Abstract

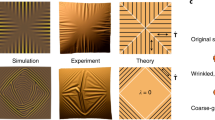

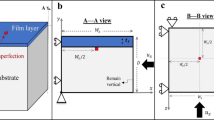

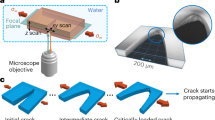

Conforming materials to rigid substrates with Gaussian curvature—positive for spheres and negative for saddles—has proven a versatile tool to guide the self-assembly of defects such as scars, pleats1,2,3,4,5, folds, blisters6,7, and liquid crystal ripples8. Here, we show how curvature can likewise be used to control material failure and guide the paths of cracks. In our experiments, and unlike in previous studies on cracked plates and shells9,10,11, we constrained flat elastic sheets to adopt fixed curvature profiles. This constraint provides a geometric tool for controlling fracture behaviour: curvature can stimulate or suppress the growth of cracks and steer or arrest their propagation. A simple analytical model captures crack behaviour at the onset of propagation, while a two-dimensional phase-field model with an added curvature term successfully captures the crack’s path. Because the curvature-induced stresses are independent of material parameters for isotropic, brittle media, our results apply across scales12,13.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Irvine, W. T. M., Vitelli, V. & Chaikin, P. M. Pleats in crystals on curved surfaces. Nature 468, 947–951 (2010).

Bausch, A. R. et al. Grain boundary scars and spherical crystallography. Science 299, 1716–1718 (2003).

Bowick, M. J. & Giomi, L. Two-dimensional matter: order, curvature and defects. Adv. Phys. 58, 449–563 (2009).

Vitelli, V., Lucks, J. B. & Nelson, D. R. Crystallography on curved surfaces. Proc. Natl Acad. Sci. USA 103, 12323–12328 (2006).

Grason, G. M. & Davidovitch, B. Universal collapse of stress and wrinkle-to-scar transition in spherically confined crystalline sheets. Proc. Natl Acad. Sci. USA 110, 12893–12898 (2013).

Holmes, D. P. & Crosby, A. J. Draping films: a wrinkle to fold transition. Phys. Rev. Lett. 105, 038303 (2010).

Hure, J., Roman, B. & Bico, J. Wrapping an adhesive sphere with an elastic sheet. Phys. Rev. Lett. 106, 174301 (2011).

DeVries, G. A. et al. Divalent metal nanoparticles. Science 315, 358–361 (2007).

Slepyan, L. I. Models and Phenomena in Fracture Mechanics 359–388 (Springer, 2002).

Folias, E. S. The stresses in a cracked spherical shell. J. Math. Phys. 44, 164–176 (1965).

Amiri, F., Millán, D., Shen, Y., Rabczuk, T. & Arroyo, M. Phase-field modeling of fracture in linear thin shells. Theor. Appl. Fract. Mech. 69, 102–109 (2014).

Rupich, S. M., Castro, F. C., Irvine, W. T. M. & Talapin, D. V. Soft epitaxy of nanocrystal superlattices. Nat. Commun. 5, 5045 (2014).

Dusseault, M. B., Maury, V., Sanfilippo, F. & Santarelli, F. J. Drilling Around Salt: Risks, Stresses, And Uncertainties (American Rock Mechanics Association, 2004).

Griffith, A. A. The phenomena of rupture and flow in solids. Phil. Trans. R. Soc. Lond. A 221, 163–198 (1921).

Rivlin, R. S. & Thomas, A. G. Rupture of rubber. I characteristic energy for tearing. J. Polym. Sci. 10, 291–318 (1953).

Freund, L. B. Dynamic Fracture Mechanics (Cambridge Univ. Press, 1990).

Hui, C.-Y., Zehnder, A. T. & Potdar., Y. K. Williams meets von Kármán: mode coupling and nonlinearity in the fracture of thin plates. Int. J. Fract. 93, 409–429 (1998).

Vitelli, V. & Turner, A. M. Anomalous coupling between topological defects and curvature. Phys. Rev. Lett. 93, 215301 (2004).

Cotterell, B. & Rice, J. R. Slightly curved or kinked cracks. Int. J. Fract. 16, 155–169 (1980).

Karma, A., Kessler, D. A. & Levine, H. Phase-field model of mode III dynamic fracture. Phys. Rev. Lett. 87, 045501 (2001).

Spatschek, R., Brener, E. & Karma, A. Phase field modeling of crack propagation. Philos. Mag. 91, 75–95 (2011).

Nelson, D. & Peliti, L. Fluctuations in membranes with crystalline and hexatic order. J. Phys. 48, 1085–1092 (1987).

Ghelichi, R. & Kamrin, K. Modeling growth paths of interacting crack pairs in elastic media. Soft Matter 11, 7995–8012 (2015).

Cheeseman, B. A. & Santare, M. H. The interaction of a curved crack with a circular elastic inclusion. Int. J. Fract. 103, 259–277 (2000).

Yuk, J. M. et al. High-resolution EM of colloidal nanocrystal growth using graphene liquid cells. Science 336, 61–64 (2012).

Price, N. J. & Cosgrove, J. W. Analysis of Geological Structures (Cambridge Univ. Press, 1990).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Yuse, A. & Sano, M. Transition between crack patterns in quenched glass plates. Nature 362, 329–331 (1993).

Sharon, E. & Efrati, E. The mechanics of non-Euclidean plates. Soft Matter 6, 5693–5704 (2010).

Acknowledgements

The authors thank E. Efrati, H. Kedia, D. Kleckner, M. Driscoll, S. Nagel, T. Witten and R. Scott for interesting discussions and J. Mazor for assistance with some supplementary experiments. Some simulations were carried out on the Midway Cluster provided by the University of Chicago Research Computing Center. We acknowledge the Materials Research and Engineering Centers (MRSEC) Shared Facilities at The University of Chicago for the use of their instruments. This work was supported by the National Science Foundation MRSEC Program at The University of Chicago (Grant DMR-1420709) and a Packard Fellowship. V.K. and V.V. acknowledge funding from FOM and NWO.

Author information

Authors and Affiliations

Contributions

W.T.M.I. and V.V. initiated this study. N.P.M. and W.T.M.I. designed experiments. N.P.M. performed and analysed the experiments and simulations. N.P.M. and V.K. constructed the analytical model. All authors interpreted the data. N.P.M., V.V. and W.T.M.I. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 4244 kb)

Supplementary Information

Supplementary Movie 1 (MOV 601 kb)

Supplementary Information

Supplementary Movie 2 (MOV 526 kb)

Supplementary Information

Supplementary Movie 3 (MOV 619 kb)

Supplementary Information

Supplementary Movie 4 (MOV 317 kb)

Supplementary Information

Supplementary Movie 5 (MOV 231 kb)

Supplementary Information

Supplementary Movie 6 (MOV 987 kb)

Supplementary Information

Supplementary Movie 7 (MOV 619 kb)

Supplementary Information

Supplementary Movie 8 (MOV 308 kb)

Rights and permissions

About this article

Cite this article

Mitchell, N., Koning, V., Vitelli, V. et al. Fracture in sheets draped on curved surfaces. Nature Mater 16, 89–93 (2017). https://doi.org/10.1038/nmat4733

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nmat4733

This article is cited by

-

2D materials-wrapped microparticles

Nature Materials (2018)

-

Autoperforation of 2D materials for generating two-terminal memristive Janus particles

Nature Materials (2018)

-

Cracks by design

Nature Materials (2017)

-

3D Printing Bioinspired Ceramic Composites

Scientific Reports (2017)