Abstract

When a spilled drop of coffee dries on a solid surface, it leaves a dense, ring-like deposit along the perimeter (Fig. 1a). The coffee—initially dispersed over the entire drop—becomes concentrated into a tiny fraction of it. Such ring deposits are common wherever drops containing dispersed solids evaporate on a surface, and they influence processes such as printing, washing and coating1,2,3,4,5. Ring deposits also provide a potential means to write or deposit a fine pattern onto a surface. Here we ascribe the characteristic pattern of the deposition to a form of capillary flow in which pinning of the contact line of the drying drop ensures that liquid evaporating from the edge is replenished by liquid from the interior. The resulting outward flow can carry virtually all the dispersed material to the edge. This mechanism predicts a distinctive power-law growth of the ring mass with time—a law independent of the particular substrate, carrier fluid or deposited solids. We have verified this law by microscopic observations of colloidal fluids.

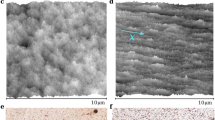

a, A 2-cm-diameter drop of coffee containing 1 wt% solids has dried to form a perimeter ring, accentuated in regions of high curvature. b, Spheres in water during evaporation, as described in the text. Multiple exposures are superimposed to indicate the motion of the microspheres.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

07 April 2021

A Correction to this paper has been published: https://doi.org/10.1038/s41586-021-03444-z

References

Parisse, F. & Allain, C. Shape changes of colloidal suspension droplets during drying. J. Phys. II 6, 1111–1119 (1996).

El Bediwi, A. B., Kulnis, W. J., Luo, Y., Woodland, D. & Unertl, W. N. Distributions of latex particles deposited for water suspensions. Mater. Res. Soc. Symp. Proc. 372, 277–282 (1995).

Denkov, N. D. et al. Mechanism of formation of two-dimensional crystals from latex particles on substrates. Langmuir 8, 3183–3190 (1992).

Laden, P. (ed.) Chemistry and Technology of Water Based Inks(Blackie Academic & Professional, London, (1997)).

TAPPI New Printing Technologies Symposium 1996(TAPPI Press, Atlanta, (1996)).

Hisatake, K., Tanaka, S. & Aizawa, Y. Evaporation of water in a vessel. J. Appl. Phys. 73, 7395–7401 (1993).

Peiss, C. N. Evaporation of small water drops maintained at constant volume. J. Appl. Phys. 65, 5235–5237 (1989).

Maxwell, J. C. Scientific Papers Vol. 2(Cambridge, (1890)).

Jackson, J. D. Classical Electrodynamics2nd edn, 77 (Wiley, New York, (1975)).

Lide, D. R. (ed.) CRC Handbook of Physics and Chemistry77th edn, 6–8, 6–218 (Chemical Rubber Publishing Co., Boca Raton, FL, (1996)).

Crocker, J. C. & Grier, D. G. Methods of digital video microscopy for colloidal studies. J. Colloid Interface Sci. 179, 298–310 (1996).

Acknowledgements

We thank H. Li, X. Shi and M. Baildon for their early contributions to this project; J. Crocker, D. Grier and A. Marcus for sharing their expertise, their image analysis code and their facilities; and S. Garoff, L. Mahadevan, S. Esipov, R. Leheny, D. Mueth, E. Ehrichs, J. Knight, S. Blanton, N. Menon, J. Cina and L. Kadanoff for discussions. This work was supported by the NSF-MRSEC, NSF and DOE.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deegan, R., Bakajin, O., Dupont, T. et al. Capillary flow as the cause of ring stains from dried liquid drops. Nature 389, 827–829 (1997). https://doi.org/10.1038/39827

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/39827

This article is cited by

-

Tuning contact line dynamics on slippery silicone oil grafted surfaces for sessile droplet evaporation

Scientific Reports (2024)

-

High-order asymptotic methods provide accurate, analytic solutions to intractable potential problems

Scientific Reports (2024)

-

Programming crack patterns with light in colloidal plasmonic films

Nature Communications (2024)

-

Optical absorbance profilometry for tracking time-resolved particle redistribution in high volume fraction colloidal droplets

Scientific Reports (2024)

-

Superhydrophobic Surface-Assisted Preparation of Microspheres and Supraparticles and Their Applications

Nano-Micro Letters (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.