Abstract

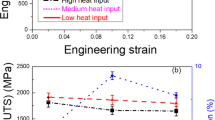

Magnesium is a light metal, with a density two-thirds that of aluminium, is abundant on Earth and is biocompatible; it thus has the potential to improve energy efficiency and system performance in aerospace, automobile, defence, mobile electronics and biomedical applications1,2,3,4,5. However, conventional synthesis and processing methods (alloying and thermomechanical processing) have reached certain limits in further improving the properties of magnesium and other metals6. Ceramic particles have been introduced into metal matrices to improve the strength of the metals7, but unfortunately, ceramic microparticles severely degrade the plasticity and machinability of metals7, and nanoparticles, although they have the potential to improve strength while maintaining or even improving the plasticity of metals8,9, are difficult to disperse uniformly in metal matrices10,11,12,13,14. Here we show that a dense uniform dispersion of silicon carbide nanoparticles (14 per cent by volume) in magnesium can be achieved through a nanoparticle self-stabilization mechanism in molten metal. An enhancement of strength, stiffness, plasticity and high-temperature stability is simultaneously achieved, delivering a higher specific yield strength and higher specific modulus than almost all structural metals.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Pollock, T. M. Weight loss with magnesium alloys. Science 328, 986–987 (2010)

Lu, K. The future of metals. Science 328, 319–320 (2010)

Nie, J. F., Zhu, Y. M., Liu, J. Z. & Fang, X. Y. Periodic segregation of solute atoms in fully coherent twin boundaries. Science 340, 957–960 (2013)

Erbel, R. et al. Temporary scaffolding of coronary arteries with bioabsorbable magnesium stents: a prospective, non-randomised multicentre trial. Lancet 369, 1869–1875 (2007)

Knochel, P. A flash of magnesium. Nature Chem . 1, 740 (2009)

Nie, J.-F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 43, 3891–3939 (2012)

Mortensen, A. & Llorca, J. Metal Matrix Composites. Annu. Rev. Mater. Res. 40, 243–270 (2010)

Liu, G. et al. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nature Mater . 12, 344–350 (2013)

Zhang, Z. & Chen, D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: a model for predicting their yield strength. Scr. Mater. 54, 1321–1326 (2006)

Ferguson, J. B., Sheykh-Jaberi, F., Kim, C. S., Rohatgi, P. K. & Cho, K. On the strength and strain to failure in particle-reinforced magnesium metal-matrix nanocomposites (Mg MMNCs). Mater. Sci. Eng. A 558, 193–204 (2012)

Tjong, S. C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 9, 639–652 (2007)

Chen, L. Y. et al. Novel nanoprocessing route for bulk graphene nanoplatelets reinforced metal matrix nanocomposites. Scr. Mater. 67, 29–32 (2012)

Ferkel, H. & Mordike, B. L. Magnesium strengthened by SiC nanoparticles. Mater. Sci. Eng. A 298, 193–199 (2001)

Sillekens, W. H. et al. The ExoMet project: EU/ESA research on high-performance light-metal alloys and nanocomposites. Metall. Mater. Trans. A 45, 3349–3361 (2014)

Xu, J. Q., Chen, L. Y., Choi, H. & Li, X. C. Theoretical study and pathways for nanoparticle capture during solidification of metal melt. J. Phys. Condens. Matter 24, 255304 (2012)

Chen, L.-Y., Peng, J.-Y., Xu, J.-Q., Choi, H. & Li, X.-C. Achieving uniform distribution and dispersion of a high percentage of nanoparticles in metal matrix nanocomposites by solidification processing. Scr. Mater. 69, 634–637 (2013)

Min, Y., Akbulut, M., Kristiansen, K., Golan, Y. & Israelachvili, J. The role of interparticle and external forces in nanoparticle assembly. Nature Mater . 7, 527–538 (2008)

Somekawa, H. & Schuh, C. A. Nanoindentation behavior and deformed microstructures in coarse-grained magnesium alloys. Scr. Mater. 68, 416–419 (2013)

Pozuelo, M., Chang, Y. W. & Yang, J. M. Effect of diamondoids on the microstructure and mechanical behavior of nanostructured Mg-matrix nanocomposites. Mater. Sci. Eng. A 633, 200–208 (2015)

Ye, J., Mishra, R. K., Sachdev, A. K. & Minor, A. M. In situ TEM compression testing of Mg and Mg-0.2 wt.% Ce single crystals. Scr. Mater. 64, 292–295 (2011)

Barnett, M. R., Keshavarz, Z., Beer, G. & Atwell, D. Influence of grain size on the compressive deformation of wrought Mg-3Al-1Zn. Acta Mater. 52, 5093–5103 (2004)

Stanford, N. & Barnett, M. R. Effect of particles on the formation of deformation twins in a magnesium-based alloy. Mater. Sci. Eng. A 516, 226–234 (2009)

Watanabe, H. Effect of second-phase precipitates on local elongation in extruded magnesium alloys. J. Mater. Eng. Perform. 22, 3450–3454 (2013)

Hutchinson, W. B. & Barnett, M. R. Effective values of critical resolved shear stress for slip in polycrystalline magnesium and other hcp metals. Scr. Mater. 63, 737–740 (2010)

Jian, W. W. et al. Ultrastrong Mg alloy via nano-spaced stacking faults. Mater. Res. Lett . 1, 61–66 (2013)

Inoue, A. et al. Novel hexagonal structure of ultra-high strength magnesium-based alloys. Mater. Trans. 43, 580–584 (2002)

Luo, A. A. Recent magnesium alloy development for elevated temperature applications. Int. Mater. Rev. 49, 13–30 (2004)

Luo, A. & Pekguleryuz, M. O. Cast magnesium alloys for elevated temperature applications. J. Mater. Sci. 29, 5259–5271 (1994)

Friedrich, H. E. & Mordike, B. L. Magnesium Technology—Metallurgy, Design Data, Applications (Springer, 2006)

Xiao, Y., Zhang, X., Chen, J. & Jiang, H. Microstructures and mechanical properties of extruded Mg-9Gd-4Y–0.6Zr-T5 at elevated temperatures. Chin. J. Nonferr. Met . 16, 709–714 (2006)

Zhilyaev, A. P. & Langdon, T. G. Using high-pressure torsion for metal processing: fundamentals and applications. Prog. Mater. Sci. 53, 893–979 (2008)

Oh, Y., Asif, S. A. S., Cyrankowski, E. & Warren, O. L. Microelectro-mechanical heater. US patent WO2011066018 A1 (2011)

Israelachvili, J. N. Intermolecular and Surface Forces 211 (Academic Press, 2011)

Hashim, J., Looney, L. & Hashmi, M. S. J. The wettability of SiC particles by molten aluminium alloy. J. Mater. Process. Technol. 119, 324–328 (2001)

Eustathopoulos, N., Nicholas, M. G. & Drevet, B. Wettability at High Temperatures 396 (Pergamon, 1999)

Zhang, D., Shen, P., Shi, L. X., Lin, Q. L. & Jiang, Q. C. Wetting and evaporation behaviors of molten Mg on partially oxidized SiC substrates. Appl. Surf. Sci. 256, 7043–7047 (2010)

Nardone, V. C. & Prewo, K. M. On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr. Metall. 20, 43–48 (1986)

Choi, H. J., Kim, Y., Shin, J. H. & Bae, D. H. Deformation behavior of magnesium in the grain size spectrum from nano- to micrometer. Mater. Sci. Eng. A 527, 1565–1570 (2010)

Gu, R. & Ngan, H. W. Size effect on the deformation behavior of duralumin micropillars. Scr. Mater. 68, 861–864 (2013)

Gong, J. & Wilkinson, A. J. A microcantilever investigation of size effect, solid-solution strengthening and second-phase strengthening for 〈a〉 prism slip in alpha-Ti. Acta Mater. 59, 5970–5981 (2011)

Choi, W. S., De Cooman, B. C., Sandlöbes, S. & Raabe, D. Size and orientation effects in partial dislocation-mediated deformation of twinning-induced plasticity steel micro-pillars. Acta Mater. 98, 391–404 (2015)

Guo, E. Y. et al. Mechanical characterization of microconstituents in a cast duplex stainless steel by micropillar compression. Mater. Sci. Eng. A 598, 98–105 (2014)

Chen, P. et al. Microscale-calibrated modeling of the deformation response of dual-phase steels. Acta Mater. 65, 133–149 (2014)

Girault, B., Schneider, A. S., Prick, C. P. & Arzt, E. Strength effects in micropillars of a dispersion strengthened superalloy. Adv. Eng. Mater. 12, 385–388 (2010)

Cordero, Z. C. et al. Powder-route synthesis and mechanical testing of ultrafine grain tungsten alloys. Metall. Mater. Trans. A 45, 3609–3618 (2014)

Acknowledgements

This work is supported in part by the National Institute of Standards and Technology (NIST). We thank Y.-W. Chang, N. Bodzin and T. McLouth at the University of California, Los Angeles, for their help with FIB experiments, micropillar testing and elastic modulus measurements. We also thank C. Cao at the University of California, Los Angeles for his help with measuring the grain size of the as-solidified Mg2Zn samples.

Author information

Authors and Affiliations

Contributions

X.-C.L. and L.-Y.C. conceived the idea and designed the experiments. L.-Y.C. and H.C. fabricated the nanocomposites. X.-C.L. and J.-Q.X. developed the theoretical model for nanoparticle dispersion. X.M. conducted the high-pressure torsion experiment. L.-Y.C. and M.P. characterized the properties and microstructures. S.B. conducted micropillar compression testing at high temperature. L.-Y.C., X.-C.L., J.-Q.X., M.P. and S.M. analysed the data. L.-Y.C., X.-C.L., M.P. and S.M. wrote the paper. J.-M.Y. supervised M.P. for TEM characterization. S.M. supervised X.M. for the high-pressure torsion experiment. X.-C.L. supervised the whole work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Extended data figures and tables

Extended Data Figure 1 Fabrication of nanocomposites.

a, Ultrasonic processing for nanoparticle feeding and dispersion. b, Vacuum evaporation for concentrating nanoparticles in magnesium.

Extended Data Figure 2 Uniform distribution of nanoparticles across the whole sample.

a, Bright-field TEM image showing the dispersed SiC nanoparticles in the magnesium matrix. b, A histogram indicating the SiC nanoparticle size distribution. c, d, Plots representing the amount of Si (wt%; c) and Vickers microhardness (Hv; d) as a function of the position in the sample (bottom, middle, top, centre and edge). Error bars represent s.d. of six data sets in d and three data sets in c.

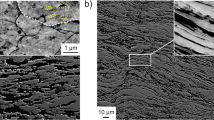

Extended Data Figure 3 TEM analysis showing non-basal deformation mechanisms in a polycrystalline sample under microcompression.

a, Bright-field TEM image showing a SiC nanoparticle embedded in the magnesium matrix. b, High-resolution TEM image from the region highlighted in a showing dislocations (indicated in yellow) terminated at stacking faults on the pyramidal  planes in a grain oriented to the

planes in a grain oriented to the  zone axis as indicated by its fast Fourier transform in c. The angle between the loading and pyramidal

zone axis as indicated by its fast Fourier transform in c. The angle between the loading and pyramidal  directions is around 30°.

directions is around 30°.

Supplementary information

SEM video showing deformation behavior of Mg2Zn sample during micro-compression test.

After yielding, Mg2Zn sample exhibits sudden slips, which results in repeated loading-unloading cycles in stress-strain curve. (MP4 36336 kb)

SEM video showing deformation behaviour of Mg2Zn (14 vol% SiC) sample during micro-compression test.

After yielding, Mg2Zn (14 vol% SiC) sample deforms uniformly without sudden slips, which results in a smooth stress-strain curve. (MP4 25737 kb)

Rights and permissions

About this article

Cite this article

Chen, LY., Xu, JQ., Choi, H. et al. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 528, 539–543 (2015). https://doi.org/10.1038/nature16445

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature16445

This article is cited by

-

Heterostructured metal matrix composites for structural applications: a review

Journal of Materials Science (2024)

-

Study of the micro-yielding behavior in a SiCp/Mg–Zn–Ca composite using synchrotron radiation diffraction

Journal of Materials Science (2024)

-

Effect of Ti Particles on the Microstructure and Mechanical Properties of AZ91 Magnesium Matrix Composites

Acta Metallurgica Sinica (English Letters) (2024)

-

Ultrafine-bubble-water-promoted nanoceramic decoration of metal powders for additive manufacturing

NPG Asia Materials (2023)

-

Strong and tough magnesium-MAX phase composites with nacre-like lamellar and brick-and-mortar architectures

Communications Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.