Abstract

Heteroepitaxial oxide-based nanocomposite films possessing a variety of functional properties have attracted tremendous research interest. Here, self-assembled vertically aligned nanocomposite (Pr0.5Ba0.5MnO3)1-x:(CeO2)x (x = 0.2 and 0.5) films have been successfully grown on single-crystalline (001) (La,Sr)(Al,Ta)O3 substrates by the pulsed laser deposition technique. Self-assembling behavior of the nanocomposite films and atomic-scale interface structure between Pr0.5Ba0.5MnO3 matrix and CeO2 nanopillars have been investigated by advanced electron microscopy techniques. Two different orientation relationships, (001)[100]Pr0.5Ba0.5MnO3//(001)[1-10]CeO2 and (001)[100]Pr0.5Ba0.5MnO3//(110)[1-10]CeO2, form between Pr0.5Ba0.5MnO3 and CeO2 in the (Pr0.5Ba0.5MnO3)0.8:(CeO2)0.2 film along the film growth direction, which is essentially different from vertically aligned nanocomposite (Pr0.5Ba0.5MnO3)0.5:(CeO2)0.5 films having only (001)[100]Pr0.5Ba0.5MnO3//(001)[1-10]CeO2 orientation relationship. Both coherent and semi-coherent Pr0.5Ba0.5MnO3/CeO2 interface appear in the films. In contrast to semi-coherent interface with regular distribution of interfacial dislocations, interface reconstruction occurs at the coherent Pr0.5Ba0.5MnO3/CeO2 interface. Our findings indicate that epitaxial strain imposed by the concentration of CeO2 in the nanocomposite films affects the self-assembling behavior of the vertically aligned nanocomposite (Pr0.5Ba0.5MnO3)1-x:(CeO2)x films.

Similar content being viewed by others

Introduction

Complex oxide-based nanocomposite films have attracted considerable research interest due to a variety of functional properties, such as multiferroicity1, superconductivity2,3,4, ferromagnetism5, and ferroelectricity6. The nanocomposite films can be achieved in laminated structure6,7,8, vertical nanocomposite architecture1,2,3,5,9, and three-dimensional framework constructed by interlayering the both4,10. Simultaneous phase separation and strain-drived self-assembly processes were first shown to result in vertically aligned nanocomposite (VAN) films related to multiferroic applications and high-temperature superconductor applications1,2,3,4. Importantly, novel and unprecedented properties could occur in the resultant VAN films, which are not present in the individual phases of the VAN films, e.g., multiferroic in the BaTiO3-CoFe2O4 nanostructures1 and enhanced flux-pinning in YBa2Cu3O7-δ films incorporating self-aligned BaZrO3 nanodots and nanorods2,3,4. Moreover, it was found that the self-assembling behavior and the physical properties of the VAN films can be influenced by the phase composition9,11 and the film growth parameters (e.g., growth temperature12,13, deposition frequency14, and substrate termination15). In fact, the molar ratio (x) of two immiscible phases influences the epitaxial strain of the nanocomposite films on the substrates. For example, the molar ratio of MgO in the nanocomposite (LiFe5O8)1-x:(MgO)x films can tune the structure of LiFe5O8 nanopillar arrays prepared on fluorophlogopite substrates. As a result, the (LiFe5O8)1-x:(MgO)x VAN films exhibit a higher saturation magnetization (Ms), small nonzero coercibity and nonzero remanence compared with the pure LiFe5O8 film11. In addition, the changing of the molar ratio of MgO in the (La0.7Ca0.3MnO3)1-x:(MgO)x nanocomposite films on MgO (001) substrates can cause phase transition of La0.7Ca0.3MnO3 from an orthorhombic (0 < x ≤ 0.1) to a rhombohedral structure (0.33 ≤ x ≤ 0.8)9.

Additionally, it is believed that two-phase boundaries in the VAN film are of great importance, which provide large vertical interfacial areas and thus induce the coupling effect between the two immiscible phases16,17. From this aspect, the VAN films possess superior properties over the single-phase films, e.g., low dielectric loss in VAN BiFeO3:Sm2O3 films16. To better understand the performance of the VAN films, it is necessary to explore the self-assembling behavior of the nanocomposite films and interface structure between two immiscible phases at the atomic scale.

The perovskite-type manganites (e.g., Ln1-xBaxMnO3 (Ln = La and Pr)) exhibit a wealth of fascinating physical properties and potential practical applications18,19. In particular, half-doped Pr0.5Ba0.5MnO3 (PBMO) shows fantastic magnetic behaviors and excellent mixed ionic/electronic conductivity, which enable it potential applications in spintronic devices and solid oxide fuel cell20,21. Recently, the (PBMO)1-x:(CeO2)x nanocomposite films were successfully fabricated, and enhanced magnetic properties (e.g., magnetoresistance and magnetization) were obtained in VAN (PBMO)1-x:(CeO2)x films compared with the pure PBMO films22,23. Furthermore, the microstructure (e.g., lattice mismatch and crystallographic orientation relationship (OR) between PBMO and CeO2) of semi-coherent PBMO/CeO2 interface in the (PBMO)0.65:(CeO2)0.35 film was presented23. Nevertheless, atomic-scale structure and chemical composition of the PBMO/CeO2 interface, and strain relaxation behavior of the (PBMO)1-x:(CeO2)x films on (001)-oriented (La,Sr)(Al,Ta)O3 (LSAT) substrates have not been investigated. In addition, the effect of epitaxial strain on the self-assembling growth of the nanocomposite films remains unclear in the (PBMO)1-x:(CeO2)x/LSAT heterosystem.

It is known that the self-assembling growth of VAN films can be accomplished by tuning the epitaxial strain imposed by changing the molar ratio (x) of two immiscible phases in the VAN films9,11. In the present contribution, to deeply understand the self-assembling behavior and the related structure-property in the (PBMO)1-x:(CeO2)x nanocomposite films, the (PBMO)1-x:(CeO2)x (x = 0.2 and 0.5) films have been prepared on LSAT (001) substrates. We focus our research interest on film-growth behaviors and heterointerface structure investigated by advanced electron microscopy techniques.

Results and Discussion

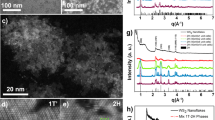

A low-magnification bright-field (BF) TEM image of (PBMO)0.5:(CeO2)0.5 film and (PBMO)0.8:(CeO2)0.2 film on LSAT substrates is displayed in Figs. 1a,b, respectively, viewed along the [100] LSAT zone axis. The thickness of the films is about 130 nm and the film-substrate interface is sharp, as indicated by a horizontal white arrow. No misfit dislocations are observed at the interface of the nanocomposite films on the LSAT substrates. Moreover, CeO2 nanopillars embedded in PBMO matrix with a width of about 10–15 nm can be recognized, as indicated by a vertical yellow arrow in Figs. 1a,b. It is noted that narrow CeO2 nanopillars with straight sidewalls only exist in the (PBMO)0.8:(CeO2)0.2 film, as demonstrated by a vertical red arrow in Fig. 1b. In most cases, the CeO2 nanopillars penetrate the whole film.

A low magnification BF-TEM image of (PBMO)0.5:(CeO2)0.5 film (a) and (PBMO)0.8:(CeO2)0.2 film (b) on LSAT substrate, recorded along the [100] LSAT zone axis. The corresponding SAED pattern of the nanocomposite film is inserted. A horizontal white arrow in (a,b) indicates the film-substrate interface. CeO2 nanopillars embedded in PBMO matrix with different dimensions are indicated by a vertical yellow arrow and a vertical red arrow, respectively. In the inserted SAED pattern, the diffraction spots from PBMO matrix are indicated by a green open square. Two sets of diffraction spots from CeO2 nanopillars are denoted by a vertical yellow arrow and a horizontal red arrow, respectively. (c) A high-resolution HAADF-STEM image of (PBMO)0.8:(CeO2)0.2 film showing two types of ORs between CeO2 and PBMO, viewed along the [100] PBMO zone axis. The interfaces is indicated by yellow dashed lines and red dashed lines.

In Figs. 1a,b, the inserted SAED pattern taken from the nanocomposite film show the intense and sharp diffraction spots, indicating high-quality epitaxy of the film. The diffraction spots from PBMO matrix can be indexed, as shown by a green open square. The diffraction spots from CeO2 nanopillars are visible, as indicated by a vertical yellow arrow. In comparison, one additional set of diffraction spots of CeO2 nanopillars appears in the SAED pattern of the (PBMO)0.8:(CeO2)0.2 film, as indicated by a horizontal red arrow in the insert in Fig. 1b. On the basis of the SAED patterns, both (PBMO)0.5:(CeO2)0.5 and (PBMO)0.8:(CeO2)0.2 film have an OR of (001)[100]PBMO//(001)[1\(\bar{1}\)0]CeO2 (OR-I) between CeO2 and PBMO. Apart from the OR-I, the OR of (001)[100]PBMO//(110)[1\(\bar{1}\)0]CeO2 (OR-II) between CeO2 and PBMO exists in the (PBMO)0.8:(CeO2)0.2 film. In fact, there is a rotation of 90° between OR-I and OR-II (See Fig. S1 of the Supplemental Material).

Fig. 1c displays a typical high-resolution HAADF-STEM image viewed along the [100] PBMO zone axis, which shows the existence of two types of OR between CeO2 and PBMO in the nanocomposite films. It is known that under the HAADF imaging conditions, the atomic columns appear dots in a dark background, and the intensity (I) of bright dots is roughly proportional to the square of the atomic number (Z) of the atom column24. The CeO2 nanopillars have a bright contrast in the PBMO matrix. It is found that CeO2/PBMO interface can be either semi-coherent or coherent along the film-growth direction, as shown by yellow dashed lines and by red dashed lines, respectively. Interfacial dislocations are visible at the semi-coherent interface, as demonstrated by a horizontal yellow arrow.

Fig. 2a shows a high-resolution HAADF-STEM image of the (PBMO)0.5:(CeO2)0.5 nanocomposite film on the LSAT substrate, viewed along the [100] LSAT zone axis. A horizontal white arrow denotes the film-substrate interface. It is found that the coherent growth of PBMO film on LSAT substrate occurs, and the relatively small lattice mismatch (0.7%) between PBMO (aPBMO = 0.3895 nm25) and LSAT (aLSAT = 0.3868 nm26) is accommodated by the lattice elastic energy. In addition, the CeO2 nanopillar epitaxially grows directly on the LSAT substrate with (001)[1\(\bar{1}\)0]CeO2//(001)[100]LSAT, which may be due to the small lattice mismatch (−1.1%) calculated by Δf = \(\frac{\sqrt{2}{a}_{{\rm{CeO}}2}-2{a}_{{\rm{LSAT}}}}{2{a}_{{\rm{LSAT}}}}\), where aCeO2 and aLSAT are the lattice parameter of CeO2 (aCeO2 = 0.5411 nm27) and LSAT, respectively. In contrast, the PBMO/CeO2 interface is semi-coherent and interfacial dislocations are observed, as demonstrated by horizontal red arrows.

(a) An atomic-resolution HAADF-STEM image of the nanocomposite film on LSAT substrate, viewed along [100] LSAT zone axis. A horizontal white arrow indicates the film-substrate interface. A white dashed curved line shows the PBMO/CeO2 interface. Interfacial dislocations at the interface are demonstrated by horizontal red arrows. A typical high-resolution HAADF-STEM image of the semi-coherent PBMO/CeO2 interface (b) and the corresponding EDS maps of Mn-Kα1 (c), Ba-Lα1 (d), Ce-Lα1 (e) and Pr-Lα1 (f), respectively. A vertical red arrow in (b) denotes the interface.

The atom-scale structure of the semi-coherent PBMO/CeO2 interface has been investigated by EDS element mapping28. Fig. 2b is a typical high-resolution HAADF-STEM image of the PBMO/CeO2 interface. The corresponding EDS maps of Mn, Ba, Ce and Pr are shown in Figs. 2c−f, respectively. In the PBMO matrix, Pr and Ba cations site at the same atomic columns, indicating that A-site disordered PBMO is obtained. According to the EDS measurements, no elemental segregation at the PBMO/CeO2 interface. In the CeO2 nanopillar, Pr and Ce site at the same atomic columns, implying that Pr3+ ions dope into CeO2 and partially replace Ce4+ ions. The substitution of Pr3+ in Ce4+ can result in the formation of (Ce,Pr)O2-δ, and oxygen vacancies generated in the (Ce,Pr)O2-δ phase retain the charge balance. The reduced ratio of Pr/Ba in PBMO and oxygen vacancies in the (Ce,Pr)O2-δ can influence the transport and magnetic properties of the nanocomposite films29,30.

Apart from the OR-I between CeO2 and PBMO, CeO2 nanopillars with the OR-II in PBMO matrix exist in the (PBMO)0.8:(CeO2)0.2 nanocomposite film. Fig. 3a shows a typical high-resolution HAADF-STEM image of the nanocomposite (PBMO)0.8:(CeO2)0.2 film on the LSAT substrate with the OR-II, viewed along the [100] LSAT zone axis. The PBMO/CeO2 interface is denoted by a red curved dashed line. In contrast to the coherent PBMO/CeO2 interface along the film-growth direction, the lateral PBMO/CeO2 interface is semi-coherent. Interfacial dislocations are observed, as indicated by vertical yellow arrows. It should be noted that CeO2 nanopillars do not grow directly on LSAT substrate. A large lattice mismatch between CeO2 and LSAT may result in the difficulty in nucleating CeO2 nanopillars on LSAT substrate with (110)[1\(\bar{1}\)0]CeO2//(001)[100]LSAT.

(a) A typical HAADF-STEM image of CeO2 nanopillar embedded in PBMO matrix with the OR-II on LSAT substrate, viewed along [100] LSAT zone axis. A horizontal white arrow indicates the film-substrate interface. A red dashed curved line denotes the PBMO/CeO2 interface. Interfacial dislocations are indicated by vertical yellow arrows. An atomic-resolution HAADF-STEM (b) and the corresponding ABF (c) image of the coherent PBMO/CeO2 interface. Interfacial CeO2 and MnO2 layer is indicated by a vertical yellow and a vertical red arrow, respectively. The oxygen column in MnO2 layer is shown by a horizontal purple arrow in (c). A typical HAADF-STEM image of coherent PBMO/CeO2 interface (d) and the corresponding EDS maps of Mn-Kα1 (e), Ba-Lα1 (f), Ce-Lα1 (g) and Pr-Lα1 (h), respectively. (i,j) The corresponding EELS maps of Ce-M4,5 edge and Pr-M4,5 edge, respectively. A vertical green, purple, red and yellow arrow indicates the PrO, BaO, MnO2 and Ce/Pr atom column at the interface, respectively.

Atomic-resolution HAADF- and ABF-STEM image of the coherent PBMO/CeO2 interface is displayed in Figs. 3b,c, respectively, recorded in the same region simultaneously and viewed along the [100] PBMO zone axis. Under the HAADF- and ABF-STEM imaging conditions, different atomic columns including cations and oxygen can be identified at the interface24,31. The interfacial CeO2 layer is indicated by a vertical yellow arrow and the terminated layer of the PMBO film is indicated by a vertical red arrow. The contrast of oxygen atoms is visible in the terminated layer in Fig. 3c, as denoted by a horizontal purple arrow. Based on the HAADF- and ABF-STEM observations, the PBMO film terminates at the MnO2 layer at the PBMO/CeO2 interface.

The structure of the coherent PBMO/CeO2 interface has been further examined by atomic-resolved EDS and EELS mapping32,33. Figs. 3d−h show a typical coherent PBMO/CeO2 interface and the corresponding EDS map of element Mn, Ba, Ce and Pr, respectively. The EDS measurement in Figs. 3g,h indicates that Pr and Ce ions occupy the same site in CeO2, which is further confirmed by EELS measurement, as shown in the EELS maps of Ce-M4,5 and Pr-M4,5 in Figs. 3i,j. At the interface, CeO2 atomic plane faces MnO2 atomic plane of PBMO. The atomic plane indicated by vertical purple arrows and vertical green arrows in Fig. 3d is BaO and PrO, respectively, which have different intensities from other (Pr0.5Ba0.5)O planes in PBMO as shown in Figs. 3f,h,j. In other words, interface reconstruction occurs at the PBMO/CeO2 interface, resulting in the formation of a single unit-cell thickness of A-site ordered PBMO structure. It is worth mentioning that the distortion of MnO6 octahedra is different between A-site ordered and disordered PBMO34. In addition, the A-site ordered PBMO occurs a ferromagnetic-paramagnetic transition at about 320 K, while A-site disordered PBMO has TC ≈ 140 K25.

It is worth noting that in our work the VAN (PBMO)1-x:(CeO2)x (x = 0.2 and 0.5) films coherently grow on the LSAT substrates. For the CeO2 nanopillars embedded in the PBMO matrix with the OR-I, with the change of the molar ratio (x) of CeO2 to PBMO, the strain of the VAN (PBMO)1-x:(CeO2)x films can be estimated by Δf = \(\frac{(1-x){a}_{{\rm{PBMO}}}+x\frac{{a}_{{\rm{CeO}}2}}{\sqrt{2}}}{{a}_{{\rm{LSAT}}}}-1\), as shown by a red line in Fig. 4. It can be seen that the strain between the VAN (PBMO)1-x:(CeO2)x films and the LAST substrates is close to zero while the molar ratio of CeO2 is about 0.39. In addition, the epitaxial strain of VAN (PBMO)0.5:(CeO2)0.5 film and VAN (PBMO)0.8:(CeO2)0.2 has an opposite sign. With the reduction of the molar ratio of CeO2 to PBMO, the compressive strain of the nanocomposite films increases, as indicated by a horizontal green arrow.

In-plane lattice mismatch between nanocomposite (PBMO)1-x:(CeO2)x film and LSAT substrate as a function of the molar ratio (x) of CeO2 to PBMO in the film for the existence of only OR-I between CeO2 and PBMO in the nanocomposite film. The gradual increase of compressive (or tensile) strain is indicated by a horizontal green (or orange) arrow.

In the VAN (PBMO)0.8:(CeO2)0.2 film, CeO2 nanopillars do appear in the PBMO matrix with either OR-I or OR-II. For CeO2 embedded in PBMO matrix with the OR-II, the CeO2 nanopillars have few CeO2 unit cells in width. Compared with the A-site disordered PBMO, the A-site ordered PBMO at the PBMO/CeO2 interface leads to the reduction of lattice parameter (1.8%)25, which can partially release the epitaxial strain of the VAN (PBMO)0.8:(CeO2)0.2 film35. Additionally, semi-coherent PBMO/CeO2 interface with interfacial dislocations appears along the in-plane direction, as demonstrated in Fig. 3a, which can also relax the compressive strain of the VAN (PBMO)0.8:(CeO2)0.2 film on the LSAT substrate. In contrast, the VAN (PBMO)0.5:(CeO2)0.5 film undertakes the tensile strain on the LSAT substrate, as shown in Fig. 4. In the case of the appearance of CeO2 nanopillars with the OR-II in PBMO matrix, the tensile strain of the nanocomposite film would be further increased, which is in agreement with the experimental observations that no OR-II occurs between CeO2 and PBMO in the VAN (PBMO)0.5:(CeO2)0.5 film.

Compare with A-site disordered PBMO, A-site ordered PBMO has a relative low Ms and high magnetoresistance at low temperatures25. Nevertheless, considering a very small volume fraction (~20%) of the A-site ordered PBMO in the (PBMO)0.8:(CeO2)0.2 film, the magnetic properties (e.g., Ms) of the (PBMO)1-x:(CeO2)x films on the LSAT substrates would be mainly affected by the epitaxial strain imposed by the CeO2 nanopillars within the films23. In other words, the volume fraction of CeO2 and the crystallographic OR between CeO2 and PBMO in the VAN films change the strain state and the magnetic properties of the PBMO film22,23. In addition, it was found that the electrical resistivity of the VAN (PBMO)0.5:(CeO2)0.5 film is over 4 times larger than that of the pure PBMO film in our previous work22. It is believed that the vertical semi-coherent phase boundary can increase the difficulty of charge carriers transport, and result in an increase of resistivity of the film system9,36. The appearance of A-site ordered PBMO at the coherent PBMO/CeO2 interface could lead to a decrease of electrical resistivity since A-site ordered PBMO has two orders lower electrical resistivity than A-site disordered PBMO25. But, the A-site ordered PBMO in the (PBMO)0.8:(CeO2)0.2 film has a very small volume fraction, which could not strongly affect the resistivity of the VAN (PBMO)0.8:(CeO2)0.2 film23. Importantly, our work demonstrates that the epitaxial strain can lead to the formation of A-site ordered PBMO at the heterointerface, which provides a strategy to fabricate A-site ordered PBMO thin films on the substrates (e.g., CeO2/YSZ buffered Si substrates37,38) by using strain engineering in the heterosystems.

In summary, the VAN (PBMO)1-x:(CeO2)x films prepared on (001)-oriented LSAT substrates have been systematically studied by advanced electron microscopy. While the VAN film under tensile strain, an OR of (001)[100]PBMO//(001)[1\(\bar{1}\)0]CeO2 occurs between CeO2 and PBMO in the film. In contrast, the VAN film under compressive strain contains two types of OR, (001)[100]PBMO//(001)[1\(\bar{1}\)0]CeO2 and (001)[100]PBMO//(110)[1\(\bar{1}\)0]CeO2 between CeO2 and PBMO. In addition, interface reconstruction occurs at the coherent PBMO/CeO2 interface, resulting in the formation of a single unit-cell-thick layer of A-site ordered PBMO at the interface. Our results demonstrate that self-assembling behavior of the nanocomposite (PBMO)1-x:(CeO2)x films can be modulated by epitaxial strain.

Material and Methods

Thin film preparation

The composite targets of (PBMO)1-x:(CeO2)x (x = 0.2 and 0.5) were sintered by a standard ceramic sintering method. The (PBMO)1-x:(CeO2)x films were fabricated on (001) LSAT single-crystalline substrates by a KrF (wavelength λ = 248 nm) excimer pulsed laser deposition system with laser energy density of 2.0 J cm−2 at 3 Hz. During the film deposition, oxygen pressure is 250 mTorr and substrate temperature is 800 °C.

Thin film characterization

Cross-sectional transmission and scanning transmission electron microscopy (TEM/STEM) specimens were prepared by focused ion beam (FIB) milling (FEI Helios NanoLab 600i)39. Diffraction contrast imaging, selected-area electron diffraction (SAED), high-angle annular dark-field (HAADF) and annular bright-field (ABF) imaging, energy dispersive X-ray spectroscopy (EDS) mapping and electron energy-loss spectroscopy (EELS) mapping were carried out on a probe aberration-corrected JEOL JEM-ARM200F equipped with an Oxford X-MaxN 100TLE spectrometer and a Gatan Enfina spectrometer, operated at 200 kV. In STEM mode, a probe size of 0.1 nm at semi-convergence angle of 22 mrad was used. HAADF and ABF detectors covered angular ranges of 90–176 and 11–22 mrad, respectively. EELS collection angle was 72 mrad and energy resolution was 1.2 eV at the dispersion of 0.3 eV/pixel.

Data availability

All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials. Additional data related to this paper may be requested from the authors.

References

Zheng, H. et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 303, 661–663 (2004).

Goyal, A. et al. Irradiation-free, columnar defects comprised of self-assembled nanodots and nanorods resulting in strongly enhanced flux-pinning in YBa2Cu3O7-δ films. Supercond. Sci. Technol. 18, 1533–1538 (2005).

Kang, S. et al. High-performance high-Tc superconducting wires. Science 311, 1911–1914 (2006).

Wee, S. et al. Self-assembly of nanostructured, complex, multication films via spontaneous phase separation and strain-driven ordering. Adv. Funct. Mater. 23, 1912–1918 (2013).

Mohaddes-Ardabili, L. et al. Self-assembled single-crystal ferromagnetic iron nanowires formd by decomposition. Nat. Mater. 3, 533–538 (2004).

Schlom, D. G. et al. Oxide nano-engineering using MBE. Mater. Sci. Eng., B 87, 282–291 (2001).

Yadav, A. K. et al. Observation of polar vortices in oxide superlattices. Nature 530, 198–201 (2016).

Lu, L. et al. Topological defects with distinct dipole configurations in PbTiO3/SrTiO3 multilayer films. Phys. Rev. Lett. 120, 177601 (2018).

Moshnyaga, V. et al. Structural phase transition at the percolation threshold in epitaxial (La0.7Ca0.3MnO3)1-x: (MgO)x nanocomposite films. Nat. Mater. 2, 247–252 (2003).

Chen, A. et al. Strain enhanced functionality in a bottom-up approach enabled 3D super-nanocomposites. Adv. Funct. Mater. 29, 1900442 (2019).

Lan, G. et al. Flexible Lithium Ferrite Nanopillar Arrays for Bending Stable Microwave Magnetism. ACS Appl. Mater. Interfaces 10, 39422–39427 (2018).

Jing, H.-M. et al. Microstructure and electrical conductivity of (Y,Sr)CoO3-δ thin films tuned by the film-growth temperature. J. Alloy. Compd. 714, 181–185 (2017).

Zheng, H., Chu, Y.-H., Ramesh, R. & Salamanca-Riba, L. Heteroepitaxially enhanced magnetic anisotropy in BaTiO3-CoFe2O4 nanostructures. Appl. Phys. Lett. 90, 113113 (2007).

Chen, A. et al. Microstructure, magnetic, and low-field magnetotransport properties of self-assembled (La0.7Sr0.3MnO3)0.5:(CeO2)0.5 vertically aligned nanocomposite thin films. Nanotechnology 22, 315712 (2011).

Fan, M. et al. Self-organized epitaxial vertically aligned nanocomposites with long-range ordering enabled by substrate nanotemplating. Adv. Mater. 29, 1606861 (2017).

Yang, H. et al. Vertical interface effect on the physical properties of self-assembled nanocomposite epitaxial films. Adv. Mater. 21, 3794–3798 (2009).

MacManus-Driscoll, J. L. Self-assembled heteroepitaxial oxide nanocomposite thin film structures: designing interface-induced functionality in electronic materials. Adv. Funct. Mater. 20, 2035–2045 (2010).

Barnabé, A., Millange, F., Maignan, A., Hervieu, M. & Raveau, B. Barium-based manganites Ln1-xBaxMnO3 with Ln = {Pr, La}: phase transitions and magnetoresistance properties. Chem. Mater. 10, 252–259 (1998).

Ueda, Y. & Nakajima, T. Novel structures and electromagnetic properties of the A-site-ordered/disordered manganites RBaMn2O6/R0.5Ba0.5MnO3 (R = Y and rare earth elements). J. Phys.-Condes. Matter 16, S573–S583 (2004).

Autret, C. et al. Magnetization steps in a noncharge-ordered manganite, Pr0.5Ba0.5MnO3. Appl. Phys. Lett. 82, 4746–4748 (2003).

Sengodan, S. et al. Layered oxygen-deficient double perovskite as an efficient and stable anode for direct hydrocarbon solid oxide fuel cells. Nat. Mater. 14, 205–209 (2015).

Shen, L. et al. Enhanced magnetic properties in epitaxial self-assembled vertically aligned nanocomposite (Pr0.5Ba0.5MnO3)0.5:(CeO2)0.5 thin films. J. Mater. Chem. C 4, 10955–10961 (2016).

Cheng, S. et al. Structural transition induced enhancement of magnetization and magnetoresistance in epitaxial (Pr0.5Ba0.5MnO3)1-x:(CeO2)x vertical aligned thin films. Cryst. Eng. Comm. 20, 5017–5024 (2018).

Mi, S. B., Jia, C. L., Vrejoiu, I., Alexe, M. & Hesse, D. Atomic-scale structure and properties of epitaxial PbZr0.2Ti0.8O3/SrRuO3 heterointerfaces. Adv. Mater. Interfaces 2, 1500087 (2015).

Trukhanov, S. V. et al. Study of A-site ordered PrBaMn2O6-δ manganite properties depending on the treatment conditions. J. Phys.-Condes. Matter 17, 6495–6506 (2005).

Pawlak, D. A. et al. Structure and spectroscopic properties of (AA’)(BB’)O3 mixed-perovskite crystals. J. Mater. Res. 20, 3329–3337 (2005).

Montini, T., Melchionna, M., Monai, M. & Fornasiero, P. Fundamentals and catalytic applications of CeO2-based materials. Chem. Rev. 116, 5987–6041 (2016).

Wu, S. Q. et al. B-site ordering and strain-induced phase transition in double-perovskite La2NiMnO6 films. Sci. Rep. 8, 2516 (2018).

Bharathi, R. N. & Sankar, S. Structural, optical and magnetic properties of Pr doped CeO2 nanoparticles synthesized by citrate–nitrate auto combustion method. J. Mater. Sci.-Mater. Electron. 29, 6679–6691 (2018).

Jing, H. M. et al. Formation of Ruddlesden–Popper faults and their effect on magnetic properties in Pr0.5Sr0.5CoO3 thin films. ACS Appl. Mater. Interfaces 10, 1428–1433 (2018).

Mi, S.-B. et al. Atomic structures of planar defects in 0.95(Na0.5Bi0.5)TiO3–0.05BaTiO3 lead-free piezoelectric thin films. J. Alloy. Compd. 636, 183–186 (2015).

Muller, D. A. et al. Atomic-scale chemical imaging of composition and bonding by aberration-corrected microscopy. Science 319, 1073–1076 (2008).

Watanabe, M., Okunishi, E. & Aoki, T. Atomic-level chemical analysis by EELS and XEDS in aberration-corrected scanning transmission electron microscopy. Microsc. Microanal. 16, 66–67 (2010).

Rondinelli, J. M. & Fennie, C. J. Octahedral rotation-induced ferroelectricity in cation ordered perovskites. Adv. Mater. 24, 1961–1968 (2012).

People, R. & Bean, J. C. Calculation of critical layer thickness versus lattice mismatch for GexSi1−x/Si strained-layer heterostructures. Appl. Phys. Lett. 47, 322–324 (1985).

Chen, A. et al. Tunable low-field magnetoresistance in (La0.7Sr0.3MnO3)0.5:(ZnO)0.5 self-assembled vertically aligned nanocomposite thin films. Adv. Funct. Mater. 21, 2423–2429 (2011).

Yamada, T., Wakiya, N., Shinozaki, K. & Mizutani, N. Epitaxial growth of SrTiO3 films on CeO2/yttria-stabilized zirconia/Si(001) with TiO2 atomic layer by pulsed-laser deposition. Appl. Phys. Lett. 83, 4815–4817 (2003).

Kim, H. et al. Self-assembled single-phase perovskite nanocomposite thin films. Nano Lett. 10, 597–602 (2010).

Jing, H.-M. et al. Atomic-scale imaging of heterointerface and planar faults in epitaxial (Pr, Sr)2CoO4 films on SrTiO3 (001) substrates. J. Cryst. Growth 511, 93–98 (2019).

Acknowledgements

The work was supported by the National Basic Research Program of China (No. 2015CB654903) and the National Natural Science Foundation of China (51471169 and 51390472).

Author information

Authors and Affiliations

Contributions

S.C., L.S. and M.L. prepared the thin film materials, L.L. and Y.D. prepared the TEM samples, S.D.C., S.Q.W. and S.B.M. conducted the electron microscopy experiments and analysis, S.D.C., L.L. and S.B.M. wrote the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cheng, SD., Lu, L., Cheng, S. et al. Self-assembling behavior and interface structure in vertically aligned nanocomposite (Pr0.5Ba0.5MnO3)1-x:(CeO2)x films on (001) (La,Sr)(Al,Ta)O3 substrates. Sci Rep 10, 2348 (2020). https://doi.org/10.1038/s41598-020-59166-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-59166-1

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.