Abstract

Understanding complex reaction systems is critical in chemistry. While synthetic methods for selective formation of products are sought after, oftentimes it is the full reaction signature, i.e., complete profile of products/side-products, that informs mechanistic rationale and accelerates discovery chemistry. Here, we report a methodology using high-throughput experimentation and multivariate data analysis to examine the full signature of one of the most complicated chemical reactions catalyzed by palladium known in the chemical literature. A model Pd-catalyzed reaction was selected involving functionalization of 2-bromo-N-phenylbenzamide and multiple bond activation pathways. Principal component analysis, correspondence analysis and heatmaps with hierarchical clustering reveal the factors contributing to the variance in product distributions and show associations between solvents and reaction products. Using robust data from experiments performed with eight solvents, for four different reaction times at five different temperatures, we correlate side-products to a major dominant N-phenyl phenanthridinone product, and many other side products.

Similar content being viewed by others

Introduction

Complex reaction networks consisting of hundreds of different species are common in many disparate types of reaction, including oxidation, pyrolysis and polymerization chemistries, with the complexity arising through the presence of many reactants or highly reactive species1. In contrast, the complex reaction networks of transition metal-catalyzed processes originate from the nature of catalysis itself, wherein there exists an interplay of distinct elementary steps that must all occur simultaneously within a single environment. Often multiple productive catalytic cycles compete with side reactions and catalyst decomposition pathways. Furthermore, variation in pre-catalyst, ligand, additive, solvent, and reaction stoichiometries, order of mixing and temperature (amongst other variables) can result in dramatic changes in catalytic speciation and hence reaction outcome(s)2,3. Catalyst speciation adds considerable complexity, an aspect that is largely ignored in chemical synthesis, with the focus placed on the product(s) yield4,5,6.

Such complex reactions are often met with trepidation by synthetic chemists, with too many variables seemingly outside of their control. Indeed, most reactions under investigation in synthetic chemistry laboratories target selective formation of a single dominant product in high yield. However, there are opportunities to be had through embracing complexity. Firstly, complex reaction manifolds provide an opportunity for serendipitous reaction discovery, which can often lead to the formation of unexpected high-value products and new reaction chemistries7,8. Hartwig and co-workers elegantly demonstrated how complexity could be deliberately employed for discovery. Subjecting complex mixtures of reagents to potential catalysts resulted in the discovery of new reactions9,10. Secondly, developing an understanding of a complex reaction and the sensitivities to reaction conditions allows management of side-product profiles, particularly with final product purity and potential toxicity in mind. This is of vital importance in industrial process development where reliability is critical. Thirdly, studying complex reactions can lead to new mechanistic understanding through the identification of competing reaction pathways and interconnected catalytic cycles, that can be used to direct traditional mechanistic studies, i.e., hypotheses built on firm foundations involving real-world substrates and side-product profiles.

The study of complex reactions is no straight-forward task, particularly for those conducting reactions in a traditional manner, one by one6. However, high-throughput experimentation (HTE) is perfectly suited for the study of complex transition-metal catalyzed reactions, as it allows the rapid assessment of the effect of reaction conditions on reaction profile, under controlled conditions, whether that be in flow or batch. Indeed, over the past 20 years HTE has become a proven tool for the discovery8,9,10,11, the expansion of and optimization of catalytic transformations in chemical synthesis12,13,14,15.

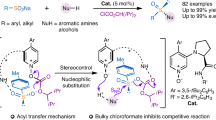

Herein we report the application of HTE and multi-variate statistical analysis to the study of a complex Pd-mediated transformation. We chose to demonstrate our approach using the Pd-mediated synthesis of N-substituted phenanthridinones 2 from 2-bromo-benzamides 1 (Fig. 1)16,17,18,19,20,21,22. This transformation is ideal since 1 is pre-configured to be reactively promiscuous, where there are multiple sites with capabilities for C-C and C-N bond formation and a benzamide group that can facilitate multiple bond activations23. This unusual reaction has been studied by several research groups and is known to generate reactive by-products and side-products (vide infra). Crucially for reaction sensitivity assessment, it can be catalyzed by a wide range of catalysts and ligands (including PPh3, P(furyl)3, L1, and IPr, Fig. 1), and shows solvent and base-dependent product selectivity19,20. The range of Pd pre-catalysts, ligands, bases, solvents, and temperatures (typically run at 100 °C or above) and reaction outcomes observed to date indicate that various catalytically active Pd-species and catalytic cycles are operating, but there is no detailed correlation analysis and conclusions are based on limited empirical evidence.

Key: The blue color in structures 1 and 2 shows the origin of the benzo-moiety. The colored disconnection bonds show different bond sites for activation by the catalyst system. Other generic colors are used to guide the eye to multiple products being formed and HTE screening positions in batch mode.

We investigate this Pd-mediated transformation from the viewpoint of complexity, rather than optimization of a major species. The approach described in this study is intended to provide a strong foundation to help facilitate and direct subsequent downstream mechanism studies on complex reaction systems. This comprehensive study uses a data science approach (Fig. 1) to systematically examine the extent of product and side-product formation in relation to solvent, temperature and reaction time. This approach allows a fuller understanding of the reaction network, providing new insight and advanced chemical knowledge. Moreover, information on the appearance of side products offers opportunities in reaction discovery that could be also useful from a safety perspective.

Further background into the selected reaction (1 → 2): Studies by refs. 19,20 have indicated an understanding behind the formation of phenanthridinones 2 from bromo-benzamides 1 (Fig. 2A, B). Oxidative addition of 1 to a putative Pd0 species A was hypothesized to give PdII intermediate B (not experimentally evidenced). Subsequent loss of HBr (base-assisted) and second oxidative addition has been proposed to result in the formation of transient PdIV species24 C (based primarily on computational studies using DFT methods, conducted with and without PH3 as a model phosphine ligand, and no observable transmetallation-type stoichiometric reaction involving PdII intermediates)19. This goes on to proceed to a key proposed biaryl PdII intermediate D (which can be depicted with different Pd coordination modes), following reductive elimination. Subsequent ipso-substitution and elimination of reactive isocyanate and/or aniline and CO2 affords 7-membered palladacycle E (not experimentally evidenced). Finally, reductive elimination generates phenanthridinone 2.

The blue color in compounds shows the origin of the benzo-moiety. A Catalytic cycle as proposed by Porée et al.—we note that discrete steps connecting D and E are required20. B Reported by-products and side-products. Note: that the relationship of PPh3 to all intermediates is not shown, but it is likely involved in various steps. C Synthesis of N-phenyl phenanthridinones 2a, 2a-d5 and 2b. D Reaction of 1a at 80 °C in DMF mediated by Pd(OAc)2/dppe (1:1, 5 mol%) under two different pre-catalyst regimes. The normalized kinetics show loss of 2-bromo-N-phenylbenzamide 1a at 1324 cm−1 monitored using a Mettler-Toledo ReactIR/silicon probe. Red square - catalyst pre stir at 20 °C; black square—catalyst pre-stir at 80 °C.

Several potentially reactive side-products have been identified including ureas 3 (derived from isocyanate and aniline)16,17 as well as symmetrical biaryls 416,20 and amides 519,20 and 616. Interestingly, ureas are known to be active ligands25,26,27,28 and reagents29 in Pd-catalyzed cross-couplings. The relationship and interplay of all these species have not been fully delineated. We recognized that HTE and data analysis of reaction outcomes offers much potential in examining further. It is of particular note that natural30 and synthetic phenanthridinones31,32,33,34,35,36 have been shown to possess a wide range of biological activities, thus a greater understanding of the reaction network would potentially aid synthesis of these useful molecular scaffolds and allow the generation of toxicological profiles for the reaction, in addition to providing a test-bed for the development of complexity embracing experimental methodologies and data analysis37.

Results

Benchmark reaction for deciphering complexity in Pd-catalyzed cross-couplings

We chose to investigate the reaction of 2-bromo-N-phenyl benzamide 1a, primarily because of the potential amide-directed C-H activation of the N-phenyl moiety. Given the ability for a range of Pd pre-catalysts and monodentate ligands to catalyze the formation of phenanthridinones 2 (Fig. 1), we planned to assess the ability of bidentate ligands to affect the transformation, particularly as their characterization in follow-on mechanistic studies (i.e., stoichiometric experiments with Pd) might be more facile. An initial pre-catalyst and ligand screen (see Supplementary Information for full details) showed that 5 mol% Pd(OAc)2 {formally high purity Pd3(OAc)6, nitrite-free}38 and dppe, with K2CO3 as base in DMF39 at 80 °C gave N-phenyl phenanthridinone 2a in 58% yield (Fig. 2C). Furuta / Kan17 and Fu / Chen22 obtained 2a in 23% and 80% yield respectively from 1a. We also determined that dppp could be used in place of dppe giving similar results. Crucially, for application to HTE, this reaction was found to be tolerant of air when employing the Pd(OAc)2/dppe pre-catalyst. Furthermore, conducting the reaction under anhydrous and oxygen-free conditions gave a yield of 2a which was 54%.

Since the right-hand disubstituted aryl ring in 2a could be incorporated from either aryl group of 1a we sought to confirm that it originates from the bromobenzene moiety (rather than the N-phenyl ring). As expected, use of deuterated benzamide 1a-d5 gave phenanthridinone 2a-d5 as a single product in 61% yield after 2 h at 130 °C. We further probed the regioselectivity of the reaction by employing methyl-substituted benzamide 1b, which afforded phenanthridinone 2b as a single regioisomeric product in 39% yield, the structure of which was confirmed by single crystal X-ray diffraction analysis and NMR spectroscopic analysis. This molecular substitution pattern confirms20 the mechanism proceeds through a biaryl intermediate to D (Fig. 2A), under our catalytic reaction conditions.

The reaction of 1a mediated by Pd(OAc)2/dppe (1:1, 5 mol%) was monitored in operando using IR spectroscopic analysis, with the consumption of 1a assessed at 80 °C in DMF using both a cold and hot pre-catalyst activation protocol (Fig. 2D). When the reaction mixture was heated from room temperature (ca. 20 °C), an induction period of ca. 10 min was evident from the color changes recorded (yellow→orange→dark red; the latter indicative of Pd0 species forming, vide infra), with the reaction nearing completion within 2.25 h. The analysis is complicated by the complete dissolution of 1a requiring heating (which can be seen by the appearance and then subsequent disappearance of 1a). Heating the pre-catalyst mixture in DMF to 80 °C for 2 min prior to addition of 1a shortens the induction period considerably (<2 min; reaction mixture a dark red color), with the reaction reaching completion within <2 h (confirmed by independent 1H NMR analysis). The difference in the pre-catalyst activation process highlights the impact on the overall reaction time. Independent reactions between Pd(OAc)2 and dppe showed that Pd0(dppe)n species (n = 1 or 2) were formed (vide infra).

Next, a robust LC-MS method for profiling the reactions from the HTE campaign (in batch mode) was developed. Generally, we observed (by chromatographic and spectroscopic methods) that many products were formed in reaction mixtures accompanying 2a, 2a-d5, and 2b, the majority of which were formed in low amounts but in significant enough quantity to warrant comprehensive profiling. This would fulfill our aspirations to gain greater understanding of this complex reaction network. Characterization of these species was achieved by LC-MS, GC-MS, flash column chromatography and preparative HPLC on the crude reaction mixtures and comparing the spectroscopic and chromatographic data with those of authentic product samples (see Supplementary Information for full details). Through this approach, we identified a total of 17 side-products and by-products of interest in the LC-MS reaction profiles (Fig. 3), many more than were revealed than in the several previous studies16,17,18,19,20,21,22.

Careful column chromatography resulted in the isolation and characterization of major side-products including symmetrical biaryl 4a, isolated in ~10% yield (analogous with 4, Fig. 2B), amide 6a16, pentacycle 7a40,41, and phenol 8a. Amides 5a and 6a are analogous to compounds 5 and 6 (Fig. 2B) identified by ref. 20 and ref. 16 respectively. Porée et al. showed that phenanthridinones 5 (where R’ = benzyl, methyl) were formed in presence of certain base cations and solvents19,20, for which definitive conclusions could not be drawn. We examined the reaction of 1a using Porée’s pre-catalyst PdCl2(PPh3)2 (5 mol%) with K2CO3 (3 equiv.) in dioxane at 105 °C, however, 5a was only formed in a trace quantity (by HPLC) in our hands.

Substituted phenol 8a possibly originates from reductive elimination from a “Ar-Pd-OH” species42, facilitated by the presence of residual water in the reaction medium. Interestingly, the formation of 8a indicates the presence of hydroxide in the system, akin to the Suzuki-Miyaura cross-coupling43,44. N-phenyl benzamide 9a likely occurs due to proto-dehalogenation, a side reaction that is common in Pd-catalyzed reactions in basic DMF reaction media, but not fully understood mechanistically45. Biaryl amide 10a, a formal cross-coupled product, was also identified. Interestingly, experiments employing deuterated 1a-d5 and methylated benzamide 1b starting materials indicated that the “new” aryl ring does not originate from 2-bromo-benzamide 1, but instead originates from the phosphine ligand (see Supplementary Information for full details). Reactions of phosphine ligands (e.g., PPh346 and dppe47) with substrates and products at Pd are known, either via liberation of phenyl moieties and phosphido (–PPh2) or phosphonium (+PPh4) ions2,3.

Other side-products identified include 11a, presumably formed through a Buchwald-Hartwig amination type reaction of 2-bromo-N-phenyl benzamide 1a with aniline 16a; arylated product 12a, which presumably arises through amide-directed C-H arylation of phenanthridinone 2a (as with biaryl 10a, the “new” aryl ring originates from the dppe ligand); and 13a, a hydrolysis product of 4a. Side-products 14a and 15a were observed when methyl ethyl ketone (MEK) was used as a solvent and likely arise through the mono- and di-α-arylation of MEK respectively48,49,50.

Furthermore, symmetrical urea 3a was observed by LC-MS along with the requisite building block, aniline 16a produced during ipso-substitution (D to E, Fig. 2A)16,17. Another aniline derived side-product, acetanilide 17a, was identified in the analytical LC-MS method. We believe that this is formed by a Pd-mediated acetylation processs5. Quinazolinedione 18a51 could be formed through a reaction of the substrate 1a with phenyl isocyanate 20a (vide infra) and then a subsequent intramolecular amination cyclization process, or a carbonylative-type process.

We observed 19a by LC-MS, which was present throughout the HTE campaign (m/z = 469). However, we were unable to delineate its structure (see Supplementary Information for full details). Thus, we have treated 19a as being an unknown species. As we demonstrate below, our approach to complex reaction analysis allows the effects of changing reaction parameters on this unknown species / contaminant to be uncovered.

Finally, we identified several species by GC-MS of the reaction mixtures that were invisible to the LC-MS method (Fig. 3). These include the expected by-product phenyl isocyanate 20a, azobenzene 21a from oxidative coupling of aniline, which is likely promoted by Pd nanoparticles52, hydrolysis product 22a and bi- and terphenyls 23, 24, and 25. Whilst these species were not included in the profiling of reaction from our HTE work vide infra, their presence confirms the high degree of complexity of the reaction under study. Moreover, the identification of these species via GC-MS, but not LC-MS highlights that the sole use of one analysis method (which is commonplace in HTE reaction screening) ought to be viewed with some caution.

With a useful LC-MS method established, we next explored the effect of changing reaction conditions on the reaction profile using HTE. Given that most reported examples of phenanthridinone 2 syntheses use polar aprotic solvents (typically DMF and DMA) at temperatures between 100–150 °C (Fig. 1), alongside the solvent effects observed by refs. 19,20, we selected to study the effect of solvent and temperature in further detail. To this end we selected seven separate solvents {DMF, propylene carbonate, acetonitrile, n-butyronitrile, methyl ethyl ketone (MEK), di-n-butyl ether and toluene} that covered a wide range of polarities, as well as a 9:1 n-Bu2O:DMF mixture (the latter solvent mixture to aid greater solubility of the reaction components). Furthermore, propylene carbonate53,54, and MEK55 were selected primarily as potentially greener and less toxic alternatives. Five temperatures between 80–120 °C (10 °C intervals) were chosen, as were several reaction time-points from 1 to 8 h to provide a temporal visualization of the altering product(s) profile. Reactions were conducted at 130 °C, but significant solvent losses were noted in these experiments leading to unreliable data. We elected to perform the HTE campaign without a catalyst pre-activation step (see Fig. 2D) to avoid variability in the experimental workflow, which facilitated the range of side-products generated to be fully explored.

Reactions were performed on a Chemspeed ISYNTH robotic platform with a solid-dispensing unit14,15,56,57,58 to expedite reaction set-up and sampling and off-line LC-MS analysis was used to generate the reaction profile (see Supplementary Information for full experimental details, including workflow schematic diagram). We rigorously assessed positional variability and reproducibility using the ISYNTH system. In total, 40 reactions were performed in triplicate, with sampling at four different time points, generating 480 reaction profiles. LC-MS alignment and peak picking were performed using automated processing (Progenesis QI)59 and relative concentrations of the reaction constituents were obtained by normalizing the mass-ion counts over the peaks of interest (see Supplementary Information for full details), resulting in a semi-quantification of the species of interest. This approach allows the study of the variation in amount of these (characterized and uncharacterized) species with changing reaction conditions and is simpler than developing an analytical method to show absolute quantities of all species (which would be a non-viable effort in most academic/industrial settings for reactions of this complexity).

Data analysis of reaction outcomes

Analysis of such large multidimensional datasets is difficult without multi-variate statistical analysis techniques to reduce dimensionality. To visualize the effects of reaction variables, we employed principal component analysis (PCA)60, an unsupervised data analysis method that allows patterns in data with multiple variables to be observed in scatter plots with minimal loss of information. This is achieved by a rotation of the multi-dimensional axes, where each axis corresponds to a different variable, in our case the integrated intensities of identified peaks from LC-MS analysis. The rotation preserves the orthogonality of the axes but the first new axis, or principal component, is chosen as the direction of maximum variance in the data, the second principal component corresponds to the next most variance (orthogonal to the first), and so on. In this way, a small subset of the new axes, or principal components, provides most of the information in the data and pairwise scatter plots showing the coordinates of the observations in relation to even just the first two principal components can reveal meaningful patterns in the data. As these new axes are obtained by a rotation, each principal component is a linear combination of the original variables or peak intensities, and the rotation matrix provides the coefficients, or loadings, of each in the linear combinations. The magnitudes of the loadings for a particular component therefore show the importance of each species to any patterns observed in the direction of that component.

We first examined data obtained at a single temperature to reduce complexity and allow the effect of time and solvent to be studied independently of temperature. At 110 °C these effects are pronounced and highlight important trends. Indeed, PCA shows clear differences between solvents (Fig. 4). For PCA plots including all times and temperatures see the Supplementary Information. The insets show the loadings for the first two principal components (PC1 and PC2) as vectors, describing the contribution of the different compounds to the patterns seen in the corresponding scores plots.

As the variance for large peaks is greater than that for small peaks, the major products dominate the analysis, and differences due to small peaks are masked unless the variables are rescaled. UV-scaling, or scaling to unit variance gives all variables equal influence on the analysis. PCA scores plots for unscaled data are shown in the Supplementary Information. Here, differences along PC1, accounting for 97.3% of the variance in the data, are related to differences between 2-bromo-benzamide 1a, the starting material, and major product 2a. As the variance involves squared values, the scores plot can be mirrored along either PC1 or PC2 and needs to be oriented by looking at the data used in the analysis (provided as supplementary material). In this case, the data shows that Bu2O observations have the highest values of 2-bromo-benzamide 1a remaining and MeCN observations have the highest values of product 4a. Thus, positive PC1 scores are associated with high amounts of 2a and negative scores with high amounts of 1a, whilst positive PC2 scores are associated with the higher levels of other products.

After scaling the data so the analysis is not dominated by the large amounts of 2-bromo-benzamide 1a and phenanthridinone 2a, PCA shows the distribution of side-products associated with different solvents (Fig. 4). After orienting the scores plot using the original data, it can be seen that, while DMF and propylene carbonate gave the greatest amount of 2a, regardless of reaction time, Bu2O led to the most 1a remaining, with a slow but steady increase in product 2a with increasing reaction time (Fig. 4A). Other solvents, notably toluene, show a dependence on reaction time with most 1-h reactions in the center of the plot. Bu2O and toluene have the lowest values of most products, except perhaps products 7a, 8a, 9a and 12a. The large positive loadings along PC1 for the major product 2a, as well as aniline 16a, and amides 5a and 6a show that DMF and propylene carbonate observations on the right of the plot are associated with greater quantities of these products. In fact, further analysis (see Fig. 5) shows that, while both solvents produce high amounts of the major product 2a, propylene carbonate produces higher quantities of 6a whereas DMF is more associated, with higher quantities of 5a and 16a.

The plot in (A) shows experiments performed at 110 °C for four different reaction times whereas (B) shows 2-h reactions performed at five different temperatures. In both cases, 13 observations were removed. The loadings, shown as vectors in the insets, indicate the contribution of the various products to the principal components.

When considering only 2-h reaction time points performed at different temperatures, PCA reveals similar patterns with solvent (Fig. 4B). Again, reactions using Bu2O have most 1a remaining. Except for the lowest temperature reactions (reactions at 80 °C in DMF and 110 °C in 9:1 n-Bu2O/DMF), DMF and propylene carbonate result in the most phenanthridinone 2a. Most solvents show higher conversion of 1a with an increase in temperature. The greater quantities of side-products in MeCN and MEK can be seen again but outcome for both BuCN and the dual solvent system is variable. In addition to product 2a, higher quantities of aniline 16a and 6a could be associated with DMF and propylene carbonate, whilst Bu2O and toluene have the lowest values. Much of the variance along PC2 is due to unusually high proportions of some compounds being recorded for a few observations, emphasized by the scaling. As the replicate experiments did not have similar outcomes, these unusual observations could be considered outliers due to reaction sampling or analysis errors.

To show any trends with reaction time or temperature more clearly, outliers were removed, and the analysis repeated. Outliers were determined by considering the similarity of replicates. For each set of replicates, the Euclidean distance to the centroid was calculated. The mean distance plus 1.5 standard deviations was set as a threshold and any replicates with a distance greater than this were removed. This threshold was chosen as it removed the worst outliers from each dataset without taking out too many observations. Figure 5 shows the results for scaled data. The reaction time data now shows that MEK is most associated with greater amounts of a combination of products 10a, 11a, 14a, 15a and 3a, while MeCN, BuCN and the dual solvent system are more related with greater amounts of products 18a and 19a (Fig. 5A). The temperature data set shows an even greater difference in the amount of these side-products for MEK and the increasing trend with temperature can be seen more clearly for MeCN, BuCN and the dual solvent system.

Although PCA gives a good indication of the products associated with the different solvents, interpretation is complicated when several variables have similar loadings. Importantly, it is the sum of the variables that contributes to the principal component in question. For example, a lower value for side-product 6a may be compensated for by a higher value for aniline 16a, leading to a similar score as a higher value for 6a with a lower value for 16a (Fig. 4B). To determine more specific relationships between solvents and reaction products, we employed correspondence analysis (CA)33. The median quantities were calculated over replicate reactions and, for each solvent, the number of observations counted with high, medium, and low quantities of each product, overall temperatures and reaction times (a total of 20 for each solvent). Quantities less than a third of the full range (i.e., the maximum minus minimum value over all solvents) for a product were defined as low, quantities between a third and two-thirds as medium, with quantities above two-thirds of the range for the product considered as high (see Table 1).

The results are shown in Fig. 6A. The strength of the association between solvents and reaction products depends on the distance from the origin (where the dotted lines cross) and on the angle between the vectors from the origin to the points representing the solvents and products. As in PCA, the association of DMF and propylene carbonate with high amounts of the phenanthridinone product 2a can be seen, but here acetanilide 17a is associated with propylene carbonate, whilst 5a and aniline 16a are associated with DMF. Furthermore, 6a is associated with both propylene carbonate and, to a lesser extent, DMF.

A Correspondence analysis74 biplot showing associations between solvents and reaction products. Key: Dim = dimension. The number of experiments (after combining replicate analyses) with high (black), medium (orange), and low (light green) quantities for each product are used in the analysis. B Bubble plot showing the number of experiments with quantities above two-thirds of the range for the product by solvent. Bubble sizes are proportional to the number of experiments, also shown where the maximum possible is 20 (i.e., 5 temperatures for 4 reaction times).

The biplot also shows that MeCN is related to relatively high amounts of Buchwald-Hartwig product 11a, whilst MEK is most associated with MEK α-arylation products 14a and 15a (as expected for the latter solvent which serves as a substrate). Other solvents, being closer to the origin, are less well discriminated.

The bubble plot in Fig. 6B provides another means for data visualization. Here, only the number of experiments with high quantities are included. It can be readily seen that product 5a is associated with reaction in DMF with 16 of the 20 reaction profiles recorded when DMF was used (5 temperatures for 4 reaction times) show relatively high quantities of 5a. Conversely, when the reaction is performed in propylene carbonate, no reactions exhibit high quantities of 5a. However, 14 of the 20 reactions show high levels of 6a. Additionally, 12 reactions show relatively high amounts of acetanilide 17a. Again, that high amounts of α-arylation products 14a and 15a are only associated with MEK, which is as expected, validating our approach.

Heatmap analysis

To garner further mechanistic insight, we used heatmaps to visualize correlations between products. The heatmap in Fig. 7 shows the strength of any correlation across all reactions between the various products. Therefore, the correlation of a product with itself along the diagonal has the strongest positive correlation. The data includes reaction solvents, temperatures, and times. For example, the similarity of MEK α-arylation products 14a and 15a is clear from the dark red block indicating a positive correlation close to 1 (highlighted by a yellow box). The strongest negative correlations (dark blue) are between 2-bromo-benzamide 1a, and the block of positively correlated products, aniline 16a, biaryl diamide 4a, 2a-derivatized compound 6a, and phenanthridinone 2a (the major product of the reaction). This negative correlation highlights that significant consumption of 1a is correlated with formation of phenanthridinone 2a and the most prevalent side products 4a and 6a.

Median values of replicate observations were used in the analysis. Key: red boxes are positive correlations and blue boxes are negative correlations (see color bar, upper left). The reaction products are ordered using hierarchical clustering, resulting in the dendrograms shown in the margins, so that similar products cluster together. The map colors show the strength of correlation, as indicated by the color bar. Specific clusters of compounds are highlighted by colored boxes, representing selected interactions.

Aniline 16a correlates with carboxylic acid 13a (with both possibly formed from the hydrolysis of 4a) and 5a. Oxidative reaction of 2a (by C-H bond activation) with urea 3a could in principle lead to both 5a and 16a, leading to positive correlations.

Other blocks of positively correlated products show 7a (oxidative cyclization product) and 9a (reductive proto-debrominated product) grouped together. Compound 11a (the Buchwald-Hartwig amination product) correlates with both 10a (phenylated product) and quinazolinedione 18a. Although not highlighted, Fig. 7 also shows the positive correlation of 5a and 16a with 2a, supported by the similar loadings in PCA and their proximity in correspondence analysis (mainly due to being produced together in DMF reactions). Such data correlations form the basis for mechanistic proposals (vide infra).

Further mechanistic analysis, supported by stoichiometric Pd chemistry experiments

To supplement our mechanistic predictions about the catalytic cycle(s) operative in this complicated chemistry, we recognized that our HTE/data analysis would be complemented by traditional stoichiometric studies involving appropriate Pd precursor compounds. The aim of this part of the study was not to provide definitive mechanistic information, but to support the connections made in the HTE/data analysis. Previously proposed catalytic cycles reported by ref. 20. were based primarily on DFT calculations using PH3 as a model for the PPh3 ligand (along with an N-methyl substrate variant of 1a). Such a model makes a PdII/PdIV catalytic cycle possible, in principle (Fig. 2A). While higher oxidation state PdIV intermediates are experimentally feasible24, evidence for the stabilization of PdIV species by phosphines is relatively limited, exceptions being PPh361 and transphos62. Indeed, the scientific community at large have often doubted Pd catalytic cycles involved phosphine-stabilized PdIV intermediates63,64. While dppe could be related to these ligands, we conducted stoichiometric 31P NMR and MS experiments to better understand dppe interactions at Pd in the catalytic system of interest 1a → 2a and other side-products and by-products.

Amatore and Jutand showed that Pd0(dppe)2 I’ and Pd0(η2-dba)(dppe) I-dba are formed from the reaction of Pd2(dba)3•dba with n dppe (n = 1 or 2) in THF65. In our hands, reaction of 1 equivalent of Pd(OAc)2 with 1 equivalent of dppe in DMF-d7 at 23 °C resulted in a mixture of Pd0(dppe)2 I’ (δ 30.10 ppm; lit. δ 30.46 ppm in THF) and PdII(dppe)(OAc)2 (δ 59.07 ppm; lit66. δ 58.9 ppm in CH2Cl2) being formed (Fig. 8). There was no evidence for phosphine oxidation or P-C bond cleavage (forming potential phosphido groups) in these experiments. As ligand dissociation from Pd0(dppe)2 I’ is thought to generate the putative unsaturated (catalytic) Pd0 species Pd0(dppe) I, evidence was gained by addition of dba to the mixture of PdII(OAc)2/1 dppe, and cross-referencing to an authentic sample of Pd0(η2-dba)(dppe) I-dba (δ 35.5 and 37.0 ppm, ∆ν1/2 = 28 Hz)65. We also note that the presence of dba in the catalytic reaction does not significantly perturb the reaction system in terms of the many products that are formed (i.e., 0.5Pd2(dba)3/1dppe is a component catalyst system). The experiment confirmed Pd0(dppe) liberation from Pd0(dppe)2 I’ in DMF-d7 at 23 °C; this latter species is an observable species, acting as a catalyst reservoir.

31P NMR (203 MHz, DMF-d7) spectral changes and confirmation of derived (pseudo)molecular ions by ESI-MS: (1) Pd2dba3·CHCl3 and dppe taken at rt, t = 0 min; (2) taken after addition of 2-bromo-benzamide 1a at rt, t = 5 min; (3) taken after 45 min heating at 80 °C; (4) taken after 16 h heating at 80 °C. We have assigned species to five phosphorus species, cross-referenced with the ESI-MS analysis (simulated ions shown in red; experimental ions in blue). The species at δ 57.35 is a trace product, derived from the formation of Pd0(dba)(dppe)/Pd0(dppe)2, which is distinct to the species at δ 56.77 ppm, formed at higher temperature, assigned to PdBr2(dppe) VIII.

We assessed oxidative addition of 2-bromo-N-phenylbenzamide 1a to a pre-synthesized mixture of Pd0(dppe)2 I’ (Fig. 6, red) and Pd0(η2-dba)(dppe) I-dba (Fig. 8, orange), derived from Pd02(dba)3•dba and 1 dppe in DMF-d7 at 23 °C. It was necessary to heat the mixture of 1a with these Pd0 species at 80 °C to give key oxidative intermediate II (Fig. 6, yellow). Two doublets appeared at δ 41.78 and δ 59.05 ppm (2JPP = 28 Hz), supporting formation of PdII(Ar)Br(dppe) II. The 31P NMR signals for oxidative addition products of this type are typically found in the δ 56–31 ppm range (in THF or DMF)67,68. In our case, the molecular fragment [M-Br]+ was verified by ESI-MS (+ve mode). A new singlet peak at δ 65.83 ppm (Fig. 8, blue) was observed, which we attribute to reaction intermediate VI, resulting from the formation of a C-C bond between two benzo-groups. This proposal is supported by the detection of the sodiated pseudo-molecular ion [VI + Na]+ by ESI-MS (+ve mode).

Another new species with a signal of δ 56.55 ppm (Fig. 8, green) forms at 80 °C, which we tentatively assign to PdII(dppe)(Br)2 VIII (Fig. 6, green). In a separate reported study an autoionization equilibrium was noted for the behavior of PdII(dppe)(OAc)2 to give [PdII(dppe)2]2+ VIII’ + Pd(OAc)266. The detection of [PdII(dppe)2]2+ VIII’ by ESI-MS (+ve mode) allows us to assign this signal to PdII(dppe)(Br)2, VIII with a similar autoionization equilibrium [PdII(dppe)2]2+ VIII’ and PdBr2 in play66. The formation of Pd black was noted at the end of this stoichiometric reaction, which is typical for these types of experiments.

Based on the complete information to hand we propose mechanistic hypotheses, as outlined in Fig. 9A. Firstly, for the catalyst activation step we have demonstrated that Pd0(dppe) I species is generated under the reaction conditions, as the likely Pd0 species in solution (in DMF), for which there are other potential reductants in the system (thus not dependent on the phosphine ligand per se, Fig. 9A). The generation of aniline 16a under the working catalytic reaction conditions could assist formation of Pd0, leading to the generation of dppe mono-oxide69 (an alternative ligand, vide infra) and acetanilide 17a, generated through acetate transfer to aniline 16a. Given the higher reaction temperatures used for the catalytic reaction there are different mechanisms possible for pre-catalyst activation and formation of Pd0 species (see Supplementary Information, Figure 15). We expect in polar aprotic solvents, e.g., DMF, that the presence of trace dimethylamine, CO and water would likely influence the reductive process.

Key: O.A. oxidative addition, R.E. reductive elimination, RDS is rate determining step. We expect all steps resulting in loss of HBr to involve base. Potential catalytic cycles for selected side-products, based on the correlations revealed by the rich data analysis (from heat maps and hierarchical clustering; highlighted by appropriate colors). We expect all steps resulting in loss of HBr to involve base. We do not preclude dppeO being an alternative ligand for Pd in these catalytic cycles, especially in solvents where there is no other potential reductant, i.e., where phosphine ligand becomes the obvious reductant. The blue color in the chemical structures shows the origin of the benzo-moiety.

We have confirmed experimentally that oxidative addition of 2-bromo-N-phenylbenzamide 1a with Pd0 species containing dppe occurs to give PdII species II containing new Pd-Br and Pd-C bonds (confirming scission of the C-Br bond in 1a). From this point, a second oxidative addition-type reaction (mechanism not characterized) of 2-bromo-N-phenylbenzamide 1a to II is necessary to generate a putative PdIV species III (following the mechanism20 hypothesized by a Porée et al.). This is critical in generating a new C-C bond between the required benzo-groups, which occurs by subsequent reductive elimination to give PdII intermediate IV. The structure of VI is supported by NMR and MS, thus IV is connected by loss of two equivalents of HBr via V (which is likely base-assisted). This could in principle occur in a single step. We propose that VI is involved in the rate determining step/state (RDS). Extrusion of phenylisocyanate 20a (which can be trapped by reaction with aniline 16a to afford the urea 3a) then affords PdII intermediate VII, which we believe to possess a high energetic barrier. An alternative pathway from V → VII is shown (via V´), involving amide hydrolysis, formation of a Pd-O bond, extrusion of CO2 and formation of aniline 16a. The final step involves reductive elimination from VII to give phenanthridinone 2a (the major and dominant product), with concomitant regeneration of the active Pd0 catalyst species “Pd0(dppe)” I.

Figure 9 further reveals how other major side-products 4a (main cycle, de-coordination from PdII intermediate IV), 5a, 6a, and 7a are connected to the main catalytic cycle. The heat map and hierarchical cluster analysis connecting 5a, 13a, and 16a, which are formed as downstream products from proposed intermediate IV, indicate that there are several exit points from the main catalytic cycle from which these side-products form.

We propose that pentacycle 7a arises through a formal oxidative C-H activation of phenanthridinone 2a. Thus, reaction of Pd(dppe)Br2 VIII with 2a would involve formation of PdII intermediate IX (loss of HBr). Cyclopalladation, with loss of HBr70 would give 6-membered ring palladacycle X. A classical reductive elimination step then forms 7a and leads to the regeneration of ‘Pd0(dppe)’ catalyst species I. The confirmed appearance of Pd(dppe)Br2 VIII in our stoichiometric Pd experiments supports this potential oxidative process. The association of proto-debrominated product 9a with the formation of 7a (revealed by the Heat Map and hierarchical cluster analysis) suggests that 2-bromo-N-phenylbenzamide 1a is capable of acting as an oxidant in this competing catalytic cycle. Organohalides acting as oxidants for Pd0 → PdII is established and has been exploited in other chemical synthesis applications71,72. We do not preclude a role for trace air in this process, serving a role to oxidize “Pd0” to “PdII” species that would be equally capable of promoting the formation of 7a through a similar sequence of steps. Qualitatively we can state that in the presence of air 7a is formed in higher quantities.

The heat map correlation of side-product 6a with 2a allows us to propose that a C-H activation process involving phenanthridinone 2a and PdII oxidative addition intermediate II is likely, giving complex XI (detailed steps not given—cycle shown in Fig. 9). Subsequent reductive elimination regenerates the “Pd0(dppe)” catalyst species I, releasing compound 6a as another side-product. Catellani et al. has suggested that compounds similar to 6 could arise by intramolecular cyclopalladation, followed by coupling with 1a and ipso-substitution16. We recognize that 6a could derive directly from intermediate VI, through phenanthridinone ring-formation, retaining the phenyl amide group. This would account for 6a having positive interactions with 2a in the correlation.

Building on the discussion above about the correlation of 5a, 13a, and 16a—Porée et al. found20 that compounds like 5 dominated under reaction conditions in which bromine–carbonate exchange and hence, rotation around the biaryl axis is disfavored. We acknowledge that 5a could be formed by reaction of urea 3a with product 2a, for which the heat map analysis shows a strong positive correlation. Hydrolysis of 4a likely occurs at PdII, thus carboxylic acid 13a and aniline 16a derived from intermediate IV.

The dppe ligand is a phenyl donor source that is transferred to 10a and 12a—it is established that phenyl-containing phosphines are capable of transferring a phenyl group at Pd47. On the other hand, hydrolysis product 8a likely derives from oxidative addition intermediate II. The heat map correlation between 10a, 11a, and 18a shows that phenyl transfer from the dppe ligand is prevalent where amination occurs. Quinazolinedione 18a formation is linked to 11a, which we propose to be formed via a carbonylative process.

Discussion

We have examined arguably one of the most complicated homogeneous-based Pd-catalyzed reactions reported in the literature – that is the reaction of 2-bromo-N-phenylbenzamide 1a to give N-phenyl phenanthridinone 2a, along with a plethora of by-products and side-products. We identified this reaction system as amenable to study better through the generation of a larger number of reaction outcomes, and profiling those reactions for all products formed in >0.1 %. Previous studies had highlighted the presence of some side-products and by-products, but the true extent of the reaction complexity was not known, moreover, the potential links between related and non-related products were not established16,17,18,19,20,21. Mechanisms had been hypothesized based on limited experimental evidence. Using automated high-throughput experimentation (HTE) methods and batch screening technologies, has enabled the effect of temperature and solvent on the reaction profile to be deduced. PCA of 480 batch reaction outcomes revealed the clear variance in starting material 1a, product 2a, and side-product profiles based upon solvent choice. Correspondence and Heat Map (with hierarchical clustering) analysis allowed us to confidently draw associations between reaction conditions and the interactions between different products. This detailed reaction profiling and statistical analysis approach has given us a better understanding of a complex reaction network and garnered new insight and chemical knowledge. Moreover, the approach we have devised can potentially serve as a blueprint for studying reaction complexity in other current and future reaction chemistries.

We can summarize our findings as follows: 1) The HTE reaction screening and associated data analysis revealed detailed information about the complexity associated with the Pd-catalyzed reaction of 1a → 2a and other side-products and by-products, involving many different types of bond activation and formation (i.e., C-Br, N-H and C-C). Post-functionalization of 2a is affected by solvent polarity, reaction temperature and time. The profile and distribution of side-products indicate that there could be advantages in exploring both higher and lower reaction temperatures, and longer and shorter reaction times, to aid in promoting formation of one particular product (for discovery purposes). 2) Kinetic profiles revealed that 1a is consumed over 1.5–2.25 h and that there is a confirmed pre-catalyst induction period (Fig. 2D), which can be reduced in time by pre-heating the mixture of Pd(OAc)2 and dppe. This approach is not commonly applied in synthetic chemistry, and we recommend that both regimes are tested in assessing the full-scope of a metal-catalyzed reaction. 3) The Pd pre-catalyst activation pathway has been examined stoichiometrically in DMF solvent, which confirmed that Pd0(dppe)n species are formed under the reaction conditions tested. While the mono-oxide of dppeO was not detected in this reaction, a potential role for this alternative hemilabile bidentate ligand is not discounted in other reaction solvents, particularly under catalytically-relevant conditions and/or where trace air is in the system. Practically speaking, the phosphine can be a sacrificial reductant for Pd(II) to Pd(0), particularly for reactions employing Pd(OAc)2. The use of Pd2(dba)3/dppe can avoid this issue, so long as O2 is minimized in the system. Furthermore, it is important to consider that the original ligands added to a catalytic reaction involving a transition metal might be different under working reaction conditions. Any structural modification could alter the ligand steric and electronic effects. For a bidentate ligand, the bite angle and hemi-lability could also be changed. 4) The heat map and hierarchal clustering correlations were evidenced by — a) Concomitant formation of pentacycle 7a with proto-debrominated benzamide 9a allows us to conclude that 1a is a potential oxidant71,72 in this competing catalytic cycle (note: we do not preclude the presence of trace air-promoting formation of 7a via oxidic PdII species); b) Positive interactions between 5a, 13a, and 16a confirm that there is an exit point from the main catalytic cycle involving species IV; c) Correlation of side-product 6a with 2a allows us to propose that a C-H activation process involving phenanthridinone 2a and PdII oxidative addition intermediate II is possible. However, it is feasible that 6a could derive from intermediate VI, thus 6a is formed along with 2a. 5) Complementary stoichiometric organopalladium studies has allowed us to gain insights into likely reaction Pd intermediates, particularly an oxidative addition intermediate and advanced downstream PdII intermediate following activation of two molecules of 2-bromo-N-phenylbenzamide 1a. There are benefits to be gained from such experiments in understanding what are the likely catalytic species and catalyst resting states, i.e., prior to conducting computational studies and more in-depth kinetic studies. 6) The rate determining step is proposed to be extrusion of phenyl isocyanate 20a, affording intermediate VII, based on the appearance of VI experimentally. To have an indication about the rate determining step can potentially aid future reaction development, particularly how this might change under varying reaction conditions.

The combined HTE, data rich analytical approach, complemented by traditional organopalladium mechanistic studies, has allowed us to gain new insight into a highly complicated Pd-mediated processes. We expect our approach in general terms, and the techniques employed, could find wide application in the field of transition metal catalysis and applied synthetic chemistry. Indeed, the full mapping out of the complexity of the reaction system (as described above), with a focus on the identification and distribution of side products and by-products, could be both a useful and rewarding point to optimize to. Moreover, profiling more broadly the complete fingerprint of a given reaction system could contribute towards a more holistic understanding of chemical reaction Tox-Profiles, as outlined by ref. 73.

Methods

Synthetic procedure for the major product, 5-phenyl-5,6-dihydrophenanthridin-6-one 2a

Pd(OAc)2 (5.6 mg, 0.025 mmol, 5 mol%), dppe (10.0 mg, 0.025 mmol, 5 mol%), and K2CO3 (138 mg, 1.0 mmol, 2.0 eq.) were placed in a Schlenk tube under N2. DMF (1.5 mL) was added, and the mixture was stirred at 80 °C for 2 min. Then, a solution of 2-bromo-N-phenylbenzamide 1a (138 mg, 0.5 mmol, 1.0 eq.) in DMF (1 mL) was added via cannula. [Air was injected into the reaction mixture via syringe (5 mL)—to assess the impact of trace air in the reaction systems]. The reaction mixture was then stirred at 80 °C for 6 h then allowed to cool to room temperature (~22 ˚C). Then, EtOAc (10 mL) was added, and the resulting mixture was filtered through Celite and washed with EtOAc (3×5 mL). The combined organic extracts were was washed with 1 M HCl(aq) (10 mL) and brine (10 mL), dried over MgSO4, filtered, and the concentrated under reduced pressure to give a crude product which was subsequently purified by flash column chromatography (SiO2, 9:1 to 8:2 petrol:EtOAc), to afford compound 2a as a white solid (39 mg, 58%).

Data availability

The raw data from the HTE screening experiments (LC-MS data) has been deposited to Research Data York (freely available). See DOI: 10.15124/37869e97-c94a-41a7-9f69-fe3ed1c10984. Representative NMR spectral data (included in the Supplementary Information document) can also be found in the same data location. Source data is also provided as a single.csv file (Supplementary Information). The single crystal X-ray diffraction files (.cif) have been deposited to the Cambridge Crystallographic Database (compound 2a, CCDC 2063167; compound 2b, CCDC 2063164; compound 4a, CCDC 2063166); compound 5a, CCDC 2081723; compound 7a, CCDC 2063165; compound S3 (supplementary reference compound), CCDC 2081724). All data are available from the corresponding authors. Source data are provided with this paper.

References

Broadbelt, L. J. & Pfaendtner, J. Lexicography of kinetic modeling of complex reaction networks. AIChE J. 51, 2112–2121 (2005).

Scott, N. W. J. et al. The ubiquitous cross-coupling catalyst system ‘Pd(OAc)2’/2PPh3 forms a unique dinuclear PdI complex: an important entry point into catalytically competent cyclic Pd3 clusters. Chem. Sci. 10, 7898–7906 (2019).

Scott, N. W. J. et al. A dichotomy in cross-coupling site selectivity in a dihalogenated heteroarene: influence of mononuclear Pd, Pd clusters, and Pd Nanoparticles—the case for exploiting Pd catalyst speciation. J. Am. Chem. Soc. 143, 9682–9693 (2021).

Amatore, C., Carre, E., Jutand, A. & M’Barki, M. A. Rates and mechanism of the formation of zerovalent palladium complexes from mixtures of Pd(OAc)2 and tertiary phosphines and their reactivity in oxidative additions. Organometallics 14, 1818–1826 (1995).

Amatore, C. & Jutand, A. Anionic Pd(0) and Pd(II) intermediates in palladium-catalyzed heck and cross-coupling reactions. Acc. Chem. Res. 33, 314–321 (2000).

Amatore, C., Jutand, A. & Thuilliez, A. Formation of palladium(0) complexes from Pd(OAc)2 and a bidentate phosphine ligand (Dppp) and their reactivity in oxidative addition. Organometallics 20, 3241–3249 (2001).

Rulev, A. Y. Serendipity or the art of making discoveries. N. J. Chem. 41, 4262–4268 (2017).

McNally, A., Prier, C. K. & MacMillan, D. W. C. Discovery of an α-amino C–H arylation reaction using the strategy of accelerated serendipity. Science 334, 1114–1117 (2011).

Robbins, D. W. & Hartwig, J. F. A simple, multidimensional approach to high-throughput discovery of catalytic reactions. Science 333, 1423–1427 (2011).

Troshin, K. & Hartwig, J. F. Snap deconvolution: an informatics approach to high-throughput discovery of catalytic reactions. Science 357, 175–181 (2017).

Allen, C. L., Leitch, D. C., Anson, M. S. & Zajac, M. A. The power and accessibility of high-throughput methods for catalysis research. Nat. Catal. 2, 2–4 (2019).

Isbrandt, E. S., Sullivan, R. J. & Newman, S. G. High throughput strategies for the discovery and optimization of catalytic reactions. Angew. Chem. Int. Ed. 58, 7180–7191 (2019).

Krska, S. W., DiRocco, D. A., Dreher, S. D. & Shevlin, M. The evolution of chemical high-throughput experimentation to address challenging problems in pharmaceutical synthesis. Acc. Chem. Res. 50, 2976–2985 (2017).

Mennen, S. M. et al. The evolution of high-throughput experimentation in pharmaceutical development and perspectives on the future. Org. Process Res. Dev. 23, 1213–1242 (2019).

Christensen, M. et al. Data-science driven autonomous process optimization. Commun. Chem. 4, 112 (2021).

Ferraccioli, R., Carenzi, D., Motti, E. & Catellani, M. A simple catalytic synthesis of condensed pyridones from O-bromoarylcarboxamides involving ipso substitution via palladacycles. J. Am. Chem. Soc. 128, 722–723 (2006).

Furuta, T. et al. Efficient synthesis of phenanthridinone derivatives via a palladium-catalyzed coupling process. Org. Lett. 9, 183–186 (2007).

Furuta, T. et al. Synthesis of axially chiral amino acid and amino alcohols via additive−ligand-free Pd-catalyzed domino coupling reaction and subsequent transformations of the product amidoaza [5] helicene. J. Org. Chem. 75, 7010–7013 (2010).

Donati, L., Michel, S., Tillequin, F. & Porée, F.-H. Selective unusual Pd-mediated biaryl coupling reactions: solvent effects with carbonate bases. Org. Lett. 12, 156–158 (2010).

Donati, L. et al. Solvent/base effects in the selective domino synthesis of phenanthridinones that involves high-valent palladium species: experimental and theoretical studies. Chem. Eur. J. 17, 12809–12819 (2011).

Caddick, S. & Kofie, W. Observations on the intramolecular heck reactions of aromatic chlorides using palladium/imidazolium salts. Tetrahedron Lett. 43, 9347–9350 (2002).

Liu, H. et al. Practical synthesis of phenanthridinones by palladium-catalyzed one-pot C–C and C–N coupling reaction: extending the substrate scope to o-chlorobenzamides. Eur. J. Org. Chem. 2016, 389–393 (2016).

Zheng, Q., Liu, C.-F., Chen, J. & Rao, G.-W. C–H functionalization of aromatic amides. Adv. Synth. Catal. 362, 1406–1446 (2020).

Sehnal, P., Taylor, R. J. K. & Fairlamb, I. J. S. Emergence of Palladium(IV) chemistry in synthesis and catalysis. Chem. Rev. 110, 824–889 (2010).

Cui, X., Zhou, Y., Wang, N., Liu, L. & Guo, Q.-X. N-phenylurea as an inexpensive and efficient ligand for Pd-catalyzed Heck and room-temperature Suzuki reactions. Tetrahedron Lett. 48, 163–167 (2007).

Smith, M. R., Kim, J. Y. & Ciufolini, M. A. Pd–arylurea complexes for the Heck arylation of crotonic and cinnamic substrates. Tetrahedron Lett. 54, 2042–2045 (2013).

Vaith, J., Rodina, D., Spaulding, G. C. & Paradine, S. M. Pd-catalyzed heteroannulation using N-arylureas as a sterically undemanding ligand platform. J. Am. Chem. Soc. 144, 6667–6673 (2022).

Cui, X., Li, J., Fu, Y., Liu, L. & Guo, Q.-X. Regioselective Pd-catalyzed indolization of 2-bromoanilines with internal alkynes using phosphine-free ligands. Tetrahedron Lett. 49, 3458–3462 (2008).

Ruiz-Castillo, P. & Buchwald, S. L. Applications of palladium-catalyzed C–N cross-coupling reactions. Chem. Rev. 116, 12564–12649 (2016).

Bisai, V., Saina Shaheeda, M. K., Gupta, A. & Bisai, A. Biosynthetic relationships and total syntheses of naturally occurring benzo [c] phenanthridine alkaloids. Asian J. Org. Chem. 8, 946–969 (2019).

Lugo, M. & Merrill, A. The father, son and cholix toxin: the third member of the DT group mono-ADP-ribosyltransferase toxin family. Toxins 7, 2757–2772 (2015).

Patil, S. et al. Synthesis and biological evaluation of novel 5(H)-phenanthridin-6-ones, 5(H)-phenanthridin-6-one diketo acid, and polycyclic aromatic diketo acid analogs as new HIV-1 integrase inhibitors. Bioorg. Med. Chem. 15, 1212–1228 (2007).

Ishida, J. et al. 4-phenyl-1,2,3,6-tetrahydropyridine, an excellent fragment to improve the potency of PARP-1 inhibitors. Bioorg. Med. Chem. Lett. 15, 4221–4225 (2005).

Dow, R. L., Chou, T. T., Bechle, B. M., Goddard, C. & Larson, E. R. Identification of tricyclic analogs related to ellagic acid as potent/selective tyrosine protein kinase inhibitors. J. Med. Chem. 37, 2224–2231 (1994).

Grese, T. A. et al. Photochemical synthesis of N-arylbenzophenanthridine selective estrogen receptor modulators (SERMs). J. Med. Chem. 44, 2857–2860 (2001).

Nakamura, M. et al. Structural development studies of anti-hepatitis C virus agents with a phenanthridinone skeleton. Bioorg. Med. Chem. 18, 2402–2411 (2010).

Egorova, K. S., Galushko, A. S. & Ananikov, V. P. Introducing tox-profiles of chemical reactions. Angew. Chem. Int. Ed. 59, 22296–22305 (2020).

Bajwa, S. E. et al. On the appearance of nitrite anion in [PdX(OAc)L2] and [Pd(X)(C^N)L] syntheses (X = OAc or NO2): photocrystallographic identification of metastable Pd(η1-ONO)(C^N)PPh3. Chem. Sci. 3, 1656–1661 (2012).

Bernini, R., Cacchi, S., Fabrizi, G. & Sferrazza, A. A simple general approach to phenanthridinones via palladium-catalyzed intramolecular direct arene arylation. Synthesis, 2008, 729–738 (2008).

Markgraf, J. H. et al. A versatile route to benzocanthinones. Tetrahedron 61, 9102–9110 (2005).

Gehring, A. P., Tremmel, T. & Bracher, F. One-pot conversion of 1-bromo-β-carboline and 1-bromocarbazole into pentacyclic compounds by Suzuki cross-coupling followed by spontaneous cyclization. Synthesis 46, 893–898 (2014).

Sergeev, A. G. et al. Palladium-catalyzed hydroxylation of aryl halides under ambient conditions. Angew. Chem. Int. Ed. 48, 7595–7599 (2009).

Amatore, C., Le Duc, G. & Jutand, A. Mechanism of palladium-catalyzed Suzuki–Miyaura reactions: multiple and antagonistic roles of anionic “bases” and their countercations. Chem. Eur. J. 19, 10082–10093 (2013).

Carrow, B. P. & Hartwig, J. F. Distinguishing between pathways for transmetalation in Suzuki−Miyaura reactions. J. Am. Chem. Soc. 133, 2116–2119 (2011).

Zawisza, A. M. & Muzart, J. Pd-catalyzed reduction of aryl halides using dimethylformamide as the hydride source. Tetrahedron Lett. 48, 6738–6742 (2007).

Goodson, F. E., Wallow, T. I. & Novak, B. M. Mechanistic studies on the aryl−aryl interchange reaction of ArPdL2I (L = Triarylphosphine) complexes. J. Am. Chem. Soc. 119, 12441–12453 (1997).

Baranano, D. & Hartwig, J. F. Carbon-heteroatom bond-forming reductive elimination. mechanism, importance of trapping reagents, and unusual electronic effects during formation of aryl sulfides. J. Am. Chem. Soc. 117, 2937–2938 (1995).

Crawford, S. M., Alsabeh, P. G., & Stradiotto, M. Palladium-catalyzed mono-α-arylation of carbonyl-containing compounds with aryl halides using dalphos ligands. Eur. J. Org. Chem. 2012, 6042–6050 (2012).

Navarro, O., Marion, N., Oonishi, Y., Kelly, R. A. & Nolan, S. P. Suzuki−Miyaura, α-Ketone Arylation and Dehalogenation Reactions Catalyzed by a Versatile N-Heterocyclic Carbene−Palladacycle Complex. J. Org. Chem. 71, 685–692 (2006).

Tan, Y. & Hartwig, J. F. Palladium-catalyzed amination of aromatic C−H bonds with oxime esters. J. Am. Chem. Soc. 132, 3676–3677 (2010).

Duangjan, C., Rukachaisirikul, V., Saithong, S. & Kaeobamrung, J. Copper-catalyzed domino reaction of carbodiimides and benzoic acid derivatives for the synthesis of quinazolinediones. Tetrahedron Lett. 59, 3537–3540 (2018).

Cai, S. et al. Room temperature activation of oxygen by monodispersed metal nanoparticles: oxidative dehydrogenative coupling of anilines for azobenzene syntheses. ACS Catal. 3, 478–486 (2013).

Schäffner, B., Schäffner, F., Verevkin, S. P. & Börner, A. Organic carbonates as solvents in synthesis and catalysis. Chem. Rev. 110, 4554–4581 (2010).

Parker, H. L., Sherwood, J., Hunt, A. J. & Clark, J. H. Cyclic carbonates as green alternative solvents for the heck reaction. ACS Sustain. Chem. Eng. 2, 1739–1742 (2014).

Byrne, F. P. et al. Tools and techniques for solvent selection: green solvent selection guides. Sustain. Chem. Process. 4, 7 (2016).

Greenaway, R. L. et al. From concept to crystals via prediction: multi-component organic cage pots by social self-sorting. Angew. Chem. Int. Ed. 58, 16275–16281 (2019).

Christensen, M. et al. Development of an automated kinetic profiling system with online HPLC for reaction optimization. React. Chem. Eng. 4, 1555–1558 (2019).

Martin, M. C. et al. Versatile methods to dispense submilligram quantities of solids using chemical-coated beads for high-throughput experimentation. Org. Process Res. Dev. 23, 1900–1907 (2019).

Nonlinear Dynaminc, accessed 23 March 2024, https://www.nonlinear.com/progenesis/qi-for-proteomics/.

Bro, R. & Smilde, A. K. Principal component analysis. Anal. Methods 6, 2812–2831 (2014).

Bayler, A., Canty, A. J., Skelton, B. W. & White, A. H. Organopalladium(IV) complexes containing phosphine ligands, and the structure of the platinum(IV) complex [PtMe3(Bpy)(PPh3)][O3SCF3] (Bpy=2,2′-bipyridine). J. Organomet. Chem. 595, 296–299 (2000).

Gillie, A. & Stille, J. K. Mechanisms of 1,1-reductive elimination from palladium. J. Am. Chem. Soc. 102, 4933–4941 (1980).

Shaw, B. L. Speculations on new mechanisms for heck reactions. N. J. Chem. 22, 77–79 (1998).

Milstein, D. & Stille, J. K. Palladium-catalyzed coupling of tetraorganotin compounds with aryl and benzyl halides. synthetic utility and mechanism. J. Am. Chem. Soc. 101, 4992–4998 (1979).

Amatore, C., Broeker, G., Jutand, A. & Khalil, F. Identification of the effective palladium(0) catalytic species generated in situ from mixtures of pd(dba)2 and bidentate phosphine ligands. determination of their rates and mechanism in oxidative addition. J. Am. Chem. Soc. 119, 5176–5185 (1997).

Bianchini, C. et al. Ligand and Solvent Effects in the Alternating Copolymerization of Carbon Monoxide and Olefins by Palladium−Diphosphine Catalysis. Organometallics 21, 16–33 (2002).

Mann, G., Baranano, D., Hartwig, J. F., Rheingold, A. L. & Guzei, I. A. Carbon−sulfur bond-forming reductive elimination involving sp-, sp2-, and sp3-hybridized carbon. mechanism, steric effects, and electronic effects on sulfide formation. J. Am. Chem. Soc. 120, 9205–9219 (1998).

Ludwig, M., Strömberg, S., Svensson, M. & Åkermark, B. An exploratory study of regiocontrol in the heck type reaction. influence of solvent polarity and bisphosphine ligands. Organometallics 18, 970–975 (1999).

Ji, Y. et al. Mono-oxidation of bidentate bis-phosphines in catalyst activation: kinetic and mechanistic studies of a Pd/xantphos-catalyzed C–H functionalization. J. Am. Chem. Soc. 137, 13272–13281 (2015).

Topczewski, J. J. & Sanford, M. S. Carbon–hydrogen (C–H) bond activation at PdIV: a frontier in C–H functionalization catalysis. Chem. Sci. 6, 70–76 (2015).

Zhao, Y. et al. Oxidative cross-coupling through double transmetallation: surprisingly high selectivity for palladium-catalyzed cross-coupling of alkylzinc and alkynylstannanes. J. Am. Chem. Soc. 128, 15048–15049 (2006).

Jin, L., Zhao, Y., Wang, H., & Lei, A. Palladium-catalyzed R(sp3)-Zn/R(sp)-SnBu3 oxidative cross-coupling. Synthesis 2008, 649–654 (2008).

Egorova, K. S., Galushko, A. D. & Ananikov, V. P. Toxicity profiles introducing tox-profiles of chemical reactions. Angew. Chem. Int. Ed. 59, 22296–22305 (2020).

Hirschfeld, H. O. A connection between correlation and contingency. Math. Proc. Camb. Philos. Soc. 31, 520–524 (1935).

Acknowledgements

We are grateful to Chemspeed Technologies Ltd to a Partnership with the University of York which led to the embedment of an ISYNTH robotic platform within our laboratories, with particular thanks to Christian Dittrich, Jake Grace, Stephane Rickling, and Andrew Stephenson for supporting our efforts with technical training and maintenance. We have been principally funded by the EPRSC for this research (EP/S009965/1; “A Fully-Automated Robotic System for Intelligent Chemical Reaction Screening”) and supported by EPSRC IAA awards and a Centre for Future Health (“CFH1 Partnership—Pharmaceutical Optimization using a Laboratory Automated Reaction Intelligent System (POLARIS)”) by the University of York. The research leading to these results has received funding from the Innovative Medicines Initiative Joint Undertaking under grant agreement no. 115360, resources of which are composed of financial contributions from the European Union’s Seventh Framework Programme (FP7/2007–2013) and EFPIA companies’ in-kind contributions (to L.A.L., D.J.M. and I.J.S.F.). The research was supported in part by another EPSRC grant, with follow-on funding for C.S.H. and J.B.E. (EP/W031914/1). I.J.S.F. and J.M.L. are currently supported by Royal Society Industry Fellowships. R.A.B. was supported by the Royal Academy of Engineering under the Research Chairs and Senior Research Fellowships scheme.

Author information

Authors and Affiliations

Contributions

I.J.S.F. conceived and designed the original research project examining the underpinning mechanistic chemistry. L.A.L. designed and executed these initial synthetic and mechanistic experiments (PhD study), directed by I.J.S.F. with co-supervision provided by D.J.M. L.A.L. was supported by work conducted by R.C. and A.P. J.B.E. conducted the in operando IR spectroscopic analyses. A high throughput screening and data analysis project laid the foundations of GEC’s PhD project, which was designed by I.J.S.F., J.M.L., J.M.S. and J.W., who all played a role in the supervision of G.E.C. Synthetic chemistry experiments, HTE, and other data analysis were conducted as part of G.E.C.’s PhD studies (major part of thesis); P.L.M. conducted supporting experiments along with G.E.C. J.T.W.B. conducted screening experiments on the Chemspeed ISYNTH system, helping to direct and guide G.E.C. Both C.S.H. and R.A.B. assisted with the design and execution of automated experiments. A.C.W., J.M. and S.H. conducted single-crystal X-ray diffraction experiments, refined data, and solved the chemical structures described in the manuscript. J.D.F. (re)synthesized the majority of organic compounds described in the manuscript. J.D.F. wrote a first draft of the manuscript and Supplementary Information documents, in consultation with I.J.S.F. and J.W. This involved assembling data from PhD theses (L.A.L. and G.E.C.), cross-referenced with other works conducted in the laboratory by others. I.J.S.F. and J.W. co-led the writing of the final manuscript, including revision and creation of figures. The experiments leading to the results described in this manuscript were conducted locally at the University of York. The project involved a collaboration (and funded research projects) with the University of Leeds (a local partner), which aided study design and implementation. Further experiments were conducted at the University of Leeds on the use of continuous flow reaction screening (led by R.B.). Those results will be reported separately. The research was not restricted or prohibited in the setting of the researchers. It was not necessary to seek local ethics approval for the program of research that led to the results described in this manuscript. Local and national guidelines were followed concerning the use of potentially hazardous substances, for which appropriate individual experimental risk assessments were made.

Corresponding authors

Ethics declarations

Competing interests

I.J.S.F. declares a potential competing interest associated with this research. All other authors do not have competing interests. Working in partnership with Chemspeed Technologies, ISYNTH equipment was embedded within the Chemistry laboratories in York in 2012. A contract with the University of York was put in place for the Chemspeed Technologies UK to be based in York from 2012–19. All research conducted on the equipment was free from direct involvement with the company. The research did not require prior approval for publication of this research. The company checked the acknowledgements section prior to submission of the manuscript for peer review.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Clarke, G.E., Firth, J.D., Ledingham, L.A. et al. Deciphering complexity in Pd–catalyzed cross-couplings. Nat Commun 15, 3968 (2024). https://doi.org/10.1038/s41467-024-47939-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-47939-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.