Abstract

A new type of modified bismaleimide (BMI) resins with good heat resistance and processing properties for advanced composites was developed. Modifiers hydrogen silsesquioxane (HSQ), dipropargyl ethers of bisphenol A, hexafluorobisphenol A, 4,4′-dihydroxydiphenyl ether and resorcinol were used to modify 4,4′-bismaleimidodiphenylmethane. The structure of the resins was verified by Fourier transform infrared spectrometry. The relationship between viscosity and temperature was used to characterize the processability of the resins. The curing behaviors of resins were investigated by a differential scanning calorimeter. The glass transition temperatures and thermal stabilities of cured resins were investigated by dynamic mechanical analysis and thermogravimetric analysis, respectively. The relationship between structures and properties of the resins was discussed, and the mechanical properties of the glass-fiber-fabric-reinforced composites were measured.

Similar content being viewed by others

Introduction

Thermosetting bismaleimide (BMI) resins have been widely used as a matrix for advanced composites in aerospace and astronautics. BMI resins possess excellent thermal and oxidative stability, as well as electrical and mechanical properties and a relatively low propensity for moisture absorption.1, 2, 3 However, unmodified BMI resins have some drawbacks, such as high melting points, high curing temperature and extreme brittleness. With the goal of increasing the toughness of BMI resins, a great deal of research has been carried out to modify them through homo- or copolymerization with such functionalized compounds as aromatic amines, epoxies, cyanates and allyphenols.4 However, to compromise between the heat resistance of modified BMI resins and the desirable mechanical properties, more effective methods are required.

Organic/inorganic hybrid materials have been widely regarded as among the most promising and rapidly emerging materials. Such hybrid materials often have good processability, toughness and thermally oxidative stability.5, 6, 7, 8 Polyhedral oligomeric silsesquioxanes (POSS) contain capped functional groups and an inner inorganic framework consisting of Si and O atoms in the ratio of 1:1.5 (SiOl.5)n. POSS-containing materials have excellent thermal stability and high glass transition and decomposition temperatures. POSS with one or more covalently bonded reactive groups is suitable for polymerization, grafting, surface bonding, blending and other transformations to build organic/inorganic hybrid materials at the molecular level.9, 10, 11, 12, 13 POSS functionalized with groups such as hydrogen,14 amine,15 vinyl,16 epoxy17 and isocyanate18 can be used as monomers or comonomers in typical polymerizations. One such POSS, hydrogen silsesquioxane (HSQ), has attracted increasing interest in scientific research and technological innovation.19, 20, 21, 22, 23, 24

A new kind of thermosetting resin with terminal propargyl groups has recently been developed as a high-performance polymer owing to its good processability, advantageous dielectric and mechanical properties and excellent thermal stability, whether in air or in a nitrogen atmosphere.25, 26, 27, 28, 29, 30

This paper presents new modified BMI resins prepared from BMI, HSQ and dipropargyl aryl ethers. We investigated the processability, mechanical properties and heat resistance of the resins and their composites.

Experimental procedure

Materials

4,4′-bismaleimidodiphenylmethane (hereafter referred to as BMI) was purchased from Hubei Honghu Chemical Company (Honghu, China). Pt-complex catalyst, dioxane and petroleum ether were purchased from Sinopharm Chemical Reagent (Shanghai, China). Glass fiber fabric (plain weave, 0.14-mm thick) was purchased from Hubei Feilihua Quartz Glass Co. Ltd (Jingzhou, China). HSQ, dipropargyl ethers of bisphenol A (DPBPA), dipropargyl ethers of hexafluorobisphenol A (DPBPF), dipropargyl ethers of 4,4′-dihydroxydiphenyl ether (DPBPE) and dipropargyl ethers of resorcinol (DPBPR) were synthesized in our laboratory.30, 31, 32

Characterization

Fourier transform infrared (FT-IR) spectra were obtained using a Nicolet 550 spectrometer (Thermo Electron Scientific Instruments Corporation, Waltham, MA, USA), and the sample powder was pressed into a pellet with KBr. Hydrogen-1 nuclear magnetic resonance (1H NMR) spectra were recorded on a AVANCE 500 (Bruker BioSpin GmbH, Rheinstetten, Germany) (500 MHz), C6D6 and dimethylsulfoxide-d6 were used as solvents and chemical shifts were reported in p.p.m. Rheological behavior was traced on a RheoStress RS600 rheometer (Thermo Haake Corporation, Paramus, NJ, USA) with a heating rate of 2 °C min−1; this was carried out on a plate with a shear rate of 0.1 s−1 in a temperature range from 50 to 220 °C. Differential scanning calorimeter analyses were performed on a 200 PC modulated system (NETZSCH-Gerätebau GmbH, Selb, Germany) at a nitrogen flow rate of 15 cm3 min−1 and a heating rate of 10 °C min−1 in a temperature range from 50 to 350 °C. Dynamic mechanical analysis (DMA) was carried out on a DMA 242 analyzer (NETZSCH-Gerätebau GmbH) operating in the double-cantilever mode from 50 to 400 °C at a frequency of 1 Hz with a programmed heating rate of 3 °C min−1. Thermogravimetric analysis (TGA) was conducted on a TGA/SDTA 851 analyzer (Mettler-Toledo (Schweiz) GmbH, Greifensee, Switzerland) under nitrogen with a heating rate of 10 °C min−1. The flexural test for the composites was carried out on a DXLL-5000 Tension Tester (D&G Machinery Equipment Co. Ltd, Shanghai, China) Tester according to China State Standard GB/T1449-2005.

Preparation of modified BMI resins

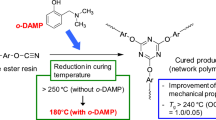

The BMI-HSQ-DPBPA resin was prepared from BMI and HSQ with DPBPA. HSQ (0.425 g, 1 mmol), BMI (11.467 g, 32 mmol) and dioxane (120 ml) were charged into a 250-ml three-necked round-bottom flask with a mechanical stirrer in the presence of a proper amount of Pt-complex catalyst. The mixture was heated to 90 °C and maintained at this temperature for 8 h under N2. After cooling to room temperature, the mixture was precipitated in 600 ml of petroleum ether, and the precipitated BMI-HSQ was obtained by filtration. Then, BMI-HSQ (11.892 g) and DPBPA (8.523 g, 14.33 mmol) were added into a 100-ml three-necked flask and stirred at 160 °C for 1 h, and the BMI-HSQ-DPBPA resin was obtained as a brown solid at ambient temperature, which was soluble in common solvents such as dioxane and tetrahydrofuran. The schematic reaction for the preparation of the resin is shown in Figure 1. The preparations of other modified BMI resins were similar to that of the BMI-HSQ-DPBPA resin. The modified resins are referred to here as BMI-HSQ-DPBPF (from DPBPF), BMI-HSQ-DPBPE (from DPBPE) and BMI-HSQ-DPBPR (from DPBPR).

For all modified BMI resins, the molar ratio of the maleimide groups (MI) (in BMI) to hydrogen (H) (in HSQ) plus propargyl groups (C≡C) (in dipropargyl ether) was 1:1. Table 1 shows the formulation of modified BMI resins.

Preparation of cured modified BMI resins

The curing of modified resins was conducted in an oven under air. The curing cycles of BMI-HSQ-DPBPA, BMI-HSQ-DPBPE and BMI-HSQ-DPBPR resins were as follows: 2 h at 180 °C, 2 h at 200 °C, 2 h at 220 °C and 5 h at 260 °C, successively, and the curing cycle for BMI-HSQ-DPBPF resin was 2 h at 180 °C, 2 h at 200 °C, 2 h at 220 °C and 5 h at 280 °C. The cured resins (BMI-HSQ-DPBPA, BMI-HSQ-DPBPF, BMI-HSQ-DPBPE and BMI-HSQ-DPBPR) are referred to as c-BMI-HSQ-DPBPA, c-BMI-HSQ-DPBPF, c-BMI-HSQ-DPBPE and c-BMI-HSQ-DPBPR, respectively.

Preparation of glass-fiber-reinforced composite

The glass fabric was used as a reinforcing material for the composite. BMI-HSQ-DPBPA resin was weighed and dissolved in dioxane. The fabric was impregnated with the solution and dried in a vacuum oven at 60 °C for 5 h. A prepreg with a resin content of about 37% was obtained and then pressed on a pressure machine under 5 MPa for 2 h at 180 °C, 2 h at 200 °C, 2 h at 220 °C and 5 h at 260 °C, successively.

Results and discussion

Preparation of BMI-HSQ and modified BMI resins

BMI-HSQ was examined by FT-IR, as shown in Figure 2. In the spectrum of BMI-HSQ, the Si–H absorption bands at 2296 cm−1 (stretching vibration) and 860 cm−1 (bending vibration) disappeared, which illustrates that Si–H groups in HSQ have reacted with C=C in imide rings of BMI through an addition reaction.

Figure 3 displays the 1H NMR spectra of HSQ, BMI and BMI-HSQ. The 1H NMR spectrum of HSQ showed a single peak at 4.2 p.p.m., assigned to Si–H, indicating that all hydrogen atoms were in the same chemical environment in the molecule. This confirmed the chemical structure of HSQ.

The 1H NMR spectrum of BMI showed four proton environments: Ha, Hb, Hc and Hd (see Figure 3). In the spectrum of BMI-HSQ, the Si–H peak at 4.2 p.p.m. disappeared, whereas two distinct peaks at 2.1 and 2.8 p.p.m. appeared, belonging to the hydrosilylation products of BMI and HSQ.

Figure 4 shows the FT-IR spectra of the series of modified BMI resins. All modified resins possessing several identical groups displayed similar absorptions. The absorption peaks at 3285 cm−1 and 2122 cm−1 belonged to the stretching vibrations of ≡C–H and C≡C, respectively, and the vibration of C–H of the benzene ring appeared at 3101 and 3041 cm−1. The peak at 1715 cm−1 was attributed to C=O in the maleimide ring. The absorption peaks at 1149 and 1181 cm−1 belonged to the C–N–C groups of maleimide and succinimide, respectively. The absorptions of the Ar–O–C band were located in the ranges of 1026–1046, 1206–1223 and 1248–1298 cm−1, and the benzene skeleton vibration was located at 1453–1610 cm−1.

Rheological behavior of modified BMI resins

The viscosity of a resin is important for its processing. A resin viscosity of 0.2–0.3 Pa s is believed to give the best overall processability for RTM. It is generally considered that a high injection and molding pressure is required when viscosity is higher than 0.5 Pa s. However, problems such as fiber displacement may occur in the mold cavity at a high injection pressure. Viscosity of the BMI-HSQ-DPBPA resin was measured by a rheometer. The viscosity response to temperature ramping at a heating rate of 2 °C min−1 is shown in Figure 5. It can be seen that viscosity decreased dramatically as temperature increased. At temperatures above 81 °C, the viscosity of the resin was below 1 Pa s. The viscosity of the resin measured at 107 and 117 °C was 0.3 and 0.2 Pa s, respectively, which is suitable for the RTM process. At temperatures higher than 196 °C, viscosity increased rapidly, which indicates that curing reactions occur at temperatures above 196 °C and that gelation occurs thereafter. The results showed that the BMI-HSQ-DPBPA resin had a relatively low viscosity at temperatures between 81 and 196 °C, thus allowing a wide processing window.

The curing reaction of modified BMI resins

Figure 6 presents differential scanning calorimeter traces of modified BMI resins at a heating rate of 10 °C min−1. It was observed that modified BMI resins showed a unimodel reaction exotherm because of their thermopolymerization. No melting endotherm appears in Figure 5, implying that modified BMI resins were noncrystalline. All modified resins showed a single wide exothermic peak, which indicates that curing reactions occurred and would facilitate the processing of resins to some extent. Table 2 listed the onset temperature (Ti), top temperature (Tp) and end temperature (Tf) of the curing exothermic peaks of the resins, which were determined mainly by curing reactivity and followed the trend of BMI-HSQ-DPBPR<BMI-HSQ-DPBPE<BMI-HSQ-DPBPA<BMI-HSQ-DPBPF.

Figure 7 presents the pathways proposed for the reaction of BMI and dipropargyl ether. In the thermopolymerization of propargyl ether and BMI, partial propargyl ether was initially subjected to chromene rearrangement and Claisen rearrangement (A); subsequently, copolymerization and autopolymerization occurred between the double bonds from the chromenes and/or maleimide rings of BMI (B), and then a simultaneous Diels-Alder reaction took place between the acetylenic bonds of propargyl ether and the double bonds of maleimide rings (C).30, 33, 34

Figure 8 displays the infrared spectra of the cured modified BMI resins. After curing, the absorption peak at 1149 cm−1 assigned to C–N–C groups shifted to 1180 cm−1 and broadened, with the peak intensity increasing. The above results indicate that the BMI participated in crosslinking reactions.

The characteristic absorptions at 3285 and 2122 cm−1 due to ≡C–H and C≡C vibrations of dipropargyl ethers disappeared, suggesting the complete consumption of dipropargyl ethers. The absorption band associated with Ar–O–C decreased, which indicates that propargyl ether groups were converted into cyclic ether or other structures. A broad absorption was noted in the region of 3300–3600 cm−1, representing OH groups in the cured resin, owing to the fact that phenolic OH groups were formed by the Claisen rearrangement of the structure of propargyl ether in the thermopolymerization process.

Thermal properties of cured modified BMI resins

Glass transition temperatures (Tg) of cured modified BMI resins were detected by DMA. Generally, the damping peak of tan δ was identified as Tg in a DMA curve because a large decrease in modulus occurred at this point. The DMA curves of cured modified resins are shown in Figure 9, and DMA and TGA analysis results are tabulated in Table 2.

The order of Tg for the cured resins was BMI-HSQ-DPBPE<BMI-HSQ-DPBPA<BMI-HSQ-DPBPF<BMI-HSQ-DPBPR. The Tgs of the former three were close to one another, having values of 337, 344 and 352 °C, respectively. By comparison, the cured BMI-HSQ-DPBPR resin possessed the highest Tg, 421 °C, which was derived from the highest curing density.

The Tg of the c-BMI-HSQ-DPBPA resin (344 °C) was higher than that of the cured BMI-DPBPA resin (320 °C).30 The cage structure of POSS would hinder the segment motion of the modified resins. For that reason, the addition of HSQ increases the Tg of the cured resin.

Thermal stability of cured modified BMI resins

The thermal stability of cured modified BMI resins was analyzed by TGA. The results are given in Figure 9 and Table 3. As shown in Figure 10, the Td5 of the cured modified resins increased as follows: c-BMI-HSQ-DPBPA<c-BMI-HSQ-DPBPE<c-BMI-HSQ-DPBPR<c-BMI-HSQ-DPBPF. The thermal stability of each resin was determined by the specific structure of the applied bisphenol derivative and the crosslinked network. As for the bisphenol structures, the moieties of C(CF3)2 in hexafluorobisphenol A possessed higher heat resistance than did the C(CH3)2 groups in bisphenol A because of the higher bond energy of C–F. Thus, the thermal stability of the c-BMI-HSQ-DPBPF resin was superior to that of the c-BMI-HSQ-DPBPA resin.

Mechanical properties of glass-fiber-reinforced composite

Table 4 lists the properties of the glass-fabric-reinforced BMI-HSQ-DPBPA composite. As shown, the composite exhibited excellent mechanical properties. The flexural strength of BMI-HSQ-DPBPA composites was 497 and 363 MPa at room temperature and at 250 °C, respectively. Thus, the retentions of flexural strength and modulus for BMI-HSQ-DPBPA composites at 250 °C were 73 and 98%, respectively. The laminar shear strength of BMI-HSQ-DPBPA composites was 31.7 MPa. Therefore, modified BMI resins are expected to be used for the matrix of advanced composites.

Conclusions

A series of BMI resins modified with HSQ, DPBPA, DPBPF, DPBPE and DPBPR were prepared. The resins exhibited excellent processability, especially the BMI-HSQ-DPBPA resin, which had a low viscosity of 0.2–0.3 Pa s at temperatures between 81 and 196 °C. The cured resins showed high heat resistance, with Tg above 330 °C and Td5 of 400 °C. The c-BMI-HSQ-DPBPR resin possessed the highest Tg, 421 °C, and the c-BMI-HSQ-DPBPF resin possessed the highest Td5, 424 °C. The glass-fiber-reinforced BMI-HSQ-DPBPA resin composites possessed good mechanical properties. The modified BMI resins would be good candidates for a high-performance matrix for advanced composites.

References

Rozenberg, B., Dzhavadyan, E. & Morgan, R. High-performance bismaleimide matrices: cure kinetics and mechanism. Polym. Adv. Technol. 13, 837–844 (2002).

Grenier-Loustalot, M. & Cunha, L. Study of molten-state polymerization of bismaleimide monomers by solid-state 13C NMR and FTIR. Polym. 39, 1833–1843 (1997).

Gu, A. High performance bismaleimide/cyanate ester hybrid polymer networks with excellent dielectric properties. Comp. Sci. Tech. 66, 1749–1755 (2006).

Yuan, Q., Huang, F. & Jiao, Y. Characterization of modified bismaleimide resin. J. Appl. Polym. Sci. 62, 459–464 (1996).

Maclachlan, M., Manners, I. & Ozin, G. New (inter) faces: polymers and inorganic materials. Adv. Mater. 12, 675–681 (2000).

Chandross, E. & Miller, R. Nanostructures: introduction. Chem. Rev. 99, 1641–1642 (1999).

Gomez-Romero, P. Hybrid organic-inorganic materials-in search of synergic activity. Adv. Mater. 13, 163–174 (2001).

Seraji, S., Wu, Y., Forbess, M., Limmer, S., Chou, T. & Cao, G. Sol-gel-derived mesoporous silica films with low dielectric constants. Adv. Mater. 12, 1695–1698 (2000).

Scott, D. Thermal rearrangement of branched-chain methylpolysiloxanes. J. Am. Chem. Soc. 68, 356–358 (1946).

Baney, R., Itoh, M., Sakakibara, A. & Suzuki, T. Silsesquioxanes. Chem. Rev. 95, 1409–1430 (1995).

Harrison, P. Silicate cage: precursors to new materials. J. Organomet. Chem. 542, 141–183 (1997).

Strachota, A., Tishchenko, G., Matejka, L. & Bleha, M. Chitosan-oligo (silsesquioxane) blend membranes: preparation, morphology, and diffusion permeability. J. Inorg. Organomet. Polym. 11, 165–182 (2002).

Li, Q., Zhou, Y., Hang, X., Deng, S., Huang, F., Du, L. & Li, Z. Synthesis and characterization of a novel arylacetylene oligomer containing POSS units in main chains. Eur. Polym. J. 44, 2538–2544 (2008).

Crivello, J. & Mallk, R. Synthesis and photoinitiated cationic polymerization of monomers with the silsesquioxane core. J. Polym. Sci. Chem. 35, 407–425 (1997).

Huang, F., Rong, Z., Shen, X., Huang, F., Du, L. & Li, Z. Organic/inorganic hybrid bismaleimide resin with octa(aminophenyl)silsesquioxane. Polym. Eng. Sci. 48, 1022–1028 (2008).

Zhang, C., Babonneau, F., Bouhomme, C., Laine, R., Soles, C., Hristov, H. & Yee, A. Highly porous polyhedral silsesquioxane polymers. synthesis and characterization. J. Am. Chem. Soc. 20, 8380–8391 (1998).

Huang, J., Xiao, Y., Mya, K., Liu, X., He, C., Dai, J. & Siow, Y. Thermomechanical properties of polyimide-epoxy nanocomposites from cubic silsesquioxane epoxides. J. Mater. Chem. 14, 2858–2863 (2004).

Neumann, D., Fisher, M., Tran, L. & Matisons, J. Synthesis and characterization of an isocyanate functionalized polyhedral oligosilsesquioxane and the subsequent formation of an organic-inorganic hybrid polyurethane. J. Am. Chem. Soc. 124, 13998–13999 (2002).

Hessel, C., Henderson, E. & Veinot, J. Hydrogen silsesquioxane: a molecular precursor for nanocrystalline Si-SiO2 composites and freestanding hydride-surface-terminated silicon nanoparticles. Chem. Mater. 18, 6139–6146 (2006).

Chang, T., Chang, T., Liu, P., Tsao, S. & Yeh, F. Investigation of the low dielectric siloxane-based hydrogen silsesquioxane (HSQ) as passivation layer on TFT-LCD. Thin Solid Film 516, 374–377 (2007).

Markovic, E., Ginic-Markovic, M., Clarke, S., Matisons, J., Hussain, M. & Simon, G. Poly(ethylene glycol)-octafunctionalized polyhedral oligomeric silsesquioxane: synthesis and thermal analysis. Macromolecules 40, 2694–2701 (2007).

Penaud, J., Fruleux, F. & Dubois, E. Transformation of hydrogen silsesquioxane properties with RIE plasma treatment for advanced multiple-gate MOSFETs. Appl. Surf. Sci. 253, 395–399 (2006).

Liu, Y. & Zheng, S. Inorganic–organic nanocomposites of polybenzoxazine with octa(propylglycidyl ether) polyhedral oligomeric silsesquioxane. J. Polym. Sci. Chem. 44, 1168–1181 (2006).

Hessel, C., Summers, M., Meldrum, A., Malac, M. & Veinot, J. Direct patterning, conformal coating, and erbium doping of luminescent nc-Si/SiO2 thin films from solution processable hydrogen silsesquioxane. Adv. Mater. 19, 3513–3516 (2007).

Agag, T. & Takeichi, T. Preparation, characterization, and polymerization of maleimido-benzoxazine monomers as a novel class of thermosetting resins. J. Polym. Sci. Polym. Chem. 44, 1424–1435 (2006).

Nair, C., Bindu, R., Krishnan, K. & Ninan, K. Bispropargyl ether resins: synthesis and structure-thermal property correlations. Eur. Polym. J. 35, 235–246 (1999).

Agag, T. & Takeichi, T. Novel benzoxazine monomers containing p-phenyl propargyl ether: polymerization of monomers and properties of polybenzoxazines. Macromolecules 34, 7257–7263 (2001).

Wan, L., Luo, Y., Xue, L. & Huang, F. Preparation and properties of a novel polytriazole resin. J. Appl. Polym. Sci. 104, 1038–1042 (2007).

Tian, J., Wan, L., Huang, J., Hu, Y., Huang, F. & Du, L. Synthesis and characterization of a novel polytriazole resin with low-temperature curing character. Polym. Adv. Technol. 18, 556–561 (2007).

Rong, Z., Huang, F., Shen, X. & Huang, F. preparation and properties of dipropargyl ether of bisphenol A-modified bismaleimide resins and composites. Polym. Composite. 29, 483–488 (2008).

Hang, X., Zhou, Y., Shen, X., Huang, F. & Du, L. Synthesis and properties of polyvinylsiloxane-silsesquioxane. Aerospace Materials and Technology 38, 54–57 (2008).

Tian, J., Wang, X., Wan, L., Hu, Y., Huang, F. & Du, L. Investigation of structure/property relationships of polytriazoles. High Perform. Polym. (in press) (2009).

Liu, F., Li, W., Wei, L. & Zhao, T. Blended resins based on a new propargyl-functional resin: synthesis, cure, and thermal properties. J. Appl. Polym. Sci. 102, 4207–4212 (2006).

Vinayagamoorthi, S., Vijayakumar, C., Alam, S. & Nanjundan, S. Structural aspects of high temperature thermosets-bismaleimide/propargyl terminated resin system-polymerization and degradation studies. Eur. Polym. J. 45, 1217 (2009).

Acknowledgements

We gratefully acknowledge the financial support of the National Basic Research Program of China (Grant no. 513xxx006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, F., Huang, F., Zhou, Y. et al. Preparation and properties of bismaleimide resins modified with hydrogen silsesquioxane and dipropargyl ether and their composites. Polym J 42, 261–267 (2010). https://doi.org/10.1038/pj.2009.335

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2009.335

Keywords

This article is cited by

-

Ano-Scale Mechanical, Viscoelastic, and Tribological Behaviors of Polyaryletherketone Modified Bismaleimide Blends

Mechanics of Composite Materials (2023)

-

Comparative experiments on amine vs. acid anhydride curing agents for epoxy resin required for automotive parts

Journal of Polymer Research (2023)

-

Evaluation of HODE-15, FDE-15, CDE-15, and BDE-15 toxicity on adult and embryonic zebrafish (Danio rerio)

Environmental Science and Pollution Research (2014)

-

Subacute oral toxicity of BDE-15, CDE-15, and HODE-15 in ICR male mice: assessing effects on hepatic oxidative stress and metals status and ascertaining the protective role of vitamin E

Environmental Science and Pollution Research (2014)