Abstract

An amphiphilic cyclic block copolymer consisting of poly(L- or D-lactide) and poly(ethylene oxide), that is, PLLA–PEO or PDLA–PEO, was synthesized from its corresponding linear triblock precursor, PLLA–PEO–PLLA or PDLA–PEO–PDLA, respectively, with alkenyl end groups. A mixture of the micellar dispersions of linear PLLA–PEO–PLLA and linear PDLA–PEO–PDLA formed a gel upon heating, whereas a mixture of the cyclic counterparts did not undergo this phase transition. These results suggest that the gelation behavior is directed by the topology of the polymer components. Furthermore, cyclic PLLA–PEO and cyclic PDLA–PEO block copolymers incorporating photocleavable o-nitrobenzyl units were synthesized. A mixture of the micellar dispersions of these block copolymers formed a gel upon ultraviolet irradiation via the ‘topological conversion’.

Similar content being viewed by others

Introduction

Polymers can be categorized as linear, branched or cyclic depending on the number of termini and branching points present, and each type exhibits different physical properties.1, 2 For example, polyethylene, a typical general-use polymer, may take the form of high-density polyethylene that has little branching in its structure; low-density polyethylene that has a large amount of branching in its structure; or linear low-density polyethylene that has short-chain branching that originates in the monomer units. These polymers differ in their physical properties including density, crystallinity and resistance to heat. Because polymers are chosen for applications based on their characteristics, the ability to control the branching within structures has greatly expanded their application.

Because of rapid technical advances in the synthetic chemistry of polymers,3 it is also now possible to control the complex branching structures of dendrimers and star polymers.4, 5 Thus, there have been numerous studies involving the synthesis of polymers with many branched and terminal structures. In contrast, cyclic polymers do not contain branched or terminal structures. Cyclic polymers have been reported to differ from linear and branching polymers in terms of physical properties like viscosity, glass transition temperature and hydrodynamic volume.6, 7 In recent years, much success has been reported in further developing their functionality,8 such as improved heat resistance in micelles,9, 10 the control of micelle particle diameters11 and control of domain intervals.12 Increasing attention is being paid to such efforts.

In this study, we used polylactic acid (PLA) in an attempt to control the properties of the material. PLA can be synthesized using biomass with corn as the raw material, and, as such, is a carbon-neutral material13 causing no increase or decrease in carbon dioxide concentration over its lifecycle. PLA has the additional benefit of being biodegradable, and its use in research is currently very popular because of the high demand for the development of environmentally friendly materials.13 PLA occurs in two forms, poly(L-lactide) (PLLA) and poly(D-lactide) (PDLA), that differ in their stereochemistry. It is known that when the two types of PLA interlock in a crystal, they form a strong stereocomplex; formation of a stereocomplex makes it possible to greatly improve the properties of PLA, including low heat resistance and poor mechanical characteristics.14, 15

Because of the stereocomplex formation, PLLA–PEO–PLLA and PDLA–PEO–PDLA, which are block copolymers of poly(ethylene oxide) (PEO) and PLA, have the ability to gel.16 These triblock copolymers form micelles in water; when heat is applied, one end of the micelle-forming polymer protrudes out from the micelle, forming a three-dimensional structure via stereocomplex formation and ultimately resulting in a gel (Scheme 1a). Because of these characteristics and its biocompatibility, PLA–PEO–PLA shows promise for use in medical fields as a material in drug delivery systems.17 Therefore, much research is focused on controlling the gelling properties of PLA–PEO–PLA.17, 18 In some studies, PLA–PEO–PLA containing short hydrophilic segments was mixed together with PLA–PEO–PLA containing long hydrophilic segments in order to finely control the gelation temperature.17 Another example of controlling gel properties through topological control is a PLA–PEO polymer with eight branches.18 This research demonstrated that the temperature and density required for gelation of the eight-branched polymer are even lower than those required for the corresponding cyclic polymers.

Thus, it is clear that differences in the topology and the ability to form a gel are related. On this basis, we synthesized cyclic PLA–PEO and compared its ability to form a gel to the corresponding linear polymers. As noted above, the terminal structure plays an important role in the gel formation; therefore, we expected the cyclic polymers, which lack a terminal structure, to have less ability to gel (Scheme 1b). We also synthesized cyclic PLLA–PEO and cyclic PDLA–PEO, which have o-nitrobenzyl (NB) groups as photocleavable units, and devised a plan to use light to perform a ‘topological conversion’ to transform cyclic polymers19, 20 with low gelation ability to form linear polymers more capable of forming a gel (Scheme 1c).

Materials and methods

Materials

Unless otherwise noted, all commercial reagents were used as received. L-lactide (>99%, Musashino Chemical Laboratory, Tokyo, Japan) and D-lactide (>99%, Musashino Chemical Laboratory) were recrystallized from dry toluene twice before use. Tetrahydrofuran (THF; >99.0%, Kanto Chemical, Tokyo, Japan) was distilled over Na wire. Toluene (>99%, Godo, Tokyo, Japan) was distilled over CaH2. For column chromatography, Wakosil C-300 (Wako Pure Chemical Industries, Osaka, Japan) was used. Synthesis was repeated several times for some polymers, resulting in slightly different average molecular weights (Mn), peak molecular weights (Mp) and polydispersity index (PDI) values for different batches of these polymers.

Synthesis of HO–PLLA–PEO–PLLA–OH and HO–PDLA–PEO–PDLA–OH

L-lactide (1.5 g, 10.4 mmol) and PEG-4600 (2.0 g, 0.49 mmol) were vacuum dried, and tin(II) 2-ethylhexanoate (Sn(Oct)2, 3.2 mg, 7.9 μmol) in a 32 mg ml−1 toluene solution was added. Toluene was removed by vacuum drying. The reaction mixture was heated at 130 °C for 12 h under nitrogen atmosphere. The reaction mixture was allowed to cool to ambient temperature and reprecipitated from CH2Cl2 into 1-propanol to yield HO–PLLA–PEO–PLLA–OH (2.3 g Mn(NMR)=1100–4200–1100, Mp(SEC),=8000, PDI=1.11) as white solid in 53% conversion. Similarly, HO–PDLA–PEO–PDLA–OH (2.1 g, Mn(NMR)=700–4100–700, Mp(SEC)=6800, PDI=1.12) was synthesized using D-lactide in 36% conversion.

Proton nuclear magnetic resonance (1H NMR): δ (p.p.m.) 1.53–1.64 (m, –CO2CH(CH3)–), 3.61–3.67 (m, –CH2CH2O–), 4.21–4.40 (m, 6H, –CH(CH3)OH, –CO2CH2CH2O–), 5.09–5.27 (m, –CO2CH(CH3)–).

Synthesis of linear PLLA–PEO–PLLA and linear PDLA–PEO–PDLA

To a dry THF solution (200 ml) containing HO–PLLA–PEO–PLLA–OH (0.45 g, 70 μmol), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDAC, 2.19 g, 11.4 mmol), and 4-dimethylaminopyridine (DMAP, 1.17 g, 9.58 mmol) was added to 4-pentenoic acid (1.18 g, 11.7 mmol), and the resulting suspension was refluxed for 30 h under nitrogen atmosphere. The reaction mixture was evaporated to dryness under reduced pressure, and the residue was dissolved in CH2Cl2. The organic phase was washed with aqueous HCl (0.3 M) and saturated aqueous NaHCO3, dried over anhydrous Na2SO4 and evaporated to dryness. The residue was reprecipitated from CH2Cl2 into 1-propanol to yield linear PLLA–PEO–PLLA (252 mg, Mn(NMR)=1200–5300–1200, Mp(SEC)=8800, PDI=1.08) as brown solid in 46% yield. Similarly, linear PDLA–PEO–PDLA (380 mg, Mn(NMR)=850–4300–850, Mp(SEC)=8000, PDI=1.09) was synthesized using HO–PDLA–PEO–PDLA–OH in 56% yield.

1H NMR: δ (p.p.m.) 1.55–1.62 (m, –CO2CH(CH3)–), 2.37–2.55 (8H, –CH2CH2CO2–), 3.61–3.73 (m, –CH2CH2O–), 4.15–4.53 (m, 4H, –CO2CH2CH2O–),4.96–5.06(d, 4H, CH2=CH–), 5.07–5.31 (m, –CO2CH(CH3)–), 5.71–6.00(m, 2H, CH2=CH−).

Synthesis of cyclic PLLA–PEO and cyclic PDLA–PEO

The first-generation Grubbs catalyst (14.7 mg, 17.9 μmol) was added to a CH2Cl2 (600 ml) solution of linear PLLA–PEO–PLLA (120 mg, 15 μmol) at 0, 24 and 48 h, and the resulting solution was refluxed for a total of 72 h. Ethyl vinyl ether (20 ml) was added, and the mixture was stirred at ambient temperature for 2.5 h. The reaction mixture was evaporated to dryness, and the residue was subjected to column chromatography on silica gel with CH2Cl2/MeOH (100/4 vol/vol) and subsequently with CH2Cl2/MeOH (10/1 vol/vol) to give crude cyclic PLLA–PEO (Mp(SEC)=5100) as black solid also containing precursor material. A portion of the crude was fractionated by preparative size-exclusion chromatography (SEC) to isolate cyclic PLLA–PEO (42 mg, Mn(NMR)=1500–4200, Mp(SEC)=5100, PDI=1.09) in 46% yield. Similarly, cyclic PDLA–PEO (52 mg, Mn(NMR)=1400–3900, Mp(SEC)=5100, PDI=1.09) was synthesized using linear PDLA–PEO–PDLA as brown solid in 33% yield.

1H NMR: δ (p.p.m.) 1.42–1.74 (m, –CO2CH(CH3)–), 2.28–2.58 (8H, =CHCH2CH2CO2–), 3.53–3.84 (m, –CH2CH2O–), 4.16–4.43 (m, 4H, –CO2CH2CH2O–), 5.10–5.24 (m, –CO2CH(CH3)–), 5.37–5.53 (m, 2H, –CH=CH–).

Synthesis of 4-((1-(4,5-dimethoxy-2-nitrophenyl)but-3-en-1-yl)oxy)-4-oxobutanoic acid

1-(4,5-Dimethoxy-2-nitro-phenyl)-but-3-ene-1-ol (4.31 g, 17.0 mmol) was dissolved in CH2Cl2 (100 ml). To this solution were added succinic acid anhydride (9.00 g, 89.9 mmol), triethylamine (9.0 ml, 64 mmol) and DMAP (215 mg, 1.76 mmol). The resulting solution was refluxed for 20 h. The reaction mixture was then washed with water and was concentrated under reduced pressure to give 4-((1-(4,5-dimethoxy-2-nitrophenyl)but-3-en-1-yl)oxy)-4-oxobutanoic acid (3.66 g) in 61% yield.

1H NMR: δ (p.p.m.) 2.38–2.84 (m, 6H, –CO2CH2CH2CO2H, CH2=CH-CH2–), 3.84–4.13(d, 6H, CH3O-Ar), 5.00–5.24(t, 2H, CH2=CH–), 5.76–5.96(m, 1H, CH2=CH–), 6.45–6.53(q, 1H, Ar-CH(CO2CH2CH2CO2H)–CH2–CH=CH2), 6.96–7.01(s, 1H, Ar–H meta to NO2), 7.58–7.64(s, 1H, Ar–H ortho to NO2).

Synthesis of photocleavable linear NB–PLLA–PEO–PLLA–NB and linear NB–PDLA–PEO–PDLA–NB

To a dry THF solution (375 ml) containing HO–PLLA–PEO–PLLA–OH (1.00 g, 151 μmol), EDAC (2.06 g, 10.7 mmol) and DMAP (1.31 g, 10.7 mmol) was added 4-((1-(4,5-dimethoxy-2-nitrophenyl)but-3-en-1-yl)oxy)-4-oxobutanoic acid (1.64 g, 4.65 mmol), and the resulting suspension was refluxed for 30 h under nitrogen atmosphere. The reaction mixture was evaporated to dryness under reduced pressure, and the residue was dissolved in CH2Cl2. The organic phase was washed with aqueous HCl (0.3 M) and saturated aqueous NaHCO3, dried over anhydrous Na2SO4 and evaporated to dryness. The reaction mixture was fractionated by preparative SEC to isolate linear NB–PLLA–PEO–PLLA–NB (651 mg, Mn(NMR) =900–3900–900, Mp(SEC)=11 000, PDI=1.09) in 67% yield. Similarly, linear NB–PDLA–PEO–PDLA–NB (797 mg, Mn(NMR)=1100–3800–1100, Mp(SEC)=11 000, PDI=1.14) was synthesized in 77% yield using HO–PDLA–PEO–PDLA–OH.

1H NMR: δ (p.p.m.) 1.55–1.65 (m, –CO2CH(CH3)–), 2.42–2.87 (12H, –CO2CH2CH2CO2–, CH2=CH-CH2-), 3.54–3.75 (m, –CH2CH2O–), 3.92–4.05(s, 12H, CH3O-Ar) 4.18–4.42 (m, 4H, –CO2CH2CH2O–), 5.10–5.25 (m, –CO2CH(CH3)–, CH2=CH–), 5.73–5.97(m, 2H, CH2=CH–), 6.42–6.57(m, 2H, Ar–CH(CHCH=CH2)CO2–) 6.97–7.06(d. 2H, Ar–H meta to NO2) 7.56–7.69(d, 2H, Ar–H ortho to NO2).

Synthesis of photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO

The second-generation Hoveyda–Grubbs catalyst (36.1 mg, 57.6 μmol) was added to a toluene solution (1.0 l) of linear NB–PLLA–PEO–PLLA–NB (200 mg, 35 μmol), and the mixture was refluxed for 50 h. Ethyl vinyl ether (20 ml) was added, and the mixture was stirred at ambient temperature for 15 h. The reaction mixture was evaporated to dryness, and the residue was subjected to column chromatography on silica gel with CH2Cl2/MeOH (100/2 vol/vol) and subsequently with CH2Cl2/MeOH (10/1 vol/vol) to give crude cyclic NB–PLLA–PEO (Mp(SEC)=6100) as black solid containing the precursors. A portion of the crude was fractionated by preparative SEC to isolate cyclic NB–PLLA–PEO (120 mg, Mn(NMR) =1800–3700, Mp(SEC)=7600) in 55% yield. Similarly, cyclic NB–PDLA–PEO (125 mg, Mn(NMR)=2300–3600, Mp(SEC)=8600, PDI=1.11) was synthesized as brown solid in 56% yield using linear NB–PDLA–PEO–PDLA–NB.

1H NMR: δ (p.p.m.) 1.35–1.72 (m, –CO2CH(CH3)–), 2.37–2.94 (12H, –CO2CH2CH2CO2–, CH2=CH-CH2-), 3.49–3.83 (m, –CH2CH2O–), 3.90–4.04(s, 12H, CH3O-Ar) 4.21–4.36 (m, 4H, –CO2CH2CH2O–), 5.01–5.28 (m, –CO2CH(CH3)–), 5.53–5.70(m, 2H, –CH=CH–), 6.30–6.50(m, 2H, Ar–CH(CHCH=CH2)CO2–) 6.90–7.05(d. 2H, Ar–H meta to NO2) 7.51–7.66(d, 2H, Ar–H ortho to NO2).

Hydrogel preparation

Micellar dispersions of linear PLLA–PEO–PLLA, linear PDLA–PEO–PDLA, cyclic PLLA–PEO, cyclic PDLA–PEO, cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO were prepared separately for hydrogel formation. A copolymer was dissolved in THF. This solution was added dropwise into water cooled in an ice bath. After sonicating the suspension, THF was evaporated from the suspension under reduced pressure in an ice bath to acquire an aqueous micellar dispersion. The polymer concentration was adjusted by adding water as needed. Two of these dispersions were blended, and the mixture was either heated or irradiated with ultraviolet (UV) light. The physical state of the mixture was determined at each temperature by turning the vial upside down. If the mixture flowed, it was reported as a sol. If it did not flow for at least 10 s, it was reported as a gel.

Results and discussion

Synthesis of cyclic PLLA–(EO)5

We previously reported on the synthesis of cyclic PLA homopolymers,21 and the same synthetic methodology was applied here to prepare cyclic amphiphilic block copolymers. Generally, mass spectrometry of block copolymers is difficult because they contain multiple types of repeating units. Thus, in this study, we first used pentaethylene glycol as an initiator to synthesize cyclic PLLA–(EO)5 and performed matrix-assisted laser desorption ionization time-of-flight mass spectrometry (MALDI TOF-MS) to verify the synthesis (Scheme 2).

Using pentaethylene glycol as an initiator in the presence of Sn(Oct)2, L-lactide was heated to 130 °C with stirring to induce ring-opening polymerization and to obtain HO–PLLA–(EO)5–PLLA–OH. The compound was analyzed using 1H NMR, SEC and MALDI-TOF MS. In the 1H NMR spectrum (Supplementary Figure S1a), signal a, originating from methyl groups in the polylactide segments, was 1.54–1.66 p.p.m.; signal b, originating from the ester-adjacent protons, was 5.10–5.23 p.p.m.; signal e, originating from ester-adjacent methylene protons and signal f, originating from methine groups of the terminal groups, were 4.20–4.41 p.p.m. We confirmed that a reaction proceeded, and determined Mn=4700. In addition, a unimodal chromatogram was obtained by SEC (Supplementary Figure S2a) and was used to calculate Mp=9000 and PDI=1.17. We also confirmed by MALDI-TOF MS that the molecular weight obtained via analysis was consistent with the calculated molecular weight. As a specific example, the calculated molecular weight for a 50-mer was 3864.45, whereas the measured value was 3863.90 (Supplementary Figure S3a). A series of peak intervals was highly consistent with the molecular weight of C3H4O2 (72), a repeating unit in polylactic acid, and the peak interval for 49-mers and 50-mers was 71.53.

Obtained HO–PLLA–(EO)5–PLLA–OH, EDAC, DMAP and 4-pentenoic acid were dissolved in THF and refluxed, yielding linear PLLA–(EO)5–PLLA (Scheme 2). The compound was analyzed using 1H NMR, SEC and MALDI-TOF MS. In a 1H NMR spectrum (Supplementary Figure S1b), signal f, originating from the methylene adjacent to the terminal ester groups, and signal g, originating from methylene adjacent to the terminal alkene units, appeared at 2.35–2.54 p.p.m.; signal h, originating from the terminal alkene units, appeared at 5.93 p.p.m.; and signal i, originating from the terminal alkene units, appeared at 5.07–5.26 p.p.m., confirming that a condensation reaction had occurred. Furthermore, Mn was determined to be 5200. In addition, a unimodal chromatogram was obtained by SEC (Supplementary Figure S2b), and Mp=9700 and PDI=1.07 were calculated for linear PLLA–PEO–PLLA. In addition, using MALDI-TOF MS (Supplementary Figure S3b), we again confirmed that the peak molecular weight obtained was highly consistent with the calculated molecular weight. The calculated molecular weight for a 60-mer, for example, was 4749.28, whereas the measured molecular weight was 4749.93. Again, an observed series of peak intervals was highly consistent with the molecular weight of C3H4O2, with the peak intervals for 59-mers and 60-mers found to be 72.25.

Obtained linear PLLA–(EO)5–PLLA and the first-generation Grubbs catalyst were dissolved in dichloromethane and refluxed in diluted conditions that caused an olefin metathesis reaction and yielded cyclic PLLA–(EO)5 (Scheme 2). The compound was analyzed using 1H NMR, SEC and MALDI-TOF MS. In the 1H NMR spectrum (Supplementary Figure S1c), signal h, originating from the internal alkene units, shifted from 5.73–5.93 p.p.m. to 5.36–5.56 p.p.m., and the terminal CH2 units disappeared, confirming that an olefin metathesis reaction proceeded. Furthermore, Mn was calculated as 3900. In addition, using SEC (Supplementary Figure S2c), Mp was determined to be 6300 for cyclic PLLA–(EO)5 that was then purified using preparative SEC (Supplementary Figure S2d), and Mp=6000 and PDI=1.22 were determined for cyclic PLLA–(EO)5. When the prefractionation molecular weight measured by SEC was compared with the precyclization molecular weight, a decrease from Mp=9700 to Mp=6300 was observed, confirming a reduction in the hydrodynamic volume was brought about by cyclization.

Using MALDI-TOF MS (Supplementary Figure S3c), we confirmed that the peak molecular weight obtained was highly consistent with the calculated molecular weight. Where the calculated molecular weight for 60-mers was 4721.23, the measured molecular weight was 4722.18. The series of peak intervals observed was highly consistent with the molecular weight of C3H4O2 with the peak interval for 59-mers and 60-mers observed as 71.98. In addition, in the case of the 60-mers, the molecular weight of 4722.18 was 27.75 less than that of the 60-mers before the cyclization (4749.93); therefore, it was also possible to confirm that a cyclization reaction proceeded as this was highly consistent with the molecular weight of an ethylene molecule, 28.

The above results from 1H NMR, SEC and MALDI-TOF MS showed a significant difference between the states of the polymers before and after the metathesis reaction, confirming the synthesis of cyclic PLLA–(EO)5. On this basis, a method for synthesizing cyclic PLA–PEO was also established.

Synthesis of cyclic PLLA–PEO and cyclic PDLA–PEO

Cyclic PLLA–PEO and cyclic PDLA–PEO were synthesized based on Scheme 3. Using PEO (Mn=4600) as an initiator, L-lactide was heated to 130 °C and stirred in the presence of Sn(Oct)2, and HO–PLLA–PEO–PLLA–OH was obtained by ring-opening polymerization (Mn(NMR)=1100–4700–1100, Mp(SEC)=8000, PDI=1.11). The compound was analyzed using 1H NMR and SEC (Supplementary Figures S4a and S6a). The same experimental procedures were applied to obtain HO–PLLA–PEO–PLDA–OH using D-lactide (Mn=700–4600–700, Mp(SEC)=6800, PDI=1.12) (Supplementary Figures S5a and S7a).

Obtained HO–PLLA–PEO–PLLA–OH or HO–PDLA–PEO–PDLA–OH, EDAC, DMAP and 4-pentenoic acid were dissolved in THF. The hydroxy end groups were esterified by reflux, and linear PLLA–PEO–PLLA or linear PDLA–PEO–PDLA, respectively, was obtained. These polymers were analyzed using 1H NMR and SEC. In the 1H NMR spectrum (Supplementary Figure S4b), signal f, originating from the methylene groups adjacent to the terminal ester groups, and signal g, originating from methylene adjacent to the terminal alkene units, appeared at 2.37–2.55 p.p.m.; signal h, originating from the terminal alkene units, appeared at 5.71–6.00 p.p.m.; and signal i, originating from the alkene units, appeared at 4.96–5.06 p.p.m., confirming that the condensation reaction proceeded. Mn was calculated as 1200–5900–1200. Linear PDLA–PEO–PDLA (Supplementary Figure S5b) was confirmed in the same manner, with a calculated Mn=850–4800–850. In addition, unimodal chromatograms were obtained by SEC, and linear PLLA–PEO–PLLA was calculated as Mp=8800, PDI=1.08 (Supplementary Figure S6b), whereas linear PDLA–PEO–PDLA was calculated as Mp=8000, PDI=1.09 (Supplementary Figure S7b).

Obtained linear PLLA–PEO–PLLA or linear PDLA–PEO–PDLA and the first-generation Grubbs catalyst were dissolved in dichloromethane. In diluted conditions, they were refluxed, causing an intramolecular olefin metathesis reaction that yielded cyclic PLLA–PEO or cyclic PDLA–PEO, respectively. The compounds were analyzed using 1H NMR and SEC. In the 1H NMR spectrum (Supplementary Figure S4c), signal h, originating from the internal alkene unit, shifted from 5.71–6.00 p.p.m. to 5.37–5.53 p.p.m., and the CH2 group of the alkene units, which had been at 4.97–5.06 p.p.m., disappeared, confirming that an olefin metathesis reaction proceeded. Furthermore, Mn was determined to be 4100–1500. Cyclic PDLA–PEO (Supplementary Figure S5c) was confirmed in the same manner, with Mn=4400–1400. The moderate isolation yields, at 46 and 33%, were due to the formation of intermolecularly reacted products that were removed by preparative gel permeation chromatography.

Furthermore, by SEC (Supplementary Figures S6c and S7c), Mp was determined to be 5100 for both cyclic PLLA–PEO and for cyclic PDLA–PEO; because we confirmed the formation of intermolecularly metathesized products, we performed purification with preparative SEC. As a result, a unimodal chromatogram was obtained by SEC (Supplementary Figures S6d and S7d), and from it Mp=5100, PDI=1.09 for cyclic PLLA–PEO and Mp=5100, PDI=1.09 for cyclic PDLA–PEO were determined. Furthermore, as measured by SEC, a comparison of prefractionation molecular weight and precyclization molecular weight showed a decrease in the cyclic PLLA–PEO molecular weight from Mp=8800 to Mp=5100, and a decrease in cyclic PDLA–PEO from Mp=8000 to Mp=5100, confirming a reduction in the hydrodynamic volume brought about by cyclization. The above results from 1H NMR and SEC showed a significant difference between the states before and subsequent to the metathesis reaction, confirming the synthesis of cyclic PLLA–PEO and cyclic PDLA–PEO.

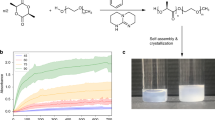

Gelation behavior of nonphotocleavable cyclic PLLA–PEO and cyclic PDLA–PEO

After fabricating cyclic PLLA–PEO and cyclic PDLA–PEO, we observed their gelation behavior in the manner previously reported.16 For comparison purposes, we performed the same gelation experiment for linear PLLA–PEO–PLLA and linear PDLA–PEO–PDLA. We also confirmed the formation of micelles using dynamic light scattering measurements. Each of linear PLLA–PEO–PLLA (20 mg) and linear PDLA–PEO–PDLA (20 mg) was dissolved in THF, and 0.2 ml of water cooled by an ice bath was added. While keeping the solution cool in ice and after exposing it to ultrasound for a several tens of seconds, THF was evaporated under reduced pressure, giving a micellar dispersion of 10 wt%. We measured the micelle diameter by dynamic light scattering. The diameters were 13.7 nm for linear PLLA–PEO–PLLA and 10.9 nm for linear PDLA–PEO–PDLA and were monodisperse (Supplementary Figures S13a and b, respectively). When each was mixed together and heated to 90 °C, gelation was observed as shown in Figure 1a. We also tested the gelation behavior for cyclic PLLA–PEO and cyclic PDLA–PEO.16 Dynamic light scattering indicated monodisperse particle diameters of 13.5 nm for cyclic PLLA–PEO and 11.3 nm for cyclic PDLA–PEO–PDLA (Supplementary Figures S13c and d, respectively). However, as seen in Figure 1b, no gelation was observed in this case. This suggests that a polymer network does not form for the micellar dispersion of the cyclic block copolymers.

Synthesis of photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO

As shown above, we experimentally ascertained that in comparison with linear PLLA–PEO–PLLA and linear PDLA–PEO–PDLA, it was difficult for cyclic PLLA–PEO and cyclic PDLA–PEO to form stereocomplexes in the micellar dispersion. Based on these experimental results, we fabricated cyclic PLLA–PEO and cyclic PDLA–PEO that contained photocleavable units. We then investigated their gelation ability introduced by the ‘topological conversion’ of cyclic polymers to linear polymers by photocleavage.

In accordance with Scheme 4, cyclic NB–PLLA–PEO and cyclic NB–PEO–PDLA were prepared. First, 1-(4,5-dimethoxy-2-nitro-phenyl)-but-3-ene-1-ol was synthesized according to previously reported methods,22 and 4-((1-(4,5-dimethoxy-2-nitrophenyl)but-3-en-1-yl)oxy)-4-oxobutanoic acid, a carboxylic acid with photocleavable unit, was synthesized in a condensation reaction with succinic anhydride. Through a condensation reaction of this carboxylic acid and HO–PLLA–PEO–PLLA–OH or HO–PDLA–PEO–PDLA–OH, alkene and photocleavable units were introduced at the termini of the polymer, and cyclic NB–PLLA–PEO or cyclic NB–PEO–PDLA, respectively, was subsequently synthesized by metathesis under diluted conditions. 1-(4,5-Dimethoxy-2-nitro-phenyl)-but-3-ene-1-ol, DMAP and succinic anhydride were mixed with triethylamine and dichloromethane, and the mixture was refluxed to cause a condensation reaction between 1-(4,5-dimethoxy-2-nitro-phenyl)-but-3-ene-1-ol and succinic anhydride. The compound was analyzed using 1H NMR. In the 1H NMR spectrum (Supplementary Figure S8), all peaks were successfully attributed. In particular, signal b, originating from aromatic rings, shifted after the reaction and appeared at 6.96–7.01 p.p.m., confirming the formation of ester groups.

HO–PLLA–PEO–PLLA–OH or HO–PDLA–PEO–PDLA–OH, EDAC, 4-((1-(4,5-dimethoxy-2-nitrophenyl)but-3-en-1-yl)oxy)-4-oxobutanoic acid and DMAP were dissolved in THF and refluxed, esterifying the hydroxy end groups to obtain linear NB–PLLA–PEO–PLLA–NB or linear NB–PDLA–PEO–PDLA–NB, respectively. The compound was analyzed using 1H NMR and SEC. In the 1H NMR spectrum (Supplementary Figure S9a), signal h, originating from the methine groups adjacent to the photocleavable units, appeared at 6.42–6.57 p.p.m.; signals 1 and m, originating from the methylene groups adjacent to the terminal alkene units and methylene groups adjacent to the terminal ester units, appeared at 3.45–3.75 p.p.m.; signal i, originating from the terminal alkene units, appeared at 5.73–5.97 p.p.m.; signals f and g, originating from aromatic rings, appeared at 7.56–7.69 p.p.m. and 6.97–7.06 p.p.m., respectively; and signal k, originating from methyl ether on aromatic rings, appeared at 3.92–4.05 p.p.m., confirming that a condensation reaction proceeded. Furthermore, Mn was determined as 900–4400–900. Linear NB–PDLA–PEO–PDLA–NB (Supplementary Figure S10a) was confirmed in the same manner, with Mn=1100–4300–1100. In addition, a unimodal chromatogram was obtained with the SEC measurement (Supplementary Figures S11a and S12a), and linear NB–PLLA–PEO–PLLA–NB was calculated as Mp=11000, PDI=1.09, whereas linear NB–PDLA–PEO–PDLA–NB was calculated as Mp=11000, PDI=1.14.

Obtained linear NB–PLLA–PEO–PLLA–NB or linear NB–PDLA–PEO–PDLA–NB and the second-generation Hoveyda–Grubbs catalyst were dissolved in toluene and, under diluted conditions, stirred at 80 °C, causing an intramolecular olefin metathesis reaction to occur, yielding cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO. The compound was analyzed using 1H NMR and SEC. In the 1H NMR spectrum (Supplementary Figure S9b), signal h, originating from the olefins, shifted from 5.73–5.97 p.p.m. to 5.53–5.70 p.p.m., confirming that the metathesis reaction proceeded. Furthermore, Mn was determined as 4200–1800. Cyclic NB–PDLA–PEO (Supplementary Figure S10b) was confirmed in the same manner, with Mn=4100–2300.

Furthermore, in SEC measurements (Supplementary Figures S11b and S12b), Mp=6100 was calculated for cyclic NB–PLLA–PEO, and Mp=7800 was calculated for cyclic NB–PDLA–PEO. Because intermolecularly coupled products were formed, we performed purification using preparative SEC. As a result, a unimodal chromatogram was obtained by SEC (Supplementary Figures S11c and S12c), and from it Mp=7600, PDI=1.20 for cyclic NB–PLLA–PEO and Mp=8600, PDI=1.11 for cyclic NB–PDLA–PEO were determined. When the prepurification molecular weight as measured by SEC was compared with the precyclization molecular weight, Mp was found to decrease from 11 000 to 6100 for cyclic NB–PLLA–PEO, a reduction by 45%. Together with the decrease seen in the molecular weight of cyclic NB–PDLA–PEO from Mp=11 000 to Mp=7800, a reduction by 30%, the synthesis was confirmed. As was the case with cyclic PLLA–PEO and cyclic PDLA–PEO, the moderate isolation yields (55 and 56%) were because of the formation of intermolecularly reacted products that were removed by preparative gel permeation chromatography.

Gelation behavior of photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO

A mixture of the micellar dispersions of photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO was tested for gelation. We examined for gelation in the manner previously reported.17 Cyclic NB–PLLA–PEO or cyclic NB–PDLA–PEO (10 mg) was dissolved in THF cooled by an ice bath, and 0.1 ml of water was added. After being exposed in this cooled state to ultrasound for several tens of seconds, the THF was evaporated under reduced pressure in an ice bath, creating a micellar dispersion of 10 wt%. Dynamic light scattering measurement showed that the particle diameters were 13.4 nm for cyclic NB–PLLA–PEO and 13.0 nm for cyclic NB–PDLA–PEO, indicating that each formed micelles with a narrow size distribution (Supplementary Figures S13e and S13f, respectively). After mixing these dispersions (Figure 2a), the mixture was UV radiated at 365 nm using an Asahi Spectra POT-365 light source (Tokyo, Japan) (980 mW cm−2 at ϕ=6 mm) for 30 min while being cooled in an ice bath and gelled as shown in Figure 2b.

Photographs of mixtures of micellar dispersions of photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO (a) before and (b) after UV irradiation, (c) non-photocleavable cyclic PLLA–PEO and cyclic PDLA–PEO after UV irradiation, (d) non–photocleavable cyclic PLLA–PEO and cyclic PDLA–PEO and a sodium carboxylate salt of a photocleavable unit after UV irradiation and (e) photocleavable cyclic NB–PLLA–PEO after ultraviolet (UV) irradiation. PDLA, poly(D-lactide); PLLA, poly(L-lactide); PEO, poly(ethylene oxide); NB, o-nitrobenzyl.

The polymer components of the gel were characterized using 1H NMR, infrared spectroscopy and SEC after evaporating water in the sample under reduced pressure. The 1H NMR spectrum (Supplementary Figure S14a) confirmed that the peak (indicated by arrows in the figure) originating from the photocleavable units had decreased and that UV irradiation had indeed caused photocleavage, as there were indications that topological conversion to linear polymers had occurred. The Mp value decreased, as determined by SEC (Supplementary Figure S14b), to 6700 in comparison with pre-photocleaving measurements of cyclic NB–PLLA–PEO (Mp=7600) and cyclic NB–PDLA–PEO (Mp=8600). Essentially, the Mp value should have increased if the ideal topological conversion had occurred, but it may have decreased because of the removal of the two NB units. Infrared spectrum measurement results are shown in Supplementary Figure S14c. The peak originating in the carbonyl group of cyclic NB–PLLA–PEO was positioned at 1757.8 cm−1, and the peak shifted to 1752.0 cm−1 upon gel formation, suggesting that a stereocomplex formed.23 From these points, we conclude that the polymers in this experiment, obtained by the topological conversion to a linear state, formed a stereocomplex and gelled.

To demonstrate that gelation stems from the stereocomplex formation, we exposed a mixture of micellar dispersions of cyclic PLLA–PEO and cyclic PDLA–PEO without photocleavable parts to UV radiation. There was no change in the fluidity when the mixed micellar dispersion was exposed to UV radiation under the same conditions as above (Figure 2c). Using NMR and SEC measurements, we ascertained that decomposition did not occur. To further investigate, a sodium carboxylate salt having photocleavable units was added to the mixed micellar dispersions of cyclic PLLA–PEO and cyclic PDLA–PEO without photocleavable units in the structure, and this mixture was exposed to UV light. However, no change in fluidity was observed (Figure 2d). Using NMR and SEC measurements, we confirmed that decomposition did not occur. This led us to conclude that the cleavage of the cyclic polymers had affected gelation.

Finally, we attempted the same experiment using only cyclic NB–PLLA–PEO. In doing so, we were able to determine that the state of fluidity remained, and there was no gelation (Figure 2e). Because the peaks in the 1H NMR spectrum of the photocleavable parts decreased (Supplementary Figure S15a), we concluded that the photocleavage occurred because of UV radiation, suggesting the topological conversion to a linear polymer. A decrease in Mp (7300) was observed by SEC (Supplementary Figure S15b). However, in the infrared spectrum, as shown in Supplementary Figure S15c, no peak shift was observed, and thus there was no stereocomplex formation. From the above, it may be concluded that stereocomplexation stimulated the gel formation upon the topological conversion.

Conclusions

We synthesized cyclic PLLA–PEO and cyclic PDLA–PEO polymers, tested their gelation and observed clear changes in gelation behavior, demonstrating the decreased gelling ability of cyclic PLA–PEO in comparison with the corresponding linear polymers. By using cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO incorporating photocleavable units, we also uncovered the existence of a characteristic photoresponsive gelation behavior based on the topological conversion. Through this set of experiments, we have been able to demonstrate the significance of the idea of ‘topological conversion’. Furthermore, because of the potential for the use of PLA–PEO block copolymers as UV-responsive gelling agents, we anticipate the effective use of the polymers reported here in the medical field, particularly in drug delivery systems.

Schematic illustrations for the possible gelation of a mixture of micellar dispersions formed from (a) linear PLLA–PEO–PLLA and linear PDLA–PEO–PDLA, (b) cyclic PLLA–PEO and cyclic PDLA–PEO and (c) photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO. PDLA, poly(D-lactide); PLLA, poly(L-lactide); PEO, poly(ethylene oxide); NB, o-nitrobenzyl.

Synthesis of cyclic PLLA–(EO)5. PLLA, poly(L-lactide); (EO)5, pentaethylene glycol.

Synthesis of cyclic PLLA–PEO and cyclic PDLA–PEO. PDLA, poly(D-lactide); PLLA, poly(L-lactide); PEO, poly(ethylene oxide).

Synthesis of photocleavable cyclic NB–PLLA–PEO and cyclic NB–PDLA–PEO. PDLA, poly(D-lactide); PLLA, poly(L-lactide); PEO, poly(ethylene oxide); NB, o-nitrobenzyl.

References

Yamamoto, T. Synthesis of cyclic polymers and topology effects on their diffusion and thermal properties. Polym. J. 45, 711–717 (2013).

Yamamoto, T. & Tezuka, Y. Topological polymer chemistry: a cyclic approach toward novel polymer properties and functions. Polym. Chem. 2, 1930–1941 (2011).

Endo, K. Synthesis and properties of cyclic polymers. Adv. Polym. Sci. 217, 121–183 (2008).

Jang, W.-D. & Aida, T. Supramolecular nanofiber formation of macrocyclic dendrimer. Macromolecules 37, 7325–7330 (2004).

Isono, T., Kondo, Y., Otsuka, I., Nishiyama, Y., Borsali, R., Kakuchi, T. & Satoh, T. Synthesis and stereocomplex formation of star-shaped stereoblock polylactides consisting of poly(L-lactide) and poly(D-lactide) arms. Macromolecules 46, 8509–8518 (2013).

Tezuka, Y. Topological polymer chemistry for designing multicyclic macromolecular architectures. Polym. J. 44, 1159–1169 (2012).

Topological Polymer Chemistry: Progress of Cyclic Polymers in Syntheses, Properties and Functions (ed. Tezuka, Y. (World Scientific, Singapore, 2013).

Yamamoto, T. & Tezuka, Y. Cyclic polymers revealing topology effects upon self-assemblies, dynamics and responses. Soft Matter 11, 7458–7468 (2015).

Honda, S., Yamamoto, T. & Tezuka, Y. Topology-directed control on thermal stability: micelles formed from linear and cyclized amphiphilic block copolymers. J. Am. Chem. Soc. 132, 10251–10253 (2010).

Honda, S., Yamamoto, T. & Tezuka, Y. Tuneable enhancement of the salt and thermal stability of polymeric micelles by cyclized amphiphiles. Nat. Commun. 4, 1574 (2013).

Zhang, B., Zhang, H., Li, Y., Hoskins, J. N. & Grayson, S. M. Exploring the effect of amphiphilic polymer architecture: synthesis, characterization, and self-assembly of both cyclic and linear poly(ethylene gylcol)-b-polycaprolactone. ACS Macro Lett. 2, 845–848 (2013).

Poelma, J. E., Ono, K., Miyajima, D., Aida, T., Satoh, K. & Hawker, C. J. Cyclic block copolymers for controlling feature sizes in block copolymer lithography. ACS Nano 6, 10845–10854 (2012).

Jamshidian, M., Tehrany, E. A., Imran, M., Jacquot, M. & Desobry, S. Poly-lactic acid: production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. 9, 552–571 (2010).

Tsuji, H. & Tezuka, Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. 12. Spherulite growth of low-molecular-weight poly(lactic acid)s from the melt. Biomacromolecules 5, 1181–1186 (2004).

Nampoothiri, K. M., Nair, N. R. & John, R. P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 101, 8493–8501 (2010).

Fujiwara, T., Mukose, T., Yamaoka, T., Yamane, H., Sakurai, S. & Kimura, Y. Novel thermo-responsive formation of a hydrogel by stereo-complexation between PLLA-PEG-PLLA and PDLA-PEG-PDLA block copolymers. Macromol. Biosci. 1, 204–208 (2001).

Abebe, D. G. & Fujiwara, T. Controlled thermoresponsive hydrogels by stereocomplexed PLA-PEG-PLA prepared via hybrid micelles of pre-mixed copolymers with different PEG lengths. Biomacromolecules 13, 1828–1836 (2012).

Hiemstra, C., Zhong, Z., Li, L., Dijkstra, P. J. & Feijen, J. In-situ formation of biodegradable hydrogels by stereocomplexation of PEG-(PLLA)8 and PEG-(PDLA)8 star block copolymers. Biomacromolecules 7, 2790–2795 (2006).

Sugai, N., Asai, S., Tezuka, Y. & Yamamoto, T. Photoinduced topological transformation of cyclized polylactides for switching the properties of homocrystals and stereocomplexes. Polym. Chem. 6, 3591–3600 (2015).

Yamazoe, S., Shestopalov, I. A., Provost, E., Leach, S. D. & Chen, J. K. Cyclic caged morpholinos: conformationally gated probes of embryonic gene function. Angew. Chem. Int. Ed. 51, 6908–6911 (2012).

Sugai, N., Yamamoto, T. & Tezuka, Y. Synthesis of orientationally isomeric cyclic stereoblock polylactides with head-to-head and head-to-tail linkages of the enantiomeric segments. ACS Macro Lett. 1, 902–906 (2012).

Burakowska, E., Zimmerman, S. C. & Haag, R. Photoresponsive crosslinked hyperbranched polyglycerols as smart nanocarriers for guest binding and controlled release. Small 5, 2199–2204 (2009).

Tsuji, H. Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol. Biosci. 5, 569–597 (2005).

Acknowledgements

This work was partially supported by KAKENHI (26288099, 15H01595 and 15K13703).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Yamamoto, T., Inoue, K. & Tezuka, Y. Hydrogel formation by the ‘topological conversion’ of cyclic PLA–PEO block copolymers. Polym J 48, 391–398 (2016). https://doi.org/10.1038/pj.2015.134

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.134

This article is cited by

-

Poly(lactic acid) based hydrogels: formation, characteristics and biomedical applications

Journal of Porous Materials (2019)