Abstract

Electrochemical synthesis can provide more sustainable routes to industrial chemicals1,2,3. Electrosynthetic oxidations may often be performed ‘reagent-free’, generating hydrogen (H2) derived from the substrate as the sole by-product at the counter electrode. Electrosynthetic reductions, however, require an external source of electrons. Sacrificial metal anodes are commonly used for small-scale applications4, but more sustainable options are needed at larger scale. Anodic water oxidation is an especially appealing option1,5,6, but many reductions require anhydrous, air-free reaction conditions. In such cases, H2 represents an ideal alternative, motivating the growing interest in the electrochemical hydrogen oxidation reaction (HOR) under non-aqueous conditions7,8,9,10,11,12. Here we report a mediated H2 anode that achieves indirect electrochemical oxidation of H2 by pairing thermal catalytic hydrogenation of an anthraquinone mediator with electrochemical oxidation of the anthrahydroquinone. This quinone-mediated H2 anode is used to support nickel-catalysed cross-electrophile coupling (XEC), a reaction class gaining widespread adoption in the pharmaceutical industry13,14,15. Initial validation of this method in small-scale batch reactions is followed by adaptation to a recirculating flow reactor that enables hectogram-scale synthesis of a pharmaceutical intermediate. The mediated H2 anode technology disclosed here offers a general strategy to support H2-driven electrosynthetic reductions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The NMR spectra for characterized compounds are available in the data repository at https://doi.org/10.6084/m9.figshare.23511828. The authors declare that all other data supporting the findings of this study are available in the paper and its Supplementary Information files.

References

Cardoso, D. S. P., Šljukić, B., Santos, D. M. F. & Sequeira, C. A. C. Organic electrosynthesis: from laboratorial practice to industrial applications. Org. Process Res. Dev. 21, 1213–1226 (2017).

Pletcher, D. & Walsh, F. C. Industrial Electrochemistry 2nd edn, 298–311 (Kluwer, 1990).

Leech, M. C., Garcia, A. D., Petti, A., Dobbs, A. P. & Lam, K. Organic electrosynthesis: from academia to industry. React. Chem. Eng. 5, 977–990 (2020).

Klein, M. & Waldvogel, S. R. Counter electrode reactions—important stumbling blocks on the way to a working electro-organic synthesis. Angew. Chem. Int. Edn 61, e202204140 (2022).

Sherbo, R. S., Delima, R. S., Chiykowski, V. A., MacLeod, B. P. & Berlinguette, C. P. Complete electron economy by pairing electrolysis with hydrogenation. Nat. Catal. 1, 501–507 (2018).

Danly, D. E. Development and commercialization of the Monsanto electrochemical adiponitrile process. J. Electrochem. Soc. 131, 435C–442C (1984).

Barrette, W. C. & Sawyer, D. T. Determination of dissolved hydrogen and effects of media and electrode materials on the electrochemical oxidation of molecular hydrogen. Anal. Chem. 56, 653–657 (1984).

Ledezma-Yanez, I., Díaz-Morales, O., Figueiredo, M. C. & Koper, M. T. M. Hydrogen oxidation and hydrogen evolution on a platinum electrode in acetonitrile. ChemElectroChem. 2, 1612–1622 (2015).

Lazouski, N., Chung, M., Williams, K., Gala, M. L. & Manthiram, K. Non-aqueous gas diffusion electrodes for rapid ammonia synthesis from nitrogen and water-splitting-derived hydrogen. Nat. Catal. 3, 463–469 (2020).

Suryanto, B. H. R. et al. Nitrogen reduction to ammonia at high efficiency and rates based on a phosphonium proton shuttle. Science 372, 1187–1191 (2021).

Hodgetts, R. Y., Du, H.-L., Nguyen, T. D., MacFarlane, D. & Simonov, A. N. Electrocatalytic oxidation of hydrogen as an anode reaction for the Li-mediated N2 reduction to ammonia. ACS Catal. 12, 5231–5246 (2022).

Fu, X. et al. Continuous-flow electrosynthesis of ammonia by nitrogen reduction and hydrogen oxidation. Science 379, 707–712 (2023).

Goldfogel, M. J., Huang, L. & Weix, D. J. in Nickel Catalysis in Organic Synthesis (ed. Ogoshi, S.) 183–222 (Wiley, 2020).

Nimmagadda, S. K. et al. Development and execution of an Ni(II)-catalyzed reductive cross-coupling of substituted 2-chloropyridine and ethyl 3-chloropropanoate. Org. Process Res. Dev. 24, 1141–1148 (2020).

Beutner, G. L. et al. A process chemistry benchmark for sp2–sp3 cross couplings. J. Org. Chem. 86, 10380–10396 (2021).

Moulik, S., Vaishnavi, B. A., Nagar, H. & Sridhar, S. in Encyclopedia of Membranes (eds Drioli, E. & Giorno, L.) 1973–1983 (Springer, 2016).

Goor, G., Glenneberg, J., Jacobi, S., Dadabhoy, J., & Candido, E. in Ullmann’s Encyclopedia of Industrial Chemistry (Wiley, 2019).

Huskinson, B. et al. A metal-free organic–inorganic aqueous flow battery. Nature 505, 195–198 (2014).

Kwabi, D. G., Ji, Y. & Aziz, M. J. Electrolyte lifetime in aqueous organic redox flow batteries: a critical review. Chem. Rev. 120, 6467–6489 (2020).

Anson, C. W. & Stahl, S. S. Mediated fuel cells: soluble redox mediators and their applications to electrochemical reduction of O2 and oxidation of H2, alcohols, biomass, and complex fuels. Chem. Rev. 120, 3749–3786 (2020).

Acemoglu, M., Baenziger, M., Krell, C. M. & Marterer, W. in Transition Metal-Catalyzed Couplings in Process Chemistry (eds Magano, J. & Dunetz, J. R.) 15–23 (Wiley, 2013).

Jennings, P. W., Pillsbury, D. G., Hall, J. L. & Brice, V. T. Carbon-carbon bond formation via organometallic electrochemistry. J. Org. Chem. 41, 719–722 (1976).

Conan, A., Sibille, S., d’Incan, E. & Périchon, J. Nickel-catalysed electroreductive coupling of α-halogenoesters with aryl or vinyl halides. J. Chem. Soc. Chem. Commun. 48–49 (1990).

Perkins, R. J., Pedro, D. J. & Hansen, E. C. Electrochemical nickel catalysis for sp2-sp3 cross-electrophile coupling reactions of unactivated alkyl halides. Org. Lett. 19, 3755–3758 (2017).

Li, H. et al. Ni-catalyzed electrochemical decarboxylative C–C couplings in batch and continuous flow. Org. Lett. 20, 1338–1341 (2018).

Perkins, R. J., Hughes, A. J., Weix, D. J. & Hansen, E. C. Metal-reductant-free electrochemical nickel-catalyzed couplings of aryl and alkyl bromides in acetonitrile. Org. Process Res. Dev. 23, 1746–1751 (2019).

DeLano, T. J. & Reisman, S. E. Enantioselective electroreductive coupling of alkenyl and benzyl halides via nickel catalysis. ACS Catal. 9, 6751–6754 (2019).

Jiao, K.-J. et al. Nickel-catalyzed electrochemical reductive relay cross-coupling of alkyl halides to aryl halides. Angew. Chem. Int. Edn 132, 6520–6524 (2020).

Franke, M. C. et al. Zinc-free, scalable reductive cross-electrophile coupling driven by electrochemistry in an undivided cell. ACS Catal. 12, 12617–12626 (2022).

Harwood, S. J. et al. Modular terpene synthesis enabled by mild electrochemical couplings. Science 375, 745–752 (2022).

Hamby, T. B., LaLama, M. J. & Sevov, C. S. Controlling Ni redox states by dynamic ligand exchange for electroreductive Csp3–Csp2 coupling. Science 376, 410–416 (2022).

Sanfilippo, D. & Rylander, P. N. Hydrogenation and dehydrogenation. Ullmann’s Encyclopedia of Industrial Chemistry (Wiley, 2009).

Everson, D. A., Shrestha, R. & Weix, D. J. Nickel-catalyzed reductive cross-coupling of aryl halides with alkyl halides. J. Am. Chem. Soc. 132, 920–921 (2010).

Preger, Y. et al. Quinone-mediated electrochemical O2 reduction accessing high power density with an off-electrode Co-N/C catalyst. Joule 2, 2722–2731 (2018).

Preger, Y. et al. Anthraquinone-mediated fuel cell anode with an off-electrode heterogeneous catalyst accessing high power density when paired with a mediated cathode. ACS Energy Lett. 5, 1407–1412 (2020).

Zhu, J., Mix, E. & Winblad, B. The antidepressant and antiinflammatory effects of rolipram in the central nervous system. CNS Drug Rev. 7, 387–398 (2001).

Piali, L. et al. Cenerimod, a novel selective S1P1 receptor modulator with unique signaling properties. Pharmacol. Res. Perspect. 5, e00370 (2017).

Liu, Y., Li, P., Wang, Y. & Qiu, Y. Electroreductive cross-electrophile coupling (eXEC) reactions. Angew. Chem. Int. Edn 62, e202306679 (2023).

Yang, J., Qin, H., Yan, K., Cheng, X. & Wen, J. Advances in electrochemical hydrogenation since 2010. Adv. Synth. Catal. 363, 5407–5416 (2021).

Peters, B. K. et al. Scalable and safe synthetic organic electroreduction inspired by Li-ion battery chemistry. Science 363, 838–845 (2019).

Zamora Zeledón, J. A., Jackson, A., Stevens, M. B., Kamat, G. A. & Jaramillo, T. F. Methods—a practical approach to the reversible hydrogen electrode scale. J. Electrochem. Soc. 169, 066505 (2022).

Acknowledgements

The authors thank B. Armstrong (EPSE) and C. Nietupski (HPL) of Merck & Co., Inc. for valuable discussions, feedback and assistance in performing the large-scale implementation of this chemistry. The authors thank C. Salazar of UW-Madison for assistance with gas-uptake experiments and A. M. Norris and M. Boasso of Merck & Co., Inc. for assistance in the preparation of Extended Data Fig. 4. Financial support for development of the mediated H2 anode was provided by the Center for Molecular Electrocatalysis, an Energy Frontier Research Center, funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences and Merck Sharp & Dohme LLC, a subsidiary of Merck & Co., Inc. The development of Ni-catalysed XEC reactions and their integration with the mediated H2 anode was supported by the NSF (PFI-RP 2122596). Spectroscopic instrumentation was partially supported by the NIH (1S10 OD020022-1) and the NSF (CHE-1048642).

Author information

Authors and Affiliations

Contributions

S.S.S., J.B.G., J.T. and M.R.J. were involved in conceptualization of the project. Lab-scale efforts were conducted by M.R.J., J.T., V.S., M.C.F., J.B.G., S.M.M.K. and L.W. Large-scale efforts were conducted by C.B., D.L., F.L., T.P.V., M.D.W., J.T. and M.R.J. This project was completed under the supervision of S.S.S., T.W.R. and D.J.W. and supported by funding acquired by S.S.S., T.W.R., D.J.W., C.M.H. and N.A.S. Manuscript writing was led by S.S.S., M.R.J. and J.T., with contributions from all authors.

Corresponding authors

Ethics declarations

Competing interests

A patent application describing a mediated H2 anode has been filed.

Peer review

Peer review information

Nature thanks Alastair Lennox and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

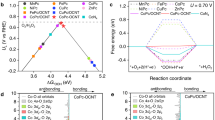

Extended Data Fig. 1 Electrochemical reduction potential measurements.

CV and OCP measurements were performed using a glassy carbon (CV) or Pt (OCP) working electrode and a platinum wire counter electrode, with CV scan rates of 10 mV s−1 (panel a) or 100 mV s−1 (panels b and c). A Ag/Ag+ reference electrode was used and calibrated to Fc+/0. a, H2/H+ OCP data showing a stable potential of −0.79 V versus Fc+/0 and complementary CV analysis, conducted at a scan rate of 10 mV s−1, showing a zero-point potential at −0.79 V versus Fc+/0. Data were collected using a solution of 0.1 M CF3SO3H (proton source) and 0.1 M NBu4PF6 (supporting electrolyte) in NMP under 1 atm of H2. b, CV data for 0.01 M Ni/ligand (1:1) solutions in NMP with 0.1 M LiBr as the supporting electrolyte. NiBr2·dtbbpy shows a single clear redox feature corresponding to a NiII/Ni0 transition; NiBr2·ttbtpy shows two redox features: a higher-potential feature corresponding to NiII/NiI and a lower-potential feature corresponding to NiI/Ni0. Ni/ligand solutions often generate mixtures of different species and the precise speciation was not investigated or explained to identify the origin of the smaller CV peaks present in these scans. c, CV analysis of a 0.01-M AQS solution in NMP. 0.1 M CF3SO3H proton source, N2 atmosphere, 0.1 M NBu4PF6.

Extended Data Fig. 2 Reduction of AQS on carbon-supported Pt and Pd catalysts at 24 °C and 70 °C under 1 atm H2.

Theoretical full substrate conversion corresponds to 100 μmol of consumed H2. Both Pd/C and Pt/C catalysts demonstrated rapid rates of AQS hydrogenation, achieving quasi-complete conversion within 15 min. Pd/C was selected owing to its lower cost. At higher temperatures, although the initial rate remained unchanged, reactivity stopped before complete substrate reduction and reduction of the catalyst loading showed progressively earlier cessation of hydrogen consumption. These data suggest that the catalyst tolerates the AQS solution at room temperature but that it deactivates at elevated temperature. The reactor bed was operated at room temperature.

Extended Data Fig. 3 Optimization of mediated H2 anode conditions for Ni XEC.

Screening on mg scale in an H-cell identified advantageous reaction conditions (top table), including choice of polar aprotic solvent (NMP), supporting electrolyte (LiBr) and substrate ratio (1:1.25 Ar:Alk). An optimal catalyst composition of 8.8 mol% dtbbpy and 2.2 mol% ttbtpy with 10 mol% NiBr2·3H2O was identified for aryl bromides. DMA, N,N-dimethylacetamide.

Extended Data Fig. 4 Schematic representation of electrochemical flow cells used to conduct Ni XEC on the gram scale.

a, Schematic depicting the symmetrical flow-cell configuration used for anodic benchmarking with a Bobbitt’s salt cathode. Carbon paper and turbulence-promoting mesh are used for both half-cells. b, Schematic depicting the flow-cell configuration used for cathodic Ni XEC. A Ni foam cathode was used for the reduction of the Ni catalyst.

Extended Data Fig. 5 Schematic representation of the system used to benchmark mediated H2 anode performance against a Bobbitt’s salt cathode with data investigating accessible current densities and ion-transport selectivity.

a, Schematic representation of the flow design for gram-scale synthesis using the mediated H2 anode. One flow loop passes the reservoir solution through a catalytic hydrogenation bed, whereas the other passes the solution through the electrochemical flow cell to enable reduction on the cathode. b, Polarization curves benchmarking kinetically accessible rates of electrochemical AQSH2 oxidation. See Fig. 3c for further analysis. c, Monitoring of [Li+] in the cathodic reservoir over time during electrolysis. Aliquots of catholyte solution were analysed using inductively coupled plasma optical emission spectroscopy to determine Li+ concentration, which is plotted on the y axis. See the Supplementary Information for details. We observe the correct starting concentration of 0.1 M, derived from the LiBr electrolyte, followed by a linear increase over time. This is consistent with the selective transport of Li+ rather than H+ ions across the Nafion cation-exchange membrane. japp, applied current density.

Extended Data Fig. 6 Ni-catalysed XEC driven by direct application of anodic H2, conducted using a fuel-cell-inspired cell with an integrated MEA.

Gaseous hydrogen was saturated with either H2O or NMP solvent and used as a terminal reductant without the use of an anodic mediator solution. See the Supplementary Information for detailed methods. a, The reaction proceeded with a steady cell voltage of −0.8 V for the allotted time. Both conversion (24%) and product yield (7%), however, were substantially lower than can be achieved using the mediated system (see Extended Data Fig. 3). We speculate that the low faradaic efficiency and the reduced product yield arise from a high rate of proton crossover to the cathode during operation. This flux provides a low-potential reduction reaction in the form of the hydrogen evolution reaction and makes formation of the protodehalogenated side product (18%) the highest-yielding product of Ni-catalysed processes. b, To control for any effect from exogenous H2O, the experiment was repeated with a ‘dry’ (solvent-saturated) hydrogen source. This approach proved untenable, as the applied cell potential reached the cutoff potential of −8 V within 15 min. This was attributed to rapid desiccation of the Nafion membrane, with solvated protons being transported across the membrane without sufficient replacement of solvent from the anode. RT, room temperature.

Extended Data Fig. 7 Electrolysis reactor components used for gram-scale synthesis and reaction time course for Ni XEC.

a, Photographs of the assembly of the Electro Syn Cell (from ElectroCell A/S) used for the mediated H2 system on the gram scale. Viton gaskets are used to separate solid components such as PTFE flow frames, turbulence mesh and 316 SS or graphite electrodes. PTFE and SS end frames are pressed together with bolts to secure the assembly. b, Time-course data for a representative Ni-catalysed XEC, depicting the optimized reaction of 1-bromo-3-phenylpropane and ethyl-4-bromobenzoate under optimized conditions: 4 mA cm−2, 0.5 M in Ar–Br substrate.

Extended Data Fig. 8 Comparison of reductants for Ni-catalysed XEC.

a, Two-electrode undivided cells used for screening conventional Zn or amine reductants (Zn anode pictured). See the Supplementary Information for detailed methods. b, Two-electrode membrane-divided H-cell for screening of the mediated H2 anode. c, Reaction screening data comparing reductant efficacy. Comparison between amine and mediated H2 reductants, with the H2 results disadvantaged by the reporting of isolated rather than assay yields, show that electron-deficient substrates can be coupled in about the same yield with either method but that sterically hindered and electron-rich substrates benefit from the divided mediated H2 conditions. A subset of these reactions was then further compared with undivided cell reductions with a Zn anode (compare 7, 10 and 14). Although some variations were observed, the results reveal comparable or improved efficacy of the mediated H2 anode relative to other anode systems for electrochemical XEC, as well as providing a foundation for larger-scale applications. DIPEA, Hünig’s base; TBAPF6, tetrabutylammonium hexafluorophosphate; rt, room temperature.

Extended Data Fig. 9 Reactor system and peripheral components used to conduct Ni XEC on the 100-g scale.

a, Schematic depicting the reactor configuration using four sets of parallel electrodes. b, Annotated photograph of the fully constituted large-scale flow-reactor system. RBF, round-bottom flask.

Extended Data Fig. 10 Electrolysis reactor components used for the synthesis of the cenerimod intermediate on the 100-g scale and associated time-course data.

a, Photographs of the assembly of the Electro Syn Cell (from ElectroCell A/S) used for mediated H2 anode synthesis of the cenerimod intermediate on the 100-g scale. b, LCAP data of product and Ar–Cl SM from the 100-g-scale synthesis of the cenerimod intermediate as a function of supplied charge. The reaction was monitored with analysis of cathodic aliquots by UPLC analysis every 20–30 min and the LCAP of the substrate and product were used to roughly monitor the degree of the reaction. LCAP was determined by integrating all SM-related peaks and dividing the area of the product by that combined area. When the reaction reached the cutoff cell voltage of 3 V after just under 4 h, the experiment was stopped. Q, charged passed.

Supplementary information

Supplementary information

Supplementary Methods, Supplementary Tables and the Supplementary Discussion

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Twilton, J., Johnson, M.R., Sidana, V. et al. Quinone-mediated hydrogen anode for non-aqueous reductive electrosynthesis. Nature 623, 71–76 (2023). https://doi.org/10.1038/s41586-023-06534-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06534-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.