Abstract

The limited surface coverage and activity of active hydrides on oxide surfaces pose challenges for efficient hydrogenation reactions. Herein, we quantitatively distinguish the long-puzzling homolytic dissociation of hydrogen from the heterolytic pathway on Ga2O3, that is useful for enhancing hydrogenation ability of oxides. By combining transient kinetic analysis with infrared and mass spectroscopies, we identify the catalytic role of coordinatively unsaturated Ga3+ in homolytic H2 dissociation, which is formed in-situ during the initial heterolytic dissociation. This site facilitates easy hydrogen dissociation at low temperatures, resulting in a high hydride coverage on Ga2O3 (H/surface Ga3+ ratio of 1.6 and H/OH ratio of 5.6). The effectiveness of homolytic dissociation is governed by the Ga-Ga distance, which is strongly influenced by the initial coordination of Ga3+. Consequently, by tuning the coordination of active Ga3+ species as well as the coverage and activity of hydrides, we achieve enhanced hydrogenation of CO2 to CO, methanol or light olefins by 4-6 times.

Similar content being viewed by others

Introduction

Hydrogen activation on solid surfaces is a central topic in catalytic processes involving hydrogen evolution, such as hydrogenation1,2,3 and hydrogen production4,5, and for fundamental mechanistic studies to develop catalyst design principles6,7.

Many studies have demonstrated that hydrogen is easily homolytically dissociated into hydrides on a single metal atom or ensembles with several metal atoms for hydrogenation reactions. However, while these supported metals exhibit high activity, they often have low selectivity due to over-hydrogenation8. Recently, oxides have emerged as a promising class of catalysts for hydrogen-related reactions including CO2 hydrogenation3, syngas conversion9,10,11, and propane dehydrogenation12, exhibiting both remarkable activity and selectivity. Metal cations on oxides are strictly isolated by the counter oxygen anions, resulting in the predominantly considered heterolytic dissociation mechanism of hydrogen13. The infrared spectroscopy (IR)14,15, inelastic neutron scattering16,17, and solid-state NMR18 have evidenced the presence of heterolytic dissociation of H2 on oxides including In2O319, CeO220,21, MgO15, ZnO14, and Ga2O318,22,23.

However, the heterolytic dissociation presents a limit for the subsequent hydrogenation on oxides, as the amount of resulting hydride may not be sufficient for the reactions involving transfer of multiple electrons and hydrogen atoms. The migration of hydrides from proximal sites24,25,26, such as spillover, ensures the catalytic cycle, but would result in high barriers up to 2-8 eV and slow down the reaction27,28. In addition, the migration of hydrides along lattice oxygen atoms increases the possibility of hydride elimination to hydroxyl, further exacerbating the hydride shortage29. To the present, rare definitive experimental proof has quantified the evolution of hydrogen on oxides, perpetuating the dilemma of hydrogen dissociation mechanism. The quantitative and time-resolved analyses of the complex dynamics of hydrogen activation remains a crucial challenge in understanding the hydrogen activation and increasing the hydrogenation ability of oxides.

Herein, we developed a spectroscopic kinetic approach that combines transient kinetic analysis with infrared spectroscopy (TKA-IR) and mass spectroscopy (TKA-MS), to differentiate the long-puzzling homolytic dissociation of hydrogen from the heterolytic pathway on Ga2O3. We showed that the homolytic dissociation of hydrogen emerges on the coordinatively unsaturated Ga3+ that formed in-situ during the initial heterolytic dissociation process. The homolytic dissociation sites are highly dependent on the initial coordination of metal cations. The octahedral Ga3+ (Ga [Oct]) on α-Ga2O3 gives a high H/surface Ga3+ ratio of 1.6 and H/OH ratio of 5.6 as a result of the homolytic dissociation, improving the hydrogenation ability for oxides. We were therefore able to achieve greatly enhanced hydrogenation catalysis by tuning the coordination of active Ga3+, and the coverage and activity of activated hydrides.

Results

Surface coordination structures of Ga2O3

Ga2O3 is a well applied material for hydrogen evolution related catalysis30,31. We synthesized Ga2O3 nanoparticles with different crystalline structures (α-, ε-, and β-Ga2O3). The identification of crystal phases was confirmed by X-ray diffraction (XRD, Supplementary Fig. 1) and high-resolution transmission electron microscopy (HRTEM, Supplementary Fig. 2) with selected area electron diffractions. The sizes of α-Ga2O3 and ε-Ga2O3 crystallites were determined to be 9-10 nm based on the Scherrer equation, while β-Ga2O3 had a mean size of 45 nm. HRTEM revealed that α-Ga2O3 was mesoporous nanorods composing of ~10 nm nanoparticles, ε-Ga2O3 was aggregates composing of ~15 nm nanoparticles, and β-Ga2O3 displayed irregular shapes. Consequently, the Ga2O3 catalysts exhibited varying surface areas within the range of 47-95 m2/g (Supplementary Table 1). To characterize the coordination structures of Ga3+ cations in Ga2O3, X-ray absorption near-edge structure (XANES) was employed (Supplementary Figs. 3-4, Supplementary Table 2). The absorptions at around 10375 and 10379 eV are attributed to tetrahedral Ga3+ (Ga[Tet]) and octahedral Ga[Oct], respectively32. The results showed that α-Ga2O3 is dominated by octahedral coordination, ε-Ga2O3 has a proportion of octahedral sites of 85%, whereas β-Ga2O3 has 50% octahedral and 50% tetrahedral sites. The results were consistent with the structures of ideal crystals.

However, the surface coordination of Ga3+ sites may vary due to structural defects or perturbations of the adsorbed species33. To investigate the surface coordination, we conducted hydrogen-adsorbed infrared spectroscopy (H2-IR). We degassed the catalysts in the Ar flow at 350 oC and then exposed them to H2 for adsorption. The H2-IR spectra revealed two IR bands at 2003 and 1980 cm−1, which were assigned to hydrides bonding to Ga[Tet] and Ga[Oct], respectively (Fig. 1a–c)22. The assignment was validated using deuterium-adsorbed IR (D2-IR) operating under the same conditions, which gave the shifted Ga[Tet]-D and Ga[Oct]-D bands at 1434 and 1420 cm−1 (Supplementary Fig. 5)34. The H2-D2 exchange monitored by IR showed the interconversion of the Ga-H and Ga-D bands upon gas switching, further verifying the assignments of Ga-H species (Supplementary Fig. 6). We also observed the appearance of O-H and O-D groups linked to tetrahedral and octahedral Ga3+ upon H2 and D2 adsorption, as evidenced by bands at 3656 and 3736 cm−1, and at 2689 and 2781 cm−1, respectively (Supplementary Figs. 7–9)35. By employing quantitative fitting of the IR spectra, we determined that the proportions of octahedral Ga3+ on the surfaces are 88%, 46%, and 17% for α-, ε-, and β-Ga2O3, respectively (Supplementary Table 2).

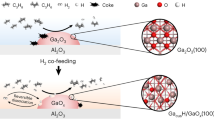

a–c H2-IR for Ga2O3 samples contacting with H2 at 350 °C. d Differential absorbance of white line peak in Ga K-edge XANES for Ga2O3 samples when changing atmosphere from Ar to H2 at 350 °C. The difference spectrum is collected at time delay 30 s after subtracting Ar-treatment spectra. Thermodynamic phase diagram for α-Ga2O3 (001) (e) and β-Ga2O3 (100) (f) contacting with H2 at different temperatures and H2 partial pressures (PH2), the phase diagram is computed based on Gibbs free energy data for the reaction (Ga2O3 + xH2 → Ga2O3–x + xH2O) from DFT calculations assuming a H2O pressure of 0.1 kPa. P0 represents the standard pressure (101.325 kPa). Source data are provided as a Source Data file.

The prevalence of octahedral sites on Ga2O3 significantly influences the evolution of surface structure and formation of oxygen vacancy (Ov), as evidenced by in-situ X-ray photoelectron spectroscopy (XPS) and time-resolved energy dispersive X-ray absorption spectroscopy (EDXAS). The catalyst was treated under 3 MPa H2 at 350 °C and was carefully transferred to the chamber without exposing to air for XPS measurements. Our results show that the H2 treatment led to a decrease of surface O to Ga ratio (O/Ga) on α-Ga2O3 from 1.43 to 1.18, corresponding to Ov concentration of 17.5% (Supplementary Fig. 10)36. In contrast, we observed fewer changes in O/Ga for ε-Ga2O3 (Ov concentration of 8.2%) and β-Ga2O3 (trace amounts of Ov) compared to α-Ga2O3, confirming a greater preference for the formation of oxygen vacancies and undercoordinated Ga3+ on α-Ga2O3 (Supplementary Fig. S10). The energy dispersive mode of EDXAS enables the tracking of fast structural change on catalysts induced by hydrogen with second-level resolution. The differential treatment of Ga K-edge XANES spectra showed a rapid decrease in white line intensity upon H2 treatment for α-Ga2O3 (Fig. 1d and Supplementary Fig. 4), supporting the formation of Ov observed in XPS. The temperature-programmed reduction (TPR) also revealed a higher reduction degree for α-Ga2O3 (Supplementary Fig. 11).

Ab-initio thermodynamics analyses were performed on the most stable α-Ga2O3 (001), ε-Ga2O3 (011) and β-Ga2O3 (100) surfaces (Supplementary Data 1, Supplementary Table 3 and Supplementary Fig. 12) to determine the Gibbs free energy change (ΔG) for the formation of oxygen vacancies as the function of temperature and H2 partial pressure (Fig. 1e, f). α-Ga2O3 (001) features honeycomb-interlinked Ga-O-Ga six-membered rings exposing Ga [Oct] and three-coordinated O3c atoms in surface. The ε-Ga2O3 (011) exposes the 50% four- and 50% five-coordinated Ga[Oct] atoms. And β-Ga2O3 (100) shows the penta-membered ring interlinked pattern with the exposure of mixed pattern of Ga [Oct] and Ga [Tet] accompanied with O3c atoms in surface (Supplementary Figs. 13–14). Under typical catalytic hydrogenation conditions of 350 °C and 3 MPa H2, α-Ga2O3 (001) surface is more prone to loss surface O3c atom with the surface Ov coverage of 1/12-1/6 monolayer. In contrast, the β-Ga2O3 (100) is less likely to lose oxygen atoms at the same conditions, as supported by XPS and XANES data. This difference in surface Ga3+ coordination environment leads to distinct pathways for H2 activation.

Homolytic H2 dissociation initiated by in-situ formed undercoordinated Ga3+

The presence of hydride and hydroxyl species has been detected through H2-IR during the exposure of Ga2O3 to H2, indicating a potentially heterolytic pathway for H2 activation (Supplementary Figs. 7–9). However, our quantitative analysis of surface hydride and hydroxyl concentrations revealed inconsistencies. The quantification was made based on the temperature-dependent exchange chemistry of surface deuterides and deuterated hydroxyls with gaseous H2 (Fig. 2a and Supplementary Fig. 15). During the H2-D2 exchange experiment, we noticed that Ga-OD at ca. 2670 cm−1 could be fully exchanged at 150 °C (Ga-OD + H2 \(\to\) Ga-OH + HD) while Ga-D at ca. 1410 cm−1 remained intact at this temperature (Fig. 2b and Supplementary Fig. 16a). Upon elevating the temperature to 350 °C, the remaining Ga-D was fully exchanged with H2 forming HD with m/z of 3 (Ga-D + H2 → Ga-H + HD, Fig. 2d and Supplementary Fig. 16b). The corresponding H2 consumptions were then measured for the quantification using TKA-MS operating at 150 and 350 °C (Fig. 2c, e and Supplementary Fig. 17, see Supplementary note 1 for details). The results reveal that the hydrogen dissociative adsorption capacity of α-Ga2O3 is 20 times higher than that of β-Ga2O3 (Supplementary Table 1). Moreover, the amounts of hydride and hydroxyl on α-Ga2O3 were 1.50 and 0.27 mmol/g respectively, with the hydride-to-hydroxyl ratio deviating greatly from the expected stochiometric value of 1 in heterolytic dissociation. Remarkably, the ratio of hydride to surface Ga3+ for α-Ga2O3 is as high as 1.6, while this ratio of ε-, β-Ga2O3 is 0.67 and 0.08 respectively, suggesting the formation of high coverage GaHx complexes (x > 1) over α-Ga2O3 (Supplementary Tables 4–7). These unexpected findings led us to speculate the presence of a second process producing extra hydrides on α-Ga2O3, i.e., the homolytic dissociation of hydrogen.

a The scheme illustrating temperature-dependent exchange chemistry of surface deuterides and deuterated hydroxyl groups with gaseous H2. b IR spectra of α-Ga2O3 during H2-exchange at 150 °C after the catalysts were saturated with D2 at 350 °C. c TKA-MS (Blue) and the amount of H2 consumption (Red) during H2-exchange at 150 °C after α-Ga2O3 were saturated with D2 at 350 °C. d IR spectra of α-Ga2O3 during H2-exchange at 350 °C after the catalysts were saturated with D2 at 350 °C. e TKA-MS (Blue) and the amount of H2 consumption (Red) during H2-exchange at 350 °C after α-Ga2O3 were saturated with D2 at 350 °C. Source data are provided as a Source Data file.

We developed a fast time-response cell for time-resolved TKA-IR, allowing us to track the dynamic evolution of H2 dissociation and understand the origin of GaHx complexes. This approach provided compelling evidences confirming the involvement of the homolytic dissociation pathway. The activated Ga2O3 catalysts were first flushed with Ar flow at 350 °C until stable and then replaced by H2 or D2 flow with an Ar residual time of ~20 s (Supplementary Fig. 18). As shown in Fig. 3a–c, the red plots correspond to the evolution of concentrations of hydroxyl species and the blue plots are those for hydride species. Upon exposure of Ga2O3 to H2, both Ga-H and Ga-OH form rapidly and intensify concurrently. In the meantime, adsorbed water was detected within the initial 10 s for all 3 catalysts, suggesting the formation of oxygen vacancies and undercoordinated Ga3+ at this stage (Supplementary Fig. 19). For α-Ga2O3, Ga-H concentration increased at a rate of 3.0 nm–2·min–1, while Ga-OH developed at an average rate of 0.5 nm–2·min–1, reaching a plateau at 240 s. However, the concentration of Ga-H species continued to rise at a rate of 0.9 nm–2·min–1 even after Ga-OH species reached stability. Ga-H species of α-Ga2O3 finally reached a plateau at 530 s, giving a high hydride-to-hydroxyl ratio of 5.6. In contrast, the saturation of ε-Ga2O3 surface occurred around 200–250 s, exhibiting a similar evolution to Ga-OH on α-Ga2O3. The final hydride-to-hydroxyl ratio was 1.3, slightly higher than the stochiometric ratio of 1 for heterolytic dissociation. For the contrasting case of β-Ga2O3, both Ga-H and Ga-OH species generated at an average rate of 0.7 nm–2·min–1. The surface of β-Ga2O3 reached saturation after 50 s with a hydride-to-hydroxyl ratio of 0.7. The quantitative and time-dependent results of hydrides and hydroxyls clearly showed that α-Ga2O3 opens a homolytic pathway for H2 dissociation. These results contrast with the general preference for heterolytic dissociation of H2 on oxides37.

a–c The evolution of surface Ga-H and Ga-OH over Ga2O3 samples with contact time of H2 at 350 °C. d H2 adsorption energy by homolytic dissociation over α-Ga2O3 (001). Red ball: O atom, gray ball: Ga atom, white ball: H atom. e Projected density of states of the Ga 4p orbital and H 1s orbital before and after the formation of GaHx hydride species on O-defective α-Ga2O3 (001). Charge density difference contour plots for heterolytic (f) and homolytic dissociation (g) of H2 on O-defective α-Ga2O3 (001). The cyan and yellow colors indicate the decrease and increase in the electron density, respectively. The 3D iso-surface value is set as 0.0014 e Å−3. Source data are provided as a Source Data file.

The density functional theory (DFT) calculation is further performed to understand H2 dissociation on O-defective α-Ga2O3 (001). As illustrated in Fig. 3d, the H2 heterolytic dissociation releases large energies of 1.65 eV first. The resulting hydride tends to migrate to the neighboring O atom, forming hydroxyl and releasing energy of 0.58 eV. Interestingly, we found that H2 homolytic dissociation in the presence of neighboring hydroxyl groups with the final Ga-H/OH ratio of 1:1 shows a negative dissociation energy of -0.46 eV (Fig. 3d). Further increasing the Ga-H/OH ratio to 2:1 also shows the negative dissociation energy (-0.55 eV, Supplementary Fig. 20). On the contrary, H2 homolytic dissociation without the prior H2 heterolytic dissociation shows the positive dissociation energy (+0.28 eV). It suggests that H2 heterolytic dissociation is the perquisite for homolytic dissociation (Supplementary Fig. 21).

To understand the promotion effect of hydroxyls in stabilizing Ga-H, we analyzed the projected density of states of the Ga3+ before and after homolytic H2 dissociation (Fig. 3e). The presence of hydroxyl and Ov leads to the large electron occupation of the valence band maximum on Ga 4p orbital with the Bader charge of 2.21 e−. Once homolytic dissociation occurs, a covalent bond between Ga 4p and H 1s orbital is established and the electrons transfer from the high-energy-level Ga 4p orbital to the low-energy-level 4p-1s hybrid orbital, leading the decrease of Bader charge to 1.66 e− for Ga atom on 4p orbital. Moreover, the charge density difference contour plots confirm the significant local electron transfer from Ga to H atom upon formation of Ga-H species (Fig. 3f–g). In the case of homolytic dissociation, the presence of hydroxyl and Ov, facilitates the transfer of more electrons from Ga to H through the reaction of 2δe− + H2 → 2Hδ- (where δ is around 0.25-0.27). The extra electrons, concurrent with the formation of neighboring hydroxyl and Ov, stabilize the Ga-H species and promote homolytic dissociation. Homolytic dissociation of H2 is also thermodynamically favored on O-defective ε-Ga2O3 (011) surface with the H2 dissociation energy of –0.55 eV and the charge transfer from Ga to H (Supplementary Figs. 22–23 and Supplementary Table 8), whereas the β-Ga2O3 (100) surface cannot dissociate the H2.

Consequently, a high coverage of hydride becomes thermodynamically favorable, which is essential for producing active hydrides for hydrogenation reactions. The time-resolved IR shows the Ga-H peak shifted towards higher wavenumbers of ca. 12 cm−1 during the exposure of α-Ga2O3 to H2, whereas only slight offsets were observed for ε-Ga2O3 and β-Ga2O3 (Supplementary Figs. 24−25). The Ga-H band shifts supported the increase of hydride coverage as the progress of homolytic dissociation. It is worth noting that the coverage of H* on metal ions was calculated close to saturation. When considering the coverage of H* on surface O of oxide (Supplementary Table 7), there still allows potential in promoting the adsorption capacity of H*.

We further investigated the preference for homolytic H2 dissociation on octahedral Ga3+ sites. The homolytic H2 dissociation on different Ga2O3 crystalline phases (α and β) was checked. Upon the formation of Ov on α-Ga2O3 (001), the Ga atoms are at a distance of 2.89 Å providing a suitable environment for homolytic H2 dissociation (Supplementary Fig. 26). Differing from the O-defective α-Ga2O3 (001) surface, the Ga-Ga distances on other surfaces are too large (e.g., 3.08 Å on β-Ga2O3 (100) surface) to dissociate H2 (Supplementary Fig. 26).

Promotion effect of H2 homolytic dissociation in CO2 hydrogenation

The homolytic dissociation of H2 leads to the formation of highly active hydride species. As evidenced by in-situ XPS in Fig. 4a, H2 treatment on α-Ga2O3 gave a shoulder at the binding energy 2.5 eV higher than the central peak in Ga 3d spectrum. This is attributed to the presence of Ga-H species with the electron transfer from Ga 4p to H 1s, where the decrease in the number of outer-shell electrons of Ga enhances the attraction of the nucleus to inner-shell electrons. Indeed, the core-level chemical shift of simulated XPS based on DFT calculation shows that the existence of Ga-H species leads to a core-level chemical shift of 0.56 eV in the higher binding energy region, which is far greater than the shifts when Ov or hydroxyl groups were present (Supplementary Table 9). Similar phenomena have been observed on CeO221,38,39. The obvious shoulder peak on α-Ga2O3 suggests the massive formation of Ga-H bond, while the feature of Ga-H species is less pronounced for ε-Ga2O3 and negligible for β-Ga2O3, due to the lower coverages of hydride in these two cases. H2 chemisorption isotherms obtained by IR (Fig. 4b and Supplementary Fig. 27) show that the formation of Ga-H for α-Ga2O3 occurs at H2 pressure as low as 0.086 mbar. Conversely, the formation of Ga-H for ε-Ga2O3 and β-Ga2O3 does not happen even at elevated pressure up to 10 mbar. During temperature-programmed surface reaction of H2 (H2-TPSR, Fig. 4c), the exchange of Ga-D and H2 on α-Ga2O3 begins at ~50 °C while that on β-Ga2O3 initiates at ~250 °C, implying the high reactivity of Ga-D with hydrogen on α-Ga2O3. These results suggest hydrogen easily undergoes dissociative adsorption on α-Ga2O3.The resulting hydrides formed by homolytic dissociation have higher surface coverage and reactivity than those from heterolytic dissociation, thereby potentially enhancing the rate of hydrogenation reactions.

a In situ Ga 3d XPS spectra of fresh Ga2O3 and Ga2O3 interacted with H2 at 350 °C, 3 MPa. b H2-chemisorption intensity of different Ga2O3 samples under different H2 partial pressure measured by IR. c H2-TPSR profiles with m/z = 3 (HD) signals in the effluents monitored by an online mass spectrometer. d CO formation rate over Ga2O3 during rWGS. Reaction conditions: H2/CO2 = 3 (v/v), 350 °C, 0.2 MPa, 9000 mL/g/h. e CH3OH formation rate over Ga2O3 during methanol synthesis. Reaction conditions: H2/CO2 = 3 (v/v), 350 °C, 3 MPa, 6000 mL/g/h. f C2=-C4= formation rate over Ga2O3 in OX-ZEO catalysis. Reaction conditions: OX/ZEO = 0.5 (mass ratio, 40–60 mesh), H2/CO2 = 3 (v/v), 350 °C, 3 MPa, 20,000 mL/g/h. Source data are provided as a Source Data file.

To verify our hypothesis regarding the promotion effect of active hydrides in hydrogenation reactions, representative CO2 hydrogenations were studied, including the reverse water gas shift reaction (rWGS), methanol synthesis and the recently discovered oxide-zeolite-based CO2-to-light olefins (OX-ZEO). In the rWGS reaction, CO formation rate on α-Ga2O3 was 10.5 mol·molGa−1·h–1. In comparison, ε-Ga2O3 and β-Ga2O3 exhibited CO formation rates of 5.7 mol·molGa–1·h–1 and 1.5 mol·molGa–1·h–1, respectively. In methanol synthesis, α-Ga2O3 showed a methanol formation rate of 0.62 mol·molGa−1·h−1, while β-Ga2O3 had almost no activity in synthesizing methanol. Both in low-pressure rWGS and high-pressure methanol synthesis, α-Ga2O3 showed more than 6 times higher CO or methanol formation rate per Ga3+ site than β-Ga2O3 at 350 °C (Fig. 4d, e and Supplementary Fig. 28).

In OX-ZEO catalysis, Ga2O3 was physically mixed with SAPO-18 zeolite to selectively convert CO2 into light olefins (C2=-C4=) (Fig. 4f and Supplementary Fig. 29). Light olefins are expected via CO2 hydrogenation on oxide and subsequent C-C coupling of intermediates in zeolites. The selectivity to light olefins for α-Ga2O3 is 26.2% in the total products and 80.1% in the hydrocarbons at the CO2 conversion of 12.5%. The light olefins selectivity for ε-Ga2O3 is 11.2% in the total products and 68.8% in the hydrocarbons at a CO2 conversion of 9.3%. The β-Ga2O3 gave a low olefin selectivity of 2.9% in the total products and 58.3% in the hydrocarbons at a conversion of 7.7%. The formation rates of light olefins are further measured at conversions lower than 5%. It was shown that, in terms of olefin formation rates, α-Ga2O3 was 0.6 times higher than ε-Ga2O3 and 3.8 times higher than β-Ga2O3. These findings indicate that GaHx derived from homolytic dissociation is efficient in hydrogenating CO2 into intermediates, which is in consistent with the observations in rWGS and methanol synthesis.

The plot of light olefins selectivity as a function of CO2 conversion provides further evidence of the higher hydrogenation ability of active GaHx over α-Ga2O3 (Supplementary Fig. 30). For α-Ga2O3, the selectivity of light olefins decreased with the increase of CO2 conversion, which is due to the over-hydrogenation of olefins to paraffins. In contrast, the olefin selectivity for β-Ga2O3 was at a low level and increased slightly with the elevation of CO2 conversion (Supplementary Figs. 31–33). Moreover, the selectivity of paraffins did not show a significant increase with increasing CO2 conversion, indicating the intrinsic low activity of β-Ga2O3 in hydrogen activation (Supplementary Fig. 34).

The high reactivity of active GaHx over α-Ga2O3 was also demonstrated with CO hydrogenation to light olefins. The selectivity to light olefins for α-Ga2O3 was 63.4% in the hydrocarbons at the CO conversion of 10.6% (Supplementary Fig. 35a). β-Ga2O3 gave a low CO conversion of 1.4% and selectivity to light olefins of 50.4%. The formation rate of light olefins for α-Ga2O3 was 6.3 times higher than β-Ga2O3 (Supplementary Fig. 35b).

Roles of activated hydrogen in CO2 hydrogenation

The mechanism of CO2 hydrogenation and the role of activated hydrogen species were further elucidated by a close look at the evolution of XANES and IR spectra during the transition between H2 and CO2. The catalysts were initially saturated with hydroxyl and hydride species by treatment with H2 flow. Upon replacing H2 with CO2, various intermediates emerged immediately and exhibited growth over time, including bicarbonate species (HCO3*) at 1630 cm−1, formate species (HCOO*) at ~1386 and ~1578 cm−1, and methoxy species (CH3O*) at 2930, 1420, and 1475 cm–1 (Fig. 5a, b and Supplementary Fig. 36)10,40,41,42. By tracking the time-resolved evolutions, it was observed that adsorbed CO2 rapidly converted into HCO3* by consuming surface hydroxyl groups on α-Ga2O3, while negligible HCO3* was observed on β-Ga2O3. Fluctuations observed in Ga K-edge XANES indicated oxygen vacancies was formed on α-Ga2O3 upon exposure to H2, which were subsequently eliminated upon introducing CO2 (Fig. 5c and Supplementary Figs. 37–39). In contrast, the formation and consumption of oxygen vacancies were found to be difficult on β-Ga2O3 during the transitions between H2 and CO2, as the white line intensity of Ga K-edge in XANES remained unchanged. The results suggest that both hydroxyls and oxygen vacancies on α-Ga2O3 participate in adsorption and activation of CO2, thereby providing α-Ga2O3 with a higher CO2 adsorption capability compared to β-Ga2O3. This is supported by CO2-TPD experiments (Supplementary Fig. 40).

The time development of IR peak intensity of Ga-H, Ga-OD, HCO3*, HCOO* and CH3O* over α-Ga2O3 (a) and β-Ga2O3 (b). The evolution of hydroxyls was studied by using D2, since the bands of OH are interfered by the overtone of CO2 (3800−3500 cm−1). c In-situ time-resolved X-ray absorption difference spectrum of Ga3+ in the near edge region of the Ga K-edge for Ga2O3 samples. The difference spectrum is obtained by subtracting Ar-treatment spectra. d The normalized IR peak intensity of Ga[Oct]-H over α-Ga2O3 and Ga[Tet]-H over β-Ga2O3 in H2/D2-CO2 switching IR. e The normalized IR peak intensity of Ga[Oct]-OD over α-Ga2O3 and Ga[Tet]-OD over β-Ga2O3 in H2/D2-CO2 switching IR. f The CH3O*/HCOO* ratio over α-Ga2O3 and β-Ga2O3 in H2/D2-CO2 switching IR. Source data are provided as a Source Data file.

Moreover, the in-situ IR experiments revealed the crucial promotion role of hydrides, as the hydrogenated CH3O* species developed in a faster rate on α-Ga2O3 than on β-Ga2O3 (Fig. 5a, b). To understand this, the evolution of hydrides (Ga-H), hydroxyls (Ga-OD) and surface intermediates were monitored during cyclical switching of CO2 and H2/D2 every half an hour at 350 °C. As shown in Fig. 5d, e and Supplementary Fig. 41, the bands of Ga-H and Ga-OD for both α-Ga2O3 and β-Ga2O3 appeared immediately upon the introduction of H2 or D2 into the cell, which then stabilized over time. When the carrier gas was replaced with CO2, most Ga-H and half of Ga-OD bands for α-Ga2O3 declined. The behaviors of Ga-H and Ga-OD species for β-Ga2O3 differ from that on α-Ga2O3. When β-Ga2O3 saturated with hydrides and hydroxyls was exposed to CO2, Ga-H could be consumed, but Ga-OD remained intact (Fig. 5d, e). Importantly, when H2 or D2 was switched back, the bands of hydrides or deuterides regenerated, and the corresponding bands for HCOO* and CH3O* gradually declined for both samples (Fig. 5f and Supplementary Fig. 42).

The Gibbs free energy profile of CO2 hydrogenation on O-defective α-Ga2O3 (001) confirms this stepwise hydrogenation of CO2* \(\to\) HCOO* \(\to\) H2COOH* \(\to\) CH2O* \(\to\) CH3O* through reactions with surface hydrides (Supplementary Table 10). Moreover, HCOO* is found to accumulate on the surface as the reaction proceeds (Supplementary Fig. 43), indicating that the hydrogenation of HCOO* is the rate-determining step. This result is also supported by the slower formation rates of deuterated methoxy (CD3O*) (rH/rD of ~1.8) (Supplementary Fig. 44). In addition, model IR experiments for formate hydrogenation demonstrated that α-Ga2O3 can hydrogenate formate species to CH3O*, while β-Ga2O3 remains inactive (Supplementary Fig. 45). Further semi-quantitative analysis of the IR peaks revealed a high CH3O*/HCOO* ratio of ~1.5 for α-Ga2O3 and a relatively low ratio of 0.3-0.5 for β-Ga2O3 (Fig. 5f).

The role of highly active hydrides on α-Ga2O3 was further verified by in-situ XPS of catalysts that were treated in H2, CO2, and the CO2-H2 mixture at 3 MPa and 350 °C for 12 h (Supplementary Fig. 46). The shoulder of hydride-adsorbed Ga species disappeared, when the catalyst was exposed to CO2 or the CO2 + H2 mixture, indicating the consumption of hydrides in the reaction with CO2. Thus, with a detailed analysis of in-situ IR, XANES, and XPS, it was elucidated that α-Ga2O3 provides an abundant supply of highly active hydrides for kinetically relevant step of HCOO* to CH3O* in CO2 hydrogenation, in contrast to β-Ga2O3, which supplies limited hydrides. Above all, the intrinsic activity of the hydrides to hydrogenate CO2 on octahedra Ga3+ of α-Ga2O3 is higher than that tetrahedral Ga3+ of β-Ga2O3 (Supplementary Fig. 47).

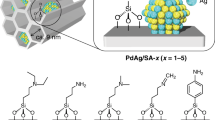

Finally, we investigated whether the promotion of homolytic H2 dissociation applies to other oxides containing octahedral Ga3+. Several binary spinel oxides including ZnGa2O4, MgGa2O4, and MnGa2O4 were studied. We used the calcination temperature to modulate the coordination structure of Ga3+ species, as the higher calcination temperature would regulate the inversion of spinel and increase the content of octahedral Ga3+ sites38,39. H2-IR results show the different distributions of coordination of Ga3+ on the surfaces (Supplementary Fig. 48). Interestingly, we found that oxides with higher fractions of octahedral Ga3+ species exhibited superior yields and selectivity of light olefins (Supplementary Fig. 49). This indicates the importance of the presence of octahedral Ga3+ species in achieving enhanced performance in hydrogenation. Additionally, we also quantified surface hydrogen species over Cu/Ga2O3 (Supplementary Figs. 50–52). Cu/α-Ga2O3 was measured to have a much higher density of Ga-H than α-Ga2O3 and Cu/β-Ga2O3, which showed high activity to convert CO2 into formate and methoxy intermediates (Supplementary Figs. 53-54). As a result, the methanol yield of Cu/α-Ga2O3 reached maximum of 0.4 mmol/gcat/h at 300 °C, which is twice higher than that of Cu/β-Ga2O3 (Supplementary Figs. 55-56). This result proved that the α-Ga2O3 can serve as the promising material synergizing with metal to activate H2 and further promote the CO2 hydrogenation reaction.

Discussion

In summary, we distinguished the homolytic and heterolytic H2 dissociation pathway over Ga2O3 by the quantitative and time-resolved analyses of the complex dynamics during hydrogen activation. The formation of hydride species on α-Ga2O3, with a non-stoichiometric ratio to hydroxyls of 5.6 and a significantly higher formation rate compared to the heterolytic H2 dissociation process, effectively demonstrates the occurrence of a homolytic dissociation pathway. This homolytic H2 cleavage benefits from a closer distance between Ga atoms over unsaturated Ga[Oct] metalloids, resulting in highly active and high-coverage hydrides. Cooperated with the oxygen vacancies and hydroxyls, the hydrides formed on α-Ga2O3 promote the adsorption of CO2 and hydrogenation of key HCOO* intermediate, leading to enhanced CO2 conversion and higher yield of valuable products including CO, methanol and light olefins. However, β-Ga2O3, which mostly consists of tetrahedral Ga3+ sites on the surface, fails to provide sufficient hydride and shows low activity for CO2 hydrogenation. The homolytic hydrogen dissociation pathways and enhanced reactivity in CO2 hydrogenation were also observed on several binary mixed oxides containing high fractions of octahedral Ga3+ species on the surfaces.

Methods

Catalyst preparation

Synthesis of Ga2O3: For α-Ga2O3, 6.0 g Gallium nitrate hydrate (Ga(NO3)2·xH2O) was dissolved in 100 mL deionized water under the magnetic stirring. Liquid ammonia solution (NH3·H2O) was added into the clear solution until the pH was raised up to 9 and then stirred for 3 more hours. The precipitate was collected with filtering and dried overnight at 80 °C. Then, the sample was heated at 500 °C for 6 h in the air. The 6.0 g Ga(NO3)3·xH2O was annealed in air at 500 °C for 6 h and white ε-Ga2O3 powder was obtained. For β-Ga2O3, 6.0 g Ga(NO3)3·xH2O was dissolved into 150 mL anhydrous ethanol. Then, the Hydrazine monohydrate (H4N2·H2O) was added into the solution dropwise under the magnetic stirring until the pH of the solution was raised up to 11. The precipitate was washed with ethanol, centrifugated and dried overnight at 80 °C. The resultant powder was finally calcined at 800 °C for 4 h in static air to obtain the sample.

Synthesis of SAPO-18 and MGa2O4. SAPO-18 samples were synthesized by treating an aluminophosphate-based gel hydrothermally43,44. 7.4 g Aluminum hydroxide hydrate (55 wt% Al2O3) was added to a solution of 85% phosphoric acid in water (6.0 g). To this mixture, 4.8 g silica sol (30% SiO2) and 8.3 g N, N-diisopropylethylamine (C8H19N) were added and a gel with the composition 1.6 C8H19N: 0.6 SiO2: Al2O3: 0.9P2O5: 50H2O was formed by stirring vigorously43,44. Subsequently, this gel was sealed in a Teflon-lined stainless autoclave and heated at 180 °C for 7 days. The solid product was recovered by filtration, washed with distilled water and dried in air at 50 °C43. Finally, the as-synthesized sample was calcined in a stream of dry oxygen at 600 °C for 10 h45. Binary metal oxides including ZnGa2O4, MgGa2O4, and MnGa2O4 were synthesized by a coprecipitation method with the pH kept at 9 ~ 10. For ZnGa2O4, 2.97 g Zn(NO3)2·6H2O and 5.11 g Ga(NO3)3 ∙ xH2O served as the precursors and their molar ratio was 1:2. For MgGa2O4, 2.56 g Mg(NO3)2·6H2O and 5.11 g Ga(NO3)3 ∙ xH2O served as the precursors and their molar ratio was 1:2. For MnGa2O4, 3.58 mL 50 wt% aqueous solutions of Mn(NO3)2 and 2.56 g Ga(NO3)3 ∙ xH2O served as the precursors and their molar ratio was 1:2. An aqueous solution of NaOH and NaHCO3 with a molar ratio of 2:1 was used as the precipitant. After precipitation at 70 °C, the suspensions were aged for 2 h under continuous stirring. The precipitates were washed with deionized water until the pH of the supernatant was ca. 7, filtered and dried at 60 °C for 12 h, and then calcined at 300 and 600 °C for 4 h in air, respectively. The samples were denoted as ZnGa2O4-300, MgGa2O4-300, MnGa2O4-300, ZnGa2O4-600, MgGa2O4-600, and MnGa2O4-600 respectively10. The commercial sources and purities of utilized reagents were listed in Supplementary Table 11.

Catalyst characterization

X-ray diffraction (XRD) of different Ga2O3 were recorded before and after reaction. XRD patterns were performed with 2θ values between 10° and 80° using a Bruker-D2 diffractometer employing the graphite filtered Cu Kα radiation (λ = 1.54056 Å). Particle size of Ga2O3 nanoparticles was calculated by Sherrer equation

Where k stands for the Sherrer constant, λ is the wavelength of X-ray, B is the full width at half maximum (fwhm) of the diffraction peak, and θ is the angle of diffraction. The specific surface areas of Ga2O3 were obtained on a Micromeritics Tristar 3000 analyzer by N2 adsorption-desorption at 77 K. Prior to the tests, all catalysts were degassed at 300 °C for 3 h. The Brunauer-Emmett-Teller (BET) method was used to calculate the specific surface areas from the isotherms46. High-resolution transmission electron microscopy (HRTEM) images were obtained by a JEOL JEM−2100 electron microscope operated at an accelerating voltage of 200 kV. The samples were ultrasonically dispersed in ethanol and a drop of the solution was placed onto a copper grid coated with a thin microgrids support film. Annular dark field scanning TEM (ADF-STEM) was operated with an Oxford X-Max 80 SDD EDX detector at 200 kV.

The electronic structure of Ga2O3 was investigated by in-situ X-ray photoelectron spectroscopy (XPS). The binding energies were calibrated using the C 1s peak at 284.6 eV as a reference. Specifically, the catalysts were pre-treated in fixed-bed reactor, and then directly moved into the glove box atmosphere to load sample stage of XPS, which allows the sample transfer without exposing to air. The CO2 hydrogenation reaction were performed under the following conditions: CO2 (flow rate is 10 mL/min), H2 (flow rate is 30 mL/min) and CO2/H2 mixture (ratio =1:3, flow rate is 40 mL/min) at 350 °C, 3.0 MPa. The atom ratio of O to Ga (nO:nGa) was calculated as follow:

Where IGa represents the integration of Ga 3d peak area in XPS. IO represents the integration of the lattice O peak area in XPS. SFGa represents the atomic sensitivity factor of Ga and SFO represents the atomic sensitivity factor of O.

Ga K-edge X-ray absorption near edge structure (XANES) experiments were undertaken at the BL05U beamline of the Shanghai Synchrotron Radiation Facility (SSRF), collecting in transmission mode using a Si (111) Bragg polychromator and a XIMEQ detector. 12 mg of the Ga2O3 was grinded for 30 min and pressed into a sheet with a diameter of 5.5 mm. The sheet was placed into an in-situ cell for test. The sample was then heated from room temperature to 350 °C under Ar flow. CO2, H2 or H2 + CO2 (H2/CO2 = 3 (v/v)) gas was purged into the reaction cell to carry out the in-situ experiments at 350 °C and 1.0 MPa. The energy dispersive mode of BL05U beamline enables the exposure time and acquisition time of X-ray absorption spectra to be 35 and 150 ms respectively. The XANES spectra were calibrated by Ga2O3 standard spectra.

The Fourier Transform Infrared Spectroscopy (FTIR, Thermo Scientific Nicolet IS50 spectrometer) was used to collect the vibrational spectra of adsorbed surface species under CO2 hydrogenation atmosphere45. In-situ FTIR experiments were carried out in an in-situ transmission cell. About 15 mg Ga2O3 was pressed into sheets with a diameter of 13 mm and packed in the in-situ cell. All the samples were degassed at 500 °C under Ar flow (30 mL/min) for 3 h to obtain the clean surface, and the spectra of samples for each measurement were then collected by subtracting the background of blank cell45. Different gases can be switched quickly through 6-way valve. The absorbance normalized to the mass of the catalysts. Generally, the in-situ reactions were carried out under 1.0 MPa, 350 °C, 40 mL/min CO2 + H2 (D2), and CO2:H2 (D2) = 1:345.

Transient kinetic analysis with infrared spectroscopy (TKA-IR, H2(D2)-IR) were carried out at 350 °C with blank transmission cell as the background. All the samples were pre-treated at 550 °C in Ar flow (100 mL/min) for 5 h to obtain the flat and pure spectra. H2 (D2) was then switched quickly through 6-way valve, and the spectra of samples for contacting H2 (D2) were collected by subtracting the background spectrum. The spectra were recorded by collecting 32 scans at a resolution of 4 cm−1. The intensity of infrared characteristic peak, such as Ga-H and Ga-OD, represents the number of the hydrogen-containing species. The outlet of the DRIFT cell was connected to online quadrupole mass spectrometer (MS), so the gas component in the effluent can be monitored and recorded by MS.

Temperature programmed surface reaction of H2 (H2-TPSR) was also performed on a Micromeritics AutoChem II 2920 apparatus connected to online MS. Typically, the Ga2O3 (100 mg) was dehydrated under Ar (30 mL/min) at 500 °C for 3 h. Then the dried samples were pretreated at 350 °C for 1 h under D2 flow (15 mL/min) to generate the Ga-D and Ga-OD. After cooling to room temperature in Ar flow, a flow rate of 15 mL/min of H2 was introduced until the MS signal was stable. The temperature was increased linearly from 50 °C to 800 °C with a rate of 10 °C·min−1. The gas component in the effluent was monitored and recorded by mass spectrometer (PIMS 1500 Photo ionization Process TOF-MS, Jinkai Instrument (DaLian) Co., Ltd.). Typically, the mass/charge ratio (m/z) value is 3 for HD, which was produced via the reaction between Ga-D and H2. The m/z values are 2 for H2 and 4 for D2 in the hydrogen isotope analysis.

H2-exchange experiment was also performed on a tubular reactor with quantitative ring (200 µL) connected to online mass spectrometer. Typically, the Ga2O3 was dehydrated under Ar (30 mL/min) at 500 °C for 3 h. Then the dried samples were pretreated at 350 °C for 1 h under D2 flow (15 mL/min) to generate the Ga-D and -OD. After the temperature cooled to 150 °C in Ar flow, then 200 µL of H2 in dosing ring was injected into the reactor cyclically until the MS signal of H2 (m/z = 2) is stable. Then the temperature increased to 350 °C in Ar flow, 200 µL of H2 in dosing ring was injected again into the reactor cyclically until the MS signal of H2 (m/z = 2) is stable. The gas component in the effluent was monitored and recorded by MS. Combined with H2-IR, the Ga-D and Ga-OD can be quantified.

H2 chemisorption experiments were conducted with a Thermo Scientific Nicolet IS50 spectrometer connected with vacuum system. In a typical procedure, 15 mg of the sample was degassed at 200 °C in Ar and evacuated at 350 °C for 30 min. Prior to the chemisorption experiments, the sample was further evacuated for 40 min. The adsorbates (H2) were introduced into the system for the measurements of chemisorption isotherms. The first chemisorption isotherm was measured in the pressure range of 0.002-10 mbar at 350 °C.

Temperature programmed reduction of H2 (H2-TPR) was performed on a Micromeritics AutoChem II 2920 apparatus. Typically, the catalyst (50 mg) was pretreated at 200 °C for 1 h under Ar flow for dehydration. After cooling to room temperature, a flow rate of 15 mL/min of H2 was introduced for the H2 reduction. Then the temperature was increased linearly from 50 °C to 600 °C with a rate of 10 °C·min−1. The gas component in the effluent was monitored and recorded by online quadrupole mass spectrometer. Temperature programmed desorption of H2 (H2-TPD) was performed on a Micromeritics AutoChem II 2920 apparatus. Typically, the catalyst (50 mg) was pretreated at 350 °C for 1 h under 10% H2/Ar flow (30 mL/min) to reduce the catalysts. After cooling to room temperature, the purging was carried out by 30 mL/min of Ar for 1 h. Then the temperature was increased linearly from 50 °C to 600 °C with a rate of 10 °C·min−1 47. The gas component in the outlet was monitored by online mass spectrometer47. Temperature programmed desorption of CO2 (CO2-TPD) was also performed on a Micromeritics AutoChem II 2920 apparatus. Typically, the catalyst (50 mg) was pretreated at 350 °C for 1 h under 10% H2/Ar flow (30 mL/min) to activate the catalysts. After cooling to room temperature, CO2 adsorption was carried out under a flow rate of 30 mL/min of CO247. Subsequently, the purging was carried out at the same temperature by 30 mL/min of Ar for 1 h47. Then the temperature was increased linearly from 50 °C to 600 °C with a rate of 10 °C·min−1. The gas component in the outlet was monitored by a thermal conductivity detector (TCD).

Catalytic testing

All experiments were performed in a glass-lined stainless steel reactor tube (8 mm inner diameter) under a continuous flow. Typically, 300 mg composite catalyst (40-60 meshes) with oxide/zeolite=1/2, 2/1 and 4/1(mass ratio) was placed in the reactor. Ar was added after the back pressure valves as the internal standard for online gas chromatography (GC) analysis. Reaction was carried out under conditions: H2/CO2 = 3 (v/v), 350 °C, 3.0 MPa, gas hourly space velocity (GHSV) = 2000−20000 mL/g/h. At the outlet of the reactor, the gases were decompressed to the atmospheric pressure and the reaction products were analyzed with online gas chromatograph (Agilent 8890), equipped with a TCD and two flame ionization detectors (FID). Oxygenates and hydrocarbons up to C12 were analyzed by FID with HP-FFAP and HP-AL/S column. A thermal conductivity detector with columns of Hayesep Q and 5 A molecular sieves packed columns for other gaseous product (including H2, CO, CO2 and CH4) was used. CH4 was taken as a reference bridge between FID and TCD. CO2 conversion, C-containing products selectivity, and yield of products were calculated as follow:

where \({F}_{CO_{2},{in}}\) and \({F}_{CO_{2},{out}}\) in Eq. (3) represented moles of CO2 at the inlet and outlet, respectively. Where N in Eq. (4) represents the carbon-containing species in all of the products. The selectivity of individual hydrocarbon CnHm (SelCnHm) among hydrocarbons (free of CO) in Eq. (6) was calculated according to

The results were obtained when the reaction had reached a steady state. The carbon balance was found to be > 95% in all the tests.

DFT calculation

All DFT calculations are performed via the plane wave VASP code48, where electron-ion interaction is represented by the projector augmented wave pesudopotential49,50,51. The exchange functional utilized is the spin-polarized GGA-PBE52. The kinetic energy cutoff is set as 450 eV53. The first Brillion zone k-point sampling utilizes the Monkhorst-Pack scheme with an automated mesh determined by 18 times of the reciprocal lattice vectors53. The energy and force criterion for convergence of the electron density and structure optimization are set at 10−6 eV and 0.05 eV/Å, respectively53.

Ab-initio thermodynamics analyses. To determine the equilibrium Ov concentration in Ga2O3 surfaces, the ab-initio thermodynamics analyses have been performed where the formula

are used to compute the free energy change as a function of temperature and H2 partial pressure. To determine the Gibbs free energy change (ΔG) per formula unit (f. u.) for the above reactions, one needs to compute

where \(G\) is the Gibbs free energy of surfaces and \(\mu\) is the chemical potential for molecules. The \(G\left[X\right]\) can be approximated by their DFT total energy \(E\left[X\right]\) with appropriate inclusion of zero-point-energy (ZPE), since it is known that the vibration entropy and the pV term contributions of solid phases are negligibly small. The chemical potential for molecules \(\mu \left[X\right]\) can be calculated as follows:

where enthalpy (H) and entropy (S) terms are taken from the standard thermodynamics data.

Data availability

All data supporting the findings of this study are available within the paper and its supplementary information files. Source data are provided with this paper.

References

Kattel, S., Ramirez, P. J., Chen, J. G., Rodriguez, J. A. & Liu, P. Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts. Science 355, 1296–1299 (2017).

Martin, O. et al. Indium oxide as a superior catalyst for methanol synthesis by CO2 hydrogenation. Angew. Chem. Int. Ed. 55, 6261–6265 (2016).

Wang, J. et al. A highly selective and stable ZnO-ZrO2 solid solution catalyst for CO2 hydrogenation to methanol. Sci. Adv. 3, e1701290 (2017).

Rodriguez, J. A. et al. Water-gas shift reaction on a highly active inverse CeOx/Cu(111) catalyst: unique role of ceria nanoparticles. Angew. Chem. Int. Ed. 48, 8047–8050 (2009).

Yao, S. et al. Atomic-layered Au clusters on alpha-MoC as catalysts for the low-temperature water-gas shift reaction. Science 357, 389–393 (2017).

van Lent, R. et al. Site-specific reactivity of molecules with surface defects-the case of H2 dissociation on Pt. Science 363, 155–157 (2019).

Karim, W. et al. Catalyst support effects on hydrogen spillover. Nature 541, 68–71 (2017).

Pan, X., Jiao, F., Miao, D. & Bao, X. Oxide-zeolite-based composite catalyst concept that enables syngas chemistry beyond Fischer-Tropsch synthesis. Chem. Rev. 121, 6588–6609 (2021).

Bai, B. et al. Tuning the crystal phase to form MnGaOx-spinel for highly efficient syngas to light olefins. Angew. Chem. Int. Ed. 62, e202217701 (2023).

Li, N. et al. Steering the reaction pathway of syngas-to-light olefins with coordination unsaturated sites of ZnGaOx spinel. Nat. Commun. 13, 2742 (2022).

Jiao, F. et al. Selective conversion of syngas to light olefins. Science 351, 1065–1068 (2016).

Xiao, H. et al. Dehydrogenation of propane over hydrothermal synthesized Ga2O3-Al2O3 catalyst in the presence of carbon dioxide. Catal. Sci. Technol. 6, 5183–5195 (2016).

Stephan, D. W. The broadening reach of frustrated Lewis pair chemistry. Science 354, aaf7229 (2016).

Eischens, R. The infrared spectrum of hydrogen chemisorbed on zinc oxide. J. Catal. 1, 180–191 (1962).

Boudart, M., Delbouille, A., Derouane, E. G., Indovina, V. & Walters, A. B. Activation of hydrogen at 78.deg.K on paramagnetic centers of magnesium oxide. J. Am. Chem. Soc. 94, 6622–6630 (2002).

Xiang, S. et al. A unique Co@CoO catalyst for hydrogenolysis of biomass-derived 5-hydroxymethylfurfural to 2,5-dimethylfuran. Nat. Commun. 13, 3657 (2022).

Juárez, R., Parker, S. F., Concepción, P., Corma, A. & García, H. Heterolytic and heterotopic dissociation of hydrogen on ceria-supported gold nanoparticles. Combined inelastic neutron scattering and FT-IR spectroscopic study on the nature and reactivity of surface hydrogen species. Chem. Sci. 1, 731–738 (2010).

Chen, H. et al. Direct detection of reactive gallium-hydride species on the Ga2O3 surface via solid-state NMR. Spectrosc. J. Am. Chem. Soc. 144, 17365–17375 (2022).

Wang, L. et al. Photocatalytic hydrogenation of carbon dioxide with high selectivity to methanol at atmospheric pressure. Joule 2, 1369–1381 (2018).

Huang, Z.-Q. et al. Understanding all-solid frustrated-lewis-pair sites on CeO2 from theoretical perspectives. ACS Catal. 8, 546–554 (2017).

Li, Z. et al. Oxidation of reduced ceria by incorporation of hydrogen. Angew. Chem. Int. Ed. 58, 14686–14693 (2019).

Collins, S. E., Baltanas, M. A. & Bonivardi, A. L. Hydrogen chemisorption on gallium oxide polymorphs. Langmuir 21, 962–970 (2005).

Vecchietti, J. et al. Insights on hydride formation over cerium-gallium mixed oxides: A mechanistic study for efficient H2 dissociation. J. Catal. 345, 258–269 (2017).

Huang, Z.-Q., Li, T.-H., Yang, B. & Chang, C.-R. Role of surface frustrated Lewis pairs on reduced CeO2(110) in direct conversion of syngas. Chin. J. Catal. 41, 1906–1915 (2020).

Bielz, T. et al. Hydrogen on In2O3: Reducibility, bonding, defect formation, and reactivity. J. Phys. Chem. C. 114, 9022–9029 (2010).

Hu, G., Wu, Z. & Jiang, D.-E. First principles insight into H2 activation and hydride species on TiO2 surfaces. J. Phys. Chem. C. 122, 20323–20328 (2018).

Klingler, R. J., Mochida, K. & Kochi, J. K. Mechanism of hydrogen transfer from metal hydrides. J. Am. Chem. Soc. 101, 6626–6637 (2002).

Fjellvag, O. S., Armstrong, J., Vajeeston, P. & Sjastad, A. O. New insights into hydride bonding, dynamics, and migration in La2LiHO3. oxyhydride. J. Phys. Chem. Lett. 9, 353–358 (2018).

Liu, Y. et al. Direct observation of accelerating hydrogen spillover via surface-lattice-confinement effect. Nat. Commun. 14, 613 (2023).

Chen, S. et al. Propane dehydrogenation: catalyst development, new chemistry, and emerging technologies. Chem. Soc. Rev. 50, 3315–3354 (2021).

Studt, F. et al. Discovery of a Ni-Ga catalyst for carbon dioxide reduction to methanol. Nat. Chem. 6, 320–324 (2014).

Akatsuka, M. et al. XAFS analysis for quantification of the gallium coordinations in Al2O3-supported Ga2O3 photocatalysts. J. Phys: Conf. Ser. 712, 012056 (2016).

Polo-Garzon, F., Bao, Z. H., Zhang, X. Y., Huang, W. X. & Wu, Z. L. Surface reconstructions of metal oxides and the consequences on catalytic chemistry. ACS Catal. 9, 5692–5707 (2019).

Gonzalez, E. A. et al. Hydrogen adsorption on β-Ga2O3(100) surface containing oxygen vacancies. Surf. Sci. 575, 171–180 (2005).

Collins, S. E., Baltanas, M. A. & Bonivardi, A. L. Infrared spectroscopic study of the carbon dioxide adsorption on the surface of Ga2O3. Polymorphs. J. Phys. Chem. B 110, 5498–5507 (2006).

Wang, Y., Pei, C., Zhao, Z.-J. & Gong, J. Kinetically rate-determining step modulation by metal-support interactions for CO oxidation on Pt/CeO2. Sci. China Chem. 65, 2038–2044 (2022).

Aireddy, D. R. & Ding, K. Heterolytic dissociation of H2 in heterogeneous catalysis. ACS Catal. 12, 4707–4723 (2022).

Coperet, C., Estes, D. P., Larmier, K. & Searles, K. Isolated surface hydrides: formation, structure, and reactivity. Chem. Rev. 116, 8463–8505 (2016).

Li, Z. et al. Interaction of hydrogen with ceria: Hydroxylation, reduction, and hydride formation on the surface and in the bulk. Chem. Eur. J. 27, 5268–5276 (2021).

Calatayud, M., Collins, S. E., Baltanas, M. A. & Bonivardi, A. L. Stability of formate species on beta-Ga2O3. Phys. Chem. Chem. Phys. 11, 1397–1405 (2009).

Heyl, D., Rodemerck, U. & Bentrup, U. Mechanistic study of low-temperature CO2 hydrogenation over modified Rh/Al2O3 catalysts. ACS Catal. 6, 6275–6284 (2016).

Wang, G. S. et al. Active sites in CO2 hydrogenation over confined VOx-Rh catalysts. Sci. China Chem. 62, 1710–1719 (2019).

Li, G. et al. Role of SAPO-18 acidity in direct syngas conversion to light olefins. ACS Catal. 10, 12370–12375 (2020).

Epelde, E. et al. SAPO-18 and SAPO−34 catalysts for propylene production from the oligomerization-cracking of ethylene or 1-butene. Appl. Catal., A 547, 176–182 (2017).

Yang, C. et al. Strong Electronic Oxide-Support Interaction over In2O3/ZrO2 for Highly Selective CO2 Hydrogenation to Methanol. J. Am. Chem. Soc. 142, 19523–19531 (2020).

Xiao, Z. et al. Tuning oxygen vacancies on mesoporous ceria nanorods by metal doping: Controllable magnetic property. Appl. Surf. Sci. 455, 1037–1044 (2018).

Wang, Z. et al. The role of CO2 dissociation in CO2 hydrogenation to ethanol on CoCu/silica catalysts. Nano Res. 16, 6128–6133 (2022).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B: Condens. Matter Mater. Phys. 50, 17953–17979 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B: Condens. Matter Mater. Phys. 59, 1758–1775 (1999).

Zhao, H. et al. The role of Cu1–O3 species in single-atom Cu/ZrO2 catalyst for CO2 hydrogenation. Nat. Catal. 5, 818–831 (2022).

Perdew, J. P. & Wang, Y. Accurate and simple analytic representation of the electron-gas correlation energy. Phys. Rev. B 45, 13244 (1992).

Ma, S., Shang, C., Wang, C.-M. & Liu, Z.-P. Thermodynamic rules for zeolite formation from machine learning based global optimization. Chem. Sci. 11, 10113–10118 (2020).

Acknowledgements

This work was supported by the Ministry of Science and Technology of China (2022YFA1503804, Y.Z.), National Natural Science Foundation of China (22102033, 22272031, Y.Z.), Science & Technology Commission of Shanghai Municipality (22ZR1408000, 22QA1401300, Y.Z.), China National Postdoctoral Program for Innovative Talents (BX20220090, C.S.Y.), China Postdoctoral Science Foundation (2022M710740, C.S.Y.), the Fundamental Research Funds for the Central Universities (20720220008, Y.Z.) and the Foundation of Key Laboratory of Low-Carbon Conversion Science & Engineering (KLLCCSE-202201, Y.Z.). We are grateful to all staff at the BL05U and BL06B beamline of the Shanghai Synchrotron Radiation Facility, Shanghai Advanced Research Institute, Chinese Academy of Sciences.

Author information

Authors and Affiliations

Contributions

C.S.Y. performed most material synthesis, characterization, and catalytic tests. C.S.Y., Y.Z. and X.B. initiated the project and wrote the manuscript. S.M. and Z.-P.L. performed the theoretical calculations and helped the manuscript drafting. F.Y., W.-P.S., and L.Z. helped with the XPS experiments. L.W. helped with the XAS experiments. D.Y. helped with the catalytic tests and IR experiments. T.L., Y.C. and Y.L. provided constructive suggestions for the work and helped with the temperature-programmed experiments. H.H. and H.D. helped with H1 NMR measurement and analysis.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Kunlun Ding and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, C., Ma, S., Liu, Y. et al. Homolytic H2 dissociation for enhanced hydrogenation catalysis on oxides. Nat Commun 15, 540 (2024). https://doi.org/10.1038/s41467-024-44711-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-44711-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.