- NEWS AND VIEWS

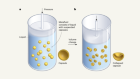

Droplet motion electrically controlled

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Rent or buy this article

Prices vary by article type

from$1.95

to$39.95

Prices may be subject to local taxes which are calculated during checkout

Nature 572, 445-446 (2019)

doi: https://doi.org/10.1038/d41586-019-02451-5

References

Yao, X., Song, Y. & Jiang, L. Adv. Mater. 23, 719–734 (2011).

Cho, S. K., Moon, H. & Kim, C.-J. J. Microelectromech. Syst. 12, 70–80 (2003).

Pollack, M. G., Fair, R. B. & Shenderov, A. D. Appl. Phys. Lett. 77, 1725–1726 (2000).

Berge, B. & Peseux, J. Eur. Phys. J. E 3, 159–163 (2000).

Hayes, R. A. & Feenstra, B. J. Nature 425, 383–385 (2003).

Krupenkin, T. & Taylor, J. A. Nature Commun. 2, 448 (2011).

Mugele, F. & Heikenfeld, J. Electrowetting: Fundamental Principles and Practical Applications (Wiley, 2018).

Li, J., Ha, N. S., Liu, T., van Dam, R. M. & Kim, C.-J. Nature 572, 507–510 (2019).

De Gennes, P. G. Rev. Mod. Phys. 57, 827–863 (1985).

Read the paper: Ionic-surfactant-mediated electro-dewetting for digital microfluidics

Read the paper: Ionic-surfactant-mediated electro-dewetting for digital microfluidics

Water flows out of touch

Water flows out of touch

Droplets leap into action

Droplets leap into action