Abstract

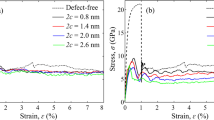

Shape-memory alloys capable of a superelastic stress-induced phase transformation and a high displacement actuation have promise for applications in micro-electromechanical systems for wearable healthcare and flexible electronic technologies. However, some of the fundamental aspects of their nanoscale behaviour remain unclear, including the question of whether the critical stress for the stress-induced martensitic transformation exhibits a size effect similar to that observed in confined plasticity. Here we provide evidence of a strong size effect on the critical stress that induces such a transformation with a threefold increase in the trigger stress in pillars milled on [001] L21 single crystals from a Cu–Al–Ni shape-memory alloy from 2 μm to 260 nm in diameter. A power-law size dependence of n = −2 is observed for the nanoscale superelasticity. Our observation is supported by the atomic lattice shearing and an elastic model for homogeneous martensite nucleation.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Delaey, L. in Materials Science and Technology Vol. 5 (eds Cahn, R. W., Haasen, P. & Kramer, E. J.) 339–404 (VCH, 1991).

Otsuka, K. & Wayman, C. M. (eds) Shape Memory Materials (Cambridge Univ. Press, 1998).

Lagoudas, D. L. (ed.) Shape Memory Alloys (Springer, 2008).

Yamauchi, K., Ohkata, I., Tsuchiya, K. & Miyazaki, S. (eds) Shape Memory and Superelastic Alloys (Woodhead, 2011).

Mañosa, L. et al. Giant solid-state barocaloric effect in the Ni–Mn–In magnetic shape-memory alloy. Nat. Mater. 9, 478–481 (2010).

Tanaka, Y. et al. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 327, 1488–1490 (2010).

Omori, T. et al. Superelastic effect in polycrystalline ferrous alloys. Science 333, 68–71 (2011).

Lai, A., Du, Z., Gan, C. L. & Schuh, C. A. Shape memory and superelastic ceramics at small scales. Science 341, 1505–1508 (2013).

Cui, J. et al. Combinatorial search of thermoelastic shape-memory alloys with extremely small hysteresis width. Nat. Mater. 5, 286–290 (2006).

Zarnetta, R. et al. Identification of quaternary shape memory alloys with near-zero thermal hysteresis and unprecedented functional stability. Adv. Funct. Mater. 20, 1917–1923 (2010).

Van Humbeeck, J. V. Shape memory alloys: a material and a technology. Adv. Eng. Mater. 3, 837–850 (2001).

Kohl, M. Shape Memory Microactuators (Springer, 2004).

Frick, C. P., Orso, S. & Arzt, E. Loss of pseudoelasticity in nickel–titanium sub-micron compression pillars. Acta Mater. 55, 3845–3855 (2007).

San Juan, J., Nó, M. L. & Schuh, C. A. Superelasticity and shape memory in micro- and nanometer-scale pillars. Adv. Mater. 20, 272–278 (2008).

San Juan, J., Nó, M. L. & Schuh, C. A. Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat. Nanotech. 4, 415–419 (2009).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Gall, K., Diao, J. & Dunn, M. L. The strength of gold nanowires. Nano Lett. 4, 2431–2436 (2004).

Greer, J. R., Oliver, W. C. & Nix, W. D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821–1830 (2005).

Greer, J. R. & De Hosson, J. T. M. Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654–724 (2011).

Clark, B. G., Gianola, D. S., Kraft, O. & Frick, C. P. Size independent shape memory behavior of nickel–titanium. Adv. Eng. Mater. 12, 808–815 (2010).

Ozdemir, N., Karaman, I., Mara, N. A., Chumlyakov, Y. I. & Karaca, H. E. Size effects in the superelastic response of Ni54Fe19Ga27 shape memory alloy pillars with a two stage martensitic transformation. Acta Mater. 60, 5670–5685 (2012).

Du, Z. et al. Size effects and shape memory properties in ZrO2 ceramic micro- and nano-pillars. Scripta Mater. 101, 40–43 (2015).

Recarte, V., Pérez-Sáez, R. B., Bocanegra, E. H., Nó, M. L. & San Juan, J. Dependence of the martensitic transformation characteristics on concentration in Cu–Al–Ni shape memory alloys. Mater. Sci. Eng. A 273–275, 380–384 (1999).

Fischer-Cripps, A. C. Nanoindentation (Springer, 2004).

Schuh, C. A. Nanoindentation studies of materials. Mater. Today 9, 32–40 (2006).

San Juan, J., Nó, M. L. & Schuh, C. A. Thermomechanical behavior at the nanoscale and size effects in shape memory alloys. J. Mater. Res. 26, 2461–2469 (2011).

San Juan, J., Nó, M. L. & Schuh, C. A. Superelastic cycling of Cu–Al–Ni shape memory alloy micropillars. Acta Mater. 60, 4093–4106 (2012).

San Juan, J. et al. In-situ nano-compression tests on shape memory alloys. Proc. 18th International Microscopy Conference 3133 (2014).

Ibarra, A., Caillard, D., San Juan, J. & Nó, M. L. Martensite nucleation on dislocations in Cu–Al–Ni shape memory alloys. Appl. Phys. Lett. 90, 101907 (2007).

Nó, M. L., Ibarra, A., Caillard, D. & San Juan, J. Stress-induced phase transformations studied by in-situ transmission electron microscopy. ICSMA-15. J. Phys. Conf. Series 240, 012002_1-8 (2010).

Vitek, V. in Dislocations and Properties of Real Materials (ed. Loretto, M.H.) 30–50 (The Institute of Metals, 1984).

Vaihle, C. & Farkas, D. Shear faults and dislocation core structure simulations in B2 FeAl. Acta Mater. 45, 4463–4473 (1997).

Dou, R. & Derby, B. A universal scaling law for the strength of metal micropillars and nanowires. Scripta Mater. 61, 524–527 (2009).

Horikawa, H., Ichinose, S., Morii, S., Miyazaki, S. & Otsuka, K. Orientation dependence of β1 → β1′ stress-induced martensitic transformation in Cu–Al–Ni alloy. Metall. Trans. A 19, 915–923 (1988).

Nó, M. L., Ibarra, A., Caillard, D. & San Juan, J. Quantitative analysis of stress-induced martensites by in situ transmission electron microscopy superelastic tests in Cu–Al–Ni shape memory alloys. Acta Mater. 58, 6181–6193 (2010).

El-Awady, J. A. et al. Pre-straining effects on the power-law scaling of size-dependent strengthening in Ni single crystals. Scripta Mater. 68, 207–2010 (2013).

Derlet, P. M. & Maaß, R. Universal power-law strengthening in metals? Scripta Mater. 109, 19–22 (2015).

Greer, J. R. & Nix, W. D. Nanoscale gold pillars strengthened through dislocation starvation. Phys. Rev. B 73, 245410 (2006).

Seo, J.-H. et al. Superplastic deformation of defect-free Au nanowires via coherent twin propagation. Nano Lett. 11, 3499–3502 (2011).

Sedlmayr, A. et al. Existence of two twinning-mediated plastic deformation modes in Au nanowhiskers. Acta Mater. 60, 3985–3993 (2012).

Ma, F., Xu, K.-W. & Chu, P. K. Surface-induced structural transformations in nanowires. Mater. Sci. Eng. R 74, 173–209 (2013).

Jennings, A. T. et al. Modeling dislocation nucleation strengths in pristine metallic nanowire under experimental conditions. Acta Mater. 61, 2244–2259 (2013).

Chen, L. Y., He, M., Shin, J., Richter, G. & Gianola, D. S. Measuring surface dislocation nucleation in defect-scarce nanostrutures. Nat. Mater. 14, 707–713 (2015).

Kastner, O. First Principles Modelling of Shape Memory Alloys (Springer, 2012).

Graczykowski, B. et al. Surface acoustic waves and elastic constants of Cu14%Al4%Ni shape memory alloys studied by Brillouin light scattering. J. Phys. D 44, 455307 (2011).

San Juan, J., Gómez-Cortés, J. F., López, G. A., Jiao, C. & Nó, M. L. Long-term superelastic cycling at nano-scale in Cu–Al–Ni shape memory alloy micropillars. Appl. Phys. Lett. 104, 011901 (2014).

Jennings, A. T. & Greer, J. R. Tensile deformation of electroplated copper nanopillars. Philos. Mag. 91, 1108–1120 (2011).

Jennings, A. T., Burek, M. J. & Greer, J. R. Microstructure versus size: mechanical properties of electroplated single crystalline Cu nanopillars. Phys. Rev. Lett. 104, 135503 (2010).

Zhang, H., Chuster, B. E., Wei, Q. & Ramesh, K. T. The design of accurate micro-compression experiments. Scripta Mater. 54, 181–186 (2006).

Novák, V., Šittner, P. & Zárubová, N. Anisotropy of transformation characteristics of Cu-base shape memory alloys. Mater. Sci. Eng. A 234–236, 414–417 (1997).

Acknowledgements

This work was supported by the Spanish Ministry of Economy and Competitiveness (MINECO), projects MAT2009-12492, MAT2012-36421 and CONSOLIDER-INGENIO 2010 CSD2009-00013, as well as by the Consolidated Research Group IT-10-310 and the ETORTEK-ACTIMAT project from the Education and Industry Departments of the Basque Government and Junta de Andalucía (INNANOMAT PAI research group TEP-946). J.F.G.-C. thanks MINECO for a PhD grant. This work made use of the FIB facilities of SGIKER from the UPV/EHU and of IMEYMAT-UCA. Co-funding from FEDER-EU and REACT projects from H-2020, grant 640241, are also acknowledged.

Author information

Authors and Affiliations

Contributions

J.M.S.J. and M.L.N. designed the experiments, developed the model and wrote the initial manuscript with input from all the authors. I.L.-F. and J.M.S.J. produced the alloys. J.F.G.-C., J.H.-S., S.I.M., A.C., M.L.N. and J.M.S.J. performed the milling of the pillars by FIB and took the SEM micrographs. J.F.G.-C. and J.M.S.J. performed the nanocompression tests. All the authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary information

Supplementary Information (PDF 1298 kb)

Supplementary Movie

Supplementary Movie (AVI 4880 kb)

Rights and permissions

About this article

Cite this article

Gómez-Cortés, J., Nó, M., López-Ferreño, I. et al. Size effect and scaling power-law for superelasticity in shape-memory alloys at the nanoscale. Nature Nanotech 12, 790–796 (2017). https://doi.org/10.1038/nnano.2017.91

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nnano.2017.91

This article is cited by

-

Shape-memory effect in twisted ferroic nanocomposites

Nature Communications (2023)

-

Large mechanical properties enhancement in ceramics through vacancy-mediated unit cell disturbance

Nature Communications (2023)

-

A highly distorted ultraelastic chemically complex Elinvar alloy

Nature (2022)

-

Nanocomposite NiTi shape memory alloy with high strength and fatigue resistance

Nature Nanotechnology (2021)

-

Investigation of nonlinear dynamic behavior of micro-beam reinforced with CNT containing SMA micro-wires considering size effect

Journal of the Brazilian Society of Mechanical Sciences and Engineering (2021)