Abstract

Anabolic metabolism can produce an array of small molecules, but yields and productivities are low owing to carbon and energy inefficiencies and slow kinetics1,2. Catabolic and fermentative pathways, on the other hand, are carbon and energy efficient but support only a limited product range3,4. We used carbon- and energy-efficient non-decarboxylative Claisen condensation reactions and subsequent β-reduction reactions, which can accept a variety of functionalized primers and functionalized extender units and operate in an iterative manner, to synthesize functionalized small molecules. Using different ω- and ω-1-functionalized primers and α-functionalized extender units in combination with various termination pathways, we demonstrate the synthesis of 18 products from 10 classes, including ω-phenylalkanoic, α,ω-dicarboxylic, ω-hydroxy, ω-1-oxo, ω-1-methyl, 2-methyl, 2-methyl-2-enolic and 2,3-dihydroxy acids, β-hydroxy-ω-lactones, and ω-1-methyl alcohols.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$209.00 per year

only $17.42 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Haslam, E. Secondary metabolism—fact and fiction. Nat. Prod. Rep. 3, 217–249 (1986).

Wenzel, S.C. & Müller, R. Formation of novel secondary metabolites by bacterial multimodular assembly lines: deviations from textbook biosynthetic logic. Curr. Opin. Chem. Biol. 9, 447–458 (2005).

Sawers, R.G. & Clark, D.P. Fermentative pyruvate and acetyl-coenzyme A metabolism. Ecosal Plus 1, http://dx.doi.org/10.1128/ecosalplus.3.5.3 (2004).

Jones, D.T. & Woods, D.R. Acetone-butanol fermentation revisited. Microbiol. Rev. 50, 484–524 (1986).

Sun, X. et al. Synthesis of chemicals by metabolic engineering of microbes. Chem. Soc. Rev. 44, 3760–3785 (2015).

Dellomonaco, C., Clomburg, J.M., Miller, E.N. & Gonzalez, R. Engineered reversal of the β-oxidation cycle for the synthesis of fuels and chemicals. Nature 476, 355–359 (2011).

Olivera, E.R. et al. Two different pathways are involved in the β-oxidation of n-alkanoic and n-phenylalkanoic acids in Pseudomonas putida U: genetic studies and biotechnological applications. Mol. Microbiol. 39, 863–874 (2001).

Vick, J.E. et al. Escherichia coli enoyl-acyl carrier protein reductase (FabI) supports efficient operation of a functional reversal of β-oxidation cycle. Appl. Environ. Microbiol. 81, 1406–1416 (2015).

Teufel, R. et al. Bacterial phenylalanine and phenylacetate catabolic pathway revealed. Proc. Natl. Acad. Sci. USA 107, 14390–14395 (2010).

Söhling, B. & Gottschalk, G. Molecular analysis of the anaerobic succinate degradation pathway in Clostridium kluyveri. J. Bacteriol. 178, 871–880 (1996).

Tucci, S. & Martin, W. A novel prokaryotic trans-2-enoyl-CoA reductase from the spirochete Treponema denticola. FEBS Lett. 581, 1561–1566 (2007).

Toth, J., Ismaiel, A.A. & Chen, J.-S. The ald gene, encoding a coenzyme A-acylating aldehyde dehydrogenase, distinguishes Clostridium beijerinckii and two other solvent-producing clostridia from Clostridium acetobutylicum. Appl. Environ. Microbiol. 65, 4973–4980 (1999).

Taguchi, S. et al. A microbial factory for lactate-based polyesters using a lactate-polymerizing enzyme. Proc. Natl. Acad. Sci. USA 105, 17323–17327 (2008).

Slater, S. et al. Multiple β-ketothiolases mediate poly(β-hydroxyalkanoate) copolymer synthesis in Ralstonia eutropha. J. Bacteriol. 180, 1979–1987 (1998).

Hoffmeister, M., Piotrowski, M., Nowitzki, U. & Martin, W. Mitochondrial trans-2-enoyl-CoA reductase of wax ester fermentation from Euglena gracilis defines a new family of enzymes involved in lipid synthesis. J. Biol. Chem. 280, 4329–4338 (2005).

Clomburg, J.M., Vick, J.E., Blankschien, M.D., Rodríguez-Moyá, M. & Gonzalez, R. A synthetic biology approach to engineer a functional reversal of the β-oxidation cycle. ACS Synth. Biol. 1, 541–554 (2012).

Lenneman, E.M., Ohlert, J.M., Palani, N.P. & Barney, B.M. Fatty alcohols for wax esters in Marinobacter aquaeolei VT8: two optional routes in the wax biosynthesis pathway. Appl. Environ. Microbiol. 79, 7055–7062 (2013).

Westin, M.A.K., Hunt, M.C. & Alexson, S.E.H. The identification of a succinyl-CoA thioesterase suggests a novel pathway for succinate production in peroxisomes. J. Biol. Chem. 280, 38125–38132 (2005).

Parke, D., Garcia, M.A. & Ornston, L.N. Cloning and genetic characterization of dca genes required for beta-oxidation of straight-chain dicarboxylic acids in Acinetobacter sp. strain ADP1. Appl. Environ. Microbiol. 67, 4817–4827 (2001).

Parales, R.E. & Harwood, C.S. Characterization of the genes encoding beta-ketoadipate: succinyl-coenzyme A transferase in Pseudomonas putida. J. Bacteriol. 174, 4657–4666 (1992).

Choi, S., Song, C.W., Shin, J.H. & Lee, S.Y. Biorefineries for the production of top building block chemicals and their derivatives. Metab. Eng. 28, 223–239 (2015).

Yu, G. et al. Enzymatic functions of wild tomato methylketone synthases 1 and 2. Plant Physiol. 154, 67–77 (2010).

Petersen, D.J. & Bennett, G.N. Purification of acetoacetate decarboxylase from Clostridium acetobutylicum ATCC 824 and cloning of the acetoacetate decarboxylase gene in Escherichia coli. Appl. Environ. Microbiol. 56, 3491–3498 (1990).

Polen, T., Spelberg, M. & Bott, M. Toward biotechnological production of adipic acid and precursors from biorenewables. J. Biotechnol. 167, 75–84 (2013).

Jullesson, D., David, F., Pfleger, B. & Nielsen, J. Impact of synthetic biology and metabolic engineering on industrial production of fine chemicals. Biotechnol. Adv. 33, 1395–1402 (2015).

Kandasamy, V. et al. Engineering Escherichia coli with acrylate pathway genes for propionic acid synthesis and its impact on mixed-acid fermentation. Appl. Microbiol. Biotechnol. 97, 1191–1200 (2013).

Koma, D., Yamanaka, H., Moriyoshi, K., Ohmoto, T. & Sakai, K. Production of aromatic compounds by metabolically engineered Escherichia coli with an expanded shikimate pathway. Appl. Environ. Microbiol. 78, 6203–6216 (2012).

Koivistoinen, O.M. et al. Glycolic acid production in the engineered yeasts Saccharomyces cerevisiae and Kluyveromyces lactis. Microb. Cell Fact. 12, 82 (2013).

Rodriguez, G.M., Tashiro, Y. & Atsumi, S. Expanding ester biosynthesis in Escherichia coli. Nat. Chem. Biol. 10, 259–265 (2014).

Park, S.J. et al. Metabolic engineering of Escherichia coli for the production of 5-aminovalerate and glutarate as C5 platform chemicals. Metab. Eng. 16, 42–47 (2013).

Kang, Y. et al. Systematic mutagenesis of the Escherichia coli genome. J. Bacteriol. 186, 4921–4930 (2004).

Shams Yazdani, S. & Gonzalez, R. Engineering Escherichia coli for the efficient conversion of glycerol to ethanol and co-products. Metab. Eng. 10, 340–351 (2008).

Baba, T. et al. Construction of Escherichia coli K-12 in-frame, single-gene knockout mutants: the Keio collection. Mol. Syst. Biol. 2, 0008 (2006).

Neidhardt, F.C., Bloch, P.L. & Smith, D.F. Culture medium for enterobacteria. J. Bacteriol. 119, 736–747 (1974).

Clomburg, J.M. et al. Integrated engineering of β-oxidation reversal and ω-oxidation pathways for the synthesis of medium chain ω-functionalized carboxylic acids. Metab. Eng. 28, 202–212 (2015).

Kim, S., Clomburg, J.M. & Gonzalez, R. Synthesis of medium-chain length (C6-C10) fuels and chemicals via β-oxidation reversal in Escherichia coli. J. Ind. Microbiol. Biotechnol. 42, 465–475 (2015).

Acknowledgements

We thank J.E. Vick, M.D. Blankschien and S. Kim for assistance with constructs; G.N. Bennett (Rice University) for gDNA of Clostridium beijerinckii; and P.G. Bodager, B. Wilson, and S.P.T. Matsuda for assistance with GC–MS techniques. This work was supported by grants from the US National Science Foundation (EEC-0813570, CBET-1134541, and CBET-1067565).

Author information

Authors and Affiliations

Contributions

R.G. conceived the work. S.C. and J.M.C. designed the experiments. S.C. constructed the plasmids and strains. S.C. and J.M.C. performed the strain characterization and analysis. S.C., J.M.C. and R.G. drafted the manuscript. All authors read, edited and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Integrated supplementary information

Supplementary Figure 1 Combinatorial synthesis of functionalized small molecules through the proposed orthogonal, iterative carbon-chain elongation platform using functionalized primers and extender units in combination with various termination pathways.

Potential products are shown for 20 different combinations of ω or ω-1-functionalities from primers (R1) and α-functionalities from extender units (R2), listed in the first column, with varying β-functionalities from intermediate nodes with varying degrees of β-reductions (β-ketoacyl-CoA, β-hydroxyacyl-CoA, enoyl-CoA and acyl-CoA). In the structures of intermediate nodes and products, functional groups from primers (R1) are displayed in red and functional groups from extender units (R2) are displayed in blue. Products shown are produced through either acid-forming termination reactions (catalyzed by ACT) or alcohol-forming termination reactions (catalyzed by ACR+ADH). n represents the number of iterations/cycles of the platform, which determines the length of CoA-thioester intermediates and products. Check marks indicate the combinations of primers and extender units evaluated in this study.

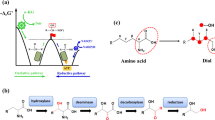

Supplementary Figure 2 Comparison of primers, extender units, pathway intermediates, enzymes, and products of (a) orthogonal iterative platform proposed and demonstrated in this study and (b) engineered reversal of β-oxidation1.

The ability of thiolases and β-reduction enzymes to function in an iterative fashion with functionalized substrates had not been demonstrated to date. The generation of these functionalized intermediates dictates the operation of the proposed platform with non-physiological intermediates that are not part of the host anabolic network and enables this orthogonal, iterative platform to facilitate the combinatorial synthesis of functionally diverse small molecules previously inaccessible by other pathways based on non-decarboxylative Claisen condensations, such as the β-oxidation reversal. Products shown are those demonstrated from the acyl-CoA node in each case, with product synthesis from additional pathway nodes also valid (See text and Figure 1b for details of all products produced in this study). In the structures of intermediate nodes, functional groups from primers are displayed in red and functional groups from extender units are displayed in blue. n represents the chain length of products.

Supplementary Figure 3 Decarboxylative and non-decarboxylative Claisen condensation reactions in biological systems.

Claisen condensations mediate the formation of carbon-carbon bonds (represented as a green, thick bond) between the α carbon of the extender unit and the carbonyl carbon of the primer. (a) The β-carboxyl group of the extender unit malonyl-CoA/ACP is released as CO2 during decarboxylative Claisen condensation with acetyl-CoA/ACP priming. Generation of malonyl-CoA/ACP requires the ATP-dependent carboxylation of acetyl-CoA. (b) Non-decarboxylative Claisen condensation directly utilizes acetyl-CoA for carbon elongation, thus circumventing ATP consumption.

Supplementary Figure 4 Products synthesized through the use of glycolyl-CoA as ω-hydroxylated primer (a, c) or α-hydroxylated extender unit (b).

(a) Total ion GC-MS chromatogram showing peak of synthesized 4-hydroxybutyric acid. (b) Enlarged region of inset in (a) showing 2,3-dihydroxybutyric acid peak. 4-hydroxybutyric acid was produced through the platform utilizing glycolyl-CoA as the primer and acetyl-CoA as the extender unit, while 2,3-dihydroxybutyric acid was produced through the platform with same enzymatic components but utilizing acetyl-CoA as the primer and glycolyl-CoA as the extender unit with termination at β-hydroxyacyl-CoA node. The following enzymes provided the individual components of the pathway: BktB (thiolase) and PhaB1 (HACDH) from Ralstonia eutropha2,3, Aeromonas caviae PhaJ (ECH)4, Treponema denticola TdTer (ECR)5 with native enzymes catalyzing the acid-forming termination and Megasphaera elsdenii transferase Pct activating glycolic acid to glycolyl-CoA. MG1655 (DE3) ΔglcD served as the host strain. (c) Production of β-hydroxy-γ-butyrolactone through the engineered platform with enzymes Pct, BktB and PhaB1 utilizing the primer glycolyl-CoA and the extender unit acetyl-CoA with termination at β-hydroxyacyl-CoA node. β-hydroxy-γ-butyrolactone is the lactone of 3,4-dihydroxybutyric acid and is generated through spontaneous or endogenous enzyme-catalyzed lactonization of 3,4-dihydroxybutyric acid or β-hydroxy intermediate 3,4-dihydroxybutyryl-CoA. glcD encodes a subunit of glycolate oxidase, an enzyme involved in the degradation of glycolic acid. Functional groups from primer and extender unit are marked in red and blue, respectively. Strains were grown as described in supplementary methods.

Supplementary Figure 5 Time course of adipic acid production, glycerol consumption, acetate production and cell growth for a fermentation conducted in a controlled bioreactor.

Strain MB263(DE3) ΔsucD overexpressing the engineered platform composed of PaaJ (thiolase), PaaH (HACDH), PaaF (ECH), TdTer (ECR), Acot8 (ACT) and Cat1 (activation enzyme) grown with glycerol as the sole carbon source (i.e. no succinic acid supplementation) with fermentation conditions as described in the Methods section. This profile corresponds to one of three independent (i.e. biological replicates) bioreactor fermentations.

Supplementary information

Supplementary Text and Figures

Supplementary Figures 1–5 and Supplementary Tables 1–5 (PDF 2662 kb)

Rights and permissions

About this article

Cite this article

Cheong, S., Clomburg, J. & Gonzalez, R. Energy- and carbon-efficient synthesis of functionalized small molecules in bacteria using non-decarboxylative Claisen condensation reactions. Nat Biotechnol 34, 556–561 (2016). https://doi.org/10.1038/nbt.3505

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nbt.3505

This article is cited by

-

Biosensor-based high-throughput screening enabled efficient adipic acid production

Applied Microbiology and Biotechnology (2023)

-

A facile process for adipic acid production in high yield by oxidation of 1,6-hexanediol using the resting cells of Gluconobacter oxydans

Microbial Cell Factories (2022)

-

Cell-free prototyping enables implementation of optimized reverse β-oxidation pathways in heterotrophic and autotrophic bacteria

Nature Communications (2022)

-

Exploring functionality of the reverse β-oxidation pathway in Corynebacterium glutamicum for production of adipic acid

Microbial Cell Factories (2021)

-

Microbial production of multiple short-chain primary amines via retrobiosynthesis

Nature Communications (2021)