Abstract

Relaxation dynamics are the central topic in glassy physics. Recently, there is an emerging view that mechanical strain plays a similar role as temperature in altering the relaxation dynamics. Here, we report that mechanical strain in a model metallic glass modulates the relaxation dynamics in unexpected ways. We find that a large strain amplitude makes a fragile liquid become stronger, reduces dynamical heterogeneity at the glass transition and broadens the loss spectra asymmetrically, in addition to speeding up the relaxation dynamics. These findings demonstrate the distinctive roles of strain compared with temperature on the relaxation dynamics and indicate that dynamical heterogeneity inherently relates to the fragility of glass-forming materials.

Similar content being viewed by others

Introduction

Glasses and supercooled liquids feature diverse and complex relaxation dynamics1,2,3,4,5,6,7,8. The most prominent relaxation mode is the so-called primary (α-) relaxation, which signals a nonequilibrium transition from a solid-like state to a viscous liquid-like state, characterized solely by the change of dynamics1,2,3,4. Recently, it has been recognized that mechanical stress (or strain) plays a similar role as temperature in the dynamics of the α relaxation in many kinds of glass-forming materials9, including colloidal glasses9,10,11, granular materials12 and metallic glasses (MGs)13,14,15,16. Initially, Liu and Nagel9 introduced the concept of a jamming diagram to unify the roles of stress, temperature and density in colloidal glasses. The pursuits of this view have also led to some scaling laws in different types of glasses to rationalize the roles of temperature, strain/stress and other variables13,17. Quantitatively, such jamming diagrams and scaling laws, however, depend on the intrinsic properties of glass-forming materials such as the interaction potentials9,18, and thus cannot be generalized across different types of glasses.

In the field of MGs, such a view and its equivalent idea that ‘stress/strain-driven glass transitions’ have particular significance as they have been taken as an essential ingredient to understand a number of crucial issues, such as the mechanical properties (strength and ductility)19,20,21, mechanisms of plastic deformation22,23, as well as the origins of shear-banding and serrated flow24,25,26. Despite its importance, we note that there is still no direct characterization of the dynamics of the α relaxation under stress/strain for MGs. Previous results were based on either apparent viscosity or structural perspectives13,14. Partly, the difficulty stems from the fact that conventional mechanical spectroscopy that probes relaxation dynamics of MGs is not applicable to nonlinear deformation regime where large stress and strain are required7,8. Therefore, the basic question whether temperature and stress indeed have similar or different role in relaxation dynamics of MGs is still not clear.

In this work, we address this issue by studying the relaxation spectra of a model MG in the parameter space of temperature, frequency and strain amplitude, via a recently proposed molecular dynamics simulation of dynamical mechanical spectroscopy (MD-DMS)27 together with structural analysis. We find that mechanical strain not only accelerates the relaxation dynamics as previously assumed but also alters it in unexpected ways: a fragile MG gradually becomes a strong one under increasing strain, together with a phenomenon of broadening the peak of α relaxation on the loss spectra only for the low-temperature side (while the high-temperature side remains almost unchanged). Structurally, these processes are accompanied by a suppression of dynamical heterogeneity at the glass transition, demonstrating the key role of dynamical heterogeneity in controlling the fragility of glass-forming materials.

Results

Relaxation spectra

The details of our model system and the protocol of MD-DMS are given in Methods. Briefly, at a temperature T, we apply a sinusoidal strain ɛ(t)=ɛA sin(2πt/tω), with a period tω (related to frequency f=1/tω) and a strain amplitude ɛA, along the x direction of a model Cu65Zr35 MG and the resulting stress σ(t) is measured. To study the strain effects on glassy dynamics, we intentionally vary ɛA from linear (elastic) to nonlinear (plastic) deformation regimes. For simplicity, this work focuses on the first Fourier component of the response stress. High-order effects due to nonlinear response will be discussed in a later work. The storage (E′) and loss (E′′) moduli are calculated as functions of T, tω and ɛA.

Figure 1a shows an example of E′ and E′′ as a function of T for a selected combination of ɛA=1.25% and tω=1,000 ps (or f=1 GHz). They exhibit the typical features of an α relaxation that is consistent with experimental DMS7,8, that is, a sudden drop of E′ as well as an asymmetrical peak of E′′ around Tα=1,000 K (the temperature corresponding to the α relaxation time τα=tω), that signal the transition from a glassy state to a supercooled liquid state. Figure 1b shows E′ and E′′ for a fixed temperature of T=800 K as a function of ɛA. One can see that for ɛA<2%, the values of E′ are high, while E′′ are low, and both are nearly independent of ɛA, indicating that the model MG is in a glassy state and responses linearly to the external mechanical oscillations. However, with further increase in ɛA, E′ decreases rapidly in a sigmoidal manner, while E′′ first increases and then decreases, with a peak around ɛA=5%. These features, phenomenally similar to Fig. 1a, indicate that the model MG enters into a liquid-like state driven by mechanical strain, that is, the α relaxation takes place at T=800 K under ɛA=5%, which is 200 K lower than for the case of ɛA=1.25%, as shown in Fig. 1a.

Figure 2a,b shows the T-dependent curves for E′ and E′′, respectively, for various values of ɛA at tω=1,000 ps. For a better view, Fig. 2c,d recasts the same data in terms of contour plots as two-dimensional (2D) functions of T and ɛA. The values of ɛA range from 0.625 to 10%, covering both elastic and plastic deformation regimes of the model MG. First, Fig. 2a,b shows a pronounced nonlinear effect on the magnitudes of E′ and E′′, which agrees with Fig. 1b. Second, Fig. 2c,d indicates that the α relaxation can be activated either by T or ɛA or a combination of both, and the α relaxation can take place at any temperature depending on ɛA. For instance, although Tα=1,000 K in the linear response regime, it is reduced to a temperature as low as 500 K when ɛA approaches 6.25%. For ɛA≥10%, we even find that the model MG always behaves like in a liquid-like state at any T in our MD-DMS, which means Tα is practically 0 K in that case. Overall, these results provide convincing evidence that strain can accelerate the relaxation dynamics and support the notion of a mechanically driven liquid–glass transition13. Third, we note that Fig. 2b reveals one intriguing feature of nonlinear effects on the first-order mechanical spectra: the E′′ peak of the α relaxation broadens substantially in the left (low T) side, while the right (high T) side of it is almost unchanged. This feature implies that strain in the nonlinear regime alters the relaxation dynamics in a distinctive way compared with temperature: if mechanical strain behaves similarly as enhanced effective temperature, then the spectra of E′′ will just shift to low T side as a whole, keeping the shape almost unchanged, and the left-side broadening of E′′ peak could not be observed. We note that a signature of similar (but much smaller) nonlinear effects is observed in experimental dielectric spectra of organic glasses, which reveal that large amplitudes of electric fields modify only the high-frequency side of the dielectric spectra of the α relaxation during a constant T measurement28,29.

Relaxation dynamics and fragility

Next, we focus on Tα, determined from the peak temperature of E′′ as a direct indicator of relaxation dynamics. Figure 3a,b shows the values of Tα as a function of tω and ɛA, respectively. One can see that Tα decreases from 1,200 to 1,000 K as tω increases from 10 to 1,000 ps for ɛA=1.25% (Fig. 3a, frequency effects), while it decreases from 1,000 K to almost below 50 K in the nonlinear response regime from ɛA=3 to 10% at a fixed tω=1,000 ps (Fig. 3b, strain effects). This suggests that mechanical strain is more effective in modifying the relaxation dynamics than temperature within the capacity of MD simulations, since MD is usually limited by timescale; however, the mechanical strain can be changed readily. Figure 3c summarizes how Tα changes as a 2D function of ɛA and tω. A general trend is that Tα decreases with ɛA for any tω in the nonlinear response regime. However, the magnitude of the decrease in Tα is larger for higher tω. For example, for tω=1,000 ps, Tα decreases from 1,000 K at ɛA<2.5% to 350 K at ɛA=7.5%, while for tω=10 ps Tα decreases only from 1,200 to 1,000 K with the same ɛA.

(a) The primary relaxation temperature Tα as a function of period tω for ɛA=1.25%. (b) Tα as a function of ɛA for tω=1,000 ps. (c) Tα as a 2D function of tω and ɛA. (d) The α relaxation dynamics as a function of 1,000/T for different ɛA as indicated in percentage. (e) The normalized fragility index m as a function of ɛA.

To quantify the effects of strain on relaxation dynamics, Fig. 3d plots the relaxation time as a function of inverse temperature. One can observe that strain modifies the relaxation dynamics in a nontrivial way. Specifically, the effects of stress are more pronounced at low temperatures than at high temperatures. Thus, the relaxation time is strongly reduced at low temperatures but less at high temperatures. In this connection, it would be useful to consider the concept of fragility30,31,32, quantified by m=dlog(τα)/d(Tg/T), that characterizes how rapidly the dynamics of a material slow down as it is cooled towards the glass transition. Liquids with large m are called fragile, while those with small m are considered strong. In our simulations, the glass transition temperature is defined as Tgsim≡Tα (tω=1,000 ps) as shown in Fig. 3d, which for those in the linear response regime agree with the temperature at which the slope of a volume–T curve would change. The resulting m values are shown in Fig. 3e and are normalized to low-strain-limit fragility, approximated by m at ɛA=0.625%. We find that m is nearly independent of ɛA in the linear response regime as expected, while, intriguingly, it shows pronounced dependence on ɛA in the nonlinear response regime and decreases to ∼1/4 of its linear response value when ɛA reaches 7.5%. Such a large reduction of m is nontrivial, as m is known to be insensitive to many external variables and is often considered an intrinsic property of glass-forming materials33. For example, m is only weakly dependent on hydrostatic pressures34. In addition, we note that the reduction of m underpins the broadening of the spectra of E′′ in Fig. 2b, as it is known that materials with a higher fragility have a relatively narrow glass transition temperature range, while the stronger materials (those with lower fragility) have a wide glass transition temperature range32.

Discussion

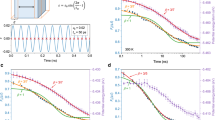

To further study the nonlinear strain effects on the relaxation dynamics and to understand why m is dramatically reduced in the nonlinear regime, we conducted a structural analysis and calculated the mean square atomic jump distance u for each atom during a time interval of Δt=tω for all the combinations of T, tω and ɛA. This choice of Δt is meant to avoid atomic displacements due to the overall deformations applied by the MD-DMS. Figure 4a,b shows the resulting probability density function p(u) for different T (where ɛA=1.25% and tω=1,000 ps remain fixed) and different ɛA (T=800 K, tω=1,000 ps), respectively. The peak position up and the width of p(u) represents the most probable atomic jump distance of all the atoms and the jump distance dispersion, respectively. The latter quantity is associated with dynamical heterogeneity. From Fig. 4a,b, one can see that both mechanical strain and temperature can increase up and broaden the distribution of p(u), which provides structural evidence for the strain-accelerated dynamics as outlined in Figs 1 and 2. Figure 4c plots p(u) at T=Tgsim=Tα (tω=1,000 ps) for different ɛA. Interestingly, we find at Tgsim that mechanical strain can reduce substantially the distribution of p(u), a signature of suppressing the dynamical heterogeneity substantially. Such a behaviour is consistent with some recent simulations and experiments, which reveal that in the presence of mechanical deformation, the dynamics of supercooled liquids are more homogenous, as the deformation reduces the correlation length and the lifetime of dynamical heterogeneity35,36. Figure 4d plots m as a function of W0.1, where W0.1 is defined as the width of p(u) at 1/10 of the maximum as an indicator of dynamical heterogeneity. Remarkably, we observe a strong correlation between m and W0.1, even where the MD-DMS covers both the linear and nonlinear response regimes. Such a correlation clearly suggests that dynamical heterogeneity is a key feature that relates to fragility of glass-forming materials. Figure 4e,f presents two typical slices of 2D vector fields of u at T=Tgsim for ɛA=1.25% and 7.5%, respectively. One can see that the u-field with ɛA=1.25% (Fig. 4e) is more heterogeneous than the one with ɛA=7.5%, corroborating that deformation reduces dynamical heterogeneity in terms of its correlation lengths at the glass transition Tgsim.

(a) Probability density p(u) for different T at tω=1,000 ps and ɛA=1.25%, temperature ranges from 100K to 1,200K for every 100K from left to right. (b) p(u) for different ɛA at T=800 K and tω=1,000 ps, the strain amplitudes are 0.625%, 1.25%, 2.5%, 3.75%, 5.0%, 6.25%, 7.5% and 10% from left to right. (c) p(u) at the simulation glass transition temperature Tgsim=Tα (tω=1,000 ps) for different ɛA of 0.626%, 1.25%, 2.5%, 3.75%, 5.0%, 6.25% and 7.5% from right to left. (d) Relation between normalized fragility m and the width of p(u) at 1/10 maximum W0.1. (e,f) 2D xy slices (20 Å<z≤24 Å) of the vector field of u at Tgsim for ɛA=1.25% and 7.5%, respectively.

The results discussed above not only demonstrate that high strain amplitudes can accelerate dynamics, as does an increase in temperature, but also that the value of τα alone does not specify the entire dynamics of the MG system. In other words, two states with identical α relaxation time (one reached by low T and high ɛA, another reached by high T and low ɛA) will not coincide regarding other aspects of the dynamics, such as fragility and dynamic heterogeneity. Our explanation is as follows: nonlinear response is reached by strain amplitudes for which the mechanical energy involved per period, ∝σAɛA, becomes comparable to or even large than kBT. In a potential energy landscape (PEL) picture37,38, higher temperature assists activation and modifies the population within a given landscape, whereas high values of ɛA are equivalent to tilting the PEL, which affects low and high barriers in different ways.

In summary, we show that mechanical strain not only accelerates the relaxation dynamics of a model MG, but also modifies it in unique ways. In particular, a fragile glass former becomes stronger under mechanical strain, and the peak of the α relaxation broadens asymmetrically. Structurally, dynamical heterogeneity at the glass transition is gradually suppressed with increasing strain amplitude. These findings emphasize the distinctive roles of strain compared with temperature on the relaxation dynamics, and provide microscopic insights to the concept of fragility as well.

Methods

Simulation details and samples

An open source LAMMPS package39 was used for the MD simulations. The model system contains N=32,000 atoms with the composition Cu65Zr35, and the constituting atoms are interacting via an embedded atom method potential40. For the sample preparations, the system was melted and equilibrated at T=3,000 K, and then cooled down to T=100 K with a cooling rate of 1012K s−1, during which the cell sizes were adjusted to give zero pressure within the constant number, pressure and temperature (NPT) ensemble. Periodic boundary conditions were applied for all the calculations.

Simulation of dynamical mechanical spectroscopy

As in the case of experimental DMS, we apply a sinusoidal strain ɛ(t)=ɛA sin(2πt/tω) along the x direction of the model MG, where tω is the period and is selected as 10, 30, 100, 300 and 1,000 ps, while ɛA is selected as 0.625, 1.25, 2.5, 3.75, 5.0, 7.5 and 10% in this work. For each MD-DMS, 10 full cycles were used, that is, t in the range (0, 10tω). We fitted the resulting stress as: σ(t)=σ0+σA sin(2πt/tω+δ) where σ0 is a constant term and usually small (σ0<0.1σA in the glassy state), δ the phase difference between stress and strain. Storage (E′) and loss (E′′) moduli are calculated as E′=σA/ɛA cos(δ) and E′′=σA/ɛA sin(δ), respectively. The MD-DMS was carried out during the cooling processes of the sample preparations, and constant number, volume and temperature (NVT) ensemble was applied during the cyclic deformations. No shear-band formation was observed during the MD-DMS simulations across the entire strain and temperature ranges.

Jump distance probability density functions p(u)

The probability density function p(u) is defined as  , where P(u) is the distribution that quantifies the probability of finding X≤u. Here we employ Δu=0.01 Å for all the calculations. Note that the probability density is normalized according to

, where P(u) is the distribution that quantifies the probability of finding X≤u. Here we employ Δu=0.01 Å for all the calculations. Note that the probability density is normalized according to  .

.

Additional information

How to cite this article: Yu, H.-B. et al. Strain induced fragility transition in metallic glass. Nat. Commun. 6:7179 doi: 10.1038/ncomms8179 (2015).

References

Lunkenheimer, P., Schneider, U., Brand, R. & Loid, A. Glassy dynamics. Contemp. Phys. 41, 15–36 (2000).

Ngai, K. L. Relaxation and Diffusion in Complex Systems Springer (2011).

Berthier, L. & Biroli, G. Theoretical perspective on the glass transition and amorphous materials. Rev. Mod. Phys. 83, 587–645 (2011).

Ediger, M. D. & Harrowell, P. Perspective: supercooled liquids and glasses. J. Chem. Phys. 137, 080901–080915 (2012).

Angell, C. A., Ngai, K. L., McKenna, G. B., McMillan, P. F. & Martin, S. W. Relaxation in glassforming liquids and amorphous solids. J. Appl. Phys. 88, 3113–3157 (2000).

Debenedetti, P. G. & Stillinger, F. H. Supercooled liquids and the glass transition. Nature 410, 259–267 (2001).

Yu, H. B., Wang, W. H. & Samwer, K. The beta relaxation in metallic glasses: an overview. Mater. Today 16, 183–191 (2013).

Yu, H. B., Wang, W. H., Bai, H. Y. & Samwer, K. The beta -relaxation in metallic glasses. Natl Sci. Rev. 1, 429–461 (2014).

Liu, A. J. & Nagel, S. R. Nonlinear dynamics - Jamming is not just cool any more. Nature 396, 21–22 (1998).

Zhang, Z. X. et al. Thermal vestige of the zero-temperature jamming transition. Nature 459, 230–233 (2009).

Agarwal, P. & Archer, L. A. Strain-accelerated dynamics of soft colloidal glasses. Phys. Rev. E 83, 041402 (2011).

Forterre, Y. & Pouliquen, O. Flows of dense granular media. Annu. Rev. Fluid Mech. 40, 1–24 (2008).

Guan, P. F., Chen, M. W. & Egami, T. Stress-temperature scaling for steady-state flow in metallic glasses. Phys. Rev. Lett. 104, 205701 (2010).

Peng, H. L., Li, M. Z. & Wang, W. H. Stress-versus temperature-induced structural evolution in metallic glasses. Appl. Phys. Lett. 102, 131908 (2013).

Zink, M., Samwer, K., Johnson, W. L. & Mayr, S. G. Validity of temperature and time equivalence in metallic glasses during shear deformation. Phys. Rev. B 74, 012201 (2006).

Liu, S. T., Jiao, W., Sun, B. A. & Wang, W. H. A quasi-phase perspective on flow units of glass transition and plastic flow in metallic glasses. J. Non-Cryst. Solids 376, 76–80 (2013).

Olsson, P. & Teitel, S. Critical scaling of shear viscosity at the jamming transition. Phys. Rev. Lett. 99, 178001 (2007).

Trappe, V., Prasad, V., Cipelletti, L., Segre, P. N. & Weitz, D. A. Jamming phase diagram for attractive particles. Nature 411, 772–775 (2001).

Wang, L. et al. Effect of temperature on the yield strength of a binary CuZr metallic glass: stress-induced glass transition. Intermetallics 26, 162–165 (2012).

Yang, B., Liu, C. T. & Nieh, T. G. Unified equation for the strength of bulk metallic glasses. Appl. Phys. Lett. 88, 221911 (2006).

Yu, H. B., Wang, W. H., Bai, H. Y., Wu, Y. & Chen, M. W. Relating activation of shear transformation zones to beta relaxations in metallic glasses. Phys. Rev. B 81, 220201 (2010).

Johnson, W. L. & Samwer, K. A universal criterion for plastic yielding of metallic glasses with a (T/Tg)2/3 temperature dependence. Phys. Rev. Lett. 95, 195501 (2005).

Chen, M. W. Mechanical behavior of metallic glasses: microscopic understanding of strength and ductility. Ann. Rev. Mater. Res. 38, 445–469 (2008).

Klaumünzer, D. et al. Probing shear-band initiation in metallic glasses. Phys. Rev. Lett. 107, 185502 (2011).

Schuh, C. A., Hufnagel, T. C. & Ramamurty, U. Overview No.144 - mechanical behavior of amorphous alloys. Acta Mater. 55, 4067–4109 (2007).

Greer, A. L., Cheng, Y. Q. & Ma, E. Shear bands in metallic glasses. Mater. Sci. Eng. R 74, 71–132 (2013).

Yu, H. B. & Samwer, K. Atomic signiture of internal friction in a model metallic glass. Phys. Rev. B 90, 144201 (2014).

Richert, R. & Weinstein, S. Nonlinear dielectric response and thermodynamic heterogeneity in liquids. Phys. Rev. Lett. 97, 095703 (2006).

Bauer, T., Lunkenheimer, P., Kastner, S. & Loidl, A. Nonlinear dielectric response at the excess wing of glass-forming liquids. Phys. Rev. Lett. 110, 107603 (2013).

Angell, C. A. Formation of glasses from liquids and biopolymers. Science 267, 1924–1935 (1995).

Böhmer, R., Ngai, K. L., Angell, C. A. & Plazek, D. J. Nonexponential relaxations in strong and fragile glass formers. J. Chem. Phys. 99, 4201–4209 (1993).

Ito, K., Moynihan, C. T. & Angell, C. A. Thermodynamic determination of fragility in liquids and a fragile-to-strong liquid transition in water. Nature 398, 492–495 (1999).

Bendert, J. C., Gangopadhyay, A. K., Mauro, N. A. & Kelton, K. F. Volume expansion measurements in metallic liquids and their relation to fragility and glass forming ability: an energy landscape interpretation. Phys. Rev. Lett. 109, 185901 (2012).

Roland, C. M., Hensel-Bielowka, S., Paluch, M. & Casalini, R. Supercooled dynamics of glass-forming liquids and polymers under hydrostatic pressure. Rep. Prog. Phys. 68, 1405 (2005).

Lee, H. N., Paeng, K., Swallen, S. F. & Ediger, M. D. Direct measurement of molecular mobility in actively deformed polymer glasses. Science 323, 231–234 (2009).

Mizuno, H. & Yamamoto, R. Dynamical heterogeneity in a highly supercooled liquid under a sheared situation. J. Chem. Phys. 136, 084505 (2012).

Stillinger, F. H. A topographic view of supercooled liquids and glass-formation. Science 267, 1935–1939 (1995).

Sastry, S., Debenedetti, P. G. & Stillinger, F. H. Signatures of distinct dynamical regimes in the energy landscape of a glass-forming liquid. Nature 393, 554–557 (1998).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Mendelev, M. I. et al. Development of suitable interatomic potentials for simulation of liquid and amorphous Cu–Zr alloys. Philos. Mag. 89, 967–987 (2009).

Acknowledgements

We thank Professor C.A. Angell for discussions regarding the definition of fragility and glass transition, as well as Dr W. Huang for discussing nonlinear dielectric effects. We are gratefully acknowledge the support from the Deutsche Forschungsgemeinschaft (DFG) within the FOR 1394 and computational service from Gesellschaft für wissenschaftliche Datenverarbeitung, Göttingen (GWDG).

Author information

Authors and Affiliations

Contributions

H.-B.Y. conducted simulations and analysed the results. R.R., R.M. and K.S. initiated the research. All the authors wrote the manuscript together.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yu, HB., Richert, R., Maaß, R. et al. Strain induced fragility transition in metallic glass. Nat Commun 6, 7179 (2015). https://doi.org/10.1038/ncomms8179

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms8179

This article is cited by

-

The role of local-geometrical-orders on the growth of dynamic-length-scales in glass-forming liquids

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.