Abstract

This article reviews recent advances in the creation of functional spaces with core-functionalized star polymers and single-chain folding/crosslinked polymers via living radical polymerization. Various core-functionalized star polymers were efficiently prepared with functional linking agents and monomers to perform unique functions. For example, they can serve as nanoreactors for active and robust catalysis in organic reactions and polymerization and as nanocapsules for selective and stimuli-responsive molecular recognition. Single-chain folding polymers were obtained from the self-folding of amphiphilic random copolymers bearing hydrophilic poly(ethylene glycol) chains and hydrophobic alkyl pendants in water, resulting in unimer micelles with dynamic hydrophobic domains. The folded structure could be further fixed via the intramolecular crosslinking of the hydrophobic interior. In addition, cation template-assisted cyclopolymerization and concurrent tandem living radical polymerization with in situ monomer transesterification were also developed for the one-pot synthesis of cyclopolymers with large in-chain cavities and gradient and sequence-controlled copolymers.

Similar content being viewed by others

Introduction

Polymers and macromolecules can provide three-dimensional compartments1, 2, 3, 4, 5, 6, 7, 8, 9, 10 and place functional groups in a specific position11 to serve as promising scaffolds for unique functional spaces. Proteins and enzymes naturally possess precision nanocavities within their globular tertiary structure where they perform selective recognition and catalysis in water. The tertiary structure consists of self-folding polymer chains with perfectly controlled primary structures. Recent advances in living radical polymerization and the initiating/catalytic systems have allowed us to tailor-make functional polymers with controlled primary structure and three-dimensional and/or branched architecture.12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22 Focusing on these features, we have recently developed functional polymer spaces (microgel-core star polymers, single-chain folding/crosslinked polymers)8, 9, 10 and functional polymer chains (cyclopolymers, sequence-controlled polymers) via ruthenium-catalyzed living radical polymerization.12, 13 These polymers perform unique functions reflecting their primary structure and specific environment (Figure 1).

With functionalization and/or primary structure control, synthetic linear polymers can be typically transformed into the following globular, compartmentalized polymers: (1) microgel-core star polymers;8, 9, 10, 23, 24, 25 (2) micelles, vesicles and polymersomes;3, 4, 5, 6 and (3) unimer micelles and single-chain polymeric nanoparticles.26, 27, 28 Among these, microgel-core star polymers comprise crosslinked microgels that are covered and solubilized by multiple linear arm polymers to be regarded as ‘solubilized gels’.29 Such star polymers are generally obtained from the intermolecular crosslinking of living polymers (or macroinitiators) with divinyl compounds in living polymerization,29, 30, 31, 32, 33, 34, 35 whereas the microgel cores of divinyl compounds have been conventionally used as a connecting point of arm polymers. Beyond such classical understanding, we regard the microgel cores of star polymers as crosslinked but solubilized functional spaces8, 9, 10, 36, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46 that are distinct from dynamic, non-crosslinked spaces such as micelles via the physical self-assembly of amphiphilic block copolymers in solvents that are poor for one of the segments.3, 4, 5

By contrast, amphiphilic or functional linear random copolymers in turn self-fold to form unimer micelles and single-chain polymeric nanoparticles with intramolecular non-covalent physical (for example, hydrophobic or hydrogen bonding) interaction and/or covalent chemical crosslinking in specific solvents.47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 60, 61, 62 The folding spaces are not only attractive as an artificial mimic of proteins and enzymes but they can also be more precisely designed because the primary structure (for example, molecular weight, composition of monomers and functional groups) of linear polymers is directly related to folding spaces.

Here, we review recent advances in the synthesis and functions of microgel-core star polymers37, 38, 39, 40, 41, 42, 43, 44, 45, 46 and single-chain folding/crosslinked polymers57, 58, 59, 60, 61 via living radical polymerization. In addition, smart synthetic strategies for cyclopolymers with large in-chain cavities63 and sequence-controlled polymers64, 65, 66 are also briefly described.

Results and Discussion

Core-functionalized star polymers

Design of microgels and arms

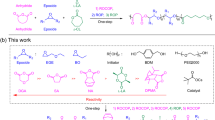

As a result of the high functionality tolerance and controllability of ruthenium catalysts,12, 13 various core-functionalized star polymers have been directly synthesized by the ruthenium-mediated linking reaction of chlorine-capped linear arm polymers (living polymers or macroinitiators) with functional divinyl linkers/monomers carrying phosphines (2), amines (3, 4), quaternary ammonium salts (5, 6), poly(ethylene glycol) (7, 8), hydroxyl groups (9), perfluorinated alkanes (10, 11) and urea groups (12); (Figure 2).8, 9, 10, 37, 38, 39, 40, 41, 42, 43, 44, 45, 46 Efficient preparation involves the following: (1) selection of catalytic systems (RuCl2(PPh3)3/n-Bu3N, Ru(Ind)Cl(PPh3)2/n-Bu3N, RuCp*Cl(PPh3)2/amino alcohol (for example, 4-dimethylaminobutanol)) and solvents (toluene, ethanol and water) suitable for arm polymers and core-forming functional linkers/monomers; and (2) optimization of the feed ratio of core-forming linkers/monomers to arm chains ([R–Cl]).

Arm polymers provide the desired solubility to star polymers. Arm chains are typically obtained from one of two methods: (1) living radical polymerization of monomers (for example, methyl methacrylate (MMA),29, 30, 36, 37, 38, 39, 40, 41, 45 poly(ethylene glycol) methyl ether methacrylate (PEGMA: Mn=475; ethylene oxide units=8.5)42, 43, 44) with a chlorine-based initiator (a chlorine-capped MMA dimer: H-(MMA)2-Cl, ethyl 2-chloro-2-phenylacetate); and (2) esterification of polymer chains (for example, poly(ethylene glycol) methyl ether (PEG-OH: Mn=5000; ethylene oxide units=113)) with an acid chloride (2-chloro-2-phenylacetyl chloride).46 The former yields hydrophobic poly(methyl methacrylate) arms (PMMA-Cl) and amphiphilic, thermosensitive poly[poly(ethylene glycol) methyl ether methacrylate] arms (PPEGMA-Cl), whereas the latter yields amphiphilic long poly(ethylene glycol) methyl ether arms (PEG-Cl; Figure 2). PMMA-arm star polymers are soluble in organic solvents including toluene, tetrahydrofuran, chloroform and N,N-dimethylformamide (DMF), whereas their PEG counterparts are soluble not only in such organic solvents but also in alcohols and water with thermoresponsive solubility.

Metal-bearing star polymer catalysts

Generally, polymer-supported metal catalysts should have high practicability and easy handling in catalysis (recovery and separation of catalysts and products, catalyst recycling).67, 68 This objective is achieved with insoluble scaffolds such as silica gel and crosslinked polystyrene, whereas the insolubility often leads to low activity and selectivity. Soluble polymer-supported metal catalysts in turn maintain an activity level that is consistent with the original homogeneous counterparts, although they sometimes cause metal leaching during reactions and in the recovery processes. Thus, it is difficult for polymer-supported catalysts to satisfy both catalytic activity and practicability.

By contrast, metal-bearing microgel star polymers are expected to exhibit high activity and selectivity together with high stability and robustness because the metal complexes are tightly supported within solubilized microgels. Focusing on this aspect, we designed metal/ligand-bearing microgel star polymers via ruthenium-catalyzed living radical polymerization with ligand-bearing monomers (2, 3).8, 9, 10, 37, 38, 39, 40, 41, 42, 43, 44 Importantly, this synthetic strategy affords a one-pot transformation of ruthenium polymerization catalysts into ruthenium-bearing star polymer catalysts, which is thus more efficient than conventional multistep procedures: (1) synthesis of ligand-bearing (co)polymers, followed by the post introduction of metals; and (2) synthesis of metal-bearing monomers, followed by (co)polymerization.

Typically, MMA was first polymerized with a chloride initiator and a ruthenium catalyst (RuCl2(PPh3)3/n-Bu3N) to yield chlorine-capped PMMA-Cl with a narrow molecular weight distribution (condition: [MMA]0/[initiator]0/[RuCl2(PPh3)3]0/[n-Bu3N]0=2000/20/10/40 mM, conv.=∼90%, 48 h, Mn=11 000, Mw/Mn=∼1.2). Then, PMMA-Cl was directly crosslinked with ethylene glycol dimethacrylate (EGDMA: 1) in the presence of a phosphine-bearing styrene derivative (2) in toluene ([1]0/[2]0/[PMMA–Cl]0=10/1.25–5/1), leading to the production of phosphine and ruthenium-bearing microgel star polymers in high yield (80∼90%; Figure 3a).37, 38, 40 During the arm-linking process, 2 is simultaneously coordinated to RuCl2(PPh3)3 (polymerization catalyst) via a ligand exchange reaction to directly encapsulate the ruthenium complex into star polymer cores. A star polymer ([2]0/[PMMA–Cl]0=5) had an absolute weight-average molecular weight (Mw) of 650 000, 35 arm numbers (Narm) and a radius of gyration (Rg) of 10 nm, as analyzed by multiangle laser light scattering coupled with size exclusion chromatography (SEC-MALLS).

Synthesis of core-functionalized star polymers via Ru-catalyzed linking reactions of arm polymers (PMMA-Cl or PEG-Cl) with functional linkers and monomers ((a) 1, 2, (b) 7, (c) 1, 11, (d) 5, (e) 12, (f) 1): [arm]0/[linker]0/[monomer]0=1/10/0 or (a) 5 or (c) 10. Catalytic system: (a) RuCl2 or (b, c) Ru(Ind) in toluene at 80 °C; (d–f) RuCp* in ethanol at 40 °C.

Mw, Narm, ligand and ruthenium content in star polymers are controllable by the feed ratio of monomers (1 and 2) to PMMA arms (r1=[1]0/[PMMA–Cl]0, r2=[2]0/[PMMA–Cl]0).38 Arm length is simply tunable by the feed ratio of MMA to an initiator (DP=[MMA]0/[initiator]0). System optimization revealed that EGDMA (r1=10) was effective for the linking of PMMA–Cl (DP=100, Mn=∼10 000). The ruthenium content in star polymers increased from 31 to 74 μmol g−1 with increasing ligand feed (r2=1.25, 2.5, 5), which was confirmed using ultraviolet-visible absorption spectroscopy (UV-vis) and inductively coupled plasma-atomic emission spectroscopy.38 A star polymer with r2=5 almost quantitatively encapsulates Ru polymerization catalysts into the core. Owing to the in-core Ru, Ru-star polymers cast on a glass plate were observed as black dots of ∼2–3 nm with transmission electron microscopy.37, 38

Metal-bearing star polymers are further functionalized and modified with arms, ligands and metal interchange. PPEGMA arms provide amphiphilic and thermosensitive solubility to star polymers bearing hydrophobic microgels.42 Core-bound metals are interchangeable from an original ruthenium [RuCl2(PPh3)3] to others (iron and nickel) via ligand exchange reaction.40, 41 Core-bound ruthenium in Ru-Star can be removed with a hydrophilic and basic phosphine [P(CH2OH)3], leading to empty star polymers with phosphine-bearing microgels (PPh3-Star; Figure 4). PPh3-Star can again enclose various metal salts and complexes (M: FeX2, NiX2, FeX2(PPh3)2, NiX2(PPh3)2, NiBr2(Pn-Bu3)2, X=Br or Cl) to provide novel metal-bearing star polymer catalysts (Metal-Star).

However, PPh3-Star cores still contain chlorine terminals and unreacted pendant olefins that may induce undesired reactions such as gelation in radical-mediated catalysis. This possibility is avoided by the core hydrogenation of Ru-Star before Ru removal.40, 41 The hydrogenation of in-core olefins and chlorine terminals is mediated by in-core ruthenium hydride (RuH2) that is directly transformed from ruthenium chloride complexes (RuCl2) with K2CO3 and 2-propanol.69 Chiral ruthenium catalysts can also be directly created in microgels with a styrene derivative carrying a chiral diamine ligand (3).10

Function-condensed star polymer capsules

In addition to phosphine (2) and diamine (3), various functional groups (4–12) can be introduced into star polymer cores via ruthenium-mediated arm-linking reaction, yielding star polymer nanocapsules that efficiently and selectively capture guest molecules within the microgel cores.8, 9, 10, 41, 45, 46 The key is to condense functional groups into microgels at a high local concentration.

A Ru(Ind)Cl(PPh3)2/n-Bu3N catalytic system is widely applicable to chlorine-capped polymethacrylate arms (PMMA–Cl, PPEGMA–Cl) and functional (di)methacrylates (4, 7–11) (Figures 3b and c). Typically, fluorous microgel star polymers are obtained from the Ru(Ind)Cl(PPh3)2-catalyzed linking reaction of PMMA–Cl (Mn=13 000) with perfluorinated alkane methacrylates (10, 11) ([1]0/[11]0/[PMMA–Cl]0=10/10/1, Mw=1 200 000, 52 arms, Rg=12 nm).45 The number of core-bound perfluorinated alkanes (NCF3) and fluorine atoms (NF) is controlled by the feed ratio of perfluorinated monomers to arms (NCF3=0–760, NF=2000–15 000). Importantly, the properties and mobility of fluorinated microgels are evaluated by 19F nuclear magnetic resonance. The mobility of in-core perfluorinated pendants is dependent on solvents; the fluorine signal is broader in DMF-d7 than in CDCl3, meaning that DMF promotes intramolecular aggregation of the perfluorinated alkanes with fluorous interaction. Confirmed by relaxation time (T1) measurements with 19F nuclear magnetic resonance, the thermal mobility of fluorinated pendants in star polymers was much lower than that in linear random counterparts.

Coupling of RuCp*Cl(PPh3)2 with amino alcohol additives effectively induces the linking reaction of hydrophilic PEG–Cl arms with polar functional linkers/monomers carrying quaternary ammonium salts (5, 6)46 and urea groups (12)10 (insoluble in organic solvents such as toluene) in ethanol, DMF, and water (Figures 3d and e). The resulting star polymers are water-soluble and have narrow molecular weight distribution (yield: ∼90%, [5 or 12]0/[PEG–Cl]0=10/1, Mw/Mn=1.1–1.3). It should be noted that RuCp*Cl(PPh3)2 has high controllability of such polar functional monomers, which is comparable to that of a non-functional EGDMA (1, Figure 3f).

Catalysis

Ruthenium complexes are widely utilized as catalysts not only for living radical polymerization but also for organic reactions (for example, oxidation and reduction).70 The catalytic activity of ruthenium-bearing star polymers was thus investigated in the oxidation of sec-alcohols,37, 39 hydrogenation of ketones43, 44 and living radical polymerization40, 41 (Figure 5). Ru-bearing star polymer catalysts obtained from direct RuCl2(PPh3)3 encapsulation with a ligand monomer (2) were employed for oxidation and hydrogenation, whereas metal-bearing counterparts were utilized for living radical polymerization via metal interchange (core hydrogenation, Ru removal, metal introduction).

Ru/2-bearing star polymers with PMMA arms (Ru-Star) were effective in the oxidation of various sec-alcohols (for example, A1–A4) with K2CO3 in acetone at 65 °C (Figure 5a).37, 39 Typically, Ru-Star (Mw=388 000, 24 arms (Mn=∼10 000), core 2: 60/star, core Ru: 15/star) homogeneously catalyzed the oxidation of 1-phenylethanol (A1) into acetophenone in high yield (90%, 8 h), even at a low catalyst feed ratio to the substrate ([substrate]0/[Ru]0=1000/1, turnover frequency (h−1)=∼110).39 The activity was greater than that obtained with a Ru-supported polystyrene gel (64%, 8 h) and a Ru-supported MMA/2 linear random copolymer (52%, 8 h). Importantly, the catalytic activity of Ru-Star depends on the ratio of 2 (ligand) to Ru in the core ([core 2]/[core Ru]); turnover frequency (h−1) increased from 110 to 300 with a decrease in the ratio [core 2]/[core Ru] from 4 to 2.5. This result suggests that coordinatively unsaturated metal species efficiently induce catalysis. This activity was in turn independent of arm length and 1 (crosslinking unit), indicating that small substrates freely diffuse in Ru-bearing microgel spaces. Ru-Star can be reused three times without any retardation of activity or decomposition of polymer via recovery under air exposure. These results demonstrate that ruthenium-bearing star polymers are active, robust and stable catalysts for organic reactions.

Because of its amphiphilic solubility, Ru-Star with PPEGMA arms (PEG Ru-Star) functions as an active and recyclable catalyst for the transfer hydrogenation of ketones (for example, K1–K9) to sec-alcohols in 2-propanol at 100 °C ([substrate]0/[Ru]0=1000/1, Figure 5b).44 PEG Ru-Star showed high activity for various substrates, including acetophenone (K1: turnover frequency=∼220 h−1), p-chloroacetophenone (K2: ∼930 h−1), cyclohexanone (K6: ∼980 h−1) and 2-octanone (K8: ∼230 h−1). In addition, PEG Ru-Star is recyclable three times in acetophenone and 2-octanone.

More intriguingly, PEG Ru-Star affords thermoregulated phase-transfer catalysis in the hydrogenation of 2-octanone (K8, hydrophobic, aliphatic substrate) in 2-propanol/H2O (1/1, v/v).43 The reaction mixture is phase-separated into an organic (upper) layer of 2-propanol and 2-octanone and an aqueous (lower) layer. In the biphasic solution, PEG Ru-Star rapidly moves from the lower aqueous layer to the upper organic layer upon heating to efficiently catalyze the hydrogenation in dispersion at 100 °C. Upon cooling the reaction solution to room temperature after the reaction, PEG Ru-Star returns to the aqueous phase. Thus, easy product recovery and efficient catalyst recycling were achieved via thermoregulated phase transfer.

Star polymer catalysts can be further applicable to living radical polymerization of methacrylates and styrene (Figure 5c).40, 41 A RuCp*-bearing star polymer (RuCp*-Star), obtained with hydrogenated PPh3-Star and [RuCp*Cl]4 (Cp*: pentamethylcyclopentadienyl), efficiently induced living radical polymerization of MMA with a chloride initiator (conv. ∼90%) to yield well-controlled PMMA with a narrow molecular weight distribution (Mw/Mn: ∼1.1) and high end functionality (end olefin: <3%).40 This result indicates that microgel cores have enough void space for growing polymer terminals that can smoothly access core-bound ruthenium. The activity and controllability were better than those obtained with an in-core ruthenium analog [RuCp*Cl(PPh3)2]. It should be noted that RuCp*-Star induces direct copolymerization of MMA and methacrylic acid (MAA) owing to efficient metal protection. Tolerance to acidic functions is further enhanced by multifunctionalization of RuCp*-Star cores with phosphine and amino groups; the Ru metal is efficiently activated and protected by the cooperative ligation of phosphine (2) and amine (4).41 The stability of iron catalysts was also improved with PPh3-Star.40

Molecular encapsulation and release

Function-condensed microgel star polymers (fluorinated core, PEG core and cation core) efficiently and selectively capture molecules within their cores and release them in response to a stimulus; this process is dependent on the core-bound functional groups (Figure 6). Typically, fluorinated star polymers with PMMA arms (Mw=2 000 000, 86 arms (Mn=∼13 000), core-F atom (10+11): 14 800/star, core-CF3 (11): 760/star) can encapsulate polyfluorinated compounds, including perfluorooctane, perfluorohexane and perfluoromethylcyclohexane, via fluorous interaction in DMF (Figure 6a).45 The efficiency for fluorous encapsulation was enhanced with an increased local concentration of perfluoroalkane pendants (11), whereas a perfluoroalkane spacer in dimethacrylate (10) is almost independent of fluorous interaction. A fluorinated star polymer selectively recognized perfluorooctane even in the presence of other fluorinated compounds (trifluoromethylbenzene: hydrophobic, trifluoroethanol: hydrophilic) and further released in-core perfluorooctane via the addition of CHCl3.

Selective encapsulation and stimuli-responsive release with star polymer nanocapsules: (a) fluorinated core star for perfluoroalkanes via fluorous interaction; (b) PEG core star for an ionic dye via cation recognition in organic solvents; (c) cation core star for an ionic dye via ionic interaction in water.

Ionic molecules (for example, Orange G: a hydrophilic dye with sulfonic acid sodium salt) are efficiently enclosed into PEG core or cation-core star polymers in various environments.46 PEG (7)-core star polymers with PMMA arms solubilized Orange G in CHCl3 (although it was originally insoluble in CHCl3) via the recognition of the dye cation (sodium) with the core-PEG spacers and released it via the addition of H2O (Figure 6b). By contrast, water-soluble cation core (quaternary ammonium salts: 5 or 1/6) star polymers with PEG arms successfully entrapped Orange G even in water via ionic interaction between the in-core ammonium cations and the dye sulfonate anions. The controlled release of core-bound dyes was also achieved via treatment with an aqueous solution of NaCl (Figure 6c).

Single-chain folding/crosslinked polymers

Amphiphilic and/or functional linear random copolymers are potentially good precursors that can self-fold (autonomously or in response to stimuli) with intramolecular physical association and/or chemical bond formation in organic solvents or water to yield unimer micelles and single-chain polymeric nanoparticles.26, 27, 28, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57, 58, 59, 60, 61, 62 In particular, PEGMA-based copolymers57, 58, 59, 60, 61, 62 are attractive because of the following: (1) their primary structure (molecular weight, composition and sequence of monomers and/or functional groups, terminal structure) can be designed and controlled by living radical polymerization; (2) their water-soluble and amphiphilic properties afford autonomous self-folding in water; (3) multiple hydrophilic PEG pendants may effectively isolate a hydrophobic methacrylate main chain and stabilize the self-folded structure in water. Self-folding of PEGMA-based copolymers in water has been triggered with intramolecular hydrophobic60, 61 and/or hydrogen-bonding57, 58, 59 interactions.

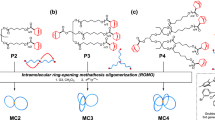

For self-folding with hydrophobic interactions,60 amphiphilic PEGMA/RMA random copolymers were synthesized by Ru(Ind)Cl(PPh3)2/n-Bu3N-catalyzed living radical copolymerization of PEGMA and hydrophobic alkyl methacrylates (RMA: e.g., dodecyl methacrylate (DMA), octadecyl methacrylate) with a chloride initiator (Mn=40 000–50 000, Mw/Mw=1.2–1.4, Figure 7a), where monomer composition (l=[PEGMA]/[initiator], m=[RMA]/[initiator], l/m=200/0–80/120) and RMA alkyl pendants (R: -CnH2n or -CnH2n+1; n=1–18) were systematically varied. Structural analysis by SEC and light scattering revealed that the content and hydrophobicity of RMA is important for self-folding: (1) PEGMA/DMA random copolymers gradually folded to become compact in water with an increase in DMA content of up to 40 mol% and in turn induced multichain aggregation in the presence of DMA at 50 mol%; (2) self-folding structures of PEGMA/RMA (160/40) random copolymers gradually became compact with increasing RMA hydrophobicity (carbon number: n). In addition, these polymers can dynamically and reversibly fold in water and unfold via methanol addition; they are more mobile upon heating and finally induce lower critical solution temperature-type phase separation.

The dynamic structures of self-folding polymers can be further fixed, that is, ‘frozen’, via the intramolecular crosslinking of the hydrophobic pendant olefins that are accumulated within the unimer micelles in water (Figure 7b).10 The single-chain crosslinked polymers maintain a self-folding structure, even in organic solvents.

Supramolecular self-assembly of pendant units is also effective for self-folding of polymers. PEGMA/BTAMA random copolymers carrying chiral benzene-1,3,5-tricarboxamide (BTA) units folded in water via the helical self-assembly of the BTA pendants with intramolecular hydrogen bonding.57, 58, 59 Interestingly, PEGMA/BTAMA random copolymers bearing ruthenium complexes efficiently catalyzed the hydrogenation of cyclohexanone within the self-folded, hydrophobic space in water.57 This approach is intriguing as an artificial mimic of enzyme function.62 The creation of a specific environment in single-chain folding/crosslinked polymers would be a promising strategy for selective and innovative catalysis.

Cyclopolymers and sequence-regulated copolymers

The placement of precision cavities and sequence-controlled units into polymer chains and spaces would also be important for unique and selective functions in addition to the construction of globular functional spaces with core-functionalized star polymers and single-chain folding/crosslinked polymers. Recently, we have developed cation template-assisted cyclopolymerization of poly(ethylene glycol) dimethacrylate (PEGnDMA: n=4–8) as a one-pot strategy to prepare cyclopolymers with large in-chain PEG rings, referred to as ‘polymeric pseudo crown ethers’ (Figure 8a).63 Cyclopolymerization71, 72, 73, 74, 75, 76 involves an alternating process of intramolecular cyclization and intermolecular addition of divinyl monomers; the adjacent location of the two olefins is thereby essential to induce efficient cyclization without gelation.

(a) Synthesis of cycloPEG polymers, referred to as ‘polymeric pseudo crown ethers’, via cation template-assisted cyclopolymerization of PEGnDMA (n=4, 5, 6, 8) for selective cation recognition. (b) Synthesis of sequence-regulated copolymers via concurrent tandem living radical polymerization with in situ transesterification of methacrylates.

In our system, a potassium cation template (KPF6) was combined with hexa(ethylene glycol) dimethacrylate (PEG6DMA) to dynamically form a pseudocyclic conformation that places two olefins adjacent to each other.63 The K+-template PEG6DMA was polymerized with RuCp*Cl(PPh3)2/n-Bu3N in cyclohexanone at 40 °C to yield well-controlled cyclopolymers with 24-membered in-chain PEG rings and high cyclization efficiency (>97%; PPEG6DMA: Mn=8000–30 000; Mw/Mn=1.2–1.5), whereas non-template PEG6DMA induced gelation. The K+ template was further effective for PEG5DMA (21-membered) and PEG8DMA (30-membered). Interestingly, PPEG6DMA showed unique cation recognition: (1) 1/1 recognition of Li+, Na+, K+, Rb+ with cyclic PEG units and 1/2 recognition of Cs+ with two adjacent cyclic PEG units; (2) selective recognition of Na+ over Li+ and Bu4N+ as well as selective recognition of K+ over Na+. Thus, template-assisted cyclopolymerization is effective for functional cyclopolymers with large in-chain rings compared with conventional cyclopolymerization of divinyl monomers with short and/or rigid spacers.71, 72, 73, 74, 75, 76

Various sequence-regulated copolymers, including gradient copolymers, are directly synthesized by concurrent tandem living radical polymerization with in situ transesterification of methacrylates (Figure 8b).64, 65, 66 The key is to polymerize MMA in the presence of metal alkoxide (Al(Oi–Pr)3 or Ti(Oi–Pr)4) and alcohols (ROH), in which metal alkoxide-catalyzed transesterification of MMA into RMA synchronizes with living polymerization to provide MMA/RMA gradient copolymers from MMA (initiating terminus) to RMA (growing terminus). Compared with conventional synthetic pathways for gradient copolymers (copolymerization of two monomers with different reactivity or copolymerization via second monomer addition),77 this tandem catalysis has the following advantages: (1) catalytic control of gradient monomer composition; (2) efficient synthesis of various gradient copolymers from common alcohols; and (3) easy access to complicated, sequence-regulated copolymers (random-gradient, gradient-block). Owing to the gradual change in monomer composition, gradient copolymers showed physical properties that differed from those of their random and block counterparts. For example, an MMA/DMA gradient copolymer had an extremely broad range of glass transition temperatures (∼170 °C).66

Conclusion

Polymeric functional spaces were created in various core-functionalized star polymers and single-chain folding/crosslinked polymers via ruthenium-catalyzed living radical polymerization. Core-functionalized star polymers were synthesized by arm-linking reactions with functional linkers and monomers for unique functions: active, robust and recyclable catalysis (oxidation, hydrogenation and living radical polymerization); and stimuli-responsive and selective molecular recognition. Amphiphilic random copolymers efficiently folded in water with intramolecular hydrophobic and/or hydrogen-bonding interactions, resulting in single-chain compartments with hydrophobic interiors. In addition, cation template-assisted cyclopolymerization and concurrent tandem polymerization with in situ monomer transformation were also developed as smart strategies to directly produce cyclopolymers with large in-chain rings and sequence-controlled copolymers (for example, gradient copolymers). In the future, the construction of polymeric functional spaces with nanocavities and sequence-controlled units would open new vistas for innovative functional applications.

References

Grayson, S. M. & Fréchet, J. M. J. Convergent dendrons and dendrimers: from synthesis to applications. Chem. Rev. 101, 3819–3867 (2001).

Jansen, J. F. G. A., de Brabander-van den Berg, E. M. M. & Meijer, E. W. Encapsulation of guest molecules into a dendritic box. Science 266, 1226–1229 (1994).

Nishiyama, N. & Kataoka, K. Nanostructured devices based on block copolymer assemblies for drug delivery: designing structures for enhanced drug function. Adv. Polym. Sci. 193, 67–101 (2006).

van Dongen, S. F. M., de Hoog, H.-P. M., Peters, R. J. R. W., Nallani, M., Nolte, R. J. M. & van Hest, J. C. M. Biohybrid polymer capsules. Chem. Rev. 109, 6212–6274 (2009).

Walther, A. & Müller, A. H. E. Janus particles: synthesis, self-assembly, physical properties, and applications. Chem. Rev. 113, 5019–5261 (2013).

Elsabahy, M. & Wooley, K. L. Strategies toward well-defined polymer nanoparticles inspired by nature: chemistry versus versatility. J. Polym. Sci. A Polym. Chem. 50, 1869–1880 (2012).

Kabanov, A. V. & Vinogradov, S. V. Nanogels as pharmaceutical carriers: finite networks of infinite capabilities. Angew. Chem. Int. Ed. 48, 5418–5429 (2009).

Terashima, T. & Sawamoto, M. In: Progress in Controlled Radical Polymerization: Materials and Applications. Matyjaszewski K., Sumerlin B. S., Tsarevski N. V., (eds). ACS Symposium Series 1101 pp 65–80 (American Chemical Society, Washington, DC, 2012).

Terashima, T. in: Encyclopedia of Polymer Science and Technology 4th edn Seidel A., (ed). pp 1–31 (John Wiley & Sons Inc., 2013).

Terashima, T. Functional star polymers via living radical polymerization: designer functional nanospaces. Kobunshi Ronbunshu 70, 432–448 (2013).

Lutz, J.-F., Ouchi, M., Liu, D. R. & Sawamoto, M. Sequence-controlled polymers. Science 341, 1238149 (2013).

Ouchi, M., Terashima, T. & Sawamoto, M. Precision control of radical polymerization via transition metal catalysis: from dormant species to designed catalysts for precision functional polymers. Acc. Chem. Res. 41, 1120–1132 (2008).

Ouchi, M., Terashima, T. & Sawamoto, M. Transition metal-catalyzed living radical polymerization: toward perfection in catalysis and precision polymer synthesis. Chem. Rev. 109, 4963–5050 (2009).

Tsarevsky, N. & Matyjaszewski, K. ‘Green’ atom transfer radical polymerization: from process design to preparation of well-defined environmentally friendly polymeric materials. Chem. Rev. 107, 2270–2299 (2007).

Matyjaszewski, K. & Tsarevsky, N. V. Nanostructured functional materials prepared by atom transfer radical polymerization. Nat. Chem. 1, 276–288 (2009).

Matyjaszewski, K. Atom transfer radical polymerization (ATRP): current status and future perspectives. Macromolecules 45, 4015–4039 (2012).

Satoh, K. & Kamigaito, M. Stereospecific living radical polymerization: dual control of chain length and tacticity for precision polymer synthesis. Chem. Rev. 109, 5120–5156 (2009).

Kamigaito, M. Recent developments in metal-catalyzed living radical polymerization. Polym. J. 43, 105–120 (2011).

Hawker, C. J., Bosman, A. W. & Harth, E. New polymer synthesis by nitroxide mediated living radical polymerizations. Chem. Rev. 101, 3661–3688 (2001).

Rosen, B. M. & Percec, V. Single-electron transfer and single-electron transfer degenerative chain transfer living radical polymerization. Chem. Rev. 109, 5069–5119 (2009).

Moad, G., Rizzardo, E. & Thang, S. H. Radical addition-fragmentation chemistry in polymer synthesis. Polymer 49, 1079–1131 (2008).

Yamago, S. Precision polymer synthesis by degenerative transfer controlled/living radical polymerization using organotellurium, organostibine, and organobismuthine chain-transfer agents. Chem. Rev. 109, 5051–5068 (2009).

Blencowe, A., Tan, J. F., Goh, T. K. & Qiao, G. G. Core cross-linked star polymers via controlled radical polymerisation. Polymer 50, 5–32 (2009).

Gao, H. & Matyjaszewski, K. Synthesis of functional polymers with controlled architecture by CRP of monomers in the presence of cross-linkers: from stars to gels. Prog. Polym. Sci. 34, 317–350 (2009).

Gao, H. Development of star polymers as unimolecular containers for nanomaterials. Macromol. Rapid Commun. 33, 722–734 (2012).

Ouchi, M., Badi, N., Lutz, J.-F. & Sawamoto, M. Single-chain technology using discrete synthetic macromolecules. Nat. Chem. 3, 917–924 (2011).

Altintas, O. & Barner-Kowollik, C. Single chain folding of synthetic polymers by covalent and non-covalent interactions: current status and future perspectives. Macromol. Rapid Commun. 33, 958–971 (2012).

Sanchez-sanchez, A., Pérez-Baena, I. & Pomposo, J. A. Advances in click chemistry for single-chain nanoparticle construction. Molecules 18, 3339–3355 (2013).

Terashima, T., Motokawa, R., Koizumi, S., Sawamoto, M., Kamigaito, M., Ando, T. & Hashimoto, T. In situ and time-resolved small-angle neutron scattering observation of star polymer formation via arm-linking reaction in ruthenium-catalyzed living radical polymerization. Macromolecules 43, 8218–8232 (2010).

Baek, K.-Y., Kamigaito, M. & Sawamoto, M. Star-shaped polymers by metal-catalyzed living radical polymerization. 1. Design of Ru(II)-based systems and divinyl linking agents. Macromolecules 34, 215–221 (2001).

Bosman, A. W., Vestberg, R., Heumann, A., Fréchet, J. M. J. & Hawker, C. J. A modular approach toward functionalized three-dimensional macromolecules: from synthetic concepts to practical applications. J. Am. Chem. Soc. 125, 715–728 (2003).

Helms, B., Guillaudeu, S. J., Xie, Y., McMurdo, M., Hawker, C. J. & Fréchet, J. M. J. One-pot reaction cascades using star polymers with core-confined catalysts. Angew. Chem. Int. Ed. 44, 6384–6387 (2005).

Chi, Y., Scroggins, S. T. & Fréchet, J. M. J. One-pot multi-component asymmetric cascade reactions catalyzed by soluble star polymers with highly branched non-interpenetrating catalytic cores. J. Am. Chem. Soc. 130, 6322–6323 (2008).

Gao, H. & Matyjaszewski, K. Synthesis of miktoarm star polymers via ATRP using the ‘in-out’ method: determination of initiation efficiency of star macroinitiators. Macromolecules 39, 7216–7223 (2006).

Shibata, T., Kanaoka, S. & Aoshima, S. Quantitative synthesis of star-shaped poly(vinyl ether)s with a narrow molecular weight distribution by living cationic polymerization. J. Am. Chem. Soc. 128, 7497–7504 (2006).

Baek, K.-Y., Kamigaito, M. & Sawamoto, M. Core-functionalized star polymers by transition metal-catalyzed living radical polymerization. 1. Synthesis and characterization of star polymers with PMMA arms and amide cores. Macromolecules 34, 7629–7635 (2001).

Terashima, T., Kamigaito, M., Baek, K.-Y., Ando, T. & Sawamoto, M. Polymer catalysts from polymerization catalysts: direct encapsulation of metal catalyst into star polymer core during metal-catalyzed living radical polymerization. J. Am. Chem. Soc. 125, 5288–5289 (2003).

Terashima, T., Ouchi, M., Ando, T., Kamigaito, M. & Sawamoto, M. Metal-complex-bearing star polymers by metal-catalyzed living radical polymerization: synthesis and characterization of poly(methyl methacrylate) star polymers with Ru(II)-embedded microgel cores. J. Polym. Sci. A Polym. Chem. 44, 4966–4980 (2006).

Terashima, T., Ouchi, M., Ando, T. & Sawamoto, M. Oxidation of sec-alcohols with Ru(II)-bearing microgel star polymer catalysts via hydrogen transfer reaction: unique microgel-core catalysis. J. Polym. Sci. A Polym. Chem. 49, 1061–1069 (2011).

Terashima, T., Nomura, A., Ito, M., Ouchi, M. & Sawamoto, M. Star-polymer-catalyzed living radical polymerization: microgel-core reaction vessel by tandem catalyst interchange. Angew. Chem. Int. Ed. 50, 7892–7895 (2011).

Terashima, T., Nomura, A., Ouchi, M. & Sawamoto, M. Efficient and robust star polymer catalysts for living radical polymerization: cooperative activation in microgel-core reactors. Macromol. Rapid Commun. 33, 833–841 (2012).

Terashima, T., Ouchi, M., Ando, T., Kamigaito, M. & Sawamoto, M. Amphiphilic, thermosensitive ruthenium(II)-bearing star polymer catalysts: one-pot synthesis of PEG armed star polymers with ruthenium(II)-enclosed microgel cores via metal-catalyzed living radical polymerization. Macromolecules 40, 3581–3588 (2007).

Terashima, T., Ouchi, M., Ando, T. & Sawamoto, M. Thermoregulated phase-transfer catalysis via PEG-armed Ru(II)-bearing microgel core star polymers: efficient and reusable Ru(II) catalysts for aqueous transfer hydrogenation of ketones. J. Polym. Sci. A Polym. Chem. 48, 373–379 (2010).

Terashima, T., Ouchi, M., Ando, T. & Sawamoto, M. Transfer hydrogenation of ketones catalyzed by PEG-armed ruthenium-microgel star polymers: microgel-core reaction space for active, versatile and recyclable catalysis. Polym. J. 43, 770–777 (2011).

Koda, Y., Terashima, T., Nomura, A., Ouchi, M. & Sawamoto, M. Fluorinated microgel-core star polymers as fluorous compartments for molecular recognition. Macromolecules 44, 4574–4578 (2011).

Fukae, K., Terashima, T. & Sawamoto, M. Cation-condensed microgel-core star polymers as polycationic nanocapsules for molecular capture and release in water. Macromolecules 45, 3377–3386 (2012).

Hill, D. J., Mio, M. J., Prince, R. B., Hughes, T. S. & Moore, J. S. A field guide to foldamers. Chem. Rev. 101, 3893–4011 (2001).

Morishima, Y., Nomura, S., Ikeda, T., Seki, M. & Kamachi, M. Characterization of unimolecular micelles of random copolymers of sodium 2-(acrylamido)-2-methylpropanesulfonate and methacrylamides bearing bulky hydrophobic substituents. Macromolecules 28, 2874–2881 (1995).

Yusa, S., Sakakibara, S., Yamamoto, T. & Morishima, Y. Fluorescence studies of pH-responsive unimolecular micelles formed from amphiphilic polysulfonates possessing long-chain alkyl carboxyl pendants. Macromolecules 35, 10182–10188 (2002).

Deans, R., Ilhan, F. & Rotello, V. M. Recognition-mediated unfolding of a self-assembled polymeric globule. Macromolecules 32, 4956–4960 (1999).

Seo, M., Beck, B. J., Paulusse, J. M. J., Hawker, C. J. & Kim, S. Y. Polymeric nanoparticles via noncovalent cross-linking of linear chains. Macromolecules 41, 6413–6418 (2008).

Foster, E. J., Berda, E. B. & Meijer, E. W. Metastable supramolecular polymer nanoparticles via intramolecular collapse of single polymer chains. J. Am. Chem. Soc. 131, 6964–6966 (2009).

Hosono, N., Gillissen, M. A. J., Li, Y., Sheiko, S. S., Palmans, A. R. A. & Meijer, E. W. Orthogonal self-assembly in folding block copolymers. J. Am. Chem. Soc. 135, 501–510 (2013).

Altintas, O., Lejeune, E., Gerstel, P. & Barner-Kowollik, C. Bioinspired dual self-folding of single polymer chains via reversible hydrogen bonding. Polym. Chem. 3, 640–651 (2012).

Cherian, A. E., Sun, F. C., Sheiko, S. S. & Coates, G. W. Formation of nanoparticles by intramolecular cross-linking: following the reaction progress of single polymer chains by atomic force microscopy. J. Am. Chem. Soc. 129, 11350–11351 (2007).

Schmidt, B. V. K. J., Fechler, N., Falkenhagen, J. & Lutz, J.-F. Controlled folding of synthetic polymer chains through the formation of positionable covalent bridges. Nat. Chem. 3, 234–238 (2011).

Terashima, T., Mes, T., de Greef, T. F. A., Gillissen, M. A. J., Besenius, P., Palmans, A. R. A. & Meijer, E. W. Single-chain folding of polymers for catalytic systems in water. J. Am. Chem. Soc. 133, 4742–4745 (2011).

Gillissen, M. A. J., Terashima, T., Meijer, E. W., Palmans, A. R. A. & Voets, I. K. Sticky supramolecular grafts stretch single polymer chains. Macromolecules 46, 4120–4125 (2013).

Artar, M., Terashima, T., Sawamoto, M., Meijer, E. W. & Palmans, A. R. A. Understanding the catalytic activity of single-chain polymeric nanoparticles in water. J. Polym. Sci. A Polym. Chem. 52, 12–20 (2014).

Terashima, T., Sugita, T., Fukae, K. & Sawamoto, M. Synthesis and single-chain folding of amphiphilic random copolymers in water. Macromolecules 47, 589–600 (2014).

Sugita, T., Matsumoto, K., Terashima, T. & Sawamoto, M. Synthesis of amphiphilic three-armed star random copolymers via living radical polymerization and their unimolecular folding properties in water. Macromol. Symp (submitted).

Giuseppone, N. & Lutz, J.-F. Catalytic accordions. Nature 473, 40–41 (2011).

Terashima, T., Kawabe, M., Miyabara, Y., Yoda, H. & Sawamoto, M. Polymeric pseudo-crown ether for cation recognition via cation template-assisted cyclopolymerization. Nat. Commun. 4, 2321 (2013).

Nakatani, K., Terashima, T. & Sawamoto, M. Concurrent tandem living radical polymerization: gradient copolymers via in situ monomer transformation with alcohols. J. Am. Chem. Soc. 131, 13600–13601 (2009).

Nakatani, K., Ogura, Y., Koda, Y., Terashima, T. & Sawamoto, M. Sequence-regulated copolymers via tandem catalysis of living radical polymerization and in situ transesterification. Am. Chem. Soc 134, 4373–4383 (2012).

Ogura, Y., Terashima, T. & Sawamoto, M. Synchronized tandem catalysis of living radical polymerization and transesterification: methacrylate gradient copolymers with extremely broad glass transition temperature. ACS Macro Lett. 2, 985–989 (2013).

Leadbeater, N. E. & Marco, M. Preparation of polymer-supported ligands and metal complexes for use in catalysis. Chem. Rev. 102, 3217–3274 (2002).

Bergbreiter, D. E., Tian, J. & Hongfa, C. Using soluble polymer supports to facilitate homogeneous catalysis. Chem. Rev. 109, 530–582 (2009).

Terashima, T., Ouchi, M., Ando, T. & Sawamoto, M. In situ hydrogenation of terminal halogen in poly(methyl methacrylate) by ruthenium-catalyzed living radical polymerization: direct transformation of ‘polymerization catalyst’ into ‘hydrogenation catalyst’. J. Am. Chem. Soc. 128, 11014–11015 (2006).

Naota, T., Takaya, H. & Murahashi, S. Ruthenium-catalyzed reactions for organic synthesis. Chem. Rev. 98, 2599–2660 (1998).

Butler, G. B. Cyclopolymerization. J. Polym. Sci. A Polym. Chem. 38, 3451–3461 (2000).

Yokota, K., Haba, O., Satoh, T. & Kakuchi, T. Cyclopolymerization. Chirality induction for the synthesis of chiroselective corand/ionophore ligands. Macromol. Chem. Phys. 196, 2383–2416 (1995).

Tunca, U. & Yagci, Y. Crown ether-containing polymers. Prog. Polym. Sci. 19, 233–286 (1994).

Alexandratos, S. D. & Stine, C. L. Synthesis of ion-selective polymer-supported crown ethers: a review. React. Funct. Polym. 60, 3–16 (2004).

Coates, G. W. & Waymouth, R. M. Enatioselective cyclopolymerization of 1,5-hexadiene catalyzed by chiral zirconocenes: a novel strategy for the synthesis of optically active polymers with chirality in the main chain. J. Am. Chem. Soc. 115, 91–98 (1993).

Ochiai, B., Ootani, Y. & Endo, T. Controlled cyclopolymerization through quantitative 19-membered ring formation. J. Am. Chem. Soc. 130, 10832–10833 (2008).

Matyjaszewski, K., Ziegler, M. J., Arehart, S. V., Grenzta, D. & Pakula, T. Gradient copolymers by atom transfer radical copolymerization. J. Phys. Org. Chem. 13, 775–786 (2000).

Acknowledgements

This research was supported by the Ministry of Education, Science, Sports and Culture through Grants-in-Aid for Creative Scientific Research (18GS0209), Scientific Research (A: 24245026) and Young Scientists (Start up: 19850010, B: 20750091, B: 24750104); the Foundation for the Promotion of Ion Engineering; and by the Mizuho Foundation for the Promotion of Sciences. I deeply thank Professors Mitsuo Sawamoto and Makoto Ouchi (Kyoto University); Masami Kamigaito (Nagoya University); Tsuyoshi Ando (Nara Institute of Science and Technology); E. W. Meijer and Anja, R. A. Palmans (Eindhoven University of Technology) for their assistance and helpful discussions. Finally, I thank all of my collaborators for sharing their experimental data.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Terashima, T. Functional spaces in star and single-chain polymers via living radical polymerization. Polym J 46, 664–673 (2014). https://doi.org/10.1038/pj.2014.57

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.57

This article is cited by

-

Development and application of pH-responsive polymers

Polymer Journal (2022)

-

Sequence-controlled polymers via reversible-deactivation radical polymerization

Polymer Journal (2018)

-

Single-chain crosslinked star polymers via intramolecular crosslinking of self-folding amphiphilic copolymers in water

Polymer Journal (2015)