Abstract

FR901379 acylase, an enzyme that catalyzes the hydrolysis of the palmitoyl moiety of the antifungal lipopeptide FR901379, was purified from the culture broth of Streptomyces sp. no. 6907 (FERM BP-5809), revealing the 80 kDa, two-subunit heterodimeric protein characteristic of the β-lactam acylase family. Using oligodeoxyribonucleotide primers constructed on the basis of the N-terminal amino acid sequence of each purified subunit, the gene was identified from a cosmid library of Streptomyces sp. no. 6907 DNA. The deduced 775 amino acid sequence corresponded to a single polypeptide chain containing two subunits, and it shared 41.7% identity with aculeacin A acylase from Actinoplanes utahensis NRRL12052. FR901379 acylase activity was found to be 250-fold higher in the recombinant Streptomyces lividans 1326 carrying the cloned gene than in the original Streptomyces sp. no. 6907 strain.

Similar content being viewed by others

Introduction

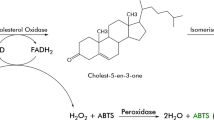

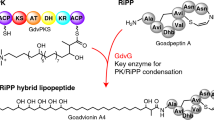

Microbial acylases are widely used to produce intermediate compounds for a number of important drugs; such acylases include penicillin G acylase,1 cephalosporin C acylase,2 echinocandin B acylase3 and aculeacin A acylase.4 Micafungin,5 which we developed commercially at Astellas, has been used worldwide in chemotherapy regimens to treat life-threatening fungal infections. This compound is semi-synthesized from acylated cyclic hexapeptide FR901379,6 a natural product of the fungus Coleophoma empetri F11899, via enzymatic deacylation of FR901379 followed by chemical reacylation with an optimized N-acyl side chain.7 We initially used aculeacin A acylase produced by Actinoplanes utahensis to remove the acyl side chain of FR901379 to yield FR179642, the intermediate compound, which eventually led to micafungin (Figure 1). However, to obtain a large quantity of FR179642 for our optimization study and to establish a basis for industrial production, a new acylase with patentability and potent activity against FR901379 was needed. A newly developed method using a rapid and simple assay can easily screen for acylase-producing microorganisms from wild actinomycetes and fungal strains freshly isolated from soil samples. This intensive screening enabled us to identify and isolate three actinomycetes and two filamentous fungi as acylase-producing microorganisms.8 Taxonomic study revealed that two of the three actinomycetes strains were species of Streptomyces anulatus, whereas the fungal strains belonged to the Verticillium and Oidiodendron genera. Another actinomycetes strain was identified as Streptomyces, but we were unable to determine its species. Of these five strains, we further studied Streptomyces sp. no. 6907 to evaluate its novelty and enzymatic potency.

In this report, we describe the purification and characterization of the acylase from Streptomyces sp. no. 6907 and its gene cloning and expression in S. lividans.

Materials and methods

Chemicals, strains and plasmid

FR901379, echinocandin B9 and aculeacin A10 were prepared from culture broths of Colephoma empetri F-11899, Aspergillus nidulans var. echinulatus A-32204 (NRRL3860), and A. aculeatus FREM BP-749, respectively. A. utahensis NRRL12052 was obtained from the Agriculture Research Service culture collection. S. lividans 1326 and pIJ702 vector were obtained from the John Innes Centre (Norwich, UK).

Culture media and conditions for enzyme production

A loopful of Streptomyces sp. no. 6907 was inoculated into the seed culture medium containing soluble starch 6%, defatted soybean powder 4% and calcium carbonate 0.5%, and then cultured at 30 °C for 3 days. The seed culture broth was inoculated into the production medium containing sucrose 4%, peanut powder 1%, dried yeast 1% and calcium carbonate 0.5%, and was then further cultured at 30 °C with rotary shaking at 250 revolutions per minute (r.p.m.) for 6 days. The fermentation process was periodically monitored by measuring pH, total residual sugar, packed mycelium volume and acylase activity. The packed mycelium volume was determined by centrifuging 10 ml of culture broth in 10-ml graduated centrifuge tube at 1640 × g for 10 min. The acylase activity was measured by an in vitro assay described below.

Measurement of FR901379 acylase activity

The acylase activity was routinely assayed by estimating the amount of FR179642 produced in the reaction mixture (1 ml), which contained 10 mg ml−1 of FR901379, 50 mM Tris-HCl buffer (pH 7.0), an enzyme preparation and 10% methanol to disperse FR901379. The reaction was carried out with shaking at 40 °C for 15 min, and was stopped with the addition of 4% acetic acid solution. The reaction mixture was then diluted with methanol and filtered through a membrane filter (0.45 μm). The resultant FR179642 was analyzed at 215 nm via HPLC with a Kaseisorb LC PO Super column (4.6 mm i.d. × 250 mm; Tokyo Kasei Kogyo, Tokyo, Japan) at a column temperature of 50 °C. A mobile solvent of 4% methanol buffered with 0.1% phosphoric acid was used at a flow rate of 1 ml min−1. One unit of acylase activity was defined as the amount of enzyme required to produce 1 μmol of FR179642 per minute at 40 °C.

Purification of the enzyme from Streptomyces sp. no. 6907

The culture broth of Streptomyces sp. no. 6907 was extracted with KCl (final concentration: 1.5 M) and filtered on no. 2 filter paper (Advantec Toyo, Tokyo, Japan). The filtrate was passed through an ultrafiltration membrane (AIP-1010, Asahi Kasei, Tokyo, Japan) for demineralization, replaced by 20 mM Tris-HCl (pH 9.0), and it was further passed though an HP-20 column. Subsequently, the eluent was absorbed on a Cl-type DEAE-Toyopearl column (Tosoh Corp, Tokyo, Japan) and eluted with a solution of 0.3 M NaCl–20 mM Tris-HCl (pH 9.0). The active fraction was applied onto a phenyl-Toyopearl column (Tosoh Corp) and eluted with a solution of 0.1 M (NH4)2SO4–50 mM Tris-HCl (pH 8.0). This eluent was then purified by HPLC using YMC-Diol column (YMC, Kyoto, Japan), with a solution of 0.2 M NaCl–0.1 M KH2PO4–Na2HPO4 (pH 7.0). Subsequently, the active fraction was again passed through an ultrafiltration membrane and further fractionated using a preparative Cosmosil 5C4-AR-300 HPLC column (Nacalai Tesque, Kyoto, Japan; mobile phase: (A) 0.5% TFA, (B) 0.5% TFA–80% acetone; A:B=60:40 to 40:60 (linear gradient)).

Determination of protein concentration and molecular weight

Protein concentration was determined using a Bio-Rad protein assay kit (Bio-Rad, Tokyo, Japan) with bovine serum albumin used as the standard. SDS-polyacrylamide gel electrophoresis (PAGE) was performed according to the procedure described by Laemmli,11 and protein in the gel was detected using either coomassie brilliant blue or silver stain. The molecular weight of the protein was determined by comparing it with molecular weight standards in the gel.

Analyses of amino acid and nucleotide sequences

The purified protein was loaded onto a glass filter pretreated with polypropylene and dried with argon gas. N-terminal amino acids of the protein were then analyzed using a protein sequencer (models 476A and 610A; Applied Biosystems, Tokyo, Japan). The nucleotide sequence of the cloned acylase gene was determined by the chain termination method using an Applied Biosystems 310 DNA sequencer (Applied Biosystems) according to the supplier’s protocol.

Construction of cosmid library

Total genomic DNA from Streptomyces sp. no. 6907 cells was obtained using Qiagen Genomic tip 20/G (Qiagen, Tokyo, Japan) according to the manufacturer’s protocol. The DNA (1 μg) was treated with Sau3AI (100 mU) at 37 °C for 10 min for partial digestion, and 1 μg of cosmid pcos6EMBL12 was treated with BamHI (5 U) at 37 °C for 1 h. The DNA solutions were then precipitated together using ethanol and dissolved in a solution with 5 μl of TE buffer (5 mM Tris-HCl, 1 mM EDTA Na2 (pH 8.0)), to which 0.7 μl of 10 × T4 DNA ligase buffer (660 mM Tris-HCl (pH 7.6), 66 mM MgCl2, 100 mM DTT, 1 mM ATP) and 0.7 μl of T4 DNA ligase solution had been added. The mixture was incubated at 22 °C for 3 h and subsequently subjected to in vitro packaging using Gigapack III XL Packaging Extract (Agilent Technologies, La Jolla, CA, USA) following the manufacturer’s protocol. The indicator strain, E. coli XL-1 Blue MRA (P2), was infected using the packaging solution to construct the cosmid library.

Culture media for S. lividans 1326 transformant

To produce the recombinant acylase, S. lividans 1326 transformants were inoculated into the medium (10 ml) containing sucrose 5%, glucose 1%, yeast extract 0.3%, bactopeptone 0.5%, meat extract 0.3%, 5 mM MgCl2, glycine 0.5% and 50 mg ml−1 of thiostrepton (pH 6.5), and cultured at 30 °C for 3 days (260 r.p.m.), while the FR901379 acylase activity in the culture broth was monitored.

Partial purification of recombinant FR901379 acylase

S. lividans 1326 transformant was inoculated into 50 ml of PM-1 medium containing modified starch 6%, defatted soybean meal powder 3%, CaCO3 0.5% and 25 μg ml−1 thiostrepton, (pH unadjusted) in a 500-ml flask, and subsequently cultured at 30 °C for 3 days. The culture (2.5 ml) was then transferred into 50 ml of SG medium containing maltose 8%, defatted soybean meal powder 3%, defatted wheat germ 3%, CaCO3 0.5% and 25 μg ml−1 of thiostrepton (pH unadjusted) in a 500-ml flask, and then cultured at 30 °C for 3 days.

Eight ml of 4 M KCl was added to 24 ml of the culture broth, and the mixture stood overnight at 4 °C. The solution was centrifuged at 10 000 r.p.m. for 10 min to obtain the supernatant, which was used as a KCl extract solution. This KCl extract solution was concentrated 10-fold using Microcon 50 (Millipore Corporation, Billerica, MA, USA) and returned to its original volume with 0.5 M sodium phosphate buffer (pH 6.0). This step was repeated twice to remove low molecular weight proteins, followed by SDS-PAGE analysis. The proteins in the gel after SDS-PAGE were transferred to a polyvinylidene fluoride membrane by electrophoresis and stained with coomassie brilliant blue. The objective band was cleaved with scissors and subjected to N-terminal amino acid sequence analysis

Results

Growth profile and FR901379 acylase productivity of Streptomyces sp. no. 6907

As shown in Figure 2, the packed mycelium volume of Streptomyces sp. no. 6907 grown in the production medium increased during the initial 24 h of cultivation, after which it remained at approximately the same level. The productivity of FR901379 acylase markedly increased from 24 to 48 h, and continued rising for the initial 120 h of cultivation.

Purification of FR901379 acylase from Streptomyces sp. no. 6907

The results of purification for FR901379 acylase from 1800 ml of the culture broth of Streptomyces sp. no. 6907 are shown in Table 1. The specific activity of the purified enzyme was 2.73 U mg−1 protein, and the total activity was 12.9 U. The native PAGE of the purified enzyme gave a single band with a molecular weight of 80 KDa (data not shown).

As a HPLC analysis detected three peaks (Figure 3a), each peak was fractionated by preparative HPLC. SDS-PAGE of these fractionated peptides revealed that their molecular weights were 61, 19 and 80 kDa (Figure 3b). Typically an enzyme in the β-lactam acylase family is initially synthesized as an inactive precursor composed of the single polypeptide with a molecular weight of 80–90 kDa. The precursor enzyme is transformed into an active, mature form composed of a small and a large subunit of ∼20 and 60 kDa, respectively, by cleavage of a short intervening polypeptide called a spacer sequence. On the basis of our results and this knowledge, we concluded that FR901379 acylase belonged to β-lactam acylase family and consisted of two peptides, a large subunit (61 kDa) and a small subunit (19 kDa).

Analysis of FR901379 acylase protein purified using a preparative YMC-Diol HPLC column. (a) Chromatogram on Cosmosil 5C4-AR-300 HPLC column. Retention times: peak 1, 13.0 min; peak 2, 13.9 min; peak 3, 12.0 min. (b) SDS-PAGE analyses of each peak fractionated using a Cosmosil 5C4-AR-300 column. Lane 1: molecular weight standard markers. Lane 2: sample before fractionation. Lane 3: peak 3. Lane 4: peak 1. Lane 5: peak 2.

Profile of purified FR901379 acylase

FR901379 acylase activity is optimal at a pH of 8–9 and a temperature of 50 °C. This enzyme can also deacylate both aculeacin A and echinocandin B. The respective Km and Vmax values were 257 μM and 14.3 U mg−1 protein for FR901379, 279 μM and 16.3 U mg−1 protein for aculeacin A, and 146 μM and 7.85 U mg−1 protein for echinocandin B.

N-terminal amino acid analysis of each subunit and primer design

Amino acid sequence analyses of the two subunits purified by SDS-PAGE revealed that the N-terminal amino acid sequences of the small and large subunits were GSGLSAVIRYTEYGIPHIVA- and SNAVAFDGSTTVNGRGLLLG-, respectively. BLASTP searches found no identical amino acid sequences in the database.

As most β-lactam acylases are encoded in order of a small subunit and a large subunit,13 we tried to directly amplify the FR901379 acylase gene from the genomic DNA of Streptomyces sp. no.6907 in PCR using degenerate forward primers designed from the N-terminal amino acid sequence of the small subunit and degenerate reverse primers designed from the N-terminal amino acid sequence of the large subunit. However, no amplified fragments were obtained. Alternatively, we initially carried out two PCRs using the degenerate forward and reverse primers constructed from the N-terminal amino acid sequences of each subunit so that the amplified fragment would be within the respective N-terminal amino acid sequence. Each PCR in 50 μl of reaction volume was carried out using 100 ng of genomic DNA from Streptomyces sp. no. 6907 and 1000 pmol of degenerate primers for the small subunit, forward (5′-CTSTCSGCSGTSATC-3′) and reverse (5′-GATGTGSGGGATSCC-3′), and for the large subunit, forward (5′-CSGTSGCSTTCGACGG-3′) and reverse (5′- SCCSAGSAGSAGSCC-3′), in the presence of 1.5 U of KOD Dash (Toyobo, Osaka, Japan). The PCR conditions were 30 cycles in a thermal cycler at 98 °C for 20 s, 60 °C for 2 s and 74 °C for 10 s. The amplified DNAs (45 bp in PCR for the small subunit and 53 bp in PCR for the large subunit) were isolated and cloned into pCR-Script Amp SK (+) (Agilent Technologies) for sequencing (Figure 4). As the expected fragments could be amplified, subsequent PCR reactions were carried out using 20 pmol of specific primers, forward (5′-ATCCGGTACACGGAGTACGG-3′; 20S), designed from the elucidated nucleotide sequence of the small subunit, and reverse (5′-CGTTCACCGTCGTGGAGCC-3′; 19L), designed from the nucleotide sequence of the large subunit in the presence of 2.5 U of KOD Dash. The PCR conditions were 30 cycles at 98 °C for 20 s, 70 °C for 2 s and 74 °C for 20 s. The amplified DNA of ∼600 bp was isolated, cloned into pCR-Script Amp SK (+), and then sequenced to compare the sequence of cloned DNA obtained in the next section.

Primer construction for gene cloning of FR901379 acylase. The nucleotide sequences of N-terminal amino acids in the small subunit (a) and large subunit (b) were determined by PCR using the degenerated primers designed from the N-terminal amino acid sequences with consideration of the preferred codons in the box for the GC-rich primer. The specific primers, 20S and 19L, were constructed from the determined nucleotide sequence, respectively.

Cloning the FR901379 acylase gene from Streptomyces sp. no. 6907

Colony direct PCR was performed on the cosmid clones using primer 20S and 19 L (20 pmol each) in GeneAmp PCR System Model 2400 (Applied Biosystems). The reaction mixture (20 μl) containing 0.2 mM each of deoxyribonucleotide triphosphates and 2.5 U of KOD Dash (Toyobo) in PCR buffer was subjected to 30 cycles of PCR consisting of 20 s of denaturing at 98 °C, 2 s of annealing at 68 °C and 20 s of polymerization at 74 °C. An amplified fragment of cosmid clone no. 133 of ∼600 bp in size was obtained, and its sequence was determined to be identical to that of the amplified fragment obtained in the previous section. The cosmid clone no. 133 was digested with EcoRI and PstI, after which the ∼8-kb digested fragment was inserted into the EcoRI/PstI site of pUC18 to produce plasmid pEP1. This plasmid was then digested with EcoRI and BamHI, and the resultant fragment of ∼5.5 kb in length was inserted into the EcoRI/BamHI site of pUC18 to produce the plasmid pEB.

The nucleotide sequence of plasmid pEB, which has a subcloned 5.5 kb fragment from the cosmid clone no. 133, was determined and deposited in GenBank under the accession number AB158476. Analysis of the nucleotide sequence revealed an open reading frame with 775 deduced amino acid residues, which included DNA sequences corresponding to the N-terminal amino acid sequences of a small and a large subunit. Comparison of the entire amino acid sequences between FR901379 acylase and aculeacin A acylase from A. utahensis NRRL1205214 showed 41.7% identity (Figure 5).

Expression and characterization of FR901379 acylase gene in S. lividans

Plasmid pSB, in which the EcoRI site of plasmid pEB was changed to a SacI site, was constructed as follows: first, a synthetic oligomer (100 pmol, 5′-AATTGAGCTC-3′) was treated with T4 polynucleotide kinase (30 U) at 37 °C for 1 h to phosphorylate the 5′-OH terminal. The reaction mixture was then heated at 70 °C for 10 min to inactivate the T4 polynucleotide kinase. Plasmid pEB (1 μg) was separately treated with EcoRI (5 U) and bacterial alkaline phosphatase (1 U) at 37 °C for 1 h to dephosphorylate the 5′ terminal. These two reaction mixtures were then ligated with Ligation High (Toyobo) to construct plasmid pSB. The plasmid pSB (5 μg) was treated with SacI (20 U) and BamHI (20 U) to give a 5.5-kb SacI–BamHI fragment containing an acylase gene. pIJ702 (2 μg),15 which is a plasmid vector from S. violaceoruber ATCC35287, were treated with SacI (10 U) and Bgl II (10 U) and ligated with a 5.7-kb SacI-BamHI fragment containing an acylase gene in the presence of Ligation High to produce pIJ702-SB. Subsequently, this plasmid was used to transform S. lividans 1326 strain15 according to a previously described method.16 Among the transformants, one strain was selected and named S. lividans 1326/pIJ702-SB.

Maximum FR901379 acylase activity to produce 30 mg of FR179642 per 1 ml of culture broth per hour was detected in the culture of S. lividans 1326/pIJ702-SB. The culture period until the acylase activity reached the maximum was shortened to 2 to 3 days for S. lividans 1326/pIJ702-SB, less than half of the typical 7 days it takes for Streptomyces sp. no. 6907 to achieve maximum acylase activity. Furthermore, maximum activity, which was 250-fold that of the original strain, was attained in the culture broth of S. lividans 1326/pIJ702-SB (Figure 6).

The N-terminal amino acid sequences of both subunits on the SDS-PAGE of KCl extract from the culture broth of S. lividans 1326/pIJ702-SB (Figure 7) were determined to be identical to those of native acylase purified from Streptomyces sp. no. 6907.

Conclusion

We successfully purified FR901379 acylase from Streptomyces sp. no. 6907, cloned its gene based on information from the N-terminal amino acid sequences derived from the purified enzyme, and achieved overexpression of the recombinant enzyme in S. lividans. Through the study described in this paper, FR901379 acylase was determined to differ from other acylases in the following aspects: first, whereas the packed mycelium volume of Streptomyces sp. no. 6907 in the culture medium increased for the initial 24 h of cultivation and remained constant thereafter, the FR901379 acylase activity continued to increase until 120 h. Boeck et al.17 demonstrated that biomass increased gradually during lipopeptide acylase production in A. utahensis until the end of cultivation, although lipopeptide acylase activity per unit of biomass peaked mid-phase. According to the reported data3 on echinocandin B acylase produced by A. utahensis, the optimal temperature of this enzyme is 60 °C. In contrast, FR901379 acylase activity markedly decreased at 60 °C.8 Second, although FR901379 acylase was composed of two different subunits, similar to the composition of other acylases, N-terminal amino acid sequence analysis of purified FR901379 acylase found no overall similarity to aculeacin A acylase, echinocandin B acylase, penicillin G acylase, or cephalosporin C acylase. Taking these observations into account, we concluded that FR901379 acylase was a novel enzyme. FR901379 acylase was successfully used in an analog study of FR901379 and has been used for the industrial production of micafungin.

Accession codes

References

Arroyo, M., de la Mata, L., Acebal, C. & Pilar Castillon, M. Biotechnological applications of penicillin acylases: state-of-the-art. Appl Microbiol Biotechnol 60, 507–514 (2003).

Otten, L. G., Sio, C. F., Vrielink, J., Cool, R. H. & Quax, W. J. Altering the substrate specificity of cephalosporin acylase by directed evolution of the β-Subunit. J. Biol. Chem. 277, 42121–42127 (2002).

Kreuzman, A. J. et al. Membrane-associated echinocandin B deacylase of Actinoplanes utahensis: purification, characterization, heterologous cloning and enzymatic deacylation reaction. J. Indust. Microbiol. Biotechnol. 24, 173–180 (2000).

Takeshima, H., Inokoshi, J., Tanaka, Y., Tanaka, H. & Omura, S. A. deacylation enzyme for aculeacin A, a neutral lipopeptide antibiotic, from Actinoplanes utahensis: purification and characterization. J. Biochem. 105, 606–610 (1999).

Hashimoto, S. Micafungin: a sulfated echinocandin. J Antibiot. 62, 27–35 (2009).

Iwamoto, T., Fujie, A., Nitta, K., Hashimoto, S., Okuhara, M. & Kohsaka, M. WF11899A, B, and C novel antifungal lipopeptides. J Antibiot. 47, 1092–1097 (1994).

Tomishima, M., Ohki, H., Yamada, A., Maki, K. & Ikeda, F. Novel echinocandin antifungals. Part 2: optimization of the side chain of the natural product FR901379. Discovery of micafungin. Bioorg. Med. Chem. Lett. 18, 2886–2890 (2008).

Ueda, S . et al. Screening and characterization of microorganisms with FR901379 acylase activity. J Antibiot. 63, 65–70 (2010).

Nyfeler, R. & Keller-Schierlein, W . Echinocandin B, in neuartigespolipeptide-antibiotikum aus Aspergillus nidulans var.echinatus: Isolierung und Bausteine. Helv. Chim. Acta. 57, 2459–2477 (1974).

Mizuno, K. et al. Studies on aculeacin. J Antibiot. 30, 297–302 (1977).

Laemmeli, U. K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227, 680–685 (1970).

Ehrich, E., Craig, A., Poustka, A., Frischauf, A. M. & Lehrach, H . A family of cosmid vectors with the multi-copy R6K replication origin. Gene 57, 229–237 (1987).

Deshpande, B. S., Ambedkar, S. S., Sudhakaran, V. K. & Shewale, J. G. Molecular biology of β-lactam acylases. World J. Microbiol. Biotechnol. 10, 129–138 (1994).

Inokoshi, J., Takeshima, H., Ikeda, H. & Omura, S. Cloning and sequencing of the aculeacin A acylase-encoding gene from Actinoplanes utahensis and expression in Streptomyces lividans. Gene 21, 29–35 (1992).

Katz, E., Thompson, C. J. & Hopwood, D. A. Cloning and Expression of the tyrosinase gene from Streptomyces antibioticus in Streptomyces lividans. J Gen. Microbiol. 129, 2703–2714 (1983).

Hopwood, D. A. et al. Genetic Manipulation of Streptomyces: A Laboratory Manual (The John Innes Foundation, Norwich, UK, 1985).

Boeck, L., Fukuda, D., Abbott, B. J. & Debono, M. Deacylation of A21978C, an acidic lipopeptide antibiotic complex, by Actinoplanes utahensis. J Antibiot. 41, 1085–1092 (1988).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ueda, S., Shibata, T., Ito, K. et al. Cloning and expression of the FR901379 acylase gene from Streptomyces sp. no. 6907. J Antibiot 64, 169–175 (2011). https://doi.org/10.1038/ja.2010.151

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/ja.2010.151

Keywords

This article is cited by

-

Novel recombinant aminoacylase from Paraburkholderia monticola capable of N-acyl-amino acid synthesis

Applied Microbiology and Biotechnology (2024)

-

Efficient side-chain deacylation of polymyxin B1 in recombinant Streptomyces strains

Biotechnology Letters (2022)

-

Deacylation of Echinocandin B by Streptomyces species: a novel method for the production of Echinocandin B nucleus

3 Biotech (2019)

-

Microbial metabolism of quorum-sensing molecules acyl-homoserine lactones, γ-heptalactone and other lactones

Applied Microbiology and Biotechnology (2014)

-

Echinocandins: production and applications

Applied Microbiology and Biotechnology (2013)