Abstract

A network polymer with photoinduced mending abilities was prepared from cinnamoyl-telechelic prepolymer of poly(butylene adipate), PBAC2, and a tetra-cinnamoyl linker, C4, by photodimerization. The photodimerization reaction of the cinnamoyl groups was analyzed using both ultraviolet (UV)/visible (vis) and infrared (IR) spectroscopy. In the reaction, the isomerization of the cinnamate group from the trans to the cis conformation competes with the dimerization reaction of cinnamates. The fractions of dimer and isomer populations estimated from the UV/vis spectra revealed that dimerization was the more preferred reaction at temperatures higher than the melting point of PBAC2. When a film of the network polymer was damaged by tapping, the cinnamate dimers dissociated to form cinnamate monomers due to the reversibility of the dimerization. To recover the network structure, these monomers could be dimerized once again through a photoirradiation process. These results show that cracks in the network polymer can be recovered through photoirradiation.

Similar content being viewed by others

Introduction

Rising prices and the depletion of natural resources such as petroleum, combined with rising environmental concerns, have prompted the development of recyclable and reworkable polymers. Reversible polymers, which can be reverted back to their initial monomers or shorter repolymerizable oligomers by marginal stimuli, are promising for this purpose. Recently, there has been an emerging interest in exploiting the reversibility of such polymers for repairing cracks on the molecular level.1, 2, 3

Polymers degrade with age due to accumulated stress and strain, the results of which manifest themselves in the formation of microcracks. Healing polymers are capable of repairing these microcracks over the serviceable lifespan of the material. Healing properties are useful for extending the working life and enhancing the safety performance of polymeric materials. Some healing mechanisms including the incorporation of healing agents into a matrix4 and the utilization of a reversible reaction have been examined. As an example of the latter, Chen et al.5, 6 synthesized a mendable polymer that was densely cross-linked using a thermally reversible Diels–Alder reaction. Cordier et al.7 reported a self-mendable elastomer networked with hydrogen bond interactions. When microcracks form in these materials, either through thermal or mechanical stress, the chemically weak dynamic bonds are preferentially cleaved. After the stress is relieved, the broken bonds reform, repairing the cracks. Mending systems based on dynamic bonding consist of chemical repair at the molecular level, which restores the original properties of the material. Moreover, these systems can even mend cracks repeatedly in the same position.

A number of publications have reported photoinduced reversible network polymers based on the dimerization of the photoreactive groups, such as benzylidenephthalimidines,8 coumarines,9, 10 anthracene11 and cinnamate.12, 13 Although various applications including photolithography9 and the fabrication of liquid crystals14 have been examined, there are only a few reports on photoinduced mendable materials using photodimerization.15, 16 Chung et al.15 developed a photomendable polymer using cinnamate dimer. A double network polymer was synthesized through the simultaneous processes of photoinduced radical polymerization of methacrylate monomers and photodimerization of the cinnamoyl groups in 1,1,1-tris-(cinnamoyloxymethyl) ethane. Cracks in this polymer were repaired with 280 nm irradiation, which promoted the recovery of the 1,1,1-tris-(cinnamoyloxymethyl) ethane-based network structure. Froimwicz et al.16 presented a photomendable hyper-branched polymer based on anthracene dimers. The surface scratches of this polymer were mended in two steps. First, using irradiation at 254 nm, anthracene dimers were de-cross-linked to liquefy the material around the scratches, and then, using 366 nm irradiation, the cross-links were restored removing the scratches.

In previous works, we have studied the recyclability, soft–hard conversion and mending ability of network polymers synthesized from telechelic prepolymers connected with reversible bonds.17, 18, 19 The main chain of the telechelics determines the basic performance of the polymers, while their functionality is regulated by their reversible groups. Therefore, the functionalities and the basic performance can be designed independently in these network polymers. In this study, we synthesized a photoinduced mendable network polymer from a cinnamoyl-telechelic poly(butylene adipate) (PBAC2) and a tetra-cinnamoyl linker (C4) connected via the photodimerization of the cinnamoyl groups (Figure 1). The photopolymerization and photomending behaviors were analyzed with UV/vis and attenuated total reflection-IR spectroscopies.

Experimental procedure

Materials

Poly(butylene adipate) diol (PBAdiol, MnNMR=1000. Gel permeation chromatography (GPC): MnGPC=1010; Mw/Mn=3.28) was obtained from Aldrich Chemical Co. (St Louis, MO, USA) Pentaerythritol and cinnamoyl chloride were purchased from Tokyo Chemical Industry Co. Ltd (Tokyo, Japan). Chloroform and methanol were purchased from Wako Pure Chemical Industries, Ltd (Osaka, Japan). Ethanol was purchased from Nacalai Tesque, Inc. (Kyoto, Japan). Anhydrous tetrahydrofuran was purchased from Kanto Chemical Co. (Tokyo, Japan). All reagents and solvents were used as received.

Analytical procedures

Ultraviolet (UV)/visible (vis) absorption spectra were collected on a U-3010 Hitachi spectrophotometer (Hitachi High-Tech Co., Tokyo, Japan). GPC measurements were performed on a Tosoh HLC 8220 GPC (Tosoh Co., Tokyo, Japan) system equipped with two TSK-Gel GMHHR-N columns purchased from Tosoh Co. (chloroform, 40 °C, 1 mg ml−1). Polystyrene standards with low polydispersity were used to construct a calibration curve. 1H-NMR (nuclear magnetic resonance) spectra of chloroform-d solutions were measured using a JEOL JNM-ECS400 NMR SYSTEM (JEOL Ltd., Tokyo, Japan) at room temperature. Fast atom bombardment mass spectroscopy measurements were performed using a JEOL JMS-600H. Attenuated total reflection-infrared spectroscopy was measured with a Thermo Scientific Nicolet iS10 equipped with a Smart iTR (Thermo Fisher Scientific Inc., Waltham, MA, USA) accessory and a ZnSe crystal. Differential scanning calorimetry was performed using a Perkin-Elmer Pyris 1 (Perkin-Elmer Inc, Waltham, MA, USA) under a N2 atmosphere. Thermograms were recorded for samples in aluminum pans. The melting point (Tm) and heat of fusion (ΔHf) were taken as the top of the peak and area under the melting endotherm, respectively, for a heating rate of 10 °C min−1 after crystallization at 20 °C for 4 min. Heat flow during isothermal crystallization was also observed at 28 °C. All samples were thermally treated by initially heating them to 60 °C followed by quenching to their crystallization temperature.

Synthesis of PBAC2

PBAdiol (2.81 g) and cinnamoyl chloride (7.07 g, 15 e.q.) were dissolved in dehydrated tetrahydrofuran (40 ml) under a N2 purge and then stirred under reflux for 3 days. After cooling to room temperature, the product was precipitated using excess ethanol at 0 °C and then dried under vacuum. Cinnamoyl-terminated PBA was obtained after dissolution in chloroform, followed with precipitation using methanol at 0 °C and subsequent drying under vacuum. The yield was 1.074 g. 1H-NMR (400 MHz, chloroform-d): δ7.71 (d, 2 H), 7.55−7.38 (m, 10 H), 6.46 (d, 2 H), 4.09−4.24 (m, 55 H), 2.33 (m, 51 H), 1.64–1.79 (m, overlapped with H2O peak), MnNMR=2900, from the relative areas of the cinnamate peak at 6.46 p.p.m. and the PBA peak at 2.33 p.p.m. GPC: MnGPC=4500; Mw/Mn=1.27.

Synthesis of C4

A mixture of pentaerythritol (0.163 g, 1.2 mmol) and cinnamoyl chloride (1.00 g, 6 mmol) was maintained at 120 °C for 3 h. After cooling, the crude product was dissolved in hot ethanol and then recrystallized from the solution. After filtration, a product was obtained with a 49% yield (1.92 g). 1H-NMR (400 MHz, chloroform-d): δ7.71 (d, 1 H), 7.49 (m, 2 H), 7.35 (m, 3 H), 6.46 (d, 1 H), 4.47 (s, 2 H); fast atom bombardment mass spectroscopy: 657.4 (MH), C41H36O8, calculated 656.24. Differential scanning calorimetry: Tm=126 °C.

Photopolymerization of PBAC2 and C4

Thin films of PBAC2 and C4 with a 1:1 molar ratio were prepared on quartz plates by spin-coating from a dilute chloroform solution at 2000 r.p.m. These films were photoirradiated with a wavelength band of 300–400 nm using a 100 W xenon lamp (LAX-Cute, Asahi spectra Co. Ltd, Tokyo, Japan) with a UVA mirror module.

Mendability test

Spin-coated film (thickness≈0.01 mm) of 1:1 molar PBAC2:C4 on quartz was polymerized with 300–400 nm photoirradiation for 10 min at 60 °C. The film was then covered with a thin glass plate (Matsunami Glass Ind., Ltd, Osaka, Japan, micro cover glass no. 1) and repeatedly tapped gently. Light with a 300–400 nm wavelength was irradiated onto the tapped samples for 10 min at 60 °C. After each step, UV/vis absorption spectrums were collected.

Results and discussion

Photoreaction of PBAC2 with C4

A PBAC2 polymer with a degree of polymerization of 13 was prepared by the esterification of PBAdiol with cinnamoyl chloride. In the 1H-NMR spectra of PBAC2, no peaks ascribed to the chain ends of the PBAdiol were observed, indicating the successive synthesis of PBAC2.

The photoreactivity of the cinnamoyl groups on PBAC2 and C4 in their bulk states were monitored by UV/vis absorption spectroscopy. Figure 2a shows the temporal evolution of the UV/vis absorption spectra for the 1:1 molar mixture of PBAC2 and C4 during photoirradiation (λ=300–400 nm) at 60 °C. The absorption at 280 nm coming from the cinnamoyl group reduceed with irradiation time, indicating that the dimerization of the cinnamoyl groups was promoted by photoirradiation.

Attenuated total reflection-infrared spectroscopy also showed the formation of the cinnamoyl dimers (Figure 3). In the spectra of the 1:1 mixture before photoirradiation, the C=C and C=O stretching bands of the cinnamoyl group appeared at 1636 cm−1 and 1716 cm−1 (as a shoulder), respectively.20 After irradiation with 300–400 nm light for 10 min, these characteristic peaks had disappeared, indicating consumption of the cinnamoyl groups.

It is well known that cinnamate takes on the trans-conformation under ambient conditions. After irradiation with UV light, both the dimerization via (2+2) cycloaddition and isomerization cause the cinnamate to take on the cis-form (Figure 1). Although the dimer has no absorption peaks between 250 and 350 nm, both the trans- and cis-monomers have absorption peaks at ≈280 nm. If the trans–cis isomerization solely proceeds, an isosbestic point appears at 250 nm.21 The disappearance of the isosbestic point in the spectra clearly showed that dimerization competes with isomerization in the sample during photoirradiation (Figure 2a).

The UV/vis absorption spectra can be analyzed quantitatively based on the following equations:22

where subscripts T, C and D denote the trans-cinnamate, cis-cinnamate and dimer, respectively; f is the mole fraction; ɛ is the molar extinction coefficients at 271 nm and Dtiso and Dtmax are, respectively, the optical densities at 250 nm (isobestic point of isomerization) and 271 nm at time t. Using these equations and the extinction coefficient data from Rennert et al.,23 the progress of the dimerization and isomerization in the 1:1 molar PBAC2:C4 mixture at 60 °C was estimated as shown in Figure 4. Initially, the isomerization to the cis-form proceeded quickly, followed by the gradual progress of the dimerization reaction. The photoreaction reached a stationary state after 14 min. At this point, the dimer had became the primary product.

The photopolymerization reactions of pure PBAC2 at room temperature were also analyzed. The irradiation time required to reach a photostationary state as well as the fractional populations of the dimer and two isomeric monomers in that state are summarized in Table 1. The cinnamate dimer was the main component of the photoreactions at 60 °C (entry 2, 4), while more trans- and cis-monomers remained in the stationary state at room temperature (entry 1, 3). This temperature dependence can be explained by the difference in the molecular mobilities of the compounds. The melting point of PBAC2 is 44 °C. At temperatures below this melting point, the mobilities of the cinnamoyl groups are restricted, promoting the progress of isomerization. More trans-monomers exist in the 1:1 molar PBAC2:C4 mixture (entry 3) than in PBAC2 (entry 1). Because four cinnamoyl groups are packed into C4, the cis-isomers may be less sterically stable at room temperature. In the molten state (60 °C), higher molecular mobility assists in the dimerization. At each temperature, the 1:1 mixture reached the stationary state faster than pure PBAC2. The stationary state of the 1:1 PBAC2:C4 contained more dimer than that of pure PBAC2. These results can be explained by the difference in the concentration of the cinnamoyl groups, which is calculated from the molecular weight of PBAC2 (MnNMR=2900) and C4 (molecular weight=656). Only 1 mol of the cinnamoyl groups are contained in 1500 g of pure PBAC2, whereas 600 g of the polymer mixture contains 1 mol of the cinnamoyl groups. This higher concentration resulted in more encounters between the two monomers, thus promoting dimerization.

The formation of network structure in the photopolymerized samples was examined using solubility testing. When the photoreacted film of pure PBAC2 was immersed in chloroform, the sample was completely washed away. Only the linear polymer of PBA was synthesized by this photopolymerization. In contrast, the photoreacted film of the 1:1 molar PBAC2:C4 polymer mixture experienced little solvation in chloroform. After immersion of this film in chloroform, the intensity of the UV/vis absorption did not change compared with the absorption before immersion (Figure 2b). An insoluble network structure was formed by the dimerization of the cinnamoyl groups in this mixture. The photodimerization in the mixture polymer linked the PBAC2 and C4 together, forming the network structure. Cinnamoyl dimers, however, must also be formed between C4 linkers and between PBAC2 prepolymers.

Isothermal crystallization of pure PBAC2 before and after photoirradiation as well as isothermal crystallization of the polymer mixture after photoirradiation was observed at 28 °C after quenching from the molten state (Figure 5a). The crystallization of PBAC2 both before and after photoirradiation was complete within 30 s, while that of the 1:1 PBAC2:C4 mixture after photoirradiation took 3 min. This slow crystallization indicates that photodimerization occurs between the cinnamoyl groups of PBAC2 and C4 to form network structures. These cross-links make the crystallization of PBA slower.

(a) Differential scanning calorimetry (DSC) curves during isothermal crystallization at 28 °C of pure PBAC2 before (broken line) and after (dotted line) photopolymerization and a 1:1 molar mixture of PBAC2/C4 after photopolymerization (solid line). (b) DSC curves of the photopolymerized 1:1 molar PBAC2:C4 mixture with a heating rate of 10 °C min−1.

Figure 5b shows the differential scanning calorimetry heating curves of photopolymerized 1:1 PBAC2:C4 crystallized from melting at 20 °C for 4 min. The curve has three endothermic peaks. The heating scans with various heating rates showed that the highest temperature peak can be ascribed to the melt–recrystallization during the heating scan. The middle temperature peak at 43 °C corresponds to the melting point of PBA (Tm≈48 °C). Photodimerization between the PBAC2 yielded long linear chains, which formed crystals similar to pure PBA. The lowest temperature peak (36 °C) can be ascribed to the melting of PBA near the cross-links made by the photoreaction of PBAC2 and C4.

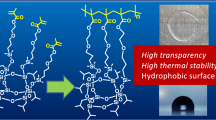

Mendability of photopolymerized 1:1 PBAC2:C4

The mending ability of the polymer mixture was analyzed with the comparison of the UV/vis spectra of the samples as-cast, as-polymerized, as-damaged and as-mended by photoirradiation. The spectra are shown in Figures 6 and 7 show a schematic representation of the mending mechanism for PBAC2:C4 network polymer mixtures. In the UV/vis absorption spectrum of a thin film of 1:1 PBAC2:C4 (I), the characteristic peak of cinnamate was observed at 280 nm. When the film was photoirradiated with 300–400 nm light for 10 min at 60 °C, the cinnamate absorbance was significantly decreased (II), indicating the progress of the photodimerization reaction. This photodimerized polymer film was then covered with a glass plate and damaged by tapping it with a finger many times. The cinnamate absorbance at 280 nm slightly increased again (III), indicating the partial cleavage of cyclobutane structure in the dimer converting to the original cinnamate structure. Because of its large ring strain, the cyclobutane structure is fragile enough to be broken by applying mechanical stress. After re-photoirradiation to the damaged film, the absorbance at 280 nm reverted back to the original intensity before tapping (IV), indicating that the cinnamate groups in the damaged films were dimerized to once again form cyclobutane rings. These results demonstrate the photoreversible mending property of the PBAC2:C4 system.

The progress of dimerization during the mending process was calculated based on equations 1, 2, 3. The fractional populations of the dimer and two isomeric monomers at each stage are summarized in Table 2. After the initial photoirradiation, the amount of the trans-monomer reduced to 3%, and the amounts of the dimer and the cis-monomer grew to 77% and 20%, respectively (II). The mechanical damage inflicted on the sample resulted in the cleavage of the cyclobutane rings used to generate cis-cinnamate (III). In all, 10% of the dimer was monomerized back to the cis-forms. By re-irradiating the sample, the dimerization proceeded again (IV). The amount of dimer recovered to 74%. This shows that the cyclobutane rings broken by mechanical stress can be repaired by photoirradiation in the PBAC2:C4 system. The recovery of the broken covalent bonds by photoirradiation can repress macrocrack formation. In addition, during this damaging and mending process, dimers located away from the damaged sections remain intact. This robust structure allows for maintenance of the sample shape.

Conclusions

A telechelic prepolymer having cinnamate end groups, PBAC2, and pentaerythritol tetracinnamate, C4, were synthesized and cross-linked by the photodimerization of the cinnamoyl groups to obtain a network polymer. The progression of the cross-linking reaction was analyzed using UV/vis and infrared spectroscopy. Although the trans–cis isomerization of the cinnamoyl groups competes with dimerization, more dimerization was found to occur at temperatures higher than the melting point of PBAC2. The mending behavior of the network polymer was also analyzed by UV/vis spectroscopy. When the cross-linked polymer was damaged, the cinnamate dimers along the crack surfaces dissociated into cinnamate monomers. Photoirradiation of the damaged sample led to the re-dimerization of the cinnamate monomers and the mending of the network polymer along the crack surfaces. The mending process results in the complete recovery of the chemical structure of the polymer. Although the prepolymers used in this study were telechelics of PBA, various photomendable polymers can be obtained by simply replacing the main chain of the telechelics.

References

van der Zwaag, V. (ed) Self Healing Materials: An Alternative Approach to 20 Centuries of Materials Science 1–385 (Springer, Netherlands, 2007).

Mauldin, T. C. & Kessler, M. R. Self-healing polymers and composites. Int. Mater. Rev. 55, 317–346 (2010).

Wu, D. Y., Meure, S. & Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 33, 479–522 (2008).

White, S. R., Sottos, N. R., Geubelle, P. H., Moore, J. S., Kessler, M. R., Sriram, S. R., Brown, E. N. & Viswanathan, S. Autonomic healing of polymer composites. Nature 409, 794–797 (2001).

Chen, X. X., Dam, M. A., Ono, K., Mal, A., Shen, H. B., Nutt, S. R., Sheran, K. & Wudl, F. A thermally re-mendable cross-linked polymeric material. Science 295, 1698–1702 (2002).

Chen, X. X., Wudl, F., Mal, A. K., Shen, H. B. & Nutt, S. R. New thermally remendable highly cross-linked polymeric materials. Macromolecules 36, 1802–1807 (2003).

Cordier, P., Tournilhac, F., Soulie-Ziakovic, C. & Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 451, 977–980 (2008).

Suh, D. H., Hayashi, Y. & Ichimura, K. Polymethacrylates with benzylidenephthalimidine side chains, 1. Photochemical characteristics of model compounds and polymers. Macromol. Chem. Phys. 199, 363–373 (1998).

Obi, M., Morino, S. & Ichimura, K. The reversion of photoalignment direction of a liquid crystal induced by a polymethacrylate with coumarin side chains. Macromol. Rapid Commun 19, 643–646 (1998).

Jackson, P. O. & O’Neil, M. An investigation of the role of cross-linking and photodegradation of side-Chain coumarin polymers in the photoalignment of liquid crystals. Chem. Mater. 13, 694–703 (2001).

Li, T., Chen, J., Mitsuishi, M. & Miyashita, T. Photolithographic properties of ultrathin polymer Langmuir–Blodgett films containing anthracene moieties. J. Mater. Chem. 13, 1565–1569 (2003).

Kihara, H. & Tamaoki, N. In situ photochemical conversion from cinnamoyl–functionalized liquid–crystalline monomers to liquid–crystalline dimers. Liquid Crystals 34, 1337–1347 (2007).

Furumi, S. & Ichimura, K. Surface-assisted photoalignment of discotic liquid crystals by nonpolarized light irradiation of photo-cross-linkable polymer thin films. J. Phys. Chem. B 111, 1277–1287 (2007).

Kawatsuki, N., Goto, K., Kawakami, T. & Yamamoto, T. Reversion of alignment direction in the thermally enhanced photoorientation of photo-cross-linkable polymer liquid crystal films. Macromolecules 35, 706–713 (2002).

Chung, C. M., Roh, Y. S., Cho, S. Y. & Kim, J. G. Crack healing in polymeric materials via photochemical [2+2] cycloaddition. Chem. Mater. 16, 3982–3983 (2004).

Froimowicz, P., Frey, H. & Landfester, K. Towards the generation of self-healing materials by means of a reversible photo-induced approach. Macromol. Rapid Commun. 32, 468–473 (2011).

Watanabe, M. & Yoshie, N. Synthesis and properties of readily recyclable polymers from bisfuranic terminated poly(ethylene adipate) and multi-maleimide linkers. Polymer 47, 4946–4952 (2006).

Ishida, K. & Yoshie, N. Two-way conversion between hard and soft properties of semicrystalline cross-linked polymer. Macromolecules 41, 4753–4757 (2008).

Yoshie, N., Watanabe, M., Araki, H. & Ishida, K. Thermo-responsive mending of polymers crosslinked by thermally reversible covalent bond: Polymers from bisfuranic terminated poly(ethylene adipate) and tris-maleimide. Polym. Degrad. Stab. 95, 826–829 (2010).

Ali, A. H. & Srinivasan, K. S. V. Photoresponsive functionalized vinyl cinnamate polymers: synthesis and characterization. Polym. Int. 43, 310–316 (1997).

Nakayama, Y. & Matsuda, T. Photocycloaddition-induced preparation of nanostructured, cyclic polymers using biscinnamated or biscoumarinated oligo(ethylene glycol)s. J. Polym Sci.: Part A: Polym. Chem. 43, 3324–3336 (2005).

Egerton, L., Pitts, E. & Reiser, A. Photocycloaddition in solid poly(vinyl cinnamate). The photoreactive polymer matrix as an ensemble of chromophore sites. Macromolecules 14, 95–100 (1981).

Rennert, J., Soloway, S., Waltcher, I. & Leong, B. Competing reactions of electronically excited 1,3-trimethylene dicinnamate. J. Am. Chem. Soc. 94, 7242–7244 (1972).

Acknowledgements

This work was supported in part by the Global COE Program for Chemistry Innovation through Cooperation of Science and Engineering from the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oya, N., Sukarsaatmadja, P., Ishida, K. et al. Photoinduced mendable network polymer from poly(butylene adipate) end-functionalized with cinnamoyl groups. Polym J 44, 724–729 (2012). https://doi.org/10.1038/pj.2012.18

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.18