Abstract

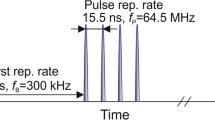

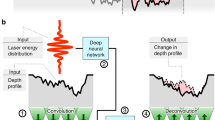

The use of femtosecond laser pulses allows precise and thermal-damage-free removal of material (ablation) with wide-ranging scientific1,2,3,4,5, medical6,7,8,9,10,11 and industrial applications12. However, its potential is limited by the low speeds at which material can be removed1,9,10,11,13 and the complexity of the associated laser technology. The complexity of the laser design arises from the need to overcome the high pulse energy threshold for efficient ablation. However, the use of more powerful lasers to increase the ablation rate results in unwanted effects such as shielding, saturation and collateral damage from heat accumulation at higher laser powers6,13,14. Here we circumvent this limitation by exploiting ablation cooling, in analogy to a technique routinely used in aerospace engineering15,16. We apply ultrafast successions (bursts) of laser pulses to ablate the target material before the residual heat deposited by previous pulses diffuses away from the processing region. Proof-of-principle experiments on various substrates demonstrate that extremely high repetition rates, which make ablation cooling possible, reduce the laser pulse energies needed for ablation and increase the efficiency of the removal process by an order of magnitude over previously used laser parameters17,18. We also demonstrate the removal of brain tissue at two cubic millimetres per minute and dentine at three cubic millimetres per minute without any thermal damage to the bulk9,11.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

29 September 2016

The x-axis numbering in Fig. 2c and 2d was corrected.

References

Gattass, R. R. & Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photon. 2, 219–225 (2008)

Yang, W., Kazansky, P. G. & Svirko, Y. P. Non-reciprocal ultrafast laser writing. Nat. Photon. 2, 99–104 (2008)

Steinmeyer, J. D. et al. Construction of a femtosecond laser microsurgery system. Nat. Protocols 5, 395–407 (2010)

Plech, A., Kotaidis, V., Lorenc, M. & Boneberg, J. Femtosecond laser near-field ablation from gold nanoparticles. Nat. Phys. 2, 44–47 (2006)

Rousse, A. et al. Non-thermal melting in semiconductors measured at femtosecond resolution. Nature 410, 65–68 (2001)

Chung, S. H. & Mazur, E. Surgical applications of femtosecond lasers. J. Biophoton. 2, 557–572 (2009)

Yanik, M. F. et al. Neurosurgery: functional regeneration after laser axotomy. Nature 432, 822 (2004)

Juhasz, T. et al. Corneal refractive surgery with femtosecond lasers. IEEE J. Sel. Top. Quant. Electron. 5, 902–910 (1999)

Serbin, J., Bauer, T., Fallnich, C., Kasenbacher, A. & Arnold, W. H. Femtosecond lasers as novel tool in dental surgery. Appl. Surf. Sci. 197–198, 737–740 (2002)

Hoy, C. L. et al. Clinical ultrafast laser surgery: recent advances and future directions. IEEE J. Sel. Top. Quant. Electron. 20, 242–255 (2014)

Loesel, F. H. et al. Non-thermal ablation of neural tissue with femtosecond laser pulses. Appl. Phys. B 66, 121–128 (1998)

Chichkov, B. N., Momma, C., Nolte, S., Alvensleben, F. & Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 63, 109–115 (1996)

Bauer, F., Michalowski, A., Kiedrowski, T. & Nolte, S. Heat accumulation in ultra-short pulsed scanning laser ablation of metals. Opt. Express 23, 1035–1039 (2015)

Vogel, A., Noack, J., Hüttman, G. & Paltauf, G. Mechanisms of femtosecond laser nanosurgery of cells and tissues. Appl. Phys. B 81, 1015–1047 (2005)

Sutton, G. P. & Biblarz, O. Rocket Propulsion Elements Ch. 14 (Wiley, 2011)

Cho, Y. I., Hartnett, J. P. & Rohsenow, W. M. Handbook of Heat Transfer 6.21 (McGraw-Hill, 1998)

Hashida, M. et al. Ablation threshold dependence on pulse duration for copper. Appl. Surf. Sci. 197–198, 862–867 (2002)

Ancona, A. et al. High speed laser drilling of metals using a high repetition rate, high average power ultrafast fiber CPA system. Opt. Express 16, 8958–8968 (2008)

Kalaycioglu, H., Eken, K. & Ilday, F. O. Fiber amplification of pulse bursts up to 20 μJ pulse energy at 1 kHz repetition rate. Opt. Lett. 36, 3383–3385 (2011)

Kalaycıoğlu, H. et al. 1 mJ pulse bursts from a Yb-doped fiber amplifier. Opt. Lett. 37, 2586–2588 (2012)

Kalaycıoğlu, H., Akcaalan, O., Yavas, S., Eldeniz, Y. B. & Ilday, F. Ö. Burst-mode Yb-doped fiber amplifier system optimized for low-repetition-rate operation. J. Opt. Soc. Am. B 32, 900–906 (2015)

Lapczyna, M., Chen, K. P., Herman, P. R., Tan, H. W. & Marjoribanks, R. S. Ultra high repetition rate (133 MHz) laser ablation of aluminum with 1.2-ps pulses. Appl. Phys. A 69, S883–S886 (1999)

Hu, W., Shin, Y. C. & King, G. Modeling of multi-burst mode pico-second laser ablation for improved material removal rate. Appl. Phys. A 98, 407–415 (2010)

Marjoribanks, R. S. et al. Ablation and thermal effects in treatment of hard and soft materials and biotissues using ultrafast-laser pulse-train bursts. Photon. Lasers Med. 1, 155–169 (2012)

Tsai, P. S. et al. All-optical histology using ultrashort laser pulses. Neuron 39, 27–41 (2003)

Meshulach, D. & Silberberg, Y. Coherent quantum control of two-photon transitions by a femtosecond laser pulse. Nature 396, 239–242 (1998)

Schwoerer, H. et al. Laser-plasma acceleration of quasi-monoenergetic protons from microstructured targets. Nature 439, 445–448 (2006)

Acknowledgements

This work was supported partially by the European Research Council (ERC) Consolidator Grant ERC-617521 NLL, the European Union (EU) FP7 CROSS TRAP and TÜBITAK under projects 112T980, 112T944 and TEYDEB-3110216. C.K. acknowledges funding from TÜBITAK - BIDEB 2211. We thank Y. Aykaç and V. Aykaç for dental experiments, T. Dalkara, M. Yemişçi Özkan, K. Kılıç for brain tissue experiments, G. Aykut for animal care and brain slicing, I. Mirza, K. Yavuz, G. Makey and M. Karatok for data acquisition and analyses, S. Karahan for histology analyses, A. Büyüksungur and BIOMATEN (METU, Ankara, Turkey) for micro-CT analyses, H. Köymen for PZT characterisation and S. Ilday, O. Tokel, H. Çelik, O. Algın and E. Atalar for critical reading of the manuscript.

Author information

Authors and Affiliations

Contributions

C.K., H.K. and F.Ö.I. designed the research and interpreted the results. H.K., P.E., S.Y., Ö.A., and C.K. developed the laser systems. H.H. and R.H. developed a high-repetition-rate fibre oscillator. C.K., D.K.K. and B.Ö. performed the laser processing experiments. B.Ç. and C.K. developed the numerical models. M.D.A. carried out brain slicing and histological examinations.

Corresponding author

Ethics declarations

Competing interests

F.Ö.I., C.K. and H.K. declare competing financial interests due to a pending patent application regarding the technique outlined in this Letter.

Additional information

Reviewer Information Nature thanks K. Mitra and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Supplementary information

Supplementary Information

This file contains Supplementary Text and Data, Supplementary Figures 1-47, Supplementary Tables 1-5, Supplementary Video legends and additional references (see Contents for more details). (PDF 16783 kb)

Animated version of the schematic description of ablation cooling in Figure 1

The colouration is based on a mapping of temperature profiles as determined from simulations for the case of 800-MHz pulses (ablation cooling regime) and 10-MHz pulses (outside of the ablation cooling regime). The time and depth coordinates are normalized to characteristic values, as defined in the section below on numerical simulations. While the simulations are 1D, we have taken the liberty of assuming that the profile stays the same in drawing cross-sectional temperature profiles for simplicity. This approximation will not, however, change the main features of the result and the movie is intended to be an illustration, and not an accurate representation of the simulation results. (MP4 288 kb)

Shot during material processing experiments using 100-MHz intra-burst repetition rate pulses and 25-kHz uniform repetition rate results on a steel target with the same power.

The major difference in the sound and plasma brightness is indicative of and consistent with roughly order of magnitude increases in ablation rates in the ablation-cooling regime. (MP4 6552 kb)

3D representation of the laser-processed brain tissue

This video shows a 3D representation of the laser-processed brain tissue obtained through micro-CT imaging. (MP4 9292 kb)

Dentine processing experiment

This video shows the dentine processing experiment using the traditional regime with same power and duration as in Supplementary Video 5. The results of this experiment are shown in Figure 3c. (MP4 693 kb)

Dentine processing experiment

This video shows the dentine processing experiment using the ablation-cooled regime with same power and duration as in Supplementary Video 4. The results of this experiment are shown in Figure 3d. (MP4 505 kb)

Source data

Rights and permissions

About this article

Cite this article

Kerse, C., Kalaycıoğlu, H., Elahi, P. et al. Ablation-cooled material removal with ultrafast bursts of pulses. Nature 537, 84–88 (2016). https://doi.org/10.1038/nature18619

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature18619

This article is cited by

-

Bi-stability in femtosecond laser ablation by MHz bursts

Scientific Reports (2024)

-

Self-evolving photonic crystals for ultrafast photonics

Nature Communications (2023)

-

Kerr Effect as a Mode Locker in Er-Doped Fiber Laser

Journal of Russian Laser Research (2023)

-

Analogy of harmonic modelocked pulses to trapped Brownian particles improves laser performance

Applied Physics B (2023)

-

Perspective on ultrashort pulse laser micromachining

Applied Physics A (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.