Abstract

Fluorescent poly(boron enaminoketonate)s (PBEKs) were synthesized via the polycycloaddition of a homoditopic nitrile N-oxide to diynes followed by other polymer reactions. Click polycycloaddition of the nitrile N-oxide to various diynes effectively produced polyisoxazoles in high yields. The polyisoxazoles were transformed into the corresponding fluorescent PBEKs by forming the poly(β-aminoenone) intermediates and reacting these intermediates with (C6F5)2BF·OEt2. The solution and solid-state optical properties of the PBEKs were evaluated by ultraviolet–visible (UV–vis) and fluorescence spectroscopy.

Similar content being viewed by others

Introduction

Boron diketonates constitute a family of boron-chelating dyes and, as fluorophores, they have attracted much attention.1, 2, 3, 4 The optical properties of boron diketonates, such as large Stokes shifts and two-photon absorption cross-sections, and their incorporation into various organic backbones make them potentially useful in molecular probe,5 laser6 and optical-sensing applications.7, 8 In the polymeric materials field, Fraser and colleagues9 reported the synthesis of a boron diketonate-containing polylactide and described its oxygen-sensing property. Moreover, Chujo and colleagues10, 11, 12 demonstrated the synthesis and emission color tuning of main-chain-type poly(boron diketonate)s. However, the difficult synthesis of boron diketonate-containing polymers restricts their applicability. Therefore, substituting a boron diketonate with a boron enaminoketonate (BEK) is attractive because it is expected that the structurally analogous BEK would act as a fluorophore with good optical properties similar to those of the boron diketonate (for a related study concerning synthesis and spectral study of fluorescent BF2 complexes with 1,3-enaminoketone ligands, see Xia et al.13).14 Indeed, Chujo and colleagues15 reported the optical properties of BEKs, such as large Stokes shifts and high molar absorption coefficients, that are quite similar to those of boron diketonates.

Recently, we reported a unique fluorescence control system consisting of a BEK placed at the end of a rotaxane axle.16 The rotaxane-based BEK was readily prepared by transforming an isoxazole-containing rotaxane that was synthesized via a stable nitrile N-oxide-based click end-capping reaction. The BEK fluorescence maximum was red-shifted, and the fluorescence quantum yield was remarkably enhanced by the wheel translation to the fluorophore. We also developed a synthetic method to produce a poly(β-aminoenone) via the catalyst-free click polycycloaddition of a homoditopic nitrile N-oxide to diynes and subsequent selective reduction of the N–O bonds.17 Therefore, it should be possible to prepare a poly(boron enaminoketonate) (PBEK) by reacting a poly(β-aminoenone) with an organoboron complex via a synthetic protocol similar to that used to prepare the rotaxane-based BEK. Here, we describe the practical synthesis and properties of new fluorescent PBEKs. We emphasize the straightforward introduction of boron enaminoketonate backbones into a polymer main chain using the catalyst-free click polymerization of a homoditopic stable nitrile N-oxide (Figure 1).

Experimental Procedure

Materials

Dichloromethane was dried over freshly activated 4 Å molecular sieves (MS 4 Å). Nitrile N-oxide C was prepared according to the literature.18 The formula numbers of all compounds given below are also used in the main text. Compounds that are not labeled in the main text are labeled with letters (A–K).

Measurements

The 1H (400 MHz), 13C (100 MHz) and 19F (400 MHz) nuclear magnetic resonance (NMR) spectra were recorded on a JEOL AL-400 spectrometer (JEOL, Tokyo, Japan) using CDCl3 and DMSO-d6 as the solvents. The 1H and 13C NMR spectra were calibrated using residual undeuterated solvent or tetramethylsilane as the internal standard. The 19F NMR spectra were calibrated using CFCl3 or fluorobenzene as the internal standard. Infrared (IR) spectra were recorded on a JASCO FT/IR-230 spectrometer (JASCO, Tokyo, Japan). Melting points were measured using a Melting Point Apparatus SMP3 (Stuart Scientific, Staffordshire, UK) instrument. Matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI–TOF MS) was measured with a Shimadzu AXIMA-CFR mass spectrometer (Shimadzu, Kyoto, Japan) using a dithranol matrix. High-resolution fast atom bombardment mass spectra (FAB-HRMS) were recorded with an ICP-MS instrument (SPQ-9000; Seiko Instruments, Chiba, Japan) at the Center for Advanced Materials Analysis, Tokyo Institute of Technology by request. Ultraviolet–visible (UV–vis) spectra of the PBEKs in solution were collected with a JASCO V-550 spectrophotometer (JASCO). Fluorescence emission spectra of the PBEKs in solution were recorded with a JASCO FP-6500 spectrofluorometer (JASCO), and the quantum yields were calculated using the fluorescence intensity of 9,10-diphenylanthracene as a reference standard. To evaluate the solid-state PBEK UV–vis and emission spectra, the polymer (poly-3 or PEG-3) was first dispersed in 2.5 ml of an Ar-saturated cyclohexane solution (0.3 mg ml−1) by reprecipitating a polymer solution in CH2Cl2 (0.2 ml). The emission spectra and quantum yields were then measured using a calibrated integrating sphere and multi-channel spectrometer (C9920-02G, Hamamatsu Photonics, Hamamatsu, Japan) under 388 nm excitation. The emission quantum yields were obtained using the emission intensities in the 400–800 nm region.

Synthesis of the model compounds used to evaluate the optical properties

Synthesis of 1-methoxy-4-trimethylsilylethynylbenzene A. Trimethylsilylacetylene (5.00 ml, 36.1 mmol) was added to a suspension of 1-iodo-4-methoxybenzene (4.58 g, 24.5 mmol), Pd(PPh3)4 (844 mg, 0.73 mmol) and CuI (140 mg, 0.73 mmol) in Et3N (80 ml) at room temperature.19 The mixture was heated to 80 °C, stirred for 3 h under an argon atmosphere, filtered and concentrated in vacuo. The crude product was purified by silica gel column chromatography (hexane/ethyl acetate=9:1) to give A (5.85 g, 28.6 mmol, quantitative yield (quant.)) as a brown oil: 1H NMR (400 MHz, 298 K, CDCl3) δ 7.40 (d, J=9.0 Hz, 2H), 6.81 (d, J=9.0 Hz, 2H), 3.81 (s, 3H) and 0.24 (s, 9H) p.p.m.

Synthesis of 1-methoxy-4-ethynylbenzene B. K2CO3 (6.77 g, 49.0 mmol) was added to a solution of A (5.85 g, 24.5 mmol) in MeOH (100 ml) at room temperature. The mixture was heated to 40 °C, stirred for 3 h under an argon atmosphere and concentrated in vacuo. Saturated aqueous NaHCO3 (150 ml) was added to the mixture, and the products were extracted with EtOAc. The combined organic layer was dried over Na2SO4, filtered and concentrated in vacuo. The crude product was purified by short flash column chromatography on silica gel (hexane/EtOAc=9:1) to yield B (3.07 g, 23.2 mmol, 95%) as a brown oil. The crude was used in the next reaction without further purification: IR (NaCl) υ 3287, 3004, 2959, 2837, 2540, 2106, 1893, 1606, 1571, 1505, 1464, 1442, 1291, 1249, 1171, 1108, 1031, 833, 641, 606 and 537 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.43 (d, J=8.9 Hz, 2H), 6.84 (d, J=8.9 Hz, 2H), 3.81 (s, 3H), 3.00 (s, 1H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 160.1, 133.8, 114.3, 114.1, 83.9, 76.2 and 55.3 p.p.m.

Synthesis of pentafluorophenyl magnesium bromide. Bromopentafluorobenzene (2.10 ml, 16.6 ml) was added dropwise to a solution of magnesium (392 mg, 16.1 mmol) in Et2O (30 ml) under an argon atmosphere at room temperature, and the mixture was refluxed for 3 h to give pentafluorophenyl magnesium bromide.20 This crude product was used in the next reaction without purification.

Synthesis of (C6F5)2BF·OEt2 5. The freshly prepared C6F5MgBr solution in Et2O (30 ml) was added all at once to a solution of BF3·OEt2 (1.02 ml, 8.04 mmol) in Et2O (20 ml) at 0 °C.20 After stirring for 30 min, the solvent was evaporated at 0 °C to give 5 as a gray solid. This crude solid was used in subsequent reaction without purification.

Synthesis of isoxazole D. Nitrile N-oxide C (500 mg, 2.51 mmol) was added to a solution of 4-ethynylanisole (498 mg, 3.77 mmol) in CHCl3 (10 ml). The solution was refluxed for 5 h. The crude product was purified by short flash column chromatography on silica gel (hexane, then CHCl3) to yield D (588 mg, 1.77 mmol, 71%) as a light brown solid: m.p. 96.9–97.9 °C; IR (potassium bromide (KBr)) υ 2935, 2835, 1613, 1512, 1433, 1353, 1304, 1254, 1176, 1078, 1026, 835, 804, 752 and 655 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.97 (d, J=8.2 Hz, 1H), 7.91 (d, J=8.6 Hz, 1H), 7.83 (d, J=9.0 Hz, 1H), 7.83 (d, J=9.0 Hz, 2H), 7.45 (dd; J=8.2, 6.8 Hz; 1H), 7.38 (dd; J=8.6, 6.8 Hz; 1H), 7.37 (d, J=9.0 Hz, 1H), 7.02 (d, J=9.0 Hz, 2H), 6.61 (s, 1H), 3.94 (s, 3H) and 3.89 (s, 3H) p.p.m.; MALDI–TOF MS (matrix/dithranol) calculated (calcd.) for C21H17NO3 [M+Na]+: 354.11, found: 354.09.

Synthesis of enaminoketone E. Mo(CO)6 (191 mg, 0.725 mmol) was added to a solution of isoxazole D (200 mg, 0.604 mmol) in CH3CN (5 ml) and water (1.2 ml). The mixture was refluxed for 10 h and then evaporated in vacuo. The crude product was purified by short flash column chromatography on silica gel (hexane/EtOAc=2:1) to yield E (174 mg, 0.522 mmol, 86%) as a brown solid. The crude was used in the next reaction without further purification: IR (KBr) υ 3449, 2935, 2838, 1595, 1503, 1378, 1252, 1174, 1076 and 1028 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 10.50 (br, 1H), 8.00 (d, J=8.5 Hz, 1H), 7.93 (d, J=8.5 Hz, 1H), 7.90 (d, J=9.0 Hz, 2H), 7.82 (d, J=8.7 Hz, 1H), 7.47 (dd; J=8.5, 6.9 Hz; 1H), 7.38 (dd; J=8.5, 6.9 Hz; 1H), 7.34 (d, J=8.7 Hz, 1H), 6.89 (d, J=9.0 Hz, 2H), 5.92 (s, 1H), 5.32 (br, 1H), 3.97 (s, 3H) and 3.84 (s, 3H) p.p.m.

Synthesis of 6. (C6H5)2BF·OEt2 (5, 70.5 mg, 0.161 mmol) was added to a solution of E (10.3 mg, 33.1 μmol) in CH2Cl2 (0.5 ml) under an argon atmosphere. The reaction mixture was stirred at room temperature for 2 h and then concentrated in vacuo. The crude product was purified by short flash column chromatography on silica gel (CHCl3) and then by high-performance liquid chromatography to yield 6 (22.3 mg, 32.9 μmol, 99%) as a yellow solid: m.p. 83.2–84.6 °C; IR (KBr) υ 3422, 2937, 2844, 1654, 1607, 1508, 1477, 1377, 1261, 1178, 1090, 979, 811, 797 and 752 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 8.01 (d, J=8.6 Hz, 2H), 8.00 (d, J=9.3 Hz, 1H), 7.85 (d, J=8.0 Hz, 1H), 7.81 (br, 1H), 7.68 (d, J=8.4 Hz, 1H), 7.48 (dd; J=8.4, 7.0 Hz; 1H), 7.42 (dd; J=8.0, 7.0 Hz; 1H), 7.34 (d, J=9.3 Hz, 1H), 6.97 (d, J=8.6 Hz, 2H), 6.15 (s, 1H), 3.89 (s, 3H) and 3.88 (s, 3H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 173.7, 168.5, 164.0, 154.6, 133.3, 131.4, 130.7, 129.0, 128.9, 128.5, 126.0, 124.9, 123.8, 118.2, 114.5, 113.0, 96.0, 56.6 and 55.9 p.p.m.; 19F NMR (400 MHz, 298 K, CDCl3) δ –137.25 (s, 2F), –157.99 (s, 1F) and –164.19 (s, 2F) p.p.m.; MALDI–TOF MS (matrix/dithranol) calcd. for C33H18BF10NO3 [M+H]+: 678.13, found: 678.14.

Synthesis of bisaldehyde F. K2CO3 (15.2 g, 110 mmol) was added to a solution of 2-hydroxy-1-naphthaldehyde (12.7 g, 73.8 mmol) and 1,8-dibromooctane (6.76 ml, 36.8 mmol) in dimethylformamide (DMF) (40 ml) at room temperature. The mixture was refluxed for 5 h. The mixture was cooled to room temperature, quenched by adding excess water and filtered. The crude product was recrystallized in CHCl3, and the resulting precipitate was washed with acetone to yield ditopic aldehyde F (13.4 g, 29.4 mmol, 80%) as a pale pink solid: m.p. 161.3–165.2 °C; IR (KBr) υ 2923, 2858, 1666, 1587, 1512, 1437, 1343, 1249, 1154, 1058, 814 and 769 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 10.93 (s, 2H), 9.28 (d, J=8.8 Hz, 2H), 8.04 (d, J=9.2 Hz, 2H), 7.77 (d, J=8.0 Hz, 2H), 7.63–7.60 (m, 2H), 7.43–7.39 (m, 2H), 7.28 (d, J=9.2 Hz, 2H), 4.23 (t, J=6.6 Hz, 4H), 1.90 (tt; J=6.6, 6.6 Hz; 4H), 1.57–1.51 (m, 4H) and 1.45–1.41 (m, 4H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 192.3, 163.9, 137.7, 131.7, 130.0, 128.6, 128.4, 125.1, 124.8, 116.9, 113.7, 69.6, 29.4, 29.4 and 26.2 p.p.m.; FAB-HRMS (matrix/NBA) calcd. for C30H31NaO4 [M+H]+: 455.2222, found: 455.2232.

Synthesis of bisoxime G. A solution of NH2OH·HCl (6.22 g, 89.5 mmol) and NaOH (4.88 g, 120 mmol) in water (150 ml) was added to a solution of ditopic aldehyde F (18.5 g, 40.7 mmol) in EtOH (150 ml) at 0 °C. The mixture was heated to 60 °C and stirred for 4 h. The solution was cooled to room temperature and quenched by adding excess water. The resulting precipitate was filtered and washed with water, methanol and hot CHCl3 to yield ditopic oxime G (0.800 g, 43.0 mmol, quant.) as a white solid. The crude was used in the next reaction without further purification: m.p. 159.6–164.5 °C; IR (KBr) υ 3297, 2941, 2857, 1632, 1593, 1513, 1463, 1440, 1318, 1247, 1181, 1063, 955, 914, 803, 751, 687 and 641 cm−1; 1H NMR (400 MHz, 298 K, DMSO-d6) δ 11.31 (s, 2H), 8.86 (d, J=8.5 Hz, 2H), 8.68 (s, 2H), 7.96 (d, J=9.0 Hz, 2H), 7.88 (d, J=8.1 Hz, 2H), 7.54–7.50 (m, 2H), 7.46 (d, J=9.0 Hz, 2H), 7.41–7.37 (m, 2H), 4.17 (t, J=6.1 Hz, 4H), 1.78 (tt; J=6.1, 6.1 Hz; 4H) and 1.49–1.37 (m, 8H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 155.9, 154.4, 131.6, 130.8, 128.7, 128.4, 127.5, 125.6, 123.8, 114.6, 113.4, 69.0, 28.8, 28.7 and 25.5 p.p.m.; FAB-HRMS (matrix/NBA) calcd. for C30H33N2O4 [M+H]+: 485.2440, found: 485.2437.

Synthesis of 1. Et3N (861 μl, 6.18 mmol) and N-chlorosuccinimide (825 mg, 6.18 mmol) were added to a mixture of ditopic oxime G (1.00 g, 2.06 mmol) in CHCl3 (400 ml) at 0 °C. The mixture was heated to 60 °C and stirred for 20 min. The mixture was cooled to room temperature and quenched by adding water. The organic layer was dried over MgSO4, filtered and concentrated in vacuo. The crude product was purified by short flash column chromatography on silica gel (CHCl3) to yield the ditopic nitrile N-oxide 1 (716 mg, 1.49 mmol, 73%) as a pale yellow solid: m.p. 119.5–120.7 °C; IR (KBr) υ 2940, 2857, 2295, 1622, 1589, 1510, 1463, 1436, 1402, 1339, 1312, 1275, 1245, 1156, 1065, 1016, 995, 909, 806, 756, 669 and 532 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.95 (d, J=8.6 Hz, 2H), 7.92 (d, J=8.9 Hz, 2H), 7.81 (d, J=8.3 Hz, 2H), 7.57 (dd; J=8.6, 7.1 Hz; 2H), 7.41 (dd; J=8.9, 7.1 Hz; 2H), 7.25 (d, J=8.3 Hz, 2H), 4.22 (t, J=6.4 Hz, 4H), 1.90 (tt; J=6.4, 6.4 Hz; 4H) and 1.59–1.47 (m, 8H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 161.3, 134.5, 133.1, 128.9, 128.8, 128.6, 125.1, 124.1, 113.5, 96.7, 69.9, 34.9, 29.4, 29.3 and 26.0 p.p.m.; FAB-HRMS (matrix/NBA) calcd. for C30H28N2O4Na [M+Na]+: 503.1947, found: 503.1962.

Synthesis of 1-hydroxy-4-trimethylsilylethynylbenzene H. Trimethylsilylacetylene (5.00 ml, 36.1 mmol) was added to a suspension of p-iodophenol (5.30 g, 24.5 mmol), Pd(PPh3)3 (844 mg, 0.73 mmol) and CuI (140 mg, 0.73 mmol) in Et3N (80 ml).21, 22 The solution was stirred for 3 h at 80 °C under an argon atmosphere, filtered and evaporated. The crude product was purified by silica gel column chromatography (hexane/ethyl acetate=9:1, then 1:1) to yield H as a black oil (4.07 g, 21.4 mmol, 87%): 1H NMR (400 MHz, 298 K, CDCl3) δ 7.36 (d, J=8.3 Hz, 2H), 6.75 (d, J=8.3 Hz, 2H) and 0.23 (s, 9H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 156.3, 134.0, 115.8, 115.4, 105.8, 92.9 and 0.34 p.p.m.

Synthesis of 1-ethynyl-4-hydroxybenzene I. K2CO3 (4.56 g, 33 mmol) was added to a solution of H (3.22 g, 16.9 mmol) in MeOH (100 ml).23 The mixture was stirred for 3 h at 40 °C under an argon atmosphere and then concentrated in vacuo. Saturated aqueous NaHCO3 (40 ml) was added to the mixture, and the products were extracted with EtOAc. The combined organic layer was dried over MgSO4, filtered and concentrated in vacuo. The crude product was purified by short flash column chromatography on silica gel (hexane/EtOAc=9:1) to yield I (0.649 g, 5.49 mmol, 32%) as a black oil. The crude was used in the next reaction without further purification: 1H NMR (400 MHz, 298 K, CDCl3) δ 7.39 (d, J=8.5 Hz, 2H), 6.78 (d, J=8.5 Hz, 2H), 5.17 (br, 1H) and 2.99 (s, 1H) p.p.m.

Synthesis of 2 using H. K2CO3 (2.38 g, 17.2 mmol) was added to a solution of H (3.27 g, 17.2 mmol) and 1,8-dibromooctane (1.40 g, 5.74 mmol) in DMF (50 ml) at room temperature. The mixture was stirred at 100 °C for 5 h and then filtered. The solution was purified by short flash column chromatography on silica gel (hexane/CHCl3=2:1). A tetrahydrofuran (THF) solution of tetra-n-butylammonium fluoride (TBAF; 1 mol ml−1, 0.5 ml) was added to a THF solution of the solid (10 ml). The solution was stirred for 1 h and then washed by saturated aqueous NH4Cl, water and brine. The organic layer was dried over MgSO4 and concentrated in vacuo. The crude product was purified by short flash column chromatography on silica gel (hexane/CHCl3=2:1, then 1:1) and high-performance liquid chromatography to yield 2 (192 mg, 0.554 mmol, 10%) as a white solid: IR (KBr) υ 3299, 2940, 2105, 1606, 1509, 1467, 1291, 1253, 1171, 1032, 837 and 610 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.41 (d, J=8.3 Hz, 2H), 6.83 (d, J=8.3 Hz, 2H), 3.95 (t, J=6.5 Hz, 2H), 2.99 (s, 1H), 1.78 (tt; J=6.5, 6.5 Hz; 2H) and 1.52–1.38 (m, 4H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 159.6, 133.7, 114.5, 114.0, 83.9, 75.8, 68.1, 29.4, 29.2 and 26.0 p.p.m.

Synthesis of 2 using I. K2CO3 (502 mg, 3.63 mmol) was added to a solution of I (300 mg, 2.54 mmol) and 1,8-dibromooctane (0.200 ml, 1.21 mmol) in DMF (5.0 ml) at room temperature. The mixture was stirred at 100 °C for 5 h. The mixture was cooled to room temperature, diluted with Et2O, washed with water and brine, dried over MgSO4, filtered and concentrated in vacuo. The crude product was purified by short flash column chromatography on silica gel (hexane/CHCl3=2:1) to yield 2 (112 mg, 0.323 mmol, 27%) as a white solid. The crude was used in the next reaction without further purification: IR (KBr) υ 3299, 2940, 2105, 1606, 1509, 1467, 1291, 1253, 1171, 1032, 837 and 610 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.41 (d, J=8.3 Hz, 2H), 6.83 (d, J=8.3 Hz, 2H), 3.95 (t, J=6.5 Hz, 2H), 2.99 (s, 1H), 1.78 (tt; J=6.5, 6.5 Hz; 2H) and 1.52−1.38 (m, 4H) p.p.m.; 13C NMR (100 MHz, 298 K, CDCl3) δ 159.6, 133.7, 114.5, 114.0, 83.9, 75.8, 68.1, 29.4, 29.2 and 26.0 p.p.m.

Synthesis of bisTsO-PEG J. Tosyl chloride (13.2 g, 122 mmol), Et3N (17.0 ml, 122 mmol) and DMAP (149 mg, 1.22 mmol) were added to a solution of PEG (Mn 2000 Da, 12.2 g, 6.10 mmol) in CH2Cl2 (40 ml) at 0 °C. The solution was stirred for 3 h. Excess Et2O was then added to the solution, and the mixture was cooled to 0 °C. The resulting precipitate was filtered and then reprecipitated in cold EtOH. The resulting solid was collected by filtration to yield J (12.4 g, 5.39 mmol, 88%) as a white solid. The crude was used in the next reaction without further purification: 1H NMR (400 MHz, 298 K, CDCl3) δ 7.79 (d, J=8.4 Hz), 7.34 (d, J=8.4 Hz), 4.16 (t, J=4.6 Hz), 3.72–3.60 (m, 4H) and 2.45 (s) p.p.m.; Tm 40 °C; Tg −41 °C; Td5 235 °C; Td10 251 °C.

Synthesis of 3. The product J (2.00 g, 0.883 mmol, Mn 2300 Da) was added to a solution of H (1.00 g, 3.64 mmol) and K2CO3 (305 mg, 2.21 mmol) in DMF (10 ml) at room temperature. The solution was stirred at 80 °C for 12 h. Excess water was then added to the solution. The products were extracted with EtOAc, dried over MgSO4 and concentrated in vacuo. The products were reprecipitated in cold MeOH and subsequently dissolved in THF (10 ml). TBAF (1 M in THF, 0.2 ml) was added to the solution that was then stirred for 1 h at room temperature. The crude product was reprecipitated in cold MeOH and purified by mixing it with activated charcoal at 50 °C for 12 h to yield 3 (539 mg, 0.245 mmol, 28%) as a white solid: 1H NMR (400 MHz, 298 K, CDCl3) δ 7.41 (d, J=8.4 Hz), 6.85 (d, J=8.4 Hz), 4.13 (t, J=4.6 Hz), 3.85 (t, J=4.6 Hz), 3.76–3.56 (m, 4H) and 3.00 (s) p.p.m.; Mn 3100; Mw 3300; Mw/Mn 1.04 (estimated by size exclusion chromatography (SEC) using polyethylene glycol (PEG) standards); Tm 46 °C; Tg −34 °C; Td5 360 °C; Td10 377 °C.

Synthesis of bisTsO-PTHF K. TsCl (9.53 g, 50.0 mmol), Et3N (6.97 ml, 50.0 mmol) and DMAP (61.1 mg, 0.500 mmol) were added to a solution of polyTHF (Mn 2900 Da, 14.5 g, 5.00 mmol) in CH2Cl2 (30 ml) at 0 °C, and the solution was stirred for 3 h. The crude product was precipitated in cold MeOH. The resulting solid was filtered to yield K (11.7 g, 3.66 mmol, 73%) as a white solid. The crude was used in the next reaction without further purification: 1H NMR (400 MHz, 298 K, CDCl3) δ 7.78 (d, J=8.2 Hz), 7.34 (d, J=8.2 Hz), 4.05 (t, J=6.4 Hz), 3.58–3.33 (m, 4H), 2.45 (s) and 1.75–1.39 (m, 4H) p.p.m.; Td5 190 °C; Td10 202 °C.

Synthesis of 4. The compound O (5.00 g, Mn 3200 Da, 1.56 mmol) was added to a solution of H (1.28 g, 4.68 mmol) and K2CO3 (305 mg, 2.21 mmol) in DMF (10 ml) at room temperature. The solution was stirred at 100 °C for 6 h. The precipitate obtained from immersion in cold MeOH was dissolved in THF (10 ml), and a THF solution of TBAF (1 mol ml−1, 0.2 ml) was then added. The solution was stirred for 1 h. The crude product was reprecipitated from cold MeOH and purified by mixing it with activated charcoal at 50 °C for 12 h to yield 4 (3.13 g, 1.01 mmol, 65%) as a white solid. The crude was used in subsequent reaction without further purification: 1H NMR (400 MHz, 298 K, CDCl3) δ 7.41 (d, J=8.8 Hz), 6.82 (d, J=8.8 Hz), 3.98 (t, J=6.1 Hz), 3.48–3.35 (m, 4H), 2.99 (s, 2H) and 1.89–1.50 (m, 4H) p.p.m.; Mn 3200; Mw 4200; Mw/Mn 1.34 (estimated by SEC using PEG standards); Tm 32 °C; Tg −71 °C; Td5 334 °C; Td10 349 °C.

Typical procedure for the polycycloaddition of homoditopic nitrile N-oxide 1 to a dialkyne: synthesis of polyisoxazole poly-1. A solution of 1 (210 mg, 0.436 mmol) and 1,8-bis(4-ethynylphenoxy)octane (151 mg, 0.436 mmol) in CHCl3 (300 μl) was refluxed for 20 h. The crude was reprecipitated in MeOH to give a solid that was filtered and dried in vacuo at room temperature for 12 h to yield poly-1 (362 mg, 0.438 mmol, quant.) as a brown solid: IR (KBr) υ 3437, 2931, 1615, 1512, 1250, 1063 and 807 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.96 (d, J=8.6 Hz, 2H), 7.89 (d, J=9.1 Hz, 2H), 7.78 (d, J=7.4 Hz, 2H), 7.73 (d, J=8.7 Hz, 4H), 7.45–7.27 (m, 6H), 6.91 (d, J=8.7 Hz, 4H), 6.57 (s, 2H), 4.04–3.98 (m, 4H), 3.93–3.49 (m, 4H), 1.76–1.66 (m, 4H), 1.63–1.58 (m, 4H) and 1.43–1.11 (m, 12H) p.p.m.; Mn 30 000 Da; Mw 51 000 Da; Mw/Mn 1.70 (estimated by SEC using polystyrene (PS) standards); Mn 12 000 Da; Mw 21 000 Da; Mw/Mn 1.81 (estimated by SEC using PEG standards); Tm 90.3 °C; Td5 323 °C; Td10 336 °C.

PEG-1: IR (KBr) υ 2875, 1619, 1512, 1463, 1351, 1252, 1108, 951 and 843 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.97–7.75 (m), 7.46–7.27 (m), 7.01–6.96 (m), 6.60 (s), 4.13–3.47 (m, 4H) and 1.65–1.17 (m) p.p.m.; Mn 16 000 Da; Mw 25 000 Da; Mw/Mn 1.60 (estimated by SEC using PEG standards); Tm 38.9 °C; Td5 277 °C; Td10 316 °C.

PTHF-1: IR (NaCl) υ 2939, 2855, 2795, 1616, 1509, 1446, 1367, 1248, 1113, 810 and 749 cm−1; 1H NMR (400 MHz, 298K, CDCl3) δ 7.98–7.91 (m), 7.83–7.74 (m), 7.49–7.29 (m), 6.95–6.93 (m), 6.60 (s), 4.21–3.22 (m, 4H) and 1.89–1.17 (m, 4H) p.p.m.; Mn 7500 Da; Mw 12 000 Da; Mw/Mn 1.66 (estimated by SEC using PEG standards); Tm 24.9 °C; Td5 269 °C; Td10 295 °C.

Typical procedure for reducing the polyisoxazoles: synthesis of poly(enaminoketone) poly-2. Mo(CO)6 (79.7 mg, 0.302 mmol) was added to a mixture of poly-1 (250 mg, 0.302 mmol) in DMF (10 ml) and water (1.0 ml). The mixture was heated to 90 °C and stirred for 12 h. The crude mixture was reprecipitated in Et2O to give a solid that was dried in vacuo at room temperature for 12 h to yield poly-2 (75.6 mg, 0.0910 mmol, 30%) as a brown solid: IR (KBr) υ 3458, 2931, 2855, 1595, 1503, 1464, 1380, 1503, 1464, 1380, 1247, 1170, 1072, 1020, 809, 785 and 749 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 10.47 (br, 2H), 8.00–7.68 (m, 10H), 7.46–7.07 (m, 6H), 6.83–6.72 (m, 4H), 5.87 (s, 2H), 5.42 (br, 2H), 4.07–3.97 (m, 4H), 3.94–3.81 (m, 4H), 1.77–1.55 (m, 8H) and 1.42–1.11 (m, 16H) p.p.m.; Mn 16 000 Da; Mw 24 000 Da; Mw/Mn 1.50 (estimated by SEC using PS standards); Mn 5600 Da; Mw 8700 Da; Mw/Mn 1.56 (estimated by SEC using PEG standards).

PEG-2: IR (KBr) υ 2880, 1964, 1731, 1597, 1530, 1505, 1468, 1348, 1251, 1111, 951, 844 and 526 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 10.49 (br), 8.02–7.79 (m), 7.47–7.27 (m), 6.85–6.82 (m), 5.88 (s), 5.58 (br), 4.09–3.46 (m, 4H) and 1.75–1.21 (m) p.p.m.; Mn 9700 Da; Mw 27 000 Da; Mw/Mn 2.77 (estimated by SEC using PEG standards).

PTHF-2: IR (NaCl) υ 2939, 2856, 2795, 1598, 1467, 1368, 1246, 1112, 955, 808 and 750 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 10.49 (br), 8.02–7.29 (m), 6.94–6.88 (m), 5.88 (s), 4.17–3.94 (m), 3.73–3.33 (m, 4H), 3.32–3.24 (m), 2.01–1.54 (m, 4H) and 1.54–1.00 (m) p.p.m.; Mn 7900 Da; Mw 44 000 Da; Mw/Mn 5.55 (estimated by SEC using PEG standards).

Typical procedure for the complexation of a poly(enaminoketone) with (C6F5)2BF 5: synthesis of poly(boron enaminoketonate) poly-3. (C6F5)2BF·OEt2 (389 mg, 887 μmol) was added to a solution of poly-2 (73.7 mg, 88.7 μmol) in anhydrous dichloromethane (1.5 ml). The solution was stirred at room temperature for 2 h. The crude product was reprecipitated in Et2O to give a solid that was dried in vacuo at room temperature for 12 h to yield poly-3 (133 mg, 87.6 μmol, 99%) as a brown solid: IR (NaCl) υ 2930, 2855, 1646, 1607, 1558, 1506, 1475, 1374, 1259, 1206, 1177, 1091, 978 and 807 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.97–7.25 (m, 18H), 6.91–6.87 (m, 4H), 6.11 (s, 2H), 4.00–3.85 (m, 8H) and 1.73–1.00 (m, 24H) p.p.m.; 19F NMR (400 MHz, 298 K, CDCl3) δ −136.90 (s, 2F), −157.83 (s, 1F) and −163.69 (s, 2F) p.p.m.; elemental analysis calcd. for the C78H56B2F20N2O6 repeating unit: C 61.68, H 3.72, N 1.84, found: C 61.89, H 4.71, N 2.06; Mn 12 000; Mw 22 000; Mw/Mn 1.84 (estimated by SEC using PEG standards); Mn 32 000 Da; Mw 57 000 Da; Mw/Mn 1.78 (estimated by SEC using PS standards); Td5 276 °C; Td10 293 °C.

PEG-3: IR (NaCl) υ 2871, 1605, 1505, 1471, 1349, 1254, 1105 and 969 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 7.97–7.26 (m), 6.96–6.93 (m), 6.13 (s), 4.13–3.43 (m, 4H) and 1.49–1.05 (m) p.p.m.; 19F NMR (400 MHz, 298 K, CDCl3) δ −136.64 (s, 2F), −157.49 (s, 1F) and −163.55 (s, 2F) p.p.m.; elemental analysis calcd. for the C160.8H221.6B2F20N2O50.4 repeating unit: C 56.96, H 6.59, N 0.83, found: C 56.33, H 6.82, N 0.86; Mn 12 000 Da; Mw 29 000 Da; Mw/Mn 2.4 (estimated by SEC using PEG standards); Tm 31.1 °C; Td5 270 °C; Td10 320 °C.

PTHF-3: IR (NaCl) υ 2940, 2857, 2359, 1606, 1508, 1466, 1368, 1250, 1112 and 976 cm−1; 1H NMR (400 MHz, 298 K, CDCl3) δ 8.00–7.27 (m), 6.94–6.88 (m), 6.12 (s), 4.08–3.95 (m), 3.66–3.51 (m, 4H), 3.25–3.22 (m), 1.98–1.56 (m, 4H) and 1.56–1.00 (m) p.p.m.; 19F NMR (400 MHz, 298 K, CDCl3) δ −136.64 (s, 2F), −157.50 (s, 1F) and −163.60 (s, 2F) p.p.m.; elemental analysis calcd. for the C230.9H361.7B2F20N2O45.2 repeating unit: C 64.64, H 8.50, N 0.65, found: C 63.43, H 8.82, N 0.68; Mn 3500 Da; Mw 7300 Da; Mw/Mn 2.1 (estimated by SEC using PS standards); Tm 22.1 °C; Td5 267 °C; Td10 299 °C.

Results and discussion

Synthesis of bis(nitrile N-oxide) 1 and poly(boron enaminoketonate)s

Building upon our previous study,24, 25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36 we selected bis(2-alkoxy-naphthalene nitrile N-oxide) as a skeleton because it should be a suitable framework for a sufficiently stabilized homoditopic nitrile N-oxide. The synthesis of the homoditopic nitrile N-oxide 1 was accomplished with a 58% overall yield via a three-step reaction (Scheme 1, m.p. 119.5–120.7 °C). The structure of 1 was determined by 1H NMR, 13C NMR, IR and FAB-HRMS measurements (see Supplementary Materials).

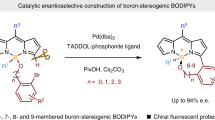

The polycycloaddition reactions of 1 with model diyne 2 and polymeric diynes 3 and 4 were performed without a catalyst by heating in refluxing CHCl3 for 12 h to give the high-molecular-weight polyisoxazoles poly-1, PEG-1 and PTHF-1, respectively, in high yields (Scheme 2 and Table 1). One regioisomer was preferentially formed as confirmed by the 1H NMR spectra16, 17 (see Supplementary Materials). Next, the N–O bonds of the isoxazole moiety in the resulting polyisoxazoles were cleaved using Mo(CO)637, 38 in a CH3CN–DMF mixture to give the corresponding poly(β-aminoenone)s poly-2, PEG-2 and PTHF-2 in high yields. From the integral ratio in the 1H NMR spectra, it was found that nearly 100% of the N−O bonds were successfully cleaved. Subsequent treatment of the poly(β-aminoenone)s with (C6F5)2BF·OEt2 afforded PBEKs (poly-3, PEG-3 and PTHF-3) in high yields. The PBEK structures were determined by 1H NMR, IR and 19F NMR spectra. The conversion of each polymer reaction was estimated to be high based on the elemental analysis results. The high reaction efficiencies for the formation of PBEKs from polyisoxazoles show that nitrile N-oxide-based click polymer synthesis is useful. The molecular weights of all the polymers were evaluated by SEC analysis (Table 1). The Mw and Mw/Mn values of the polyisoxazoles and their corresponding PBEKs were fairly consistent, indicating that the polyisoxazoles were efficiently modified without degrading the trunk polymer (see Supplementary Materials). On the other hand, the Mw and Mw/Mn values of the poly(β-aminoenone)s were inconsistent with those of the other compounds. Although the precise reason for these discrepancies is not clear, this might be attributed to a partial interchain aggregation of the β-aminoenone moieties and/or strong interactions between the β-aminoenone moieties and the SEC stationary phase.

Thermal and optical properties of PBEKs

Table 2 summarizes the thermal properties of the resulting polymers. All the polyisoxazoles and PBEKs, except for poly-3, were crystalline polymers, as suggested by their observed melting temperatures.16 Their crystallinity can be attributed to the interactions between the aromatic groups in the polymer main chain. The sufficiently high thermal decomposition temperatures indicated that the resulting polymers were stable.

Figure 2 shows the UV–vis and fluorescence spectra of the PBEKs in a CH2Cl2 solution, and Table 3 summarizes the results. For each of the PBEKs, the UV–vis absorption maximum occurred at nearly the same wavelength with a high molar absorption coefficient (ɛ) of ∼380–389 nm (Table 3). The Stokes shifts were sufficiently high, suggesting that the boron enaminoketonate skeleton could be successfully used in molecular probes.

(a) Ultraviolet–visible (UV–vis) and (b) fluorescence spectra of poly-3 (red line), PEG-3 (blue line) and PTHF-3 (green line) (20 μM in CH2Cl2, 293 K) and photographs of CH2Cl2 solutions of (c) PEG-3 irradiated with 254 nm light. A full color version of this figure is available at the Polymer Journal online.

The CH2Cl2 solutions of the polymers exhibited photoluminescence emission maxima at ∼451–453 nm when excited at their absorption maxima. The fluorescence quantum yields (ΦF) of poly-3, PEG-3 and PTHF-3 were 0.04, 0.05 and 0.07, respectively.39 These ΦF values are consistent with those of the poly(boron diketonate)s reported by Chujo and colleagues.10, 11, 12 To understand the PBEK photophysical properties, model compound 6 was prepared (Figure 3), and its UV–vis and fluorescence spectra were measured (see Supplementary Materials). The UV–vis absorption maximum of 6 was observed at 389 nm with a high molar absorption coefficient (ɛ=1.9 × 104 M−1 cm−1).

In addition, the emission maximum and fluorescence quantum yield (ΦF) of 6 were 452 nm and 0.06, respectively (see Supplementary Materials). These photophysical properties were in good agreement with those of the PBEKs, suggesting that the neighboring chromophore (boron enaminoketonate skeleton and naphthyl) units within the PBEKs did not interact in the ground and excited states. These results also show that the sequential transformation of the polyisoxazole allows the boron enaminoketonate skeleton to be efficiently introduced into the polymer framework.

The electronic states of 6 were also investigated with density functional theory at the B3LYP/6-31G level of the theory (Figure 3). The calculated highest occupied molecular orbital and lowest unoccupied molecular orbital of 6 were mainly located on the π orbital of the boron enaminoketonate moiety, indicating that the lowest excited state of 6 is the π–π* excited state.11, 15 In addition, the naphthalene moiety of 6 minimally affected the π extension of the emissive framework because of the distorted structure.

To evaluate the solid-state PBEK emission spectra, we estimated the fluorescence spectra of emulsified poly-3 and PEG-3. The emulsions were prepared by precipitating a CH2Cl2 solution of the polymer into excess cyclohexane, a poor solvent. As a result, these spectra exhibited broad peaks because of polymer aggregation (Figure 4). Both solid-state ΦF values were approximately the same as those obtained in solution without collisional quenching of the excited state by π–π stacking.40

Conclusions

In conclusion, we developed a procedure for synthesizing PBEKs by using stable homoditopic nitrile N-oxide 1 in a catalyst-free click polymerization and performing subsequent polymer transformations. Good optical properties, such as large Stokes shifts and ΦF values, were obtained and were the same as those of poly(boron diketonate)s, and this indicates that the BEK skeleton is a useful substitute for boron diketonates. The results are broadly applicable to not only polymeric materials but also supramolecular chemistry because we previously reported the effective synthesis of rotaxanes and polyrotaxanes via cycloaddition reactions involving stable nitrile N-oxides.16, 27, 30, 33, 36 The study of stimuli-responsive fluorescence switching systems using BEK-containing supramolecular skeletons is an important area of future research.

Synthesis of homoditopic nitrile N-oxide 1. A full color version of this scheme is available at the Polymer Journal online.

Synthesis of the polyisoxazoles and their transformation into poly(boron enaminoketonate)s (PBEKs). A full color version of this scheme is available at the Polymer Journal online.

References

Halik, M. & Hartmann, H. Synthesis and characterization of new long-wavelength-absorbing oxonol dyes from the 2,2-difluoro-1,3,2-dioxaborine type. Chem. Eur. J. 5, 2511–2517 (1999).

Cogné-Laage, E., Allemand, J.-F., Ruel, O., Baudin, J.-B., Croquette, V., Blanchard-Desce, M. & Jullien, L. Diaroyl(methanato)boron difluoride compounds as medium-sensitive two-photon fluorescent probes. Chem. Eur. J. 10, 1445–1455 (2004).

Ono, K., Yoshikawa, K., Tsuji, Y., Yamaguchi, H., Uozumi, R., Tomura, M., Taga, K. & Saito, K. Synthesis and photoluminescence properties of BF2 complexes with 1,3-diketone ligands. Tetrahedron 63, 9354–9358 (2007).

Maeda, H., Mihashi, Y. & Haketa, Y. Heteroaryl-substituted C3-bridged oligopyrroles: potential building subunits of anion-responsive π-conjugated oligomers. Org. Lett. 10, 3179–3182 (2008).

Haugland, R. P. The Handbook–A Guide to Fluorescent Probes and Labeling Technologies 10th ed ed. Spence M. T. Z., Chapter 1, Section 1.4 (Molecular Probes, Eugene, OR, 2005).

Pavlopoulos, T. G., Boyer, J. H. & Sathyamoorthi, G. Laser action from a 2,6,8-position trisubstituted 1,3,5,7-tetramethylpyrromethene-BF2 complex: part 3. Appl. Opt. 37, 7797–7800 (1998).

Sanchez-Barragan, I., Costa-Fernandez, J. M., Sanz-Medel, A., Valledor, M. & Campo, J. C. Room-temperature phosphorescence (RTP) for optical sensing. Trends Anal. Chem 25, 958–967 (2006).

Galletta, M., Puntoriero, F., Campagna, S., Chiorboli, C., Quesada, M., Goeb, S. & Ziessel, R. Absorption spectra, photophysical properties, and redox behavior of ruthenium(II) polypyridine complexes containing accessory dipyrromethene-BF2 chromophores. J. Phys. Chem. A 110, 4348–4358 (2006).

Zhang, G., Chen, J., Payne, S. J., Kooi, S. E., Demas, J. N. & Fraser, C. L. Multi-emissive difluoroboron dibenzoylmethane polylactide exhibiting intense fluorescence and oxygen-sensitive room-temperature phosphorescence. J. Am. Chem. Soc. 129, 8942–8943 (2007).

Nagai, A., Kokado, K., Nagata, Y. & Chujo, Y. 1,3-Diketone-based organoboron polymers: emission by extending π-conjugation along a polymeric ligand. Macromolecules 41, 8295–8298 (2008).

Nagai, A., Kokado, K., Nagata, Y., Arita, M. & Chujo, Y. Highly intense fluorescent diarylboron diketonate. J. Org. Chem. 73, 8605–8607 (2008).

Tanaka, K., Tamashima, K., Nagai, A., Okawa, T. & Chujo, Y. Facile modulation of optical properties of diketonate-containing polymers by regulating complexation ratios with boron. Macromolecules 46, 2969–2975 (2013).

Xia, M., Wu, B. & Xiang, G. Synthesis, structure and spectral study of two types of novel fluorescent BF2 complexes with heterocyclic 1,3-enaminoketone ligands. J. Fluorine Chem. 129, 402–408 (2008).

Macedo, F. P., Gwengo, C., Lindeman, S. V., Smith, M. D. & Gardinier, J. R. β-diketonate, β-ketoiminate, and β-diiminate complexes of difluoroboron. Eur. J. Inorg. Chem. 2008, 3200–3211 (2008).

Yoshii, R., Nagai, A., Tanaka, K. & Chujo, Y. Highly emissive boron ketoiminate derivatives as a new class of aggregation-induced emission fluorophores. Chem. Eur. J. 19, 4506–4512 (2013).

Koyama, Y., Matsumura, T., Yui, T., Ishitani, O. & Takata, T. Fluorescence control of boron enaminoketonate using a rotaxane shuttle. Org. Lett. 15, 4686–4689 (2013).

Lee, Y.-G., Koyama, Y., Yonekawa, M. & Takata, T. New click chemistry: polymerization based on 1,3-dipolar cycloaddition of a homo ditopic nitrile N-oxide and transformation of the resulting polymers into reactive polymers. Macromolecules 42, 7709–7717 (2009).

Koyama, Y., Seo, A. & Takata, T. Polymer modification exploiting stable nitrile N-oxide. Nippon Gomu Kyokaishi 84, 111–116 (2011).

Cai, M., Sha, J. & Xu, Q. MCM-supported bidentate phosphine palladium(0) complex: a highly active and recyclable catalyst for the Sonogashira reaction of aryl iodides. Tetrahedron 63, 4642–4647 (2007).

Yoshino, J., Kano, N. & Kawashima, T. Synthesis of the most intensely fluorescent azobenzene by utilizing the B-N interaction. Chem. Commun. 43, 559–561 (2007).

Duchateau, R., Lancaster, S. J., Thornton-Pett, M. & Bochmann, M. Synthesis of Cyclopentadienyl-, Indenyl-, and Fluorenylbis(pentafluorophenyl)boranes as ligands in titanium and zirconium half-sandwich complexes. The crystal structures of [C13H9B(C6F5)2·t-BuNH2], [C13H8SiMe3B(C6F5)2], and {η5-C5H4B(C6F5)2}TiCl3 . Organometallics 16, 4995–5005 (1997).

Hirose, T. & Matsuda, K. Self-assembly of amphiphilic fluorescent dyes showing aggregate-induced enhanced emission: temperature dependence of molecular alignment and intermolecular interaction in aqueous environment. Chem. Commun. 45, 5832–5834 (2009).

Pirali, T., Gatti, S., Di Brisco, R., Tacchi, S., Zaninetti, R., Brunelli, E., Massarotti, A., Sorba, G., Canonico, P. L., Moro, L., Genazzani, A. A., Tron, G. C. & Billington, R. A. Hybrid nanoparticles with CO2-responsive shells and fluorescence-labelled magnetic cores. Chem. Med. Chem. 2, 437–440 (2007).

Koyama, Y., Yonekawa, M. & Takata, T. New click chemistry: click polymerization via 1,3-dipolar addition of homo-ditopic aromatic nitrile oxides formed in situ. Chem. Lett. 37, 918–919 (2008).

Lee, Y.-G., Yonekawa, M., Koyama, Y. & Takata, T. Synthesis of a kinetically stabilized homoditopic nitrile N-oxide directed toward catalyst-free click polymerization. Chem. Lett 39, 420–421 (2010).

Lee, Y.-G., Koyama, Y., Yonekawa, M. & Takata, T. Synthesis of main-chain-type polyrotaxanes by new click polymerization using homoditopic nitrile N-oxides via rotaxanation-polymerization protocol. Macromolecules 43, 4070–4080 (2010).

Matsumura, T., Ishiwari, F., Koyama, Y. & Takata, T. C-C bond-forming click synthesis of rotaxanes exploiting nitrile N-oxide. Org. Lett. 12, 3828–3831 (2010).

Koyama, Y. & Takata, T. Polymer synthesis exploiting nitrile N-oxide. Kobunshi Ronbunshu 68, 147–159 (2011).

Yonekawa, M., Koyama, Y., Kuwata, S. & Takata, T. Intramolecular 1,3-dipolar cycloaddition of nitrile N-oxide accompanied by dearomatization. Org. Lett. 14, 1164–1167 (2012).

Jang, K., Miura, K., Koyama, Y. & Takata, T. Catalyst- and solvent-free click synthesis of cyclodextrin-based polyrotaxanes exploiting a nitrile N-oxide. Org. Lett. 14, 3088–3091 (2012).

Koyama, Y., Miura, K., Cheawchan, S., Seo, A. & Takata, T. Cascade functionalization of unsaturated bond-containing polymers using ambident agents possessing both nitrile N-oxide and electrophilic functions. Chem. Commun. 48, 10304–10306 (2012).

Koyama, Y., Wang, C., Miura, K., Cheawchan, S., Seo, A. & Takata, T. Development of nitrile N-oxide agents directed toward catalyst-free solid-state modification of common polymers. Hyomen 50, 228–238 (2012).

Iguchi, H., Uchida, S., Koyama, Y. & Takata, T. Polyester-containing α-cyclodextrin-based polyrotaxanes: synthesis by living ring-opening polymerization, polypseudorotaxanation, and end capping using nitrile N-oxide. ACS Macro Lett. 2, 527–530 (2013).

Wang, C., Koyama, Y., Yonekawa, M., Uchida, S. & Takata, T. Polymer nitrile N-oxides directed toward catalyst- and solvent-free click grafting. Chem. Commun. 49, 7723–7725 (2013).

Cheawchan, S., Koyama, Y., Uchida, S. & Takata, T. Catalyst-free click cascade functionalization of unsaturated-bond-containing polymers using masked-ketene-tethering nitrile N-oxide. Polymer (Guildf). 54, 4501–4510 (2013).

Yuki, T., Koyama, Y., Matsumura, T. & Takata, T. Click annulation of pseudo[2]rotaxane to [2]catenane exploiting homoditopic nitrile N-oxide. Org. Lett. 15, 4438−4441 (2013).

Nitta, M. & Higuchi, T. Mo(CO)6-induced N-O cleavage of isoxazoles. A convenient route to pyridine-4(1H)-ones. Heterocycles 38, 853–857 (1994).

Li, C.-S. & Lacasse, E. Synthesis of pyran-4-ones from isoxazoles. Tetrahedron Lett. 43, 3565–3568 (2002).

Ishida, H., Tobita, S., Hasegawa, Y., Katoh, R. & Nozaki, K. Recent advances in instrumentation for absolute emission quantum yield measurements. Coord. Chem. Rev. 254, 2449–2458 (2010).

Sato, T., Jiang, D.-L. & Aida, T. A blue-luminescent dendritic rod: poly(phenyleneethynylene) within a light-harvesting dendritic envelope. J. Am. Chem. Soc. 121, 10658–10659 (1999).

Acknowledgements

This work was supported by JSPS KAKENHI Grant Numbers 24685023 and 25102510.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Matsumura, T., Koyama, Y., Uchida, S. et al. Fluorescent poly(boron enaminoketonate)s: synthesis via the direct modification of polyisoxazoles obtained from the click polymerization of a homoditopic nitrile N-oxide and diynes. Polym J 46, 609–616 (2014). https://doi.org/10.1038/pj.2014.31

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.31

Keywords

This article is cited by

-

Synthesis, spectral and electrochemical properties of selected boron ketiminates with aminocoumarin fragment

Monatshefte für Chemie - Chemical Monthly (2018)