSβCyD components in beads. The molar ratio of the adsorbed phenol into the β-CyD moiety in the PSβCyD polymer beads was expected to be 1 or at most 2, if the sorption mechanism was solely because of the formation of an inclusion complex between the CyD moiety in the beads and the phenol through host–guest interactions. However, the adsorption behavior of the polymer beads cannot be completely described by this mechanism because the molar ratio of the adsorbed phenol onto the PSβCyD polymer beads was largest 10.7 at run 6. Thus, physical adsorption in the PSβCyD polymer network and chemical interactions via the hydrogen bonding formed with phenol between hydroxyl and/or amide groups were also involved in the present sorption process as described by Crini and Morcellet.14, 16, 17 Hence, the polymer network space formed between IEA residue units in the PSβCyD was greatly influenced of the physical adsorption of phenol. In our previous work,14 we reported the molar ratios of the adsorbed phenol onto the polymer beads obtained from crosslinking βCyD with hexamethylene diisocyanate having β-CyD component at 507 and 319 μmol g resin−1 as 5.5 and 9.5, respectively. In addition, the porosity of each of the polymer beads was also measured as 44% and 47% from Pore Master 60-GT. The higher phenol adsorption capacity showed the polymer beads containing lower β-CyD component and having larger porosity. It was indicated that forming polymer network space moderately arranged of CyD components without too little and/or too much was very important.

Therefore, the PSβCyD polymer beads obtained from run 6 were selected as the best ones from the results of general properties and a performance of guest adsorption.

Conclusion

Our developed preparation method of polymer with β-CyD components is highly convenient because it enabled us to obtain beaded β-CyD polymer without further addition of a crosslinking agent.

Synthesis pathway of photo-crosslinked β-CyD polymer through β-CyD derivatives bearing polysubstituted photo-crosslinkable groups. A full color version of this figure is available at Polymer Journal online.

Preparation of photo-crosslinked β-CyD polymer beads. A full color version of this figure is available at Polymer Journal online.

References

Szejtli, J. Introduction and general overview of cyclodextrin chemistry. Chem. Rev. 98, 1743–1753 (1998).

Li, Y., Guo, H., Zhanga, Y., Zhenga, J., Li, Z., Yang, C. & Lu, M. Synthesis of copolymers with cyclodextrin as pendants and its end group effect as superplasticizer. Carbohydr. Polym. 102, 278–287 (2014).

Wang, J. & Ming, J. Polymeric self-assembly into micelles and hollow spheres with multiscale cavities driven by inclusion complexation. J. Am. Chem. Soc. 128, 3703–3708 (2006).

Liu, X., Gou, S., Ye, Z., Lai, N., Liang, L., Jiang, W., Gou, S., Ye, Z., Feng, M. & Lai, N. Synthesis and evaluation of novel water-soluble copolymers based on acrylamide and modular β-cyclodextrin. Carbohydr. Polym. 96, 47–56 (2013).

Zou, C., Wu, H., Ma, L. & Lei, Y. Preparation and application of a series of novel anionic acrylamide polymers with cyclodextrin sides. J. Appl. Polym. Sci. 119, 953–961 (2011).

Zou, C., Zhao, P., Hu, X., Yan, X., Zhang, Y., Wang, X., Song, R. & Luo, P. β-cyclodextrin-functionalized hydrophobically associating acrylamide copolymer for enhanced oil recovery. Energy Fuels 27, 2827–2834 (2013).

Mohamad, S., Sarih, N. M. & Asman, S. Influence of polymer morphology on the adsorption behaviors of molecularly imprinted polymer-methacrylic acid functionalized β-cyclodextrin. J. Appl. Polym. Sci. 132, ROMBUNNO.42720 (2015).

Nazi, M., Malek, R. M. A. & Kotek, R. Modification of β-cyclodextrin with itaconic acid and application of the new derivative to cotton fabrics. Carbohydr. Polym. 88, 950–958 (2012).

Jiang, X., Qi, Y., Wang, S. & Tian, X. New amphoteric flocculant containing beta-cyclodextrin, synthesis, charaterization and decolorization properties. J. Hazard Mater. 173, 298–304 (2010).

Takadera, T. & Yonehara, Y. Study on continuous bio-ethanol fermentation process utilizing recombinant microorganism immobilized in/on supporting media composed of photo-curing materials. Jpn Res. Coat. 148, 10–16 (2007).

Morita, K. & Izumida, H. The removal technique of toxic substances from various drainage: carrier for wastewater treatment 'KP pearl'. Jpn Sangyo to Kankyo 32, 83–86 (2003).

Tanaka, J. Nitrifying bacteria adhered on resinous carriers used in advanced sewage treatment system. Jpn Res. Coat. 139, 2–11 (2002).

Tanaka, A. & Iida, T. in Enzymes in Nonaqueous Solvents Vol. 15 (eds Vulfson, E. N., Halling, P. J. & Holland, H. L.) 19–30 (Humana Press, Totowa, NJ, USA, 2001)

Yamasaki, H., Makihata, Y. & Fukunaga, K. Preparation of crosslinked β-cyclodextrin polymer beads and their application as a sorbent for removal of phenol from wastewater. J. Chem. Technol. Biotechnol. 83, 991–997 (2008).

Yamasaki, H., Makihata, Y. & Fukunaga, K. Efficient phenol removal of wastewater from phenolic resin plants using crosslinked cyclodextrin particles. J. Chem. Technol. Biotechnol. 81, 1271–1276 (2006).

Crini, G. & Morcellet, M. Synthesis and applications of adsorbents containing cyclodextrins. J. Sep. Sci. 25, 789–813 (2002).

Crini, G., Janus, L., Morcellet, M., Torri, G. & Morin, N. Sorption properties toward substituted phenolic derivative in water using macroporous polyamines containing β-cyclodextrin. J. Appl. Polym. Sci. 73, 2903–2910 (1999).

Acknowledgements

This work was partly supported by a Research for Promoting Technological Seeds (No.12-095) from Japan Science and Technology Agency, and by a research promotion grant from the Conference for Reduction of Energy & Heat-trapping Gas in the Ube Industrial Complex (2007-2008). We are grateful to Mercian Co., Ltd (Tokyo) and Meiwa Plastic Industries, Ltd (Ube) for the provision of RINGDEX- B and phenolic waste water, respectively.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Yamasaki, H., Odamura, A., Makihata, Y. et al. Preparation of new photo-crosslinked β-cyclodextrin polymer beads. Polym J 49, 377–383 (2017). https://doi.org/10.1038/pj.2016.127

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.127

This article is cited by

-

Photocrosslinked β-cyclodextrin polymer beads and their use as sorbent for phenol removal from wastewater

Polymer Bulletin (2023)

-

Preparation of photocrosslinked spherical hydrogels bearing β-cyclodextrin and application in immobilizing microbes to decompose organic pollutants

Polymer Journal (2022)

-

Removal of emerging contaminants from wastewater using advanced treatments. A review

Environmental Chemistry Letters (2022)

-

Using an Inhibitor to Prevent Plasticizer Migration from Polyurethane Matrix to EPDM Based Substrate

Chinese Journal of Polymer Science (2019)