Abstract

Metamagnetic shape memory alloys have aroused considerable attraction as potential magnetic refrigerants due to the large inverse magnetocaloric effect associated to the magnetic-field-induction of a reverse martensitic transformation (martensite to austenite). In some of these alloys, the austenite phase can be retained on cooling under high magnetic fields, being the retained phase metastable after field removing. Here, we report a giant direct magnetocaloric effect linked to the anomalous forward martensitic transformation (austenite to martensite) that the retained austenite undergoes on heating. Under moderate fields of 10 kOe, an estimated adiabatic temperature change of 9 K has been obtained, which is (in absolute value) almost twice that obtained in the conventional transformation under higher applied fields. The observation of a different sign on the temperature change associated to the same austenite to martensite transformation depending on whether it occurs on heating (retained) or on cooling is attributed to the predominance of the magnetic or the vibrational entropy terms, respectively.

Similar content being viewed by others

Introduction

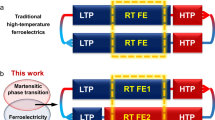

Magnetic shape memory alloys display unique properties associated to the occurrence of a thermoelastic martensitic transformation (MT) between magnetically ordered structural phases. The MT (a reversible first order solid-solid transformation) typically takes place between a high temperature phase (austenite) and a low temperature phase with lower crystalline symmetry (martensite) and distinct magnetic characteristics due to their different crystallographic structures. In particular, in the so-called metamagnetic shape memory alloys, the MT takes place between a ferromagnetic austenite and a weak magnetic martensitic phase1,2,3, so the large magnetization drop taking place at the MT allows the induction of the reverse MT from martensite to austenite by an applied magnetic field4. In fact, the magnetic field shifts the transformation temperature, T m , to lower temperatures, stabilizing the high magnetization phase. Magnetic-field-induced martensitic transformations under reasonable magnetic fields have been reported in Ni-Co-Mn-In4, Ni-Mn-In5, Ni-Mn-Sn6, Ni-Co-Mn-Sn7, Ni-Mn-Sb8, Ni-Co-Mn-Al9 and Ni-Co-Mn-Ga10 alloys, and the interesting properties related to this effect are being actively investigated because of their potential applications (sensors, actuators, damping, energy harvesting, etc.). Furthermore, since the different magnetic exchange interactions in each of the structural phases result in a discontinuity in the magnetic entropy at the MT, the magnetic induction of the MT may lead to giant magnetocaloric effects in these alloys, which may then be adiabatically cooled by application of a magnetic field. These large magnetocaloric effects make these materials especially interesting for room temperature magnetic refrigeration applications11,12,13,14,15,16,17,18,19,20,21,22.

As a consequence of the counterbalance between the vibrational and the magnetic contributions to the entropy change at the transformation, the forward MT can be inhibited (arrested) on cooling by the application of a strong magnetic field23,24,25,26,27,28,29,30,31,32, and hence the austenitic phase be stabilized at low temperatures, far below T m . The magnetically retained austenite evolves to martensite as soon as the field is removed or reduced27, but, depending on both the temperature and the applied field, a significant (even large) amount of austenite may still persist after the magnetic field removing (apart from an instantaneous partial phase change, the reduction in the applied field leads to a small time-dependent evolution of the transformed fraction26). On heating, this metastable austenite transforms to martensite through an ‘anomalous’ forward MT, whose associated magnetocaloric effect has not still been evaluated. In this work, we analyze the characteristics of the retained austenite and determine the entropy change linked to such a peculiar MT in a Ni-Mn-In-Co alloy. We show that the low temperature regime in which it occurs favors the predominance of the magnetic contribution (at the expense of the vibrational one) to the total entropy change, and this leads to the observation of a direct magnetocaloric effect (ΔS < 0), contrary to the inverse effect (ΔS > 0 ) observed in the conventional forward MT. A large adiabatic temperature change of 9 K under a moderate applied field of 10 kOe is reported for the ‘anomalous’ forward MT. This is almost twice the values obtained in the conventional forward transformation under higher applied fields, and one of the largest values obtained in magnetic shape memory alloys.

Results and Discussion

To kick off, let us describe the magnetization behavior of the Ni-Mn-In-Co alloy. The ZFC-FC magnetization measurement at 100 Oe (red dots) in Fig. 1 shows a jump at around 250 K linked to the standard martensitic transformation, as well as a temperature splitting around 50 K corresponding to a spin-glass like behavior already reported29. Likewise, the magnetization on cooling under a 60 kOe magnetic field evidences the above mentioned decrease of T m with the increasing applied field. On the other hand, taking into account that the saturation magnetization of the martensite at 10 K lies around 20 emu/g27, the high magnetization value measured at this temperature (~105 emu/g) on cooling under a 60 kOe field indicates the presence of a high quantity of magnetically-retained austenite. The subsequent removal of the magnetic field at 10 K allows a partial transition to martensite, as pointed out by the small decrease in magnetization after switching on again the magnetic field (empty blue dot).

A direct evidence of both the austenite retention after field removing and the phase evolution upon subsequent heating is presented in Fig. 2, where we show neutron diffraction measurements performed after field cooling, once the external magnetic field is set to zero at 10 K. In effect, the sample cooled from 300 K under a 50 kOe magnetic field shows a mixture of austenite and martensite at 10 K. The anomalous MT from retained austenite to martensite on heating is evidenced by the reduction of intensity the (200)A austenitic reflection at 2θ = 47.5° (λ = 2.41 Å) and the corresponding increase in the martenstic one around 52°. The austenitic peak intensity does not cancel out due to the coincidence of martensitic and austenitic reflections at the same angle. Conversely, as expected, the conventional reverse MT from martensite to austenite takes place on heating above 200 K, where the austenitic peak intensity starts increasing (and the martensite peak intensity starts decreasing).

As shown in Fig. 3, the stability of the retained austenite can be assessed from the magnetization values measured on cooling under different applied fields and the corresponding values after switching off and then on again the magnetic field. In fact, using the values of the saturation magnetization at 10 K for austenite and martensite (126.5 and 22.3 emu/g, respectively27), the magnetization changes can be transformed in mass fraction evolutions. Thus, for instance, a sample cooled under 70 kOe retains around 92% of austenite before field reduction, 70% of which remains at zero magnetic field (blue circles, right axis). Similar behavior is found on cooling under different magnetic fields above 55 kOe, with the same fraction value of remaining austenite after field removing (around 70% in all cases). Lower magnetic fields, in turn, are not able to retain such high amount of austenite on cooling, and lower fractions of austenite are observed (i.e. 56% at 50 kOe). Therefore, a 70% of austenite seems to be the upper limit of retained phase at 10 K, below which no evolution is observed after field removing.

From a crystallographic point of view, the structural state of the retained austenite at 10 K under magnetic fields above 55 kOe (70% of austenite) and its change during heating is the same as that occurring at 265 K on ZFC during the forward MT. Nevertheless, their intrinsic properties are different because of the different temperature range involved. In particular, the large magnetization of the retained austenite at low temperatures makes it metastable against martensite, which is the stable phase at low temperatures, since the transition to a non-magnetic martensitic phase requires the disordering of the magnetic moments, thus implying an increase in the energy of the system. The transition to martensite must indeed occur on heating once temperature provides that enough energy to destroy the magnetic order. In order to illustrate it, Fig. 4a shows the evolution of the magnetization as a function of temperature M(T) under different magnetic fields below 10 kOe (as explained below, higher fields retain some of austenitic phase on heating). The magnetization drop observed on heating above 10 K accounts for the forward retained-austenite to martensite MT, which takes place at higher temperatures on increasing the magnetic field. In any case, only the martensitic phase is present in the alloy at 100 K for those applied fields. The inset in Fig. 4a shows the field dependence of the magnetization at 150 K obtained from the curves shown in Fig. 4a (and those obtained at higher fields, not shown here). Below 10 kOe the magnetization approaches to the saturation value in martensite at 150 K, whereas the large increase in saturation magnetization observed for higher magnetic fields points out to a growing austenite retention. On further heating, the standard reverse MT occurs above 225 K. The magnetization decrease linked to the conventional forward MT taking place on subsequent cooling is shown in Fig. 4b.

Field dependent thermo-magnetization. (a,b) Upper panel: Magnetization M(T) at 100, 200, 500, 1000, 2000, 4000, 6000, 80000 and 10000 Oe, measured during heating after Field Cooling under 70 kOe to 10 K. The inset shows the M(H) curve at 150 K. Lower panel: Magnetization M(T) at 100, 200, 500, 1000, 2000, 4000, 6000, 80000 and 10000 Oe, measured during cooling (forward MT).

Briefly, after cooling in a strong enough magnetic field, an anomalous forward MT first occurs on heating (corresponding to 70% of austenite) and then a complete standard reverse MT at higher temperatures follows (Fig. 4a), whereas the standard forward MT occurs on cooling (Fig. 4b). Therefore, the same forward austenite to martensite transformation can be produced by heating and by cooling. The entropy change linked to the different MT sequences and its influence on the refrigeration capacity linked to the magnetocaloric effect can be evaluated from magnetization measurements. Nevertheless, to carefully analyze the thermo-magnetization curves, Fig. 5 shows the field dependence of the magnetization at 20 K (the same qualitative behavior is observed in the 20–50 K temperature range) beginning with the demagnetization curve from 10 kOe and the subsequent magnetization process.

As expected, the initial high magnetization (around 80 emu/g) agrees with the corresponding value of the thermo-magnetization curve in Fig. 4a and the field reduction decreases the magnetization (demagnetization). Nevertheless, the subsequent magnetization reaches a maximum (around 50 emu/g) lower than that found at the beginning. This is a clear evidence of the austenite to martensite transformation occurring during field removing. Once the transformation occurs, the low magnetic field is not able to induce the system to re-transform again back to the initial state as a consequence of the non-reversibility of the transformation.

The magnetocaloric effect is defined as the temperature change ΔT produced when a magnetic field is applied or removed under adiabatic condition, or equivalently, as the entropy change ΔS in isothermal conditions. In a first approximation, both terms are related through the specific heat (C p ) of the sample by33

According to classical thermodynamics, the magnetic entropy change ΔS as a consequence of a magnetic field increase can be indirectly measured by the magnetization curves shown in Fig. 3 and using the following expression33,

and negative (positive) values of the entropy change are expected when the magnetization decreases (increases) with temperature for the full set of applied fields. In the same way, a magnetic field reduction induces an entropy change \(S(T,0)-S(T,H)=-{\rm{\Delta }}S\) (hereinafter ΔS will be associated to magnetic filed increases a −ΔS to magnetic field reductions).

Due to the irreversibility depicted in Fig. 5, the use of the data in Fig. 4 to calculate the entropy change has only significance for the magnetic field reduction obtained from the initial out of equilibrium state. Under this condition, the field reduction induces the austenite to martensite transformation. The measured entropy change −ΔS (field removing) at 10 kOe linked to the ‘anomalous’ forward MT is shown in Fig. 6a at low temperatures. Figure 6a also shows at higher temperatures the entropy change linked to the reverse MT on heating (empty red circles) and to the forward MT on cooling (full blue circles). The ‘anomalous’ MT produces a negative ΔS entropy change while both the reverse and the standard forward MT positive values. Focusing on the low temperature transformation, the measured entropy change is the same to that calculated from M(H) demagnetization curves in the 20–50 K temperature range (see full red circles in the inset in Fig. 6). The use of the subsequent magnetizations, Fig. 5b, would give the true reversible entropy change, but this value cannot be estimated form data in Fig. 4. The inset in Fig. 6a also shows the entropy change obtained during the magnetization process (red squared symbols). In this case, the entropy changes ΔS are half of the values obtained during the demagnetization process but is still negative.

MCE effect as a function of temperature. a, b, (a) Entropy change −Δ S(T) = S(T, 0) − S(T, H) at 10 kOe on heating after Field Cooling under 70 kOe (open circles) and during cooling (full circles) with no magnetic field. The inset shows the comparison between the entropy change measured from data in Fig. 4(a) (empty red dots) with that obtained using demagnetization (full red dots) and magnetization (full red squares) M(H) curves. (b)Temperature change Δ T(T) under a 10 kOe magnetic field reduction estimated through equation (2). The inset shows the heat capacity measured during heating after a ZFC process.

The same austenite to martensite transformation on heating (anomalous) and on cooling (standard) shows opposite sign entropy changes. The total entropy change linked to the MT has mainly vibrational, magnetic and electronic contributions, ΔS = Δ Svib + Δ Smag + Δ Selec , the electronic one being much lower and therefore usually neglected. During the transformation from paramagnetic martensite to ferromagnetic austenite ∆S vib > 0 and ∆S mag < 0 typically occur34,35. In the temperature range of the standard MT, the vibrational contribution is larger and the magnetic-field-induced austenite increases the entropy of the system \((\frac{\partial M}{\partial T} > 0)\). On the contrary, the vibrational entropy of both phases approaches to zero at very low temperatures and therefore the vibrational contribution to the MT is expected to be very small. Furthermore, the lower is the temperature, the higher the magnetic entropy contribution. Thus, in the range where the retained austenite is metastable (below 50 K) the magnetic contribution to the total entropy dominates \((\frac{\partial M}{\partial T} < 0)\) and, accordingly, |∆S mag | > |∆S vibr |.

Figure 6b shows the temperature change associated to a 10 kOe magnetic field reduction. ∆T has been estimated through expression (1), using the heat capacity (C p ) measured during heating (without applied magnetic field) shown in inset in Fig. 6b. To correct the differences (around 10%) between C p of the austenite and martensite phases36, the used capacity was increased by a 7% which corresponds to a 70% of maximum retained austenite. On heating and around the forward anomalous MT negative temperature changes are observed but around the standard forward and reverse MT positive values appear. Interestingly, a remarkable high value of the adiabatic temperature change (~9 K) is observed around the ‘anomalous’ forward MT under a moderate applied field of 10 kOe. This is almost twice that obtained in the conventional forward transformation under higher applied fields (∆T ~ 6 K)22, and one of the largest values obtained in magnetic shape memory reported both by direct and indirect methods37. The large temperature change obtained is simply a consequence of the low specific heat value at low temperatures. The entropy change linked to the Martensitic Transformation is similar at low and high temperatures but the temperature change at low temperature is higher due to the smaller value of the specific heat.

This giant magnetocaloric effect linked to the undercooled austenite phase shows the relevance of the entropy contributions and in particular the outstanding role of the magnetic entropy. In the conventional forward martensitic transformation taking place in metamagnetic shape memory alloys, the magnetic contribution to the total entropy change at the transformation is always counterbalanced by the vibrational one, the latter being always higher. In the limit, both contributions would cancel each other resulting in the absence of transformation. In the present case, in turn, the retention of ferromagnetic austenite and the low temperature regime in which it transforms to martensite favors the, otherwise impossible, predominance of the magnetic contribution to the total entropy change at the transformation, as long as the vibrational entropy of both phases approaches to zero. This leads to the peculiar situation where the sign on the temperature change associated to the austenite to martensite transformation is different depending on whether it occurs on cooling (conventional) or on heating (retained), and highlights the outstanding role of magnetism on driving the structural transformation. From the application point of view, the magnetocaloric effect at low temperatures could compete with other materials like molecular magnetic compounds for magnetic refrigeration at cryogenic temperatures38,39, while the occurrence of direct and inverse magnetocaloric effects associated to the same forward martensitic transformation could be useful in the design of refrigeration devices based on more complex thermodynamic processes.

Methods

A Ni45Mn36.7In13.3Co5 alloy was produced by arc-melting followed by several consecutive re-melting in order to homogenize the ingot. After 24 h homogenization at 1170 K under vacuum, samples were annealed at 1070 K for 1800 s and slowly cooled in air to obtain an ordered alloy. Differential Scanning Calorimetry (DSC) analysis reveals that in zero field the martensite to austenite transition peak maximum appears at A p = 258 K. The transformation entropy, estimated as the latent heat ΔH (2.6 J/g) divided by DSC peak temperature, A p , is ΔS tr = 10 ± 1 J/(kg.K) and the Curie temperature, T c = 386 K. The heat capacity C p was measured using a PPMS system. The temperature dependences of the magnetization M(T) H at different applied magnetic fields were determined using a Quantum Design MPMS XL-7 SQUID magnetometer. The evolution during heating of the arrested austenite in the Ni-Mn-In-Co metamagnetic shape memory alloy has been analyzed by in situ neutron diffraction performed in the D20 diffractometer (λ = 2.41 Å) at the Institute Laue-Langevin.

References

Sutou, Y. et al. Magnetic and martensitic transformations of NiMnX (X = In, Sn, Sb) ferromagnetic shape memory alloys. Appl. Phys. Lett. 85, 4358 (2004).

Krenke, T. et al. Martensitic transitions and the nature of ferromagnetism in the austenitic and martensitic states of Ni−Mn−Sn alloys. Phys. Rev. B 72, 014412 (2005).

Krenke, T. et al. Ferromagnetism in the austenitic and martensitic states of Ni−Mn−In alloys. Phys. Rev. B 73, 174413 (2006).

Kainuma, R. et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 439, 957–960 (2006).

Oikawa, K. et al. Effect of magnetic field on martensitic transition of Ni46Mn41In13 Heusler alloy. Appl. Phys. Lett. 88, 122507 (2006).

Koyama, K. et al. Observation of field-induced reverse transformation in ferromagnetic shape memory alloy Ni50Mn36Sn14. Appl. Phys. Lett. 88, 132505 (2006).

Kainuma, R. et al. Metamagnetic shape memory effect in a Heusler-type Ni43Co7Mn39Sn11 polycrystalline alloy. Appl. Phys. Lett. 88, 192513 (2006).

Du, J. et al. Magnetocaloric effect and magnetic-field-induced shape recovery effect at room temperature in ferromagnetic Heusler alloy Ni–Mn–Sb. J. Phys. D: Appl. Phys. 40, 5523 (2007).

Kainuma, R., Ito, W., Umetsu, R. Y., Oikawa, K. & Ishida, K. Magnetic field-induced reverse transformation in B2-type NiCoMnAl shape memory alloys. Appl. Phys. Lett. 93, 091906 (2008).

Yu, S. Y. et al. Realization of magnetic field-induced reversible martensitic transformation in NiCoMnGa alloys. Appl. Phys. Lett. 91, 102507 (2007).

Krenke, T. et al. Inverse magnetocaloric effect in ferromagnetic Ni–Mn–Sn alloys. Nat. Mat. 4, 450–454 (2005).

Han, Z. D. et al. Large magnetic entropy changes in the Ni45.4Mn41.5In13.1 ferromagnetic shape memory alloy. Appl. Phys. Lett. 89, 182507 (2006).

Krenke, T. et al. Magnetic superelasticity and inverse magnetocaloric effect in Ni-Mn-In. Phys. Rev. B 75, 104414 (2007).

Moya, X. et al. Cooling and heating by adiabatic magnetization in the Ni50Mn34In16 magnetic shape-memory alloy. Phys. Rev. B 75, 184412 (2007).

Bhobe, P. A., Priolkar, K. R. & Nigam, A. K. Room temperature magnetocaloric effect in Ni–Mn–In. Appl. Phys. Lett. 91, 242503 (2007).

Zhang, X. et al. Combined giant inverse and normal magnetocaloric effect for room-temperature magnetic cooling. Phys. Rev. B 76, 132403 (2007).

Sharma, V. K. et al. Magnetocaloric effect in Heusler alloys Ni50Mn34In16 and Ni50Mn34Sn16. J. Phys. Condens. Matter. 19, 496207 (2007).

Han, Z.D. et al. Low-field inverse magnetocaloric effect in Ni50−xMn39+xSn11 Heusler alloys. Appl. Phys Lett. 90, 042507 (2007).

Ajaya, J., Nayak, K., Suresh, K. G. & Nigam, A. K. Giant inverse magnetocaloric effect near room temperature in Co substituted NiMnSb Heusler alloys. J. Phys. D: Appl. Phys. 42, 035009 (2009).

Planes, A., Mañosa, Ll. & Acet, M. Magnetocaloric effect and its relation to shape-memory properties in ferromagnetic Heusler alloys. J. Phys.: Condens. Matter. 21, 233201 (2009).

Recarte, V., Pérez-Landazábal, J. I., Kustov, S. & Cesari, E. J. Entropy change linked to the magnetic field induced martensitic transformation in a Ni-Mn-In-Co Shape Memory Alloy. Appl. Phys. 107, 053501 (2010).

Liu, J., Gottschall, T., Skokov, K. P., Moore, J. K. & Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nature Mater. 11, 620 (2012).

Sharma, V. K., Chattopadhyay, M. K. & Roy, S. B. Kinetic arrest of the first order austenite to martensite phase transition in Ni50Mn34In16: dc magnetization studies. Phys. Rev. B 76, 140401 (2007).

Ito, W. et al. Martensitic and magnetic transformation behaviors in Heusler-type NiMnIn and NiCoMnIn metamagnetic shape memory alloys. Metal. Mater. Trans. A 38, 759 (2007).

Ito, W. et al. Kinetic arrest of martensitic transformation in the NiCoMnIn metamagnetic shape memory alloy. Appl. Phys. Lett. 92, 021908 (2008).

Pérez-Landazábal, J. I., Recarte, V., Sánchez-Alarcos, V., Kustov, S. & Cesari, E. Non-equilibrium martensitic transformation in metamagnetic shape memory alloys. J. Alloys and Comp. 536, S277 (2012).

Pérez-Landazábal, J. I. et al. Magnetic field induced martensitic transformation linked to the arrested austenite in a Ni-Mn-In-Co shape memory alloy. J.Appl. Phys. 109, 093515 (2011).

Lakhani, A., Bahnerjee, A., Chaddah, P., Chen, X. & Ramanujan, R. V. Magnetic glass in shape memory alloy: Ni45Co5Mn38Sn12. J. Phys. Condens. Matter. 24, 386004 (2012).

Pérez-Landazábal, J. I. et al. Magnetic properties of the martensitic phase in Ni-Mn-In-Co metamagnetic shape memory alloys. Appl. Phys Lett. 102, 101908 (2013).

Siruguri, V. et al. Neutron diffraction evidence for kinetic arrest of first order magneto-structural phase transitions in some functional magnetic materials. J. Phys. Condens. Matter. 25, 496011 (2013).

Shen, J. L. et al. Kinetic arrest and de-arrest in Mn50Ni36Sn9Co5 ferromagnetic shape memory alloy. Phys. Status Sol. 253, 1923 (2016).

Croïgneau, G., Polcar, L., Courtois, P., Lachkar, P. & Bourgault, D. Austenite arrest in polycrystalline Ni-Mn-Co-In films. J. Alloys Comp. 693, 700 (2017).

Pecharsky, V. K., Gschneidner, K. A. Jr., Pecharsky, A. O. & Tishin, A. M. Thermodynamics of the magnetocaloric effect. Phys. Rev. B 64, 144406 (2001).

Kustov, S., Corró, M. L., Pons, J. & Cesari, E. Entropy change and effect of magnetic field on martensitic transformation in a metamagnetic Ni–Co–Mn–In shape memory alloy. Appl. Phys. Lett. 94, 191901 (2009).

Recarte, V. et al. Entropy change linked to the martensitic transformation in metamagnetic shape memory alloys. Acta Mater. 60, 3168 (2012).

Vasilev, A. N. et al. On the electronic origin of the inverse magnetocaloric effect in Ni-Co-Mn-In Heusler alloys. J. Phys. D: Appl. Phys. 43, 055004 (2010).

Moya, X., Kar-Narayan, S. & Mathur, M. D. Caloric materials near ferroic phase transition. Nature Mater. 13, 439 (2014).

Lorusso, G. et al. Dense Metal-Organic Framework for Enhanced Magnetic Refrigeration. Advanced materials. 25, 4653 (2013).

Evangelisti, M. et al. Cryogenic Magnetocaloric Effect in a Ferromagnetic Molecular Dimer. Angew. Chem. 29, 6548 (2011).

Acknowledgements

This work has been carried out with the financial support of the Spanish “Ministerio de Economía y Competitividad” (AEI/FEDER,UE) (Project numbers MAT2015-65165-C2-R and MAT2014-56116-C4-1-R). The Institute Laue-Langevin is acknowledged for the allocated neutron beamtime (experiment ILL-5-31-2029).

Author information

Authors and Affiliations

Contributions

J.I.P., V.R. and V.S. planned the experiments in collaboration with C.G. and E.C.J.J.B. performed the magnetic measurements. J.A.R., designed and analyzed the neutron diffraction experiments. The calorimetric measurements were carried out by J.S. All authors discuss the results and analyzed the data. The Manuscript was prepared by J.I.P. in collaboration with the other co-authors.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pérez-Landazábal, J.I., Recarte, V., Sánchez-Alarcos, V. et al. Giant direct and inverse magnetocaloric effect linked to the same forward martensitic transformation. Sci Rep 7, 13328 (2017). https://doi.org/10.1038/s41598-017-13856-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-13856-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.