Abstract

In the present study, cellulose, one of the most abundant natural polymers, was adopted as a membrane material for optical resolution. The membrane was prepared from cellulose, and it selectively transported l-glutamic acid (l-Glu) from racemic mixtures of Glu with a concentration gradient as the driving force. A molecularly imprinted cellulose membrane, which was constructed from cellulose and l-Glu, showed d-glutamic acid (d-Glu) permselectivity, which is thought to be due to a strong interaction between l-Glu and the molecularly imprinted cellulose membrane. The performance of both membranes was significantly dependent on LiCl, which was used to dissolve cellulose into an N,N-dimethylactamide (DMAc) solvent. The permselectivity increased with the LiCl concentration and asymptotically reached a maximum value at higher LiCl concentrations. The affinity constant of LiCl for the LiCl recognition sites in both membranes was 65 mol−1 dm3.

Similar content being viewed by others

Introduction

Our daily life is heavily dependent on oil. Such a dependence on oil should be reduced so that we can develop a sustainable environment and society. To this end, naturally occurring or ‘green’ polymers, their derivatives, and wastes from food and other industries should be utilized as raw materials for polymeric derivatives. For these reasons, the authors’ research group has developed membranes from various raw materials, such as agarose for pervaporation,1, 2, 3 egg shell membranes for chiral separation,4 gelatin for vapor permeation,5 proteins from Geobacillus thermodenitrificans DSM465 for vapor permeation6 and molecular recognition,7, 8 DNA for gas9 and chiral separations,10, 11 soybean polysaccharides for pervaporation,12 chitosan for chiral separation13 and vapor permeation,14 chicken feathers for optical resolution15 and chitin nanofibers for chiral separation.16, 17

Cellulose is one of the most abundant natural polymers. Cellulose consists of a single constitutional repeating unit, d-glucose, linked through carbons 1 and 4 by β linkages. Cellulose is found widely in nature and is the major constituent of the cell wall of plants. It is one of the most abundant polymeric materials in nature. It shows good stability in water, common solvents, acids and bases. Because of these properties, cellulose is a promising candidate material for separation membranes. Although derivatives of cellulose, such as acetyl cellulose18, 19, 20 and cellulose triacetate,21 have been investigated as membrane materials for chiral separation, cellulose itself has not yet been studied. In the present study, cellulose was adopted as a membrane material for the optical resolution and the chiral separation of racemic mixtures of glutamic acid as a model racemate. Through the present study, cellulose was also revealed to be a promising raw material for the recognition of metal ions, such as lithium ions.

Experimental procedure

Materials

Hardwood-based cellulose was purchased from Nacalai Tesque Inc. (Kyoto, Japan) and used as received. As provided by the supplier, the degree of polymerization of the cellulose sample was ca. 630 and the crystallinity was 85–90%. N,N-Dimethylacetamide (DMAc), LiCl, d-glutamic acid (d-Glu), l-glutamic acid (l-Glu) and NaN3 were obtained from Nacalai Tesque, Inc. and used without further purification. Water purified with an ultrapure water system (Simpli Lab, Millipores S. A., Molsheim, France) was used.

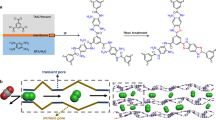

Preparation of membranes

A control cellulose membrane was prepared as follows: DMAc was used as the solvent for the dissolution of cellulose. Following the previously published procedures,22, 23, 24 0.603 g of cellulose (mole number of anhydroglucose unit, 3.72 × 10−3 mol) was suspended in 20.0 cm3 of DMAc at 100 °C for 30 min. Then, 1.60 g of LiCl (3.78 × 10−2 mol) was added, and the solution was stirred at 100 °C. After the cellulose had completely dissolved in the LiCl/DMAc solution, the cellulose solution was stirred for an additional 2 h and then slowly cooled to ambient temperature.

An l-Glu molecularly imprinted cellulose membrane was prepared following the protocol for the preparation of the control cellulose membrane. In all, 0.269 g (1.83 × 10−3 mol) of the print molecule, l-Glu, was simultaneously added when LiCl was added to the cellulose/DMAc suspension. In the present study, the imprinting ratio, which was defined to be the mole ratio of the molar amount of the print molecule to that of cellulose (anhydroglucose unit), (l-Glu)/(cellulose), was fixed at 0.49. The mole ratio of the amount of LiCl to that of cellulose (anhydroglucose unit), (LiCl)/(cellulose), was determined to be 10.2.

The prepared cast solutions were poured into flat laboratory dishes with diameters of 85.3 mm and dried at 70 °C for 7 days. After drying, the membranes were immersed in water to extract LiCl or LiCl and the print molecule (l-Glu) until those could be hardly detected in water by a conductometric analysis for LiCl and liquid chromatography for L-Glu.

The average thickness of the control membrane and the l-Glu molecularly imprinted membrane was ca. 27.5 and 32.1 μm, respectively.

Adsorption of racemic mixture of Glu to the membranes

The membranes were immersed in aqueous solutions of a racemic mixture of Glu at a concentration of 1.0 × 10−4 mol dm−3. The membranes were allowed to equilibrate at 40 °C. Sodium azide (0.02 wt.%) was added as a fungicide. The adsorption study was carried out with and without LiCl (0.10 mol dm−3). In the present study, the amounts of racemic Glu adsorbed in the membranes were too low to be precisely determined by sampling the solution after equilibrium had been reached. Therefore, the amounts of adsorbed Glu were determined as follows: the equilibrated membranes were removed from the immersing solutions, blotted free of residual solution adhering on the surface, and then transferred to aqueous NaN3 solutions to desorb the racemic Glu from the membranes. In the case where the adsorption study was conducted without LiCl, the desorption was done without LiCl and vice versa.

Solution aliquots were collected after equilibrium had been reached and those for desorption were used for quantitative estimations by liquid chromatography (Jasco PU-2080, equipped with a UV detector (Jasco UV-2075, Hachioji, Japan)), using a CHIRALPAK MA(+) column (5.0 × 4.6 mm (i.d.)) and aqueous copper sulfate as the eluent.

The amounts of Glu measured in the desorption solutions determined the amounts of Glu adsorbed in the membranes. The adsorption selectivity SA(L/D) is defined as

where (l-Glu) and (d-Glu) are the amounts of l-Glu and d-Glu adsorbed in the membranes, respectively, and [l-Glu] and [d-Glu] are the concentrations of l-Glu and d-Glu in the solution after equilibrium had been reached.

Chiral separation of racemic mixture of Glu

A 3.0 cm2 membrane was tightly fixed with Parafilm between two chambers of a permeation cell. The volume of each chamber was 40.0 cm3. An aqueous solution of racemic Glu was placed in the left chamber (L side), and deionized water or aqueous LiCl solution (0–0.50 mol dm−3) was placed in the right chamber (R side). The concentration of racemic Glu was fixed at 1.0 × 10−4 mol dm−3. NaN3 (0.02 wt.%) was added to both chambers as a fungicide. All experiments were carried out at 40 °C. The aqueous solutions in both chambers were stirred with a magnetic stirrer. The revolution rate of the magnetic stirrer was maintained as constant as possible, although the rate could not be determined. An aliquot was drawn from the permeate side (R side) at each sampling time. The amounts of the d-Glu and l-Glu transported through the membrane were determined using liquid chromatography as described earlier.

The flux, J (mol cm cm−2 h−1), is defined as

where [i-Glu]R is the concentration of i-Glu (i=D or L) in the right-hand side chamber (permeate side), t is time (h), VR (cm3) is the volume of the right-hand side chamber, δ (cm) is the membrane thickness and A (cm2) represents the membrane area.

The permselectivity for i-Glu, αi/j, is defined as the flux ratio, Ji/Jj, divided by the concentration ratio in the left-hand side chamber (feed side), [i-Glu]L/[j-Glu]L:

Adsorption of LiCl by membranes

The amounts of LiCl adsorbed by the membranes were obtained as follows: the membranes, which had reached equilibrium in aqueous LiCl solutions, were removed from the immersing solutions, blotted free of solution adhering on the surface, and then transferred to aqueous NaN3 solutions to desorb LiCl from the membranes.

Aliquots of the LiCl solutions of adsorption after equilibrium had been reached and those for desorption were sampled for quantitative estimations using an AA-6500 Shimadzu Atomic Absorption Spectrophotometer (Shimadzu, Kyoto, Japan).

Results and Discussion

Adsorption selectivity

The chiral recognition abilities of both membranes were investigated using racemic Glu as a model racemate. In the present study, a large amount of LiCl was used to dissolve cellulose in DMAc in the membrane preparation process. The mole ratio of LiCl to the anhydroglucose unit of cellulose in the cast solution was determined to be 10.2. LiCl was expected to function as a print molecule to form LiCl or Li-recognition sites in both the control and the l-Glu molecularly imprinted membranes. In other words, cellulose was converted into a LiCl recognition material by alternative molecular imprinting.25, 26, 27, 28 To this end, the adsorption of the racemic mixture of Glu was carried out with and without LiCl (0.10 mol dm−3) in a racemic mixture. The adsorption selectivities are summarized in Table 1. The results revealed that there were recognition sites for l-Glu in both the l-Glu molecularly imprinted cellulose membrane and the control membrane. For racemic mixtures of Glu with or without LiCl, the adsorption selectivity for l-Glu in the l-Glu molecularly imprinted membrane was higher than that for the control membrane. This finding led to the conclusion that the presence of l-Glu during the membrane preparation process was important for the adaptation of the membrane to the molecular shape of l-Glu and the alignment of functional groups to facilitate l-Glu interactions with cellulose. In other words, l-Glu was used as a print molecule to construct l-Glu molecular recognition sites.

The fact that the control membrane also showed adsorption selectivity for l-Glu was likely due to the chiral nature of cellulose. Cellulose consists of β(1→4) linked d-Glucose. Presumably, if cellulose that was formed from l-glucose units was adopted as the raw material, then that cellulose would show d-isomer adsorption selectivity.

From Table 1, the amounts of adsorbed d-Glu and l-Glu in the absence of LiCl in the racemic solution were lower than those in the presence of LiCl in the racemic mixture. This observation can be explained as follows: (1) in the construction of the l-Glu molecularly imprinted cellulose membrane, the adduct of l-Glu and LiCl was an effective print molecule (that is, a complex); and (2) the candidate material to be converted into the molecular recognition membrane was a cellulose/LiCl complex (that is, not only cellulose). The selective ability of the l-Glu-constructed molecular recognition site had the highest efficiency under the same conditions as those of other membranes. As a result, the amounts of Glu in the membrane adsorbed from aqueous racemic mixture solutions of Glu and LiCl were higher than those from solutions without LiCl. From the proposed mechanism for the dissolution of cellulose in the DMAc/LiCl solvent system22 and the summarized results in Table 1, the second explanation (2) is believed to be more rational than the first explanation (1).

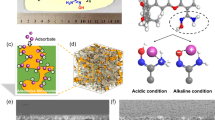

A tentative adsorption scheme of a racemic mixture of Glu and LiCl in membranes with or without LiCl is shown in Figure 1. The presence of LiCl in the solvent patterned its recognition site during the membrane preparation process. As a result, there were LiCl recognition sites in both membranes. When the racemic mixture of Glu (in the absence of LiCl) was contacted with the membrane, Glu, which has dimensions larger than that of LiCl, was not incorporated onto the LiCl recognition site. (The molar volume of LiCl was roughly estimated to be 20.5 cm3 mol−1 from its molecular weight (42.39) and density (2.07 g cm−3 from ref. 29). That of Glu was estimated to be 100.8 cm3 mol−1 from its molecular weight (147.15) and density (1.46 g cm−3 from ref. 30).) However, when racemic mixtures with LiCl were contacted with the membrane, LiCl was adsorbed on the LiCl recognition site.

From the adsorption selectivities of these two types of membranes, as summarized in Table 1, they were also expected to show optical resolution capabilities. The membrane transport phenomena were anticipated to be dependent on the presence of LiCl. To this end, the membrane transport phenomena of the control and the l-Glu molecularly imprinted cellulose membranes were studied with and without LiCl.

Membrane transport

Figure 2 shows the time-transport curves of d-Glu and l-Glu through the control cellulose membrane without LiCl (1) and with 5.0 × 10−2 mol dm−3 LiCl (2) or 3.0 × 10−1 mol dm−3 LiCl (3) on both the L and R sides. The control cellulose membrane preferentially transported l-Glu over the antipode. The permselectivity toward l-Glu increased with an increasing LiCl concentration in the solution. The value increased from 1.11 to 1.38 via 1.27. The results for the l-Glu molecularly imprinted cellulose membrane are shown in Figure 3. The permselectivity was increased from 1.09 to 1.27 via 1.18 with an increasing LiCl concentration in both chambers as observed in the enantioselective transport of the racemic mixture of Glu in Figure 2. Unlike the control cellulose membrane, d-Glu was preferentially transported through the l-Glu molecularly imprinted cellulose membrane. In the membrane transport of the l-Glu imprinted membrane, the observed permselectivity was opposite to that of its adsorption selectivity, which has been reported in the previous optical resolution studies.31, 32, 33, 34 A relatively strong interaction between l-Glu and the membrane retarded the diffusion of l-Glu within the membrane. As a result, the antipode, d-Glu, was selectively transported through the l-Glu imprinted membrane as shown in Figure 3.

The dependence of permselectivity on the LiCl concentration for these two types of membrane is shown in Figure 4. In both profiles, the permselectivity is approximately linearly proportional to the LiCl concentration for low LiCl concentrations. The permselectivity asymptotically increased with the LiCl concentration; at higher LiCl concentrations, the permselectivity was not dependent on the LiCl concentration. These profiles are shown in Figure 4 and reflect the adsorption isotherms of LiCl in the LiCl-specific recognition sites. Using the data presented in Figure 4, the affinity constant between LiCl and the LiCl recognition sites, which were formed during the membrane preparation process, was determined. The ratio of the concentration of LiCl recognition sites that specifically incorporated LiCl to the total concentration of LiCl recognition sites in the membrane is represented by equation (4):

where [Site-LiCl] is the concentration of LiCl recognition sites specifically incorporating LiCl, [Site]0 is the total concentration of LiCl recognition sites in the membrane, Ks is the affinity constant between LiCl and a LiCl recognition site and [LiCl] is the LiCl concentration in aqueous solution, in which the membrane was equilibrated. The ratio, [Site-LiCl]/[Site]0, can also be represented by equation (5):

where αi/j,0, αi/j,LiCl and αi/j,∞ are the permselectivities observed without LiCl, at a given LiCl concentration [LiCl], and at infinite LiCl concentrations, respectively. The relationships obtained using equation (5) for these two types of membrane are shown in Figure 5. The affinity constant for these membranes was determined to be 65 mol−1 dm3. In the present study, the molecular imprinting ratio, that is, the amount of LiCl to that of the repeating unit of cellulose, was determined to be 10.2. The decrease in the imprinting ratio may theoretically lead to an increase in the affinity constant.35 Both the control and the l-Glu imprinted membranes had the same affinity constants because they were prepared from the same LiCl/DMAc solution. As expected, LiCl worked well as a dissolving agent of cellulose and as a print molecule. l-Glu also functioned well as a print molecule to construct l-Glu recognition sites in the l-Glu molecularly imprinted cellulose membrane. In the molecularly imprinted cellulose membranes, there were two types of molecular recognition sites: one for l-Glu (or an l-Glu/LiCl adduct) and the other for LiCl, as schematically shown in Figure 1.

It is interesting to quantitatively measure the adsorption isotherms of LiCl for both the control and l-Glu molecularly imprinted membranes. To this end, the amounts of LiCl adsorbed in the membrane were studied for two conditions: at LiCl concentrations of 5.0 × 10−2 mol dm−3 and at LiCl concentrations of 5.0 × 10−1 mol dm−3. The results for the adsorption of LiCl are summarized in Table 2. The concentrations of LiCl adsorbed in both membranes and the calculated adsorption isotherms of LiCl are shown in Figure 6. An extrapolation of the observed data reveals positive intercepts. Therefore, the adsorption isotherm of LiCl is thought to consist of non-specific adsorptions and adsorption on the LiCl recognition site. In other words, LiCl was incorporated into the membranes by a dual adsorption mechanism. As a result, the adsorption isotherm of LiCl can be represented by equation (6):

where [LiCl]m is the concentration of LiCl in the membrane and kA is the adsorption constant for non-specific adsorption. Taking values of [LiCl]m from Table 2 and a KS value of 65 mol−1 dm3 as determined by Figure 5, the kA and [Site]0 values for both membranes were determined using equation (6). Their values and the KS value are summarized in Table 3. Figure 6 shows the calculated adsorption isotherms for both membranes using the parameters in Table 3.

The results observed in the present study suggest that other commodity polymeric materials, such as nylon 6, nylon 66, have the potential to incorporate LiCl recognition sites because they were prepared in LiCl/DMAc solutions. Investigations in this direction are currently being pursued.

Conclusions

The membranes prepared from cellulose selectively transported l-Glu from a racemic mixture of Glu by using a concentration gradient as the driving force for membrane transport. The molecularly imprinted cellulose membrane that was fabricated from cellulose and l-Glu showed d-Glu permselectivity. This is believed to be due to a relatively strong interaction between l-Glu and the molecularly imprinted cellulose membrane. The membrane performance also depended on the LiCl concentration in the cellulose solvent. The permselectivity increased with increasing LiCl concentration up to a maximum value. The affinity constant of LiCl for the LiCl recognition sites in both membranes was 65 mol−1 dm3.

References

Yoshikawa, M., Yoshioka, T., Fujime, J. & Murakami, A. Pervaporation separation of MeOH/MTBE through agarose membranes. J. Membr. Sci 178, 75–78 (2000).

Masaki, K. & Yoshikawa, M. Pervaporation of aqueous organic mixtures through agarose membranes. Membrane 26, 155–157 (2001).

Yoshikawa, M., Masaki, K. & Ishikawa, M. Pervaporation of aqueous organic mixtures through agarose membranes. J. Membr. Sci 205, 293–300 (2002).

Kondo, Y. & Yoshikawa, M. Egg shell membranes for chiral separation. Membrane 26, 228–230 (2001).

Yoshikawa, M., Higuchi, A,. Ishikawa, M., Guiver, M. D. & Robertson, G. P. Vapor permeation of aqueous 2-propanol solutions through gelatin/Torlon polyamide-imide) blended membranes. J. Membr. Sci 243, 89–95 (2004).

Yoshikawa, M., Kawamura, K., Ejima, A., Aoki, T., Watanabe, K., Guiver, M. D. & Robertson, G. P. Thermostable natural protein polymers from Geobacillus thermodenitrificans DSM465 as membrane materials for vapor permeation. Membrane 29, 384–387 (2004).

Yoshikawa, M., Kawamura, K., Ejima, A., Aoki, T., Sakurai, S. & Hayashi, K. Green polymers from Geobacillus thermodenitrificans DSM465-Candidates for molecularly imprinted materials. Macromol. Biosci. 6, 210–215 (2006).

Yoshikawa, M., Kawamura, K. & Watanabe, K. Evaluation of the recognition ability of molecularly imprinted protein by surface Plasmon resonance (SPR) spectroscopy. Membrane 32, 40–44 (2007).

Matsuura, T., Sada, T., Yoshikawa, M. & Ogata, N. Oxygen permselective membranes from DNA-lipid complexes. Membrane 31, 281–283 (2006).

Yoshikawa, M., Maruhashi, M., Iwamoto, Y. & Ogata, N. Chiral separation of racemic amino acids through DNA-polydiallyldimethylammonium polyion complex membranes. Macromol. Symp. 249-250, 557–561 (2007).

Yoshikawa, M., Maruhashi, M., Iwamoto, Y. & Ogata, N. Optical resolution of amino acids through DNA-poly(vinylbenzyl)trimethyl- ammonium polyion complex membranes. Polym. J. 39, 1193–1198 (2007).

Yoshikawa, M., Nakai, K., Komatsubara, D. & Nakao, A. State of water in soybean polysaccharide membranes and their pervaporation performance. Membrane 33, 118–123 (2008).

Iwamoto, Y., Yoshikawa, M., Yamaoka, K. & Ogata, N. Optical resolution with membranes derived from marine polymers. Desal. Water Treat. 17, 268–274 (2010).

Iwamoto, Y., Shimizu, T., Murai, Y., Yoshikawa, M. & Ogata, N. Vapor permeation of bioethanol with quaterinized chitosan-lipid complex membranes. Membrane 35, 201–204 (2010b).

Sueyoshi, Y., Hashimoto, T., Yoshikawa, M. & Watanabe, K. Transformation of intact chicken feathers into chiral separation membranes. Waste Biomass Valor. 2, 303–307 (2011).

Sueyoshi, Y., Hashimoto, T., Yoshikawa, M. & Ifuku, S. Chitin nanofiber membranes for chiral separation. Sustain. Agr. Res 1, 42–47 (2012).

Shiomi, K. & Yoshikawa, M. Multi-stage chiral separation with electrospin chitin nanofiber membranes. Sep. Purif. Technol. 118, 300–304 (2013).

Izumi, J., Yoshikawa, M. & Kitao, T. Enantioselective permeation of racemic Glutamic acid through alternative molecularly imprinted cellulose acetate membranes. Membrane 22, 149–154 (1997).

Yoshikawa, M., Ooi, T. & Izumi, J. Alternative molecularly imprinted membranes from a derivative of natural polymer, cellulose acetate. J. Appl. Polym. Sci. 72, 493–499 (1999).

Sueyoshi, Y., Fukushima, C. & Yoshikawa, M. Molecularly imprinted nanofiber membranes from cellulose acetate aimed for chiral separation. J. Membr. Sci. 357, 90–97 (2010).

Kawasaki, T. & Yoshikawa, M. Nanofiber membranes from cellulose triacetate for chiral separation. Desal. Water Treat. 51, 5080–5088 (2013).

McCormick, C., Callais, P. A. & Hutchinson, B. H. Jr. Solution studies of cellulose in lithium chloride and N,N-dimethylacetamide. Macromolecules 18, 2394–2401 (1985).

Kim, C.-W., Frey, M. W., Marquez, M. & Joo, Y. L. Preparation of submicron-scale, electrospun cellulose fibers via direct dissolution. J. Polym. Sci. B Polym. Phys. 43, 1673–1683 (2005).

Ma, C., Xu, X.-L., Xie, S.-M., Lv, Y.-C., Shan, H.-Q. & Yuan, L.-M. Chiral separation of D,L-mandelix acid through cellulose membranes. Chirality 23, 379–382 (2011).

Michaels, A.S., Baddour, R. F., Bixler, H. J. & Choo, C. Y. Conditioned polyethylene as a permselective membrane. Ind. Eng. Chem. Process Des. Dev. 1, 14–25 (1962).

Yoshikawa, M. in Molecular and Ionic Recognition with Imprinted polymers (ACS Symposium Series 703) (eds Bartsch R. A., Maeda M.) Ch. 12 170–187 ((ACS, Washington, DC, 1998).

Piletsky, S. A., Panasyuk, T. L., Piletskaya, E. V., Nicholls, I. A. & Ulbricht, M. Receptor and transport properties of imprinted polymer membranes–a review. J. Membr. Sci 157, 263–278 (1999).

Yoshikawa, M. Molecularly imprinted polymeric membranes. Bioseparation 10, 277–286 (2002).

International Critical Tables of Numerical Data, Physics, Chemistry and Technology 43 (McGraw-Hill, New York, NY, USA, 1028

CRC Handbook of Chemistry and Physics 1st Student Edition (ed. Weast R. C.) C-708 ((CRC Press, Inc., Boca Raton, Florida, USA, 1988).

Masawaki, T., Sasano, M. & Tone, S. Optical resolution of an amino acid by an enantioselective ultrafiltreation membrane. J. Chem. Eng. Jpn 25, 33–39 (1992).

Taki, K., Arita, I., Satoh, M. & Komiyama, J. Selective transport of D,L-tryptophan through poly(L-glutamic acid) membranes. J. Polym. Sci. B Polym. Phys 37, 1035–1041 (1999).

Yoshikawa, M. & Izumi, J. Chiral recognition sites converted from tetrapeptide derivatives adopting racemates as print molecules. Macromol. Biosci. 3, 487–498 (2003).

Wang, H.-D., Chu, L.-Y., Song, H., Yang, J.-P., Xie, R. & Yang, M. Preparation and enantiomer separation characteristics of chitosan/β-cyclodextrin cmposite membranes. J. Membr. Sci 297, 262–270 (2007).

Taniwaki, K., Hyakutake, A., Aoki, T., Yoshikawa, M., Guiver, M. D. & Robertson, G. P. Evaluation of the recognition ability of molecularly imprinted materials by surface plasmon resonance (SPR) spectroscopy. Anal. Chim. Acta 489, 191–198 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakai, Y., Yoshikawa, M. Cellulose as a membrane material for optical resolution. Polym J 47, 334–339 (2015). https://doi.org/10.1038/pj.2014.106

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.106

This article is cited by

-

Natural rubber composites with Grits waste from cellulose industry

Journal of Material Cycles and Waste Management (2020)

-

Renewable polymeric materials for electronic applications

Polymer Journal (2017)