Abstract

Many established, but also potential future applications of NiTi-based shape memory alloys (SMA) in biomedical devices and solid-state refrigeration require long fatigue life with 107–109 duty cycles1,2. However, improving the fatigue resistance of NiTi often compromises other mechanical and functional properties3,4. Existing efforts to improve the fatigue resistance of SMA include composition control for coherent phase boundaries5,6,7 and microstructure control such as precipitation8,9 and grain-size reduction3,4. Here, we extend the strategy to the nanoscale and improve fatigue resistance of NiTi via a hybrid heterogenous nanostructure. We produced a superelastic NiTi nanocomposite with crystalline and amorphous phases via severe plastic deformation and low-temperature annealing. The as-produced nanocomposite possesses a recoverable strain of 4.3% and a yield strength of 2.3 GPa. In cyclic compression experiments, the nanostructured NiTi micropillars endure over 108 reversible-phase-transition cycles under a stress of 1.8 GPa. We attribute the enhanced properties to the mutual strengthening of nanosized amorphous and crystalline phases where the amorphous phase suppresses dislocation slip in the crystalline phase while the crystalline phase hinders shear band propagation in the amorphous phase. The synergy of the properties of crystalline and amorphous phases at the nanoscale could be an effective method to improve fatigue resistance and strength of SMA.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The datasets that support the findings of this study are available in the figshare repository, https://doi.org/10.6084/m9.figshare.13116578. Source data are provided with this paper.

Code availability

The codes for the finite element modelling are available in the figshare repository, https://doi.org/10.6084/m9.figshare.13116578.

References

Wu, Y., Ertekin, E. & Sehitoglu, H. Elastocaloric cooling capacity of shape memory alloys—role of deformation temperatures, mechanical cycling, stress hysteresis and inhomogeneity of transformation. Acta Mater. 135, 158–176 (2017).

Cui, J. et al. Demonstration of high efficiency elastocaloric cooling with large ΔT using NiTi wires. Appl. Phys. Lett. 101, 073904 (2012).

Delville, R., Malard, B., Pilch, J., Sittner, P. & Schryvers, D. Transmission electron microscopy investigation of dislocation slip during superelastic cycling of Ni-Ti wires. Int. J. Plast. 27, 282–297 (2011).

Ahadi, A. & Sun, Q. Stress-induced nanoscale phase transition in superelastic NiTi by in situ X-ray diffraction. Acta Mater. 90, 272–281 (2015).

Chluba, C. et al. Ultralow-fatigue shape memory alloy films. Science 348, 1004–1007 (2015).

Cui, J. et al. Combinatorial search of thermoelastic shape-memory alloys with extremely small hysteresis width. Nat. Mater. 5, 286–290 (2006).

Ni, X., Greer, J. R., Bhattacharya, K., James, R. D. & Chen, X. Exceptional resilience of small-scale Au30Cu25Zn45 under cyclic stress-induced phase transformation. Nano Lett. 16, 7621–7625 (2016).

Gall, K. & Maier, H. J. Cyclic deformation mechanisms in precipitated NiTi shape memory alloys. Acta Mater. 50, 4643–4657 (2002).

Hou, H. et al. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 366, 1116–1121 (2019).

Eggeler, G., Hornbogen, E., Yawny, A., Heckmann, A. & Wagner, M. Structural and functional fatigue of NiTi shape memory alloys. Mater. Sci. Eng. A. 378, 24–33 (2004).

Hua, P., Chu, K., Ren, F. & Sun, Q. Cyclic phase transformation behavior of nanocrystalline NiTi at microscale. Acta Mater. 185, 507–517 (2020).

Paranjape, H. M., Bowers, M. L., Mills, M. J. & Anderson, P. M. Mechanisms for phase transformation induced slip in shape memory alloy micro-crystals. Acta Mater. 132, 444–454 (2017).

Chen, J., Zhang, K., Kan, Q., Yin, H. & Sun, Q. Ultra-high fatigue life of NiTi cylinders for compression-based elastocaloric cooling. Appl. Phys. Lett. 115, 093902 (2019).

Zhang, K., Kang, G. & Sun, Q. High fatigue life and cooling efficiency of NiTi shape memory alloy under cyclic compression. Scr. Mater. 159, 62–67 (2019).

Wang, Y., Li, J., Hamza, A. V. & Barbee, T. W. Ductile crystalline–amorphous nanolaminates. Proc. Natl Acad. Sci. USA 104, 11155–11160 (2007).

Tian, L. et al. Approaching the ideal elastic limit of metallic glasses. Nat. Commun. 3, 609 (2012).

Tsuchiya, K. et al. Production of TiNi amorphous/nanocrystalline wires with high strength and elastic modulus by severe cold drawing. Scr. Mater. 60, 749–752 (2009).

Sergueeva, A. V., Song, C., Valiev, R. Z. & Mukherjee, A. K. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing. Mater. Sci. Eng. A. 339, 159–165 (2003).

Koike, J., Parkin, D. M. & Nastasi, M. Crystal-to-amorphous transformation of NiTi induced by cold rolling. J. Mater. Res. 5, 1414–1418 (1990).

Estrin, Y. & Vinogradov, A. Extreme grain refinement by severe plastic deformation: a wealth of challenging science. Acta Mater. 61, 782–817 (2013).

Waitz, T., Kazykhanov, V. & Karnthaler, H. P. Martensitic phase transformations in nanocrystalline NiTi studied by TEM. Acta Mater. 52, 137–147 (2004).

Yin, H., He, Y., Moumni, Z. & Sun, Q. Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int. J. Fatigue 88, 166–177 (2016).

Chu, K., Yan, K., Ren, F. & Sun, Q. A dual-pillar method for measurement of stress-strain response of material at microscale. Scr. Mater. 172, 138–143 (2019).

Ezaz, T., Wang, J., Sehitoglu, H. & Maier, H. J. Plastic deformation of NiTi shape memory alloys. Acta Mater. 61, 67–78 (2013).

Chen, H. et al. Unprecedented non-hysteretic superelasticity of [001]-oriented NiCoFeGa single crystals. Nat. Mater. 19, 712–718 (2020).

Li, M. P. & Sun, Q. P. Nanoscale phase transition behavior of shape memory alloys—closed form solution of 1D effective modelling. J. Mech. Phys. Solids 110, 21–37 (2018).

Ovid’ko, I. A., Valiev, R. Z. & Zhu, Y. T. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci. 94, 462–540 (2018).

Gunderov, D. et al. Features of the mechanical behavior of ultrafine-grained and nanostructured TiNi alloys. Mater. Today Proc. 4, 4825–4829 (2017).

Gómez-Cortés, J. F. et al. Size effect and scaling power-law for superelasticity in shape-memory alloys at the nanoscale. Nat. Nanotechnol. 12, 790–796 (2017).

Greer, J. R. & De Hosson, J. T. M. Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater. Sci. 56, 654–724 (2011).

Acknowledgements

This work was financially supported by the Hong Kong Research Grants Council (GRF project no. 16208420) and the Science, Technology and Innovation Commission of Shenzhen Municipality (project no. SGDX2019081623360564) and the National Natural Science Foundation of China (project no. 11532010). The neutron diffraction was conducted at BL20 iMATERIA of J-PARC MLF (proposal nos. 2018B0109, 2019A0102 and 2019PM3002). We are grateful for Q. Li’s (Wuhan University) help in processing the neutron diffraction data and H. Lin’s (HKUST) assistance in measuring the elastocaloric property. All data supporting the findings of this study are available within the paper.

Author information

Authors and Affiliations

Contributions

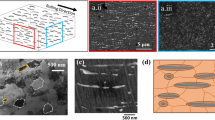

P.H. and Q.S. designed the experiments and wrote the manuscript. Data came from all authors. M.X. did the cold rolling. P.H. did the heat treatment, fabrication and nanocompression of micropillars, SEM, TEM characterization and finite element analysis. Y.O. performed the neutron diffraction at BL20 iMATERIA of J-PARC MLF. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Nanotechnology thanks Jun Cui and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Effects of sample size on the stress-strain responses of the NiTi crystalline-amorphous nanocomposite.

The sizes of the macro-pillar are 1 mm × 1 mm × 2 mm. The quasi-static compression of the two samples was conducted at the strain rate of 5 × 10−3 s−1 at room temperature (298 K).

Extended Data Fig. 2 Temperature oscillation of the NiTi crystalline-amorphous nanocomposite macro-pillars under 20 Hz cyclic compression.

a, Cyclic stress-strain responses. b, Temperature oscillation. The sizes of the macro-pillars are 1 mm × 1 mm × 2 mm. ΔT: Amplitude of temperature oscillation. COP = λΔT/H: coefficient of cooling performance. λ = 3.225 MJ/(m3 · K): heat capacity per unit volume. H: hysteresis loop area, equals to the density of the dissipated work.

Supplementary information

Supplementary Information

Supplementary Figs. 1–13.

Source data

Source Data Fig. 2

Source data for Fig. 2.

Source Data Fig. 3

Source data for Fig. 3. The unprocessed source images are available in figshare (DOI: 10.6084/m9.figshare.13116578).

Source Data Fig. 4

Source data for Fig. 4. The unprocessed source images are available in figshare (DOI: 10.6084/m9.figshare.13116578).

Source Data Extended Data Fig. 1

Source data for Extended Data Fig. 1.

Source Data Extended Data Fig. 2

Source data for Extended Data Fig. 2.

Rights and permissions

About this article

Cite this article

Hua, P., Xia, M., Onuki, Y. et al. Nanocomposite NiTi shape memory alloy with high strength and fatigue resistance. Nat. Nanotechnol. 16, 409–413 (2021). https://doi.org/10.1038/s41565-020-00837-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-020-00837-5

This article is cited by

-

Continuous and efficient elastocaloric air cooling by coil-bending

Nature Communications (2023)

-

Direct-Current-Assisted Healing for Functional Degradation of Nanocrystalline Superelastic NiTi Shape Memory Alloys

Metallurgical and Materials Transactions A (2023)

-

Heterogeneous Structure-Induced Excellent Functional Properties in Shape Memory Alloys: A Review

JOM (2023)

-

Materials, physics and systems for multicaloric cooling

Nature Reviews Materials (2022)

-

A regime beyond the Hall–Petch and inverse-Hall–Petch regimes in ultrafine-grained solids

Communications Physics (2022)