Abstract

Nanocomposite gels containing chitosan as a network polymer and chitin nanowhiskers as reinforcing fillers were prepared by cross-linking with the blocked isocyanate hexamethylene-1,6-di-(aminocarboxysulfonate) (HDS). Young’s modulus and stress at break of the nanocomposite gels increased to maximum values of 169 and 135 kPa, respectively, with increase in whisker content up to 13.3%, whereas the degree of swelling decreased from 357 to 33.0.

Similar content being viewed by others

Introduction

Cellulose and chitin, the two dominant natural polysaccharides, usually occur in nature as fine fibrillar structures called microfibrils.1, 2, 3, 4 A single microfibril consists of several tens of elementary fibrils, in which 30–40 cellulose or chitin molecules are aligned parallel to the long axis. As a result, a single microfibril can be considered as an almost perfect crystal of cellulose or chitin with a slight degree of crystal distortion, yielding the crystalline forms of cellulose I (parallel alignment of cellulose molecules), α-chitin (anti-parallel alignment of chitin molecules) or β-chitin (parallel). The dimensions, especially the widths of these microfibrils, strongly depend on their origins. The widths are about 20 nm for cellulose microfibrils of tunicates and algaes,5, 6 5–10 nm for ramie and cotton,7, 8, 9 2–4 nm for wood pulps10, 11 and about 5–10 nm for chitin microfibrils derived from shells of crabs or shrimps.12, 13 The microfibril cross-sections for bacterial cellulose are 10 × 50 nm.14 It is estimated that the lengths of all these microfibrils are at least several micrometers.

Acid hydrolysis of native cellulose or chitin under appropriate conditions causes breakdown of the microfibrils into shortened rod-like particles, yielding stable aqueous colloidal suspensions of cellulose or chitin microcrystals.7, 8, 9, 10, 11, 12, 13, 15, 16 The widths of these rod-like microcrystals, commonly referred to as nanocrystals or nanowhiskers, are similar to those of their original microfibrils, whereas their lengths are reduced to 100–200 nm for microfibrils obtained from higher plants, and 1–2 μm for those from tunicins and algaes.6 The colloidal suspensions of nanowhiskers are typical liquid crystals, showing strong flow birefringence under polarized light11 and spontaneous formation of chiral nematic7, 10, 13 or nematic8 ordering.

One of the outstanding characteristics of cellulose or chitin nanowhiskers is their high level mechanical property. The crystal modulus of cellulose I was estimated as 138 GPa by means of X ray diffractometry of a crystalline cellulose sample under stress,17 and as 150 GPa by direct bending measurement using the probe of an atomic force microscope.18 Although measurement of the stress at break of cellulose crystals has not yet been performed, the value is estimated to be in the order of 10 GPa.3 Values of the crystal modulus were reported as 41 GPa for α-chitin19 and 150 GPa for β-chitin.20

As these nanowhiskers are anisotropic nanoparticles with extremely high modulus and strength along their long axes, their utilization as fillers for nanocomposites, that is, composite materials with internal nano-ordered structures, has been widely investigated,2, 3, 4, 15 since the pioneering report by Favier et al.21 In addition to their high strength, the polysaccharide nanowhiskers have several useful advantages in comparison with conventional inorganic fillers, including facile chemical modification via surface hydroxyl or primary amino groups, and high degree of biodegradability. Although some of the previous studies20, 21 have employed nanocomposite films in which nanowhiskers were dispersed without directional order, more recent studies have produced several new types of nanocomposites, including an electrospun non-woven mat of poly(vinyl alcohol) containing cellulose nanowhiskers,22 and a drawn poly(vinyl alcohol) fiber in which cellulose whiskers are uniaxially oriented.23, 24

In the present study, use of chitin nanowhiskers for reinforcement of chemically cross-linked hydrogels was investigated. One of the most successful instances of incorporation of colloidal particles into gels is the so-called nanocomposite gel containing organic polymer/inorganic particle networks.25, 26 Nanocomposite gels prepared by polymerization of N-isopropyl acrylamide in the presence of inorganic clay particles showed several striking properties, including drawability up to 1400% of their original lengths and excellent mechanical properties (tensile strength >300 kPa). The incorporation of cellulose or chitin nanowhiskers was expected to yield similarly effective reinforcement of gels.

Several recent studies15, 27, 28 have enabled preparation of hydrogels reinforced with cellulose nanowhiskers. A combination of chitin nanowhiskers and chitosan for preparation of nanocomposite gels will be promising for utilization of cationic tough gels for antimicrobial applications, as well as a starting material having many primary amino groups as reaction points for subsequent introduction of other chemical moieties. Besides a study on surgical gels containing chitin nanofibrils,15 such a chitosan/chitin nanowhisker gel does not seem to be realized, probably because the basic cross-linking conditions used for preparation of celluose nanocomposite gels will result in significant aggregations of both chitosan molecules and chitin nanowhiskers. In the present study, a modified (blocked) isocyanate cross-linker, with two isocyanate groups blocked with sulfonate counterions to enhance stability in an aqueous environment, was used for preparation of a nanocomposite network of chitosan and chitin nanowhiskers. We especially focused on changes in Young's modulus, compressive strength and degree of swelling with change in whisker content.

Materials and Methods

Materials

Chitosan powder (Daichitosan PVL) was kindly provided by Dainichiseika Color & Chemicals Mfg. Co., Ltd. (Tokyo, Japan). According to the supplier's specifications, the molecular weight of the chitosan was in the range 5–20 × 104 g mol−1, as determined by gel permeation chromatograph measurements using pullulan standards. The degree of deacetylation was found to be 83%, from the results of the colloidal titration described in the Measurements section. Chitin powder from crab shell was purchased from Tokyo Chemical Industry Co., Ltd. (Tokyo, Japan). All other reagents were of reagent grade and were purchased from Wako Pure Chemical Industries, Ltd. (Osaka, Japan). All reagents were used without further purification.

Preparation of chitin nanowhiskers

An aqueous suspension of chitin nanowhiskers was prepared according to a previous study.13 In brief, 2 g of chitin powder was hydrolyzed with 50 ml of boiling 3 M hydrochloric acid for 3 h, followed by dilution of the acid by repeated centrifugation (3 000 r.p.m., 5 min) until a turbid supernatant containing nanowhiskers was obtained. The supernatant thus obtained was dialyzed against deionized water using dialysis tubing (Viskase Companies, Darien, IL, USA, molecular weight cut-off 12–14 kg mol−1) until the outside water was neutral. The dialyzed suspension was sonicated with a Biologics 150VT unit (Biologics, Inc., Manassas, VA, USA) for 1 min, then concentrated up to about 5 wt% by so-called osmotic compression,7 that is, immersion of dialysis tubing containing nanowhisker suspension in a about 10% aqueous solution of poly(ethylene glycol) with molecular weight 2.0 × 104 g mol−1. Finally, the suspension was diluted again with deionized water to the desired solids content (0.5–2.5 wt%). The final yield of nanowhiskers was 55–60% relative to the initial weight of chitin powder.

Synthesis of HDS

The blocked isocyanate cross-linker HDS was synthesized according to a previous study.29, 30 Hexamethylene diisocyanate (6.73 g, 40 mmol) was added to Na2S2O5 (8.36 g, 44 mmol) solution in deionized water (15.5 ml), and the mixture was stirred for 20 h at room temperature. The white precipitate formed by pouring the turbid mixture into acetone was collected by suction filtration and dried in vacuo. The product was then re-dissolved in water (30 ml), separated from insoluble solids by filtration, re-precipitated with acetone, isolated by filtration and vacuum-dried. The final yield of product (white powder) was 84%. Chemical shift values in 1H and 13C nuclear magnetic resonance (NMR) spectra were similar with those in Welsh et al.30.

1H NMR (D2O, 3-(trimethylsilyl)-1-propanesulfonic acid sodium salt, 400 MHz): δ (p.p.m.) 1.34 (4 H), 1.57 (4 H), 3.28 (4 H). 13C NMR (D2O, 3-(trimethylsilyl)-1-propanesulfonic acid sodium salt, 100 MHz): δ (p.p.m.) 28.11, 30.53, 42.87 and 168.01.

Preparation of chitosan/chitin whisker nanocomposite gels

Chitosan solution was prepared by dissolving chitosan (2 g) in 5 wt% acetic acid (20 g). After removal of a trace amount of insoluble particles (the amount was negligible for the subsequent calculation of chitosan concentration), 10 g of the chitosan solution was thoroughly mixed with an equal weight of chitin nanowhisker suspension or water. Several 20 g aliquots containing 4.55 wt% chitosan (0.909 g, 4.48 × 10−3 mol –NH2), 2.27 wt% acetic acid (0.454 g) and varying content of chitin nanowhiskers ranging from 0 to 1.25 wt% were prepared. To each of these aliquots, HDS (1.62 g, 4.30 × 10−3 mol) was added and mixed. The mixtures were transferred to a mold comprising two glass plates with a 5-mm-thick spacer of silicon rubber, and gelation was allowed to occur by standing at 60 °C for 48 h. The resulting chitosan/chitin nanowhisker gels were immersed for 2 days in sufficient deionized water, with successive exchanges of water, to remove acetic acid or low-molecular weight impurities.

A whisker content parameter, the percentage of whisker weight relative to the total weight of all network components (including chitosan, chitin whiskers and HDS without sulfate counterions) was evaluated as follows; 10 g of the chitosan solution, which was prepared according to the procedure stated above, contained 0.909 g of chitosan and 0.455 g of acetic acid. Ten grams of a chitin nanowhisker suspension with solids content x wt% (containing 0.1x g of solid whiskers) was added, followed by addition of 1.62 g of HDS. Assuming that all HDS molecules were involved in cross-linking, the total network weight increased by 1.62 × (168.21/376.31)=0.724 g, where 168.21 is the increase in molecular weight after cross-linking by a single HDS molecule, and 376.31 is the molecular weight of HDS. Whisker content relative to total solid content of the nanocomposite gels can thus be calculated from the equation

Values of x=0.5, 1.0, 2.0 and 2.5 correspond to whisker contents of 2.97%, 5.77%, 10.9% and 13.3%, respectively.

To estimate whether the chitin nanowhiskers in the nanocomposite gels are cross-linked with network of chitosan chains, the solubility of the chitin nanowhiskers in a good solvent of chitin were examined. Methanol saturated with calcium chloride dihydrate was prepared according to the previous report.31 Two gels with whisker content of 2.97 and 0%, respectively, (namely, the latter is a cross-linked chitosan gel), swollen with water, were cut into cubical pieces of about 8 mm length, and immersed in the 20 ml of methanol/CaCl2 solvent separately. These gels were refluxed for 2 days in an oil bath at 90 °C with an exchange of the solvent at 24 h heating.

Measurements

1H NMR at 400 MHz and 13C NMR at 100 MHz were recorded in D2O with a Bruker AVANCE400 spectrometer (Bruker Biospin KK., Yokohama, Japan) at room temperature. Chemical shifts were referenced by 3-(trimethylsilyl)-1-propanesulfonic acid sodium salt for 0 p.p.m.

Morphologies of the chitin nanowhiskers were observed with a transmission electron microscope (JEOL JEM-2100, JEOL Ltd., Tokyo, Japan). A drop of a very dilute suspension was dried on a carbon-coated Formvar film spread on a copper specimen grid (Okenshoji Co. Ltd., Tokyo, Japan), and examined at 80 kV using the defocus contrast technique.

The degree of deacetylation of chitosan was determined by colloidal titration.32, 33 Chitosan powder (0.25 g) was dissolved in 5 wt% aqueous acetic acid to give a total solution weight of 100 g. An aliquot (1.000 g) of the solution was diluted with 30 ml of deionized water, followed by titration with 2.5 mM (N/400) potassium poly(vinyl sulfate) solution using a few drops of toluidine blue solution as indicator. The degree of deacetylation was calculated from the equation

where v is the volume (in ml) of potassium poly(vinyl sulfate) solution required for the titration.

The amount of surface amino groups of the chitin nanowhiskers was determined by conductometric titration.33 A whisker suspension (7.00 g, 1.98 wt%, containing 139 mg whiskers) was diluted with 100 ml of deionized water. After addition of 1 ml of 0.1 M HCl, the pH and conductivity of the sample were recorded after every addition of 1 ml of 0.01 M NaOH per minute. The two well-defined inflection points in the conductivity versus volume of NaOH graph indicated neutralization of strong acid (HCl) and protonated amino groups; the amino group content per gram of chitin nanowhiskers was calculated from the volume of 0.01 M NaOH between the inflection points.

Compressive mechanical measurements were performed with a Shimadzu EZ-S universal testing machine (Shimadzu Corporation, Kyoto, Japan), using a 50-N load cell and a circular compression plate 10 mm in diameter, at compression rate 1 mm min−1. Averaged values of Young’s modulus and the stress at break were determined from 10 replicated measurements for each gel. Mechanical properties of the two gels with whisker content of 2.97 and 0% was further examined after slow drying of the latter on a Teflon sheet at room temperature for about 1 week to achieve a similar level of swelling ratio (see Results and Discussion section for details).

The degree of swelling, Q, of the nanocomposite gels was determined according to the equation Q=Ws/Wd, where Ws is the weight of gel fully swollen with deionized water (Ws was typically between 1 and 5 g) and Wd is the weight of residual solids after the gels were dried at 105 °C overnight. Typically, it took several days for a complete swelling of the gels. The results of three replicated measurements were averaged for each gel.

Results and Discussion

Characterization of chitin nanowhiskers

The electron micrograph in Figure 1 of the chitin nanowhiskers obtained by hydrochloric acid hydrolysis shows nanowhiskers 6–8 nm in width and 100–200 nm long, similar to those obtained in a previous study.13 The amount of surface amino groups of the whiskers, derived from the inherent amino groups in the native chitin samples,13, 34 was 299 μmol g−1 chitin whiskers. Assuming the dimensions 7 × 7 × 150 nm for a single nanowhisker, and density 1.425 g cm−3 for crystalline α-chitin, specific lateral surface area is calculated to be 4.01 × 1020 nm2 g−1 chitin (cross-sectional area was omitted because of the absence of amino groups). These values for amino-group contents and specific lateral surface area give a surface charge density value of 0.45 nm−2, which is close to the previously reported values of 0.5–0.6 nm−2.34

Preparation of chitosan/chitin whisker nanocomposite gels

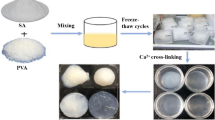

Mixing of a chitosan solution in aqueous acetic acid, chitin nanowhisker suspension and HDS, and subsequent cross-linking at 60 °C for 48 h yielded an opaque homogeneous nanocomposite hydrogel, as shown in Figure 2a. In the process of repeated immersion of the gel in deionized water to remove impurities, no leaching of whiskers from the gels was observed. The gel with 0% chitin nanowhiskers was transparent.

(a) Appearance of the chitosan/chitin whisker nanocomposite gel with whisker content 10.2 wt%. (b) Appearance of the chitosan/chitin whisker nanocomposite gel with whisker content 2.97 wt% (left) and the chitosan gel without incorporation of the chitin nanowhiskers (right), after refluxing in methanol/CaCl2 solvent for 2 days. Both scale bars show 1 cm.

Dai et al.27 reported preparation of nanocomposite gels consisting of cellulose nanowhiskers and cellulose derivatives, including carboxymethylcellulose and hydroxyethylcellulose, by cross-linking with divinyl sulfone in 0.1 M NaOH. Although divinyl sulfone is known to effectively cross-link hydroxyl groups in alkaline conditions,35, 36 it does not seem to be used for cross-linking chitosan/chitin nanowhisker systems. The reason is that amino groups in chitosan and on the surface of chitin nanowhiskers are not protonated in 0.1 M NaOH, as the pKa values for both are around 6.3, resulting in insolubility of chitosan and strong aggregation of chitin nanowhiskers owing to the absence of electrostatic repulsion. Consequently, it was anticipated that preparation of homogeneous chitosan/chitin nanowhisker gels by cross-linking with divinyl sulfone in 0.1 M NaOH would not be successful. Cross-linking of the chitosan/chitin nanowhisker system with HDS was, however, successful. The occurrence of HDS-mediated cross-linking in water suggests that hydroxyl groups cannot attack blocked isocyanate groups because of their lower nucleophilicity than that of primary amino groups. We show a schematic cross-linking situation in Figure 3, in which the primary amino groups in chitosan and on the surface of chitin nanowhiskers are cross-linked with HDS.

Confirmation of cross-link formation between chitin nanowhiskers and chitosan molecules is significant, but finding its chemical evidence is very difficult and may be impossible, because components of both chitin and chitosan are essentially identical, that is, glucosamine and N-acetylglucosamine. Any chemical analysis cannot differentiate glucosamine residues from chitin and those from chitosan. At present, we can demonstrate only indirect evidence instead of chemical analysis. A chitin nanowhisker/chitosan nanocomposite gel and a cross-linked chitosan gel were refluxed in methanol saturated with calcium chloride, which is reported to be a good solvent for chitin.31 If chitin nanowhiskers are free from cross-linking and are embedded separately in the nanocomposite gel, the methanol/CaCl2 solvent penetrated into the gels will readily dissolve chitin nanowhiskers and make the gel transparent. The result was quite opposite; appearances of the both gels did not change as shown in Figure 2b, although they were slightly shrunk according to solvent exchange. The nanocomposite gels were still opaque, and it suggests that the dense cross-linking between chitin nanowhiskers and chitosan molecule lowered an accessibility of the methanol/CaCl2 solvent, resulting in insolubilization of the chitin nanowhiskers.

Mechanical properties of the chitosan/chitin whisker nanocomposite gels

Values of Young's modulus, stress at break and degree of swelling of the chitosan/chitin whisker nanocomposite gels, together with their whisker content are summarized in Table 1. Remarkable increases in mechanical properties, for example a 66.8-fold increase in Young's modulus (from 2.53 to 168.9 kPa) and 41.5-fold increase in stress at break (from 3.24 to 134.5 kPa), were observed on increasing whisker content from 0 to 13.3%, whereas the degree of swelling decreased to about a tenth (from 356.9 to 33.0). Although these tendencies are similar to those reported for nanocomposite gels containing cellulose nanowhiskers,27 which showed 1.5–2-fold increase in gel modulus with whisker content of ∼40%, the present results indicate far higher levels of enhancement of mechanical properties. The chitosan/chitin nanocomposite gels showed a lower value of swelling ratio than that of the gel without incorporation of chitin nanowhiskers, probably because tying by rigid nanowhiskers suppressed free expansion of a network of chitosan chains. Our results may also imply another possibility that the improved mechanical properties observed for the gels with a higher whisker content are due to their lower degrees of swelling. To exclude this possibility, we prepared two gels with different whisker content and a similar level of swelling ratio by slow drying of the gels, as described in the last two lines in Table 1, followed by mechanical tests. The results of the higher Young's modulus and stress at break still clearly show the effective reinforcement with chitin nanowhiskers.

For strengthening of gels, reinforcing whiskers are required to connect to a network by at least more than two cross-linking points per single whisker, as otherwise whiskers do not bear stress nor strengthen gels. To estimate numbers of cross-linking points per single whisker in the gels, amino groups of chitin nanowhiskers and chitosan molecules were measured using titration techniques. According to the recipe described in the Materials and Methods section, the calculated molar numbers of total surface amino groups on chitin nanowhiskers, those of total amino groups in chitosan molecules and those of protected isocyanate groups (−NHCOSO3Na) were 4.48 × 10−3 mol (in 0.909 g of chitosan), 7.48 × 10−5 mol (on 0.25 g of chitin nanowhiskers) and 8.60 × 10−3 mol (in 1.62 g of HDS), respectively, for the nanocomposite gels with whisker content of 13.3%. The former two results can be converted into values of 1 890 surface amino groups per single chitin nanowhisker and about 740 amino groups in a single chitosan molecule. The amount of HDS is excess for total amino groups, so the possibility of a lack of cross-linkers to give only one cross-link on a single whisker is implausible. In the forthcoming investigations, the actual numbers of cross-links should be elucidated by other techniques, including a use of tagged cross-linkers or estimation from dynamic mechanical measurements.

Conclusion

Chitosan/chitin whisker nanocomposite gels can be prepared by HDS-mediated cross-linking of chitosan and chitin whiskers. Young’s modulus and stress at break of the nanocomposite gels increased with increase in whisker content up to 13.3%, whereas the degree of swelling decreased. Although the observed enhancement in mechanical properties clearly showed effective reinforcement by the chitin nanowhiskers, the improvement may be partially due to the decreased degree of swelling with increase in whisker content. The degree of swelling, and hence the mechanical properties, may also be affected by cross-link density. It is intended to further investigate the changes in the mechanical properties of the nanocomposite gels in relation to the degree of swelling at various electrolyte concentrations.

References

Flemming, K., Gray, D. G. & Matthews, S. Cellulose crystallites. Chem. Eur. J 7, 1831–1835 (2001).

de Souza Lima, M. M. & Borsali, R. Rodlike cellulose microcrystals: structure, properties, and applications. Macromol. Rapid Commun. 25, 771–787 (2004).

Azizi Samir, M. A., Alloin, F. & Dufresne, A. Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6, 612–626 (2005).

Habibi, Y., Lucia, L. A. & Rojas, O. J. Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem. Rev. 110, 3479–3500 (2010).

Chanzy, H. & Henrissat, B. Electron microscopy study of the enzymic hydrolysis of Valonia cellulose. Carbohydr. Polym. 3, 161–173 (1983).

Sugiyama, J., Chanzy, H. & Maret, G. Orientation of cellulose microcrystals by strong magnetic fields. Macromolecules 25, 4232–4234 (1992).

Araki, J., Wada, M., Kuga, S. & Okano, T. Birefringent glassy phase of a cellulose microcrystal suspension. Langmuir 16, 2413–2415 (2000).

Araki, J. & Kuga, S. Effect of trace electrolyte on liquid crystal type of cellulose microcrystals. Langmuir 17, 4493–4496 (2001).

Dong, X. M., Kimura, T., Refol, J.-F. & Gray, D. G. Effects of ionic strength on the isotropic-chiral nematic phase transition of suspensions of cellulose crystallites. Langmuir 12, 2076–2082 (1996).

Revol, J.-F., Bradford, H., Giasson, J., Marchessault, R. H. & Gray, D. G. Helicoidal self-ordering of cellulose microfibrils in aqueous suspension. Int. J. Biol. Macromol. 14, 170–172 (1992).

Araki, J., Wada, M., Kuga, S. & Okano, T. Flow properties of microcrystalline cellulose suspension prepared by acid treatment of native cellulose. Colloids Surf. A 142, 75–82 (1998).

Marchessault, R. H., Morehead, F. F. & Walter, N. M. Liquid crystal systems from fibrillar polysaccharides. Nature 184, 632–633 (1959).

Revol, J.-F. & Marchessault, R. H. In vitro chiral nematic ordering of chitin crystallites. Int. J. Biol. Macromol. 15, 329–335 (1993).

Brown, R. M., Willison, J. H. & Richardson, C. L. Cellulose biosynthesis in Acetobacter xylinum: visualization of the site of synthesis and direct measurement of the in vitro process. Proc. Natl. Acad. Sci. USA 73, 4565–4569 (1976).

Muzzarelli, R. A. A., Morganti, P., Morganti, G., Palombo, P., Palombo, M., Biagini, G., Belmonte, M. M., Giantomassi, F., Orlandi, F. & Muzzarelli, C. Chitin nanofibrils/chitosan glycolate composites as wound medicaments. Carbohydr. Polym. 70, 274–284 (2007).

Araki, J., Wada, M. & Kuga, S. Steric stabilization of a cellulose microcrystal suspension by poly(ethylene glycol) grafting. Langmuir 17, 21–27 (2001).

Nishino, T., Takano, K. & Nakamae, K. Elastic modulus of the crystalline regions of cellulose polymorphs. J. Polym. Sci. B Polym. Phys 33, 1647–1651 (1995).

Iwamoto, S., Kai, W., Isogai, A. & Iwata, T. Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromolecules 10, 2571–2576 (2009).

Nishino, T., Matsui, R. & Nakamae, K. Elastic modulus of the crystalline regions of chitin and chitosan. J. Polym. Sci. B Polym. Phys. 37, 1191–1196 (1999).

Paillet, M. & Dufresne, A. Chitin whisker reinforced thermoplastic nanocomposites. Macromolecules 34, 6527–6530 (2001).

Favier, V., Chanzy, H. & Cavaille, J. Y. Polymer nanocomposites reinforced by cellulose whiskers. Macromolecules 28, 6365–6367 (1995).

Peresin, M. S., Habibi, Y., Zoppe, J. O., Pawlak, J. J. & Rojas, O. J. Nanofiber composites of polyvinyl alcohol and cellulose nanocrystals: manufacture and characterization. Biomacromolecules 11, 674–681 (2010).

Uddin, A. J., Araki, J. & Gotoh, Y. Toward ‘strong’ green nanocomposites: polyvinyl alcohol reinforced with extremely oriented cellulose whiskers. Biomacromolecules 12, 617–624 (2011).

Uddin, A. J., Araki, J. & Gotoh, Y. Extremely oriented tunicin whiskers in poly(vinyl alcohol) nanocomposites. Polym. Int. 60, 1230–1239 (2011).

Haraguchi, K. & Takehisa, T. Nanocomposite hydrogels: a unique organic–inorganic network structure with extraordinary mechanical, optical, and swelling/de-swelling properties. Adv. Mater. 14, 1120–1124 (2002).

Haraguchi, K., Takehisa, T. & Fan, S. Effects of clay content on the properties of nanocomposite hydrogels composed of poly(N-isopropylacrylamide) and clay. Macromolecules 35, 10162–10171 (2002).

Dai, Q. & Kadla, J. F. Effect of nanofillers on carboxymethyl cellulose/hydroxyethyl cellulose hydrogels. J. Appl. Polym. Sci. 114, 1664–1669 (2009).

Abitbol, T., Johnstone, T., Quinn, T. M. & Gray, D. G. Reinforcement with cellulose nanocrystals of poly(vinyl alcohol) hydrogels prepared by cyclic freezing and thawing. Soft Matter 7, 2373–2379 (2011).

Lin-Gibson, S., Walls, H. J., Kennedy, S. B. & Welsh, E. R. Reaction kinetics and gel properties of blocked diisocyanate crosslinked chitosan hydrogels. Carbohydr. Polym. 54, 193–199 (2003).

Welsh, E. R., Schauer, C. L., Qadri, S. B. & Price, R. R. Chitosan cross-linking with a water-soluble, blocked diisocyanate. 1. Solid State. Biomacromolecules 3, 1370–1374 (2002).

Tamura, H., Nagahama, H. & Tokura, S. Preparation of chitin hydrogel under mild conditions. Cellulose 13, 357–364 (2006).

Ueno, K. & Kina, K. Colloid titration – a rapid method for the determination of charged colloid. J. Chem. Educ. 62, 627–629 (1985).

Araki, J., Kagaya, K. & Ohkawa, K. Synthesis and characterization of polyrotaxane–amino acid conjugates: a new synthetic pathway for amino-functionalized polyrotaxanes. Biomacromolecules 10, 1947–1954 (2009).

Li, J., Revol, J.-F., Naranjo, E. & Marchessault, R. H. Effect of electrostatic interaction on phase separation behaviour of chitin crystallite suspensions. Int. J. Biol. Macromol. 18, 177–187 (1996).

Anbergen, U. & Oppermann, W. Elasticity and swelling behaviour of chemically crosslinked cellulose ethers in aqueous systems. Polymer 31, 1854–1858 (1990).

Araki, J. Polyrotaxane derivatives. II. Preparation and characterization of ionic polyrotaxanes and ionic slide-ring gels. J. Polym. Sci. A Polym. Chem 49, 2199–2209 (2011).

Acknowledgements

We greatly appreciate the kind donation of chitosan by Dr Takanori Sannan (Dainichiseika Color & Chemicals Mfg. Co., Ltd.). We are also grateful to Professor Yasuo Gotoh (Shinshu University) for the use of the universal testing machine, and to the Satellite Venture Business Laboratories of Shinshu University for the use of an electron microscope. This research was partially supported by the Ministry of Education, Culture, Sports, Science, and Technology, by way of a Grant-in-Aid for Young Scientists (B), 22750202, 2010. This study was also performed through the Program for Dissemination of Tenure-Track System funded by the Ministry of Education and Science, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Araki, J., Yamanaka, Y. & Ohkawa, K. Chitin-chitosan nanocomposite gels: reinforcement of chitosan hydrogels with rod-like chitin nanowhiskers. Polym J 44, 713–717 (2012). https://doi.org/10.1038/pj.2012.11

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.11

Keywords

This article is cited by

-

Rapid and facile quantification of surface amino groups on chitin nanowhiskers and nanofibers via spectrophotometry

Polymer Journal (2024)

-

Valorization of Colombian fique (Furcraea bedinghausii) for production of cellulose nanofibers and its application in hydrogels

Scientific Reports (2020)

-

Design and applications of man-made biomimetic fibrillar hydrogels

Nature Reviews Materials (2019)

-

Influence of Homogenization Technique and Blend Ratio on Chitosan/Alginate Polyelectrolyte Complex Properties

Journal of Medical and Biological Engineering (2018)

-

Crosslinked carboxylated SBR composites reinforced with chitin nanocrystals

Journal of Polymer Research (2016)