Abstract

Thin film growth of iron chalcogenides by pulsed laser deposition (PLD) is still a delicate issue in terms of simultaneous control of stoichiometry, texture, substrate/film interface properties and superconducting properties. The high volatility of the constituents sharply limits optimal deposition temperatures to a narrow window and mainly challenges reproducibility for vacuum based methods. In this work we demonstrate the beneficial introduction of a semiconducting FeSe1−xTex seed layer for subsequent homoepitaxial growth of superconducting FeSe1−xTex thin film on MgO substrates. MgO is one of the most favorable substrates used in superconducting thin film applications, but the controlled growth of iron chalcogenide thin films on MgO has not yet been optimized and is the least understood. The large mismatch between the lattice constants of MgO and FeSe1−xTex of about 11% results in thin films with a mixed texture, that prevents further accurate investigations of a correlation between structural and electrical properties of FeSe1−xTex. Here we present an effective way to significantly improve epitaxial growth of superconducting FeSe1−xTex thin films with reproducible high critical temperatures (≥17 K) at reduced deposition temperatures (200 °C–320 °C) on MgO using PLD. This offers a broad scope of various applications.

Similar content being viewed by others

Introduction

The superconducting iron-chalcogenide FeSe1−xTex has been intensively studied since 20081 and is rated as a candidate for high-field applications because of its high critical current densities up to magnetic fields of 30 T2. A high sensitivity of the superconducting transition temperature, Tc, to strain was reported as well3,4. A tunable Tc, for example, may be of advantage in future applications. Among the class of Fe-based superconductors the binary FeSe, FeTe and the ternary FeSe1−xTex are structurally the most simplest compounds. They consist of stacked layers of Fe2X2 (X = chalcogen) where atoms are tetrahedrally coordinated (inverse PbO structure). Thus, it is widely believed as an easy-to-grow and easy-to-control system, however, thin film fabrication as well as the final processing of conductors still suffer serious difficulties5. The control of the stoichiometry, for example, is very challenging because of the high volatility of selenium and tellurium. A stoichiometric transfer at high deposition temperatures, TD, is not guaranteed even using pulsed laser deposition (PLD). In order to counterbalance the volatility, recently FeSe1−xTex film deposition on CaF2 at reduced substrate temperatures was investigated6.

Several previous studies were devoted to a discussion of the correlation between structural and superconducting properties7,8,9,10,11,12,13,14,15,16,17,18. The first comparative study of FeSe1−xTex film growth on different substrates by Hanawa et al. proposed MgO, CaF2 and LaAlO3 as appropriate because no oxide interlayer formation was observed12. Despite the clean interface between FeSe1−xTex film and MgO substrate, the superconducting properties, especially Tc, is lowest when compared to FeSe1−xTex film deposition on other substrates. The highest Tc for thin films of FeSe1−xTex grown by PLD reported so far reach 21 K on LaAlO313, 23 K on CaF214.

However, the substrate/film interface lacks seriously homogeneity in stoichiometry and texture, especially for CaF2 substrates and thus challenges Fe chalcogenide and Fe pnictide thin film deposition for electronic applications. Attempts to better control nucleation exist for BaFe2−xCoxAs2 films such as the introduction of a SrTiO3- (“template engineering”)19 or Fe-buffer20. In the case of iron chalcogenides a satisfactory solution is missing. Thersleff suggested the implementation of an iron buffer layer might also work for other Fe based superconductors which was shown by Iida et al.21. However, this iron buffer layer, a conductive shunt, displays ferromagnetic properties that have to be taken into account for interpretation of experimental results as well as for possible device operation. A beneficial diffusion barrier was introduced by Ichinose et al.22 for the FeSe1−xTex thin film growth on CaF2 substrates. In the case of the deposition on MgO substrates, the seed layer is clearly not a diffusion barrier, but decreases the lattice constant mismatch, enables deposition at lower temperatures and, therefore, results in better controllable growth of superconducting FeSe1−xTex thin films.

MgO is one of the most favorable substrates for a broad range of applications, has certain advantages compared to other substrates and is frequently used in thin film applications: (a) it is a cheap material with high thermal stability and chemical compatibility; (b) it has furthermore a low dielectric constant and low dielectric losses favorable for applications based on high frequencies. Finally, MgO is easily deposited biaxially textured on technologically useful templates such as Hastelloy tapes via the ion-beam assisted deposition (IBAD) process as used for high current carrying conductors. However, as already anticipated above, the direct deposition of FeSe1−xTex on MgO is characterized by diverging results and insufficient reproducibility.

In this work the beneficial implementation of a semiconducting FeSe1−xTex seed layer for subsequent homoepitaxial growth of a superconducting FeSe1−xTex film is presented. As we will demonstrate, this novel approach allows to improve control and reproducibility of structural and superconducting properties of FeSe1−xTex thin films. Unlike the iron buffer layer, the FeSe1−xTex seed layer shows no metallic, but semiconducting behavior at low temperatures without detrimental ferromagnetism. Furthermore, it may be advantageous for conductor fabrication on IBAD-MgO or other applications.

Results

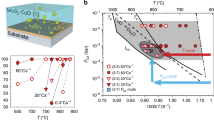

Films grown directly on MgO (100)

We first analyze FeSe1−xTex film growth on MgO (001) substrates. In order to find optimal deposition parameters, we started with the conditions reported as optimum by Bellingeri et al.13,23. In contrast to this reference we did not find superconductivity in films grown above a deposition temperature of 380 °C. In addition various out-of-plane orientations different from  were observed for TD > 430 °C (see supplement S I). Below this temperature down to 280 °C the films are c-axis textured. However, the in-plane orientation of the FeSe1−xTex grains [Fig. 1(a)] commonly show two distinguished epitaxial relationships, as X-ray diffraction (XRD) confirms. In particular for TD ≤ 300 °C: grains grown cube-on-cube, i.e. (001)[100]FeSe1−xTex ║(001)[100]MgO and grains with 45° in-plane rotated orientation (001)[110]FeSe1−xTex ║(001)[100]MgO are found. Although two films grown at 340 °C and at 300 °C show only a single epitaxial relationship, a more detailed investigation on the reproducibility performed at TD = 300 °C demonstrates a lack of controllability and a significant variance in the results [Fig. 1(b)]. In addition, for films grown below 300 °C, the mosaicity becomes significantly larger (see supplement S II).

were observed for TD > 430 °C (see supplement S I). Below this temperature down to 280 °C the films are c-axis textured. However, the in-plane orientation of the FeSe1−xTex grains [Fig. 1(a)] commonly show two distinguished epitaxial relationships, as X-ray diffraction (XRD) confirms. In particular for TD ≤ 300 °C: grains grown cube-on-cube, i.e. (001)[100]FeSe1−xTex ║(001)[100]MgO and grains with 45° in-plane rotated orientation (001)[110]FeSe1−xTex ║(001)[100]MgO are found. Although two films grown at 340 °C and at 300 °C show only a single epitaxial relationship, a more detailed investigation on the reproducibility performed at TD = 300 °C demonstrates a lack of controllability and a significant variance in the results [Fig. 1(b)]. In addition, for films grown below 300 °C, the mosaicity becomes significantly larger (see supplement S II).

In-plane texture of FeSe1−xTex thin films on MgO (001).

XRD ϕ-scans of the FeSe1−xTex (101) reflection (2θ = 28.1°, Ψ = 57.0°) (a) for different deposition temperatures. For comparison, ϕ-scan of the MgO (202) reflection. (b) For various films grown at the same temperature, TD = 300 °C. Intensities are plotted logarithmically. The *indicates the same thin film.

In order to compare the texture of different thin film samples and quantify the degree of texture admixture we introduce a texture coefficient

with I[100] and I[110] the integral intensity of the cube-on-cube grown and the 45 ° in-plane rotated grown texture component respectively. Based on this texture coefficient we classify the samples as follows. For  > 0.95 the sample is nearly or fully in-plane textured, for

> 0.95 the sample is nearly or fully in-plane textured, for  < 0.95 the thin film has a mixed texture. For τ > 0 the cube-on-cube grown texture component is predominant and for τ < 0 the 45 ° rotated component prevailed.

< 0.95 the thin film has a mixed texture. For τ > 0 the cube-on-cube grown texture component is predominant and for τ < 0 the 45 ° rotated component prevailed.

For TD > 320 °C the structural and electrical properties of the grown thin films are in good accordance to the results of Huang et al.11. As is evident from our investigation the superconducting transition temperature increases with decreasing TD and has a maximum of Tc,90 = 19.7 K at TD = 300 °C [Fig. 2(a)]. However in this regime of TD the texture is not well controllable obstructing the reproducibility [Fig. 1(b)].

By comparing structural properties and Tc,90 (supplement S III) we can classify different regimes: FeSe1−xTex films with Tc,90 comparable or above the Tc,90 of the target can be grown between TD = 260 °C and 360 °C [Fig. 2(a)]. However, epitaxial film growth is only favored above 300 °C. At 300 °C and below, a second grain orientation (45° -rotated) starts to significantly compete with the cube-on-cube texture. This competition is already observable from grain nucleation, as is confirmed by reflection high energy electron diffraction (RHEED) [Fig. 3]. For films with 0.95 <  < 0 (mixed texture) Tc,90 increases with increasing

< 0 (mixed texture) Tc,90 increases with increasing  [Fig. 2(b)]. Correspondingly, the superconducting transition width,

[Fig. 2(b)]. Correspondingly, the superconducting transition width,  , increases with increasing texture admixture (decreasing

, increases with increasing texture admixture (decreasing  ) as shown in Fig. 2(c). Notable is that in mixed textured samples the 45 ° in-plane rotated texture component always is dominant.

) as shown in Fig. 2(c). Notable is that in mixed textured samples the 45 ° in-plane rotated texture component always is dominant.

From RHEED imaging [Fig. 3] information on the structure of the thin films is obtained during film growth. We compare three films made at the same deposition conditions (TD = 300 °C).

The RHEED images of the thin film with τ = 1 show clearly visible reflections (streaks) directly from the beginning [Fig. 3(a1)] until the end [Fig. 3(a2)] of the deposition. This indicates a very fast nucleation and formation of the texture as well as a very smooth surface. From the spacing of the streaks ( ) the in-plane orientation can be determined as cube-on-cube.

) the in-plane orientation can be determined as cube-on-cube.

In Fig. 3(b1),(b2) RHEED images of the film with τ = −1 are shown. In contrast to the cube-on-cube grown thin film, even after 2500 pulses the RHEED pattern is very blurred and the streaks are hard to determine. This indicates that the nucleation during the growth of this sample took much longer time than at the deposition of the thin film with τ = 1. After 20000 pulses the streaks are more pronounced but still very blurry reflecting the high mosaicity and the broad peaks of the ϕ-scans. The distance of the streaks (1/a) confirms a 45° rotated orientation of the FeSe1−xTex thin film with respect to the substrate orientation. The absence of additional reflexes is again an evidence for a smooth surface.

The RHEED images of the highly mixed textured sample (τ = −0.1) shows streaks for both orientations, cube-on-cube grown ( ) and 45 ° rotated (

) and 45 ° rotated ( ), already at the beginning of the deposition [2500 pulses, Fig. 3(c1)]. These streaks are quite blurry but still well pronounced and become sharper with the ongoing deposition. At the end of the deposition [Fig. 3(c2)] the reflections of both orientations are very sharp and very pronounced. The slightly higher intensity of the reflections of the 45 ° rotated grains compared to the intensity of the streaks of the cube-on-cube grown grains of the sample reders the ratio of these two fractions (τ ≈ −0.1). In the RHEED pattern of this thin film there are also no additional reflexes observable.

), already at the beginning of the deposition [2500 pulses, Fig. 3(c1)]. These streaks are quite blurry but still well pronounced and become sharper with the ongoing deposition. At the end of the deposition [Fig. 3(c2)] the reflections of both orientations are very sharp and very pronounced. The slightly higher intensity of the reflections of the 45 ° rotated grains compared to the intensity of the streaks of the cube-on-cube grown grains of the sample reders the ratio of these two fractions (τ ≈ −0.1). In the RHEED pattern of this thin film there are also no additional reflexes observable.

Homoepitaxial growth of thin FeSe1−xTex films using a seed layer

In order to control epitaxial growth at low TD and simultaneously ensure high Tc,90 we propose a novel method that is based on homoepitaxial growth of FeSe1−xTex. Therefore, a thin FeSe1−xTex seed layer is deposited at 400 °C on MgO(001). This epitaxially grown (cube-on-cube) layer is semiconducting [Fig. 4]. The normal state resistance of the seed layer is ≈200 Ω at 100 K [Fig. 4(c)]. The normal state resistance of a superconducting FeSe1−xTex layer is ≈10 to 20 Ω at 100 K regardless of whether it is deposited directly on a MgO substrate or on a seed layer. The ratio of  is ≈1/20 at 100 K and decreases with decreasing temperature. Therefore, the seed layer has negligible detrimental effects on further transport investigations.

is ≈1/20 at 100 K and decreases with decreasing temperature. Therefore, the seed layer has negligible detrimental effects on further transport investigations.

FeSe1−xTex seed layer characterization: (a) XRD θ−2θ -scan of a seed layer with pure c-axis orientation out-of-plane. (b) XRD ϕ-scan of a seed layer with the epitaxial relation (001)[100]FeSe1−xTex ║(001)[100]MgO. Intensities are plotted logarithmically. (c) R vs. T of the 20 nm FeSe1−xTex seed layer grown on MgO(001).

Subsequent to the growth of the seed layer, the temperature of the substrate is reduced and another FeSe1−xTex layer is deposited. As confirmed by XRD measurements the FeSe1−xTex layers are grown with a single texture component with the epitaxial relation: (001)[100]FeSe1−xTexsc layer ║(001)[100]FeSe1−xTexseed ║(001)[100]MgO [Fig. 5]. For the full width at half maximum (FWHM, Δϕ) of the peaks of the in-plane orientation, a strong increase is observeable with decreasing TD in the sample series without seed layer. In contrast, the Δϕ of the seeded films is more or less constant until a TD of 200 °C (see supplement S II).

Seeded films furthermore have a smoother surface as atomic force microscope (AFM) images support (see supplement S IV). The root-mean-square (rms) roughness was evaluated with the WSXM software package24. The film without seed layer (TD = 300 °C, τ = 1) has a rough surface (rms: 0.88 nm) compared to a very smooth profile of the film with seed layer (TD = 240 °C, rms: 0.38 nm).

Electrical resistance measurements [Fig. 6(a)] for different TD where the highest Tc,90 was found for thin films with (TD = 240 °C) and without (TD = 300 °C) seed layer demonstrate the improved reproducibility using the seed layer. The curves of the samples without seed layer show a large spread in Tc,90 as well as of the superconducting transition width. In contrast to that, results for seeded films were fully reproducible [black and red solid symbols in fig. 6 (a)].

(a) Temperature dependence of the normalized resistance (RN = R(22 K)) for thin films without (TD = 300°C) and with (TD = 240 °C) seed layer. The *marks the samples without seed layer. (b) Comparison of Tc,90 of the samples with and without seed layer in dependence of TD. The gray shaded area indicates the deposition temperature window for high Tc,90 thin films without seed layer, the light red area indicates the TD window for high Tc,90 samples with seed layer. The horizontal dashed line indicates Tc,90 of the target, the black and red dashed lines are guides to the eye.

Improved control of Tc,90 is gained in seeded films for low deposition temperatures. The optimal deposition temperature window broadens (240 °C–320 °C) for films with high Tc,90 (≥17 K) as can be seen in Fig. 6(b). Even though the films grown at TD > 320 °C show only a single epitaxial relation to the substrate with sharp reflections in the XRD scans [Fig. 5, supplement Fig. S 2], indicating a high crystalline quality, the thin films show a low Tc,90 (<17 K) similar to the high- TD samples without seed layer, assuming an additional mechanism partially suppressing superconductivity in these films.

Conclusion

To summarize, we have overcome some challenges reported for the thin film growth of iron chalcogenides using PLD. We have demonstrated that homoepitaxial FeSe1−xTex thin film growth (i.e. the use of a FeSe1−xTex seed) with the above described procedure is a very powerful method for optimization with respect to reproducibility.

High deposition temperatures result in high mobility of the ions on the substrate surface. The resulting deposited layer thus is epitaxially grown but does not show superconductivity. When used as a seed layer, a subsequent deposition of the same target material at lower temperatures results in a homoepitaxial growth of superconducting FeSe1−xTex films. Due to the smaller lattice mismatch between FeSe1−xTex and the FeSe1−xTex seed compared to MgO and, possibly, to a much better chemical compatibility, epitaxial growth is ensured at lower temperatures.

The method presented in this article opens a significantly broader window of deposition temperatures for high- Tc,90 films and ensures good epitaxial growth. We also found, that in a wide interval (240 °C–320 °C) the deposition temperature is not crucial for the superconducting properties of the thin film. Furthermore it grants access to MgO which is one of the most favorable single crystal substrates for thin film fabrication. Because of the similar structur within the ab-plane, we predict that this semiconducting seed layer will also be adoptable for other iron based superconductors more difficult to grow using PLD. This technique is easy to implement in the film growth process and may be of advantage for a vast variety of applications.

Methods

The analyzed thin film samples in this report were prepared by PLD using a Lambda Physics LPX 305 KrF-excimer laser  in an ultra-high-vacuum-chamber with a base pressure of

in an ultra-high-vacuum-chamber with a base pressure of  . The target - substrate distance is about 40 mm. The used targets were grown by a modified Bridgman-process with a nominal stoichiometry of Fe:Se:Te = 2:1:1 resulting in a bulk Tc,90 of 11 K25,26.

. The target - substrate distance is about 40 mm. The used targets were grown by a modified Bridgman-process with a nominal stoichiometry of Fe:Se:Te = 2:1:1 resulting in a bulk Tc,90 of 11 K25,26.

For the direct (unseeded) preparation of the samples the target material was deposited on the substrate at deposition temperatures, TD, from 260 °C to 530 °C at a laser repetition rate of 7 Hz. For the seeded FeSe1−xTex films, a FeSe1−xTex layer with a thickness of about 20 nm was deposited at 400 °C with a laser repetition rate of 10 Hz. The as-grown film was cooled to the deposition temperature in the range of 200 °C–340 °C for a subsequent homoepitaxial FeSe1−xTex layer, deposited at a laser repetition rate of 7 Hz.

The superconducting films have a thickness of about 120 nm ± 30 nm confirmed by film cross-sections cut by a focused ion beam (Ga ions) and imaged by scanning electron microscopy. The film growth was monitored in-situ by RHEED evaluated with the KSA400 software.

XRD θ−2θ-scans were measured in a Philips X’Pert with Cu-Kα or Co-Kα-radiation. The ϕ-scans for the (101) peak of FeSe1−xTex were measured in a Philips X’Pert PW3040 equipped with a four circle goniometer with Cu-Kα-radiation in Bragg-Brentano-geometry.

R(T) measurements were made in a Quantum Design Physical Properties Measurement System (PPMS). Tc,90 describes the temperature where the resistance reached 90% of the normal state resistance above transition.

Surface morphology was examined with an Digital Instruments AFM Dimension 3100 with a Nanoscope IIIA controller in tapping mode.

Additional Information

How to cite this article: Molatta, S. et al. Interface control by homoepitaxial growth in pulsed laser deposited iron chalcogenide thin films. Sci. Rep. 5, 16334; doi: 10.1038/srep16334 (2015).

References

Hsu, F.-C. et al. Superconductivity in the PbO-type structure a-FeSe. P. Natl. Acad. Sci. USA 105, 14262–14264 (2008).

Si, W. et al. Iron-chalcogenide FeSe0.5Te0.5 coated superconducting tapes for high field applications. Appl. Phys. Lett. 98, 262509 (2011).

Gooch, M., Lorenz, B., Huang, S. X., Chien, C. L. & Chu, C. Pressure effects on strained FeSe0.5Te0.5 thin films. J. Appl. Phys. 111, 112610 (2012).

Horigane, K., Takeshita, N., Lee, C.-H., Hiraka, H. & Yamada, K. First Investigation of Pressure Effects on Transition from Superconductive to Metallic Phase in FeSe0.5Te0.5 . J. Phys. Soc. Jpn. 78, 063705 (2009).

Haindl, S. et al. Thin film growth of Fe-based superconductors: from fundamental properties to functional devices. A comparative review. Rep. Prog. Phys. 77, 046502 (2014).

Yuan, P. et al. High performance FeSe0.5 Te0.5 thin films grown at low temperature by pulsed laser deposition. Supercond. Sci. Tech. 28, 065009 (2015).

Molatta, S. Einfluss dynamischer Verspannung auf supraleitende Eigenschaften in FeSe1−xTex Schichten. Diploma thesis, TU Dresden (2014).

Tsukada, I. et al. Epitaxial Growth of FeSe0.5Te0.5 Thin Films on CaF2 Substrates with High Critical Current Density. Appl. Phys. Express 4, 053101 (2011).

Yeh, K.-W. et al. Tellurium substitution effect on superconductivity of the a-phase iron selenide. Europhys. Lett. 84, 37002 (2008).

Imai, Y. et al. Systematic Comparison of Eight Substrates in the Growth of FeSe0.5Te0.5 Superconducting Thin Films. Appl. Phys. Express 3, 043102 (2010).

Huang, S. X., Chien, C. L., Thampy, V. & Broholm, C. Control of Tetrahedral Coordination and Superconductivity in FeSe0.5Te0.5 Thin Films. Phys. Rev. Lett. 104, 217002 (2010).

Hanawa, M. et al. Empirical Selection Rule of Substrate Materials for Iron Chalcogenide Superconducting Thin Films. Jpn. J. Appl. Phys. 51, 010104 (2012).

Bellingeri, E. et al. Tc = 21 K in epitaxial FeSe0.5Te0.5 thin films with biaxial compressive strain. Appl. Phys. Lett. 96, 102512 (2010).

Imai, Y., Sawada, Y., Nabeshima, F. & Maeda, A. Suppression of phase separation and giant enhancement of superconducting transition temperature in FeSe1−xTex thin films. P. Natl. Acad. Sci. USA 112, 1937–1940 (2015).

Bellingeri, E. et al. Tuning of the superconducting properties of FeSe0.5Te0.5 thin films through the substrate effect. Supercond. Sci. Tech. 25, 084022 (2012).

Tsurkan, V. et al. Physical properties of FeSe0.5Te0.5 single crystals grown under different conditions. Eur. Phys. J. B 79, 289–299 (2011).

Kawale, S. et al. Comparison of Superconducting Prop- erties of FeSe0.5Te0.5 Thin Films Grown on Different Substrates. IEEE T. Appl. Supercon. 23, 7500704 (2013).

Horide, T., Sanyoushi, M., Ichinose, A. & Matsumoto, K. Influence of strain and composition on Tc in FeSe1−xTex films. J. Appl. Phys. 116, 213906 (2014).

Lee, S. et al. Template engineering of Co-doped BaFe2As2 single-crystal thin films. Nat. Mater. 9, 397–402 (2010).

Thersleff, T. et al. Coherent interfacial bonding on the FeAs tetrahedron in Fe/Ba(Fe1−xCox)2As2 bilayers. Appl. Phys. Lett. 97, 022506 (2010).

Iida, K. et al. Generic Fe buffer layers for Fe-based su- perconductors: Epitaxial FeSe1−xTex thin films. Appl. Phys. Lett. 99, 202503 (2011).

Ichinose, A. et al. Microscopic analysis of the chemical reaction between Fe(Te, Se) thin films and underlying CaF2 . Supercond. Sci. Tech. 26, 075002 (2013).

Bellingeri, E. et al. High quality epitaxial FeSe0.5Te0.5 thin films grown on SrTiO3 substrates by pulsed laser deposition. Supercond. Sci. Tech. 22, 105007 (2009).

Horcas, I. et al. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. In- strum. 78, 013705 (2007).

Schulze, M. Synthese und Charakterisierung von supraleitenden Proben im System Eisen-Selen-Tellur. Diploma thesis, TU Dresden (2010).

Prokeš, K. et al. Structural Inhomogeneities in FeTe0.6Se0.4: Relation to Superconductivity. accepted in J. Cryst. Growth (2015).

Acknowledgements

S.M. thanks L. Schultz for supervision, J. Hänisch, K. Iida, F. Kurth, S. Oswald and S. Kaschube for fruitful discussions, M. Kühnel and J. Scheiter for technical support. S.M. acknowledges financial funding from DFG-GRK 1621, S.H. from DFG (project HA5934/3-2) and SW from DFG in project WU595/3-1 (Emmy-Noether project) and the SPP (BU887/15-1) and by Bundesministerium für Bildung und Forschung (BMBF) in the ERA.Net RUS program (project #245 FeSuCo).

Author information

Authors and Affiliations

Contributions

S.M. and S.T. have grown the films and conducted the experiments, S.M., S.H., S.T. and R.H. analyzed the results, S.M. and S.H. have written the manuscript, M.S. and S.W. provided the target material and R.H., S.T. and S.M. designed the experiment. All authors have discussed the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Molatta, S., Haindl, S., Trommler, S. et al. Interface control by homoepitaxial growth in pulsed laser deposited iron chalcogenide thin films. Sci Rep 5, 16334 (2015). https://doi.org/10.1038/srep16334

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep16334

This article is cited by

-

High-performance Fe(Se,Te) films on chemical CeO2-based buffer layers

Scientific Reports (2023)

-

Enhancing the PLD Films Quality Through an In Situ Method

Journal of Inorganic and Organometallic Polymers and Materials (2022)

-

Origin of the emergence of higher T c than bulk in iron chalcogenide thin films

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.