Abstract

Biochar derived from waste biomass has proven as a promising sorbent for removal of heavy metals from wastewater. However, proper disposal of such a heavy metal-containing biochar is challengeable. The major objective of this study is to create a reuse way by converting the heavy metal-loaded biochar into supercapacitor. Two biochars were produced from dairy manure and sewage sludge, respectively, and subjected to sorption of Ni from solution, and then the Ni-loaded biochar underwent microwave treatments for fabrication of supercapacitor. The specific capacitance of biochar supercapacitor increased with Ni loading, especially the Ni-loaded biochar further treated with microwave in which the capacitance increased by over 2 times, compared to the original biochar supercapacitors. The increase of capacitance in the Ni-loaded biochar supercapacitor following microwave treatment was mainly attributed to the conversion of Ni into NiO and NiOOH, which was evidenced by X-ray diffraction and X-ray photoelectron spectroscopy. The biochar supercapacitors, especially microwave-treated Ni-loaded biochar supercapacitors exhibited the high stability of specific capacitance, with less than 2% loss after 1000 charge-discharge cycles. This study demonstrated that Ni-loaded biochar can be further utilized for generation of supercapacitor, providing a potential way for the reuse of exhausted carbonaceous sorbents.

Similar content being viewed by others

Introduction

Biochar is a carbonaceous solid material produced through pyrolysis of the waste biomass such as manure, wood chips, and sewage sludge1,2,3. Therefore, biochar is rich in oxygenated groups, such as carboxyl, hydroxyl, and phenolic surface function groups and has meaningful properties such as stability, low cost, porosity, nontoxicity, and sustainability4. These specific structure and properties contribute to the wide application of biochar. For example, biochar shows a great capacity for sorbing heavy metals such as Ni2+, Cd2+, Co2+, and Pb2+ in the aqueous solution. Liu et al. used Phragmites australis-derived biochar as the sorbent for sorption of Ni(II) from the aqueous solution, obtaining a sorption capacity of 19.2 mg g−1 5. The biochar produced from broiler litter manure could sorb 59.7 mg g−1 Pb2+, 2.02 mg g−1 Cd2+, 16.5 mg g−1 Cu2+, and 1.76 mg g−1 Ni2+ 6. The heavy metals retained in the biochar are difficult to be desorbed, which makes the sorbent become hazardous waste if they are not well disposed7. Therefore, how to properly deal with the metal-loaded biochar may become a challenge.

Many studies have been done by using carbonaceous materials such as activated carbon and carbon nanotube as electrodes for microbial fuel cell and supercapacitors8,9,10. Supercapacitor, an essential electric device for energy storage, is undergoing rapid development with its potentially broad applications in automobiles, uninterruptible power supplies, power grid, renewable energy, consumer electronics, and industry11,12,13. Small-scale supercapacitors can be integrated with microelectronic devices to work as stand-alone power sources or as efficient energy storage units complementing batteries and energy harvesters, leading to wider use of these devices in many industries14. To a great extent, the performance of supercapacitors depends on the electrode material and structure which has been generally categorized into two major classes15: (1) pseudo-capacitive materials such as metal hydroxides, transition metal oxides and conducting polymers; (2) composite materials in which charging-discharging follows an electric double-layer mechanism. Recently, composites materials possessing both of electric double-layer and pseudo-capacitive characteristics received extensive concern16. Carbon materials, such as activated carbon, carbon fiber, carbon cloth, carbon nanotube, graphene, etc. are applied to the electrodes for their significant electrical conductivity and electrochemical stability17,18,19. However, such carbon materials are of high cost or nanotoxicity, which limit their wide applications. Therefore, developing lower cost carbon materials with higher specific capacitance and promoting electrochemical properties is perceptibly attractive20.

One of such candidates to modify low grade carbon material into high performance electrode material for supercapacitors is adding metal oxide, especially transition metal oxides such as MnO2, NiO, Co3O4, V2O5, and CuO21,22,23. Among those metal oxides, NiO is considered to be one of the most attractive materials due to its good redox activity and high theoretical specific capacitance (2584 F g−1)24. For high-performance supercapacitors, a wide variety of hierarchical NiO micro/nanostructures, including nanosheets, nanotubes, hollow microspheres, flower-like microspheres have been investigated24,25,26,27. Although great progress has been made, it is still a great challenge to make a balance between excellent pseudo capacitive performance and simplicity of the synthetic pathway of NiO.

We hypothesized that the Ni-loaded biochar could be further reused as a potential material for generation of supercapacitors with both pseudo capacitive and electric double-layer properties. These may not only solve the Ni-loaded sorbent waste disposal but also expand a significant utilization of biochar as an effective energy storage device, both of which has great environmental significance. Therefore, the first part of this work was obtaining Ni-loaded biochar; the second part focused on preparation of supercapacitors by using the obtained Ni-loaded biochar, and the last part elucidated the underlying mechanisms for electrochemical performance of the biochar supercapcitor.

Results and Discussion

Characterization of biochar and Ni-loaded biochar

The contents of C in the original DM and SS biochars were 65.1% and 77.6%, respectively (Table 1), which was within the normal range of C for biochar28. After Ni sorption, C in the DM and SS biochars were reduced, especially in the biochars with microwave treatment, C was reduced to 55.3%. In correspondence, O increased from 8.10% and 16.6% to 35.2% and 39.3% for DM-Ni-MW and SS-Ni-MW, respectively. There was no detectable Ni in both original DM and SS biochars, however, after sorption both biochars contained 1.60% and 1.19% Ni, respectively (Table 1). This further demonstrated that biochar is an effective sorbent for sorption of Ni5. With the microwave treatment, Ni concentrations in the DM-Ni-MW and SS-Ni-MW biochar were elevated to as high as 3.85% and 3.26%, respectively (Table 1).

The FTIR spectra showed that after Ni was sorbed, the peak of CO32− at 1480 cm−1 29 in the DM and SS biochars shifted from 1481 cm−1 to 1490 cm−1, and from 1487 cm−1 to 1496 cm−1, respectively (Fig. 1). The results indicated that the sorption of Ni on biochar was probably through the combination of Ni2+ and CO32−, possibly present as NiCO3. In addition, strong and wide peaks at 960–920 cm−1 assigned to PO43 were observed in both biochars, and Ni-loaded induced the peak PO43− in DM and SS biochars shifted from 929 cm−1 to 945 cm−1 and from 964 cm−1 to 944 cm−1, respectively. The observation indicated a possible formation of Ni3(PO4)2 during the sorption of Ni on biochar. Many studies proved that sorption of heavy metals by biochar could be attributed to their precipitation with biochar-inherent anion ions such as CO32− and PO43− 30,31,32 Complexation of Ni with O-containing groups is also possible although not significant shift of the peaks of O-containing group, especially the peaks of 3000–3600 cm−1 associated with phenolic-OH, was observed before and after Ni sorption (Fig. 1).

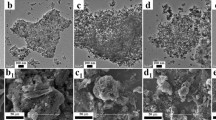

The specific surface area of original DM and SS biochars were 37.4 m2 g−1 and 47.0 m2 g−1 respectively, which were within the general range of biochar as reported before33,34. Ni-loaded had little influence on the surface area. However, after microwave treatment, the specific surface areas of both Ni-loaded DM and SS biochars were reduced (Table 1). These may be caused by the newly generated fine particles which could block the pores, resulting in the decrease in surface area35,36. The consistent decrease in the micro-, meso-, and macro-pore volume of biochar further supported the possibility of pore blocking and correspondingly decrease of the surface area.

Oxidation of biochars with microwave treatment

Microwave treatment could capture/transfer more O element on biochar samples, resulting in oxidation of the surface groups on samples37,38,39. Microwave irradiation activates substances by three mechanisms which are dipole polarization, ionic conduction, and the combination of two which was called interfacial polarization. It shortened reaction time by interacting with the reaction mixtures on a molecular level, leading to an accelerated rate of reaction and hence the oxidation of organic or inorganic groups40,41. By comparing Ni-loaded biochars before and after MW treatment, the peaks of PO43− remained less changed, mainly due to the higher stability of Ni3(PO4)2. However, the peaks of CO32− in both Ni-loaded biochars shifted back (from 1490 cm−1 to 1483 cm−1 for DM, and 1496 cm−1 to 1489 cm−1 for SS), indicating a possible transformation of NiCO3 during MW treatment. XRD analysis evidenced the presence of oxidized Ni particles, i.e., formation of NiO at the peaks of 2θ degree = 37°, 44.5°, and 66° 42 in both SS-Ni-MW and DM-Ni-MW biochars (Fig. 2). No peaks of NiCO3 or Ni3(PO4)2 were shown in both DM-Ni and SS-Ni samples, probably because of low concentration. The Ni concentrations in DM-Ni and SS-Ni were 1.60% and 1.19% (Table 1), below the detection limit of XRD. In addition to NiO, another Ni oxide, NiOOH was also formed which was confirmed by XPS analysis (Fig. 3). For both DM-Ni-MW and SS-Ni-MW biochars, the Ni2p1/2 and Ni2p3/2 photopeaks located at 873 and 856 eV with their satellites of 879 and 862 eV were assigned to Ni oxide-bearing compounds NiOOH and NiO, respectively43. The formation of NiO is important as it could improve specific capacitance44. Note that the noise signals in original DM and SS biochar are due to the presence of limited Ni.

Those results showed that the microwave treatment succeeded in the transformation of sorbed Ni on the biochar samples into Ni oxide particles. The transformation of Ni during the whole process from sorption to microwave treatment could be proposed as follows:

Sorption:

Microwave activation:

C and O peaks in both biochars were also analyzed, showing the existence of a variety of C groups (Figure S2 and Table S2): aromatic C at 284.71–284.75 eV, hydroxyl C at 285.56–286.16 eV, quinine C at 287.10–49 eV, and carboxyl/ester C at 288.03–289.07 eV. All chemical C bond shifted less after sorption and MW oxidation (Figure S2), which could be explained by the high stability of carbon framework. The O-containing groups are shown in Figure S2 and summarized in Table S2-quinine O at 531.11–531.64 eV, carboxyl/ester O at 532.00–533.54 eV, and anhydride O at 532.84–533.4045. Microwave oxidation induced all O-containing groups shift, especially carboxyl/ester O whose shift was much more obvious, it is probably due to break of (-C-OO)2Ni or (-C-O)2Ni. The increase in O-containing functional groups could contribute to the pseudo-capacitance43.

Electrochemical characteristics of biochar supercapacitors

The cyclic voltammetry curves for all biochar supercapacitors are shown in Fig. 4. Diagrams for all samples show typical electrochemical double layer (EDL) characteristics between −0.3 and +0.5 V versus Hg/HgO (saturated calomel electrode, SCE) in 0.5 M KOH with a pH value of 8.2 (0.43 V–1.23 V vs RHE). The O reduction wave between −0.1 and +0.5 V corresponded to the reduction of O-containing functional groups such as quinone and ketone as discussed before. The voltammograms obtained from the DM-Ni-MW and SS-Ni-MW biochars had a pseudo-rectangular-like shape which also increased with increasing san rate (Fig. 4). The pseudo-rectangular-like shape is close to the ideal EDL capacitive response46. This is attributed to the longer time available for electron to access the micropore of biochar due to the presence of NiO or NiOOH.

Microwave activated Ni-loaded biochar supercapacitor showed the highest specific capacitance, compared to the original biochar and Ni-loaded supercapacitors (Table 2). The capacitance of DM-Ni-MW and SS-Ni-MW were 123 F g−1 and 100 F g−1, increased by 2.14 and 2.01 times, respectively, compared to their original biochar supercapacitors (39.1 F g−1 and 33.2 F g−1, respectively). It was found that both double-layer capacitance and Faradic pseudo-capacitance existed in the metal oxide/carbon composites. The amount of electric charge stored in double-layer depends primarily on the electrode surface. Obviously, the surface area of supercapacitors was not responsible for the increase in the capacitance since the surface area decreased from the original biochar to microwave-treated Ni-loaded biochar (Table 1). The enhanced capacitance of activated Ni-loaded biochar supercapacitor was most likely attributed to the presence of NiO24,27. More similar work proved that metal oxides such as NiO and Co2O3 could enhance capacitance of supercapacitors21.

The Ni oxides particles in the electrochemistry system could undergo the following reaction to donate or accept electrons44:

Figure 5 shows the electrochemical impedance spectroscopy (EIS) of all biochar supercapacitors. The calculated resistance values by fitting Re(Z) are listed in Table 2. All Re(Z) data showed that the Ni-loaded and MW treatment process led to the decrease of resistance. The Re(Z) in DM-Ni-MW and SS-Ni-MW were reduced by 3.35 and 2.49 times, compared to the original DM and SS biochar supercapacitors (Table 2). Resistance decrease was because of more conductor in the samples with the Ni-loaded. With the further MW treatment, the inner structure become more highly ordered and porous and NiO/NiOOH was formed, resulting in the easier conductor and correspondingly the decrease in the resistance. This result was similar to the other NiO/carbon based composite electrode in which formation of NiO has a significant promotion for electrochemical properties43.

After1000 charge-discharge cycles, the change in the specific capacitance was less, with only 3.5% and 4.5% lost for DM and SS biochar supercapacitors, respectively (Figure S5 and Table 2). It indicated that the high capacitance stability of biochar supercapacitors, especially for the activated Ni-loaded supercapacitors. The loss in the specific capacitance of DM-Ni-MW and SS-Ni-MW was only 1.6% and 1.8%, respectively (Table 2).

Conclusions

This study showed that Ni-loaded dairy manure and sewage sludge biochars can be further reused for the supercapacitor production. Further treatment with microwave activation could increase the capacitance. The increase of capacitance in the Ni-loaded biochar supercapacitor following microwave treatment was mainly attributed to the conversion of Ni(II) into NiO and NiOOH. The biochar supercapacitors, especially microwave-treated Ni-loaded biochar supercapacitor exhibited the high stability of specific capacitance, with less than 2% loss after 1000 charge-discharge cycles. To improve the specific capacitance, future study will be conducted to test more strong activation method for example, chemical oxidation and plasma oxidation. Note that single heavy metal Ni was used as an example by converting the Ni-loaded biochar into supercapacitor in this paper. In fact, the practical wastewater may contain multiple heavy metals such as Cu, Zn, etc. Sorption of multiple heavy metals could affect the properties of the loaded biochar as supercapacitors. In the future, an attempt will be made on the reuse way of exhausted biochars after sorbing multi-metals in practical wastewater and determination of the effect of co-adsorbed metals on the properties of the biochar as supercapacitors.

This is the first study that reports reuse of transition metal-adsorbed-biochar. More importantly, the way created in this work may not only solve the heavy metal-laden sorbent waste disposal but also expand utilization of biochar as an effective energy storage device, both of which has a great significance of environmental sustainability.

Materials and Methods

Preparation of biochar and Ni-loaded biochar

Two waste biomasses, sewage sludge and dairy manure were collected from a wastewater treatment plant and a livestock farm in Shanghai, respectively. The waste biomasses were then air-dried to constant weight. The details for biochar production were described in a previous work49. Specifically, the dried manure and sewage sludge was put in a stainless steel reactor and heated in a Muffle Furnace under <0.5% O2 condition at 600 °C for 4 h. The solid residue left in the reactor after heating was C-rich material and called as biochar. The resulted biochar was ground in a ball-milling machine and passed through a 0.5-mm sieve for later experiment. Biochars derived from dairy manure and sewage sludge were referred to as DM and SS, respectively.

To obtain Ni-loaded biochar, the batch sorption experiment was performed. Specifically, 0.20 g biochar was added into 40 mL of 0–200 mg L−1 Ni(NO3)2 solution in a series of 50-mL polypropylene tubes. The mixture of biochar and Ni(NO3)2 solution was shaken at 240 rpm for 24 h under room temperature (20 ± 2 °C). After equilibrium, solution and solid were separated by centrifugation using 0.45-μm water-filtration-membrane. The filtrate was acidified to pH < 2.5 with concentrated HNO3 for Ni analysis by using flame atomic absorption spectrometry (FAAS, Zeeman Z 2000, Hitachi, Japan). The residue retained on the filter was Ni-loaded biochar and collected for further activation and fabrication of supercapacitors. For simplicity, Ni-loaded DM and SS biochars were referred to as DM-Ni and SS-Ni, respectively.

Activation of Ni-loaded biochar

In order to promote electrochemical property of biochar, microwave (MW) oxidation were employed to activate Ni-loaded biochar. It has been reported that MW oxidation is an effective method for activation of carbon materials, and the details for activation was described previously37,38,39,40. Specifically, about 3.0 g Ni-loaded biochar (DM-Ni and SS-Ni) was put in a PTFE cube with 5.0 ml deionized water, and heated in microwave oven under 1000 W power for 30 min. The DM-Ni and SS-Ni biochars activated by microwave oxidation were referred to as DM-Ni-MW and SS-Ni-MW, respectively.

Characterization of biochar

The composition, structure, and porosity of all biochar samples were characterized by using a variety of analytical methods. Elemental composition of C, H, and N in all biochars was analyzed by using an element analyzer (Vario EL III, Elemental, Germany). The Brunauere-Emmete-Teller (BET) method was used to measure the specific surface area, micropore volume, and mesopore volume of all biochars using BET-N2 analyzer (JW-BK222, JWGB, China) (Figure S4). To explore the mechanism of Ni sorption, Ni transformation, and interaction between Ni and biochar, X-ray photoelectron spectroscopy (XPS, AXIS Ultra DLD, Shimadzu Kratos, Japan), X-ray diffraction (XRD, D/max-2200/PC, Rigaku, Japan) and Fourier transform infrared spectrometry (FTIR, IR Prestige 21 FTIR, Shimadzu, Japan) were employed. For the sample preparation, all biochars were sieved through 170-mesh to remove most of bigger-size char, which was attempted to concentrate Ni for detection.

Fabrication of biochar supercapacitors

The supercapacitors were prepared from original, Ni-loaded, and activated Ni-loaded biochars by employing a dry-mixture method50: Painting biochar slurry onto stainless steel wire, and then cut it into rectangle shape with a size of 10 mm × 5 mm × 0.3 mm. The biochar slurry was prepared by mixing with Polytetrafluoroethylene (PTFE) at a 1.5:8.5 mass ratio of PTFE to biochar. To form the electrode, the biochar slurry was pressed onto the stainless steel wire for 10 min under 6 × 105 pa force. The active electrode mass loaded on each stainless steel was about 0.5 mg for DM and 0.1 mg for SS, and the resulted thickness of an electrode was 700 μm, which contains a layer of biochar (300 μm) and the other layer of stainless steel (400 μm).

Electrochemical characterization of supercapacitors

The inorganic electrolyte used was 0.5 M KOH. The details for electrode preparation are described elsewhere47. The electrical conductivity of biochar supercapacitors was measured by using a three-probe method. Cyclic voltammetry measurement was performed by using a potentiostat48. The impedance of the fabricated supercapacitors was measured by using an impedance spectroscopy, with a frequency range of 1 Hz –10 KHz and potential amplitude of 10 mV. The specific capacitance was calculated from cyclic voltammetry characteristics and expressed in Farads per gram of biochar deposited on the stainless steel. The calculation equation is given below:

S is the integrated area of cyclic voltammetry, v is the scanning rate, and V is the scanning potential range.

Additional Information

How to cite this article: Wang, Y. et al. Converting Ni-loaded biochars into supercapacitors: Implication on the reuse of exhausted carbonaceous sorbents. Sci. Rep. 7, 41523; doi: 10.1038/srep41523 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Cao, X. & Harris, W. Properties of dairy-manure-derived biochar pertinent to its potential use in remediation. Bioresource Technology 101, 5222–5228 (2010).

Yu, X. Y., Ying, G. G. & Kookana, R. S. Reduced plant uptake of pesticides with biochar additions to soil. Chemosphere 76, 665–671 (2009).

Lu, H. et al. Relative distribution of Pb2+ sorption mechanisms by sludge-derived biochar. Water Research 46, 854–862 (2012).

Zhu, L. et al. Biochar of corn stover: Microwave-assisted pyrolysis condition induced changes in surface functional groups and characteristics. Journal of Analytical & Applied Pyrolysis 115, 149–156 (2015).

Liu, P., Yue, M. & Zhang, H. Adsorptive Performance of Ni(II) from Aqueous Solutions Using Biochar Made of Phragmites australis by Adding Ammonium Polyphosphate as Flame Retardant. 2016, 1–6 (2016).

Uchimiya, M. et al. Immobilization of Heavy Metal Ions (CuII, CdII, NiII, and PbII) by Broiler Litter-Derived Biochars in Water and Soil. Journal of Agricultural & Food Chemistry 58, 5538–5544 (2010).

Hizal, J. et al. Heavy metal removal from water by red mud and coal fly ash: an integrated adsorption–solidification/stabilization process. Desalination & Water Treatment 51, 7181–7193 (2013).

Logan, B., Cheng, S. A., Watson, V. & Estadt, G. Graphite fiber brush anodes for increased power production in air-cathode microbial fuel cells. Environmental Science & Technology 41, 3341–3346 (2007).

Frackowiak, E. & Béguin, F. Carbon materials for the electrochemical storage of energy in capacitors. Carbon 39, 937–950 (2001).

Geng, Z. et al. Facile synthesis of hierarchical porous carbon for supercapacitor with enhanced electrochemical performance. Materials Letters 182, 1–5 (2016).

Lam, L. T. & Louey, R. Development of ultra-battery for hybrid-electric vehicle applications. Journal of Power Sources 158, 1140–1148 (2006).

Wang, G., Zhang, L. & Zhang, J. A review of electrode materials for electrochemical supercapacitors. ChemInform 41, 797–828 (2012).

Choi, W., Howze, J. W. & Enjeti, P. Fuel-cell powered uninterruptible power supply systems: Design considerations. Journal of Power Sources 157, 311–317 (2006).

Yu, G., Xie, X., Pan, L., Bao, Z. & Cui, Y. Hybrid nanostructured materials for high-performance electrochemical capacitors. Nano Energy 2, 213–234 (2013).

Snook, G. A., Kao, P. & Best, A. S. Conducting-polymer-based supercapacitor devices and electrodes. Journal of Power Sources 196, 1–12 (2011).

Zhai, Y. et al. Carbon Materials for Chemical Capacitive Energy Storage. Advanced Materials 23, 4828–4850 (2011).

Zhang, K., Zhang, L. L., Zhao, X. S. & Wu, J. Graphene/polyaniline nanofiber composites as supercapacitor electrodes. Chemistry of Materials 22, 1392–1401 (2010).

Yu, D. et al. Scalable synthesis of hierarchically structured carbon nanotube-graphene fibres for capacitive energy storage. Nature Nanotechnology 9, 555–562 (2014).

Sun, S. et al. Fabrication of hollow NiCo2O4 nanoparticle/graphene composite for supercapacitor electrode. Materials Letters 182, 23–26 (2016).

Bello, A. et al. Microwave synthesis: Characterization and electrochemical properties of amorphous activated carbon-MnO2 nanocomposite electrodes. Journal of Alloys & Compounds 681, 293–300 (2016).

Su, L., Wang, Y., Sha, Y. & Hao, M. Ternary active site Co3O4/NiO/MnO2 electrode with enhanced capacitive performances. Journal of Alloys & Compounds 656, 585–589 (2016).

Liu, Y. et al. Enhanced electrochemical performance of hybrid SnO2@MOx (M=Ni, Co, Mn) core-shell nanostructures grown on flexible carbon fibers as the supercapacitor electrode materials. Journal of Materials Chemistry A 3, 3676–3682 (2015).

Samiee, M. & Jian, L. Pseudocapacitive Properties of Two-dimensional Surface Vanadia Phases Formed Spontaneously on Titania. Acs Applied Materials & Interfaces 8 (2016).

Min, J. et al. Self-Assembly of Parallelly Aligned NiO Hierarchical Nanostructures with Ultrathin Nanosheet Subunits for Electrochemical Supercapacitor Applications. Acs Applied Materials & Interfaces 8 (2015).

Hakamada, M., Abe, T. & Mabuchi, M. Electrodes from carbon nanotubes/NiO nanocomposites synthesized in modified Watts bath for supercapacitors. Journal of Power Sources 325, 670–674 (2016).

Xu, J., Li, L., He, F., Lv, R. & Yang, P. A Novel double-shelled C@NiO hollow microsphere: Synthesis and application for electrochemical capacitor. Electrochimica Acta 148, 211–219 (2014).

Wu, Q., Liu, Y. & Hu, Z. Flower-like NiO microspheres prepared by facile method as supercapacitor electrodes. Journal of Solid State Electrochemistry 17, 1711–1716 (2013).

Zhao, L. et al. Copyrolysis of Biomass with Phosphate Fertilizers To Improve Biochar Carbon Retention, Slow Nutrient Release, and Stabilize Heavy Metals in Soil. Acs Sustainable Chemistry & Engineering 21, 409–414 (2016).

Meng, J. et al. Adsorption characteristics of Cu(II) from aqueous solution onto biochar derived from swine manure. Environmental Science and Pollution Research 21, 7035–7046 (2014).

Cao, X. D., Ma, L., Gao, B. & Harris, W. Dairy-manure derived biochar effectively sorbs lead and atrazine. Environmental Science & Technology 43, 3285–3291 (2009).

Xu, X. et al. Removal of Cu, Zn, and Cd from aqueous solutions by the dairy manure-derived biochar. Environmental Science and Pollution Research 20, 358–368 (2013).

Xu, X., Cao, X. & Zhao, L. Comparison of rice husk- and dairy manure-derived biochars for simultaneously removing heavy metals from aqueous solutions: role of mineral components in biochars. Chemosphere 92, 955–961 (2013).

Wang, Z., Shen, D., Shen, F. & Li, T. Phosphate adsorption on lanthanum loaded biochar. Chemosphere 150, 1–7 (2016).

Zhao, L., Cao, X. D., Mašek, O. & Zimmerman, A. Heterogeneity of biochar properties as a function of feedstock sources and production temperatures. Journal of hazardous materials 256–257, 1–9 (2013).

Harry, I. D., Saha, B. & Cumming, I. W. Surface properties of electrochemically oxidised viscose rayon based carbon fibres. Carbon 45, 766–774 (2007).

Jafari, A. et al. Ultrafiltration of natural organic matter from water by vertically aligned carbon nanotube membrane. Journal of Environmental Health Science and Engineering 13, 1–9 (2015).

Zhang, L., Cui, L., Wang, Z. & Dong, Y. Modification of Activated Carbon Using Microwave Radiation and Its Effects on the Adsorption of SO2 . Journal of Chemical Engineering of Japan 49, 52–59 (2016).

Park, S. E. & Sujandi. Green approaches via nanocatalysis with nanoporous materials: Functionalization of mesoporous materials for single site catalysis. Current Applied Physics 8, 664–668 (2008).

Yin, S., Shen, P. K., Song, S. & Jiang, S. P. Functionalization of carbon nanotubes by an effective intermittent microwave heating-assisted HF/H2O2 treatment for electrocatalyst support of fuel cells. Electrochimica Acta 54, 6954–6958 (2009).

Badamali, S. K., Luque, R., Clark, J. H. & Breeden, S. W. Microwave assisted oxidation of a lignin model phenolic monomer using Co(salen)/SBA-15. Catalysis Communications 10, 1010–1013 (2009).

Hashisho, Z., Rood, M. J., Barot, S. & Bernhard, J. Role of functional groups on the microwave attenuation and electric resistivity of activated carbon fiber cloth. Carbon 47, 1814–1823 (2009).

Deraz, N. M., Selim, M. M. & Ramadan, M. Processing and properties of nanocrystalline Ni and NiO catalysts. Materials Chemistry & Physics 113, 269–275 (2009).

Trung, N. B. et al. Facile synthesis of three-dimensional graphene/nickel oxide nanoparticles composites for high performance supercapacitor electrodes. Chemical Engineering Journal 264, 603–609 (2015).

Meng, T., Ma, P. P., Chang, J. L., Wang, Z. H. & Ren, T. Z. The Electrochemical Capacitive Behaviors of NiO Nanoparticles. Electrochimica Acta 125, 586–592 (2014).

Singh, B., Fang, Y., Cowie, B. C. C. & Thomsen, L. NEXAFS and XPS characterisation of carbon functional groups of fresh and aged biochars. Organic Geochemistry 77, 1–10 (2014).

Wang, H. et al. Capacitance effects superimposed on redox processes in molecular-cluster batteries: a synergic route to high-capacity energy storage. Chemistry - A European Journal 19, 11235–11240 (2013).

Gupta, R. K., Dubey, M., Kharel, P., Gu, Z. & Fan, Q. H. Biochar activated by oxygen plasma for supercapacitors. Journal of Power Sources 274, 1300–1305 (2015).

Jiang, J. et al. Highly ordered macroporous woody biochar with ultra-high carbon content as supercapacitor electrodes. Electrochimica Acta 113, 481–489 (2013).

Xu, X., Cao, X., Zhao, L., Zhou, H. & Luo, Q. Interaction of organic and inorganic fractions of biochar with Pb(II) ion: further elucidation of mechanisms for Pb(II) removal by biochar. Rsc Advances 4, 44930–44937 (2014).

Jin, H., Wang, X., Gu, Z. & Polin, J. Carbon materials from high ash biochar for supercapacitor and improvement of capacitance with HNO3 surface oxidation. Journal of Power Sources 236, 285–292 (2013).

Acknowledgements

This work was supported by the National Natural Science Foundation of China: (21537002). The FAAS and XPS analysis were conducted at Instrumental Analysis Center of Shanghai Jiao Tong University.

Author information

Authors and Affiliations

Contributions

Y.W. conceived and carried out most of the experiments, analyzed the data, and wrote the manuscript. Y.Z. and L.P. conducted the electrochemical characterization experiments, X.C., X.X., L.Z. helped analyze the results. D.Y. and J.J. provided important advices. All authors discussed the results, contributed to this work, and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wang, Y., Zhang, Y., Pei, L. et al. Converting Ni-loaded biochars into supercapacitors: Implication on the reuse of exhausted carbonaceous sorbents. Sci Rep 7, 41523 (2017). https://doi.org/10.1038/srep41523

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep41523

This article is cited by

-

A sustainable bio-based char as emerging electrode material for energy storage applications

Scientific Reports (2024)

-

The Application of Biochar as Heavy Metals Adsorbent: The Preparation, Mechanism, and Perspectives

International Journal of Environmental Research (2024)

-

Goethite Enhances the Immobilization of Pb2+ by Biochar: Formation of Biochar-Goethite-Pb Ternary Complexes

Water, Air, & Soil Pollution (2023)

-

Recycling waste nickel-laden biochar to pseudo-capacitive material by hydrothermal treatment: roles of nickel-carbon interaction

Carbon Research (2022)

-

Facile method to prepare biochar–NiO nanocomposites as a promisor material for electrochemical energy storage devices

Chemical Papers (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.