Abstract

High-functioning/high-performance polymer nanocomposites have been intensively studied by using nanocarbons such as carbon nanotubes and graphene, which possess excellent properties derived from the rigid structures of the carbon backbones. However, in general, nanocarbons tend to agglomerate in polymer matrices due to van der Waals forces and low reactivity, thus resulting in defects at the interfaces. The high potentials of nanocarbons cannot be exploited unless nanocarbons are highly dispersed in polymer matrices with favorable interfacial interactions. For a few decades, considerable effort has been expended to improve the dispersibilities and interfacial interactions of polymer/nanocarbon nanocomposites. This review describes recent advances in designs of polymer/nanocarbon nanocomposites while focusing on our research on the high potential of nanodiamond-reinforced polymer nanocomposites.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Nirmalraj P, Santos MC, Mario J, Rios S, Davila D, Vargas F, et al. Polymer–nanocarbon topological and electronic interface. Langmuir. 2018;34:6225–30.

Lazarenko A, Vovchenko L, Matzui L, Kozachenko V, Prylutskyy Y, Scharff P, et al. Thermal diffusivity of nanocarbon composites. Polym Comp. 2011;32:14–17.

Bao W, Pickel AD, Zhang Q, Chen Y, Yao Y, Wan J, et al. Flexible, high temperature, planar lighting with large scale printable nanocarbon paper. Adv Mater. 2016;28:4684–91.

Nadiv R, Shachar G, Peretz-Damari S, Varenika M, Levy I, Buzaglo M, et al. Performance of nanocarbon loaded polymer composites: dimensionality matters. Carbon. 2018;126:410–8.

Moradi M, Mohandesi JA, Haghshenas DF. Mechanical properties of the poly(vinyl alcohol) based nanocomposites at low content of surfactant wrapped graphene sheet. Polymer. 2015;60:207.

Castell P, Cano M, Maser WK, Benito AM. Combination of two dispersants as a valuable strategy to prepare improved poly (vinyl alcohol)/carbon nanotube composites. Comp Sci Technol. 2013;80:101–7.

Usrey ML, Strano MS. Controlling single-walled carbon nanotube surface adsorption with covalent and noncovalent functionalization. J Phys Chem C. 2009;13:12443–53.

Gong X, Liu J, Baskaran S, Voise RD, Young JS. Surfactant-assisted processing of carbon nanotube/polymer composites. Chem Mater. 2000;12:1049–52.

Wang Y, Xiong S, Wang X, Chu J, Zhang R, Gong M, et al. Covalently bonded polyaniline-reduced graphene oxide/single-walled carbon nanotubes nanocomposites: influence of various dimensional carbon nanostructures on the electrochromic behavior of PANI. Polym J. 2020;52:783–92.

Zheng H, Zhang W, Li B, Zhu J, Wang C, Song G, et al. Recent advances of interphases in carbon fiber-reinforced polymer composites: a review. Compos B Eng. 2022;233:109639.

Moniruzzaman M, Winey KI. Polymer nanocomposites containing carbon nanotubes. Macromolecules. 2006;39:5194–205.

Cho BG, Hwang SH, Park M, Park JK, Park YB, Chae HG. The effects of plasma surface treatment on the mechanical properties of polycarbonate/carbon nanotube/carbon fiber composites. Compos B Eng. 2019;160:436–45.

Ogawa D, Morimune-Moriya S, Nakamura K. Effective polymerization technique for plasma-treated multiwalled carbon nanotubes to maximize wear resistance of composite polyurethan. J Vac Sci Technol B. 2022;40:022803.

Chang CM, Liu YL. Functionalization of multiwalled carbon nanotubes with nonreactive polymers through an ozone-mediated process for the preparation of a wide range of high performance polymer/carbon nanotube composites. Carbon. 2010;48:1289–97.

Park SJ, Park SJ. Effect of ozone-treated single-walled carbon nanotubes on interfacial properties and fracture toughness of carbon fiber-reinforced epoxy composites. Compos A Appl Sci Manuf. 2020;137:105937.

Bhandari S, Khastgir D. Synergistic effect of simultaneous dual doping in solvent-free mechanochemical synthesis of polyaniline supercapacitor comparable to the composites with multiwalled carbon nanotube. Polymer. 2015;81:62–69.

Liu T, Phang IY, Shen L, Chow SY, Zhang WD. Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6. Compos Macromol. 2004;37:7214–22.

Lee CH, Liu JY, Chen SL, Wang YZ. Miscibility and properties of acid-treated multi-walled carbon nanotubes/polyurethane nanocomposites. Polym J. 2007;39:138–46.

Scaffaro R, Maio A, Tito AC. High performance PA6/CNTs nanohybrid fibers prepared in the melt. Compos Sci Technol. 2012;72:1918–23.

Danileno VV. On the history of the discovery of nanodiamond synthesis. Phys Solid State. 2004;46:595–9.

Krüger A, Kataoka F, Ozawa M, Aleksenskii A, Vul’ AY, Fujino Y, et al. Unusually tight aggregation in detonation nanodiamond: Identification and disintegration. Carbon. 2005;43:1722–30.

Taylor WH. Structure and properties of diamond. Nature. 1947;159:729–31.

Field JE. The mechanical and strength properties of diamond. Rep Prog Phys. 2012;75:126505.

Huang Q, Yu D, Xu B, Hu W, Ma Y, Wang Y, et al. Nanotwinned diamond with unprecedented hardness and stability. Nature. 2014;510:250–3.

Zhang X, Liu T, Sreekumar TV, Kumar S, Moore VC, Hauge RH, et al. Poly (vinyl alcohol)/SWNT composite film. Nano Lett. 2003;3:1285–8.

Zhao X, Zhang Q, Chen D, Lu P. Enhanced mechanical properties of graphene-based poly (vinyl alcohol) composites. Macromolecules. 2010;43:2357–63.

Cheng HKF, Sahoo NG, Tan YP, Pan Y, Bao HN, Li L, et al. Poly (vinyl alcohol) nanocomposites filled with poly(vinyl alcohol)-grafted graphene oxide. ACS Appl Mater Interfaces. 2012;4:2387–94.

Lee WJ, Clancy AJ, Fernández-Toribio JC, Anthony DB, White ER, Solano E, et al. Interfacially grafted single-walled carbon nanotube/poly(vinyl alcohol) composite fibers. Carbon. 2019;146:162–71.

Shin YE, Cho JY, Yeom J, Ko H, Han JT. Electronic textiles based on highly conducting poly(vinyl alcohol)/carbon nanotube/silver nanobelt hybrid fibers. ACS Appl Mater Interfaces. 2021;13:31051–8.

Zhou T, Chen F, Tang C, Bai H, Zhang Q, Deng H, et al. The preparation of high performance and conductive poly(vinyl alcohol)/graphene nanocomposite by reducing graphite oxide with sodium hydrosulfite. Comp Sci Technol. 2011;71:1266–70.

Amirilargani M, Tofighy MA, Mohammadi T, Sadatnia B. Novel poly(vinyl alcohol)/multiwalled carbon nanotube nanocomposite membranes for pervaporation dehydration of isopropanol: poly(sodium 4-styrenesulfonate) as a functionalization agent. Ind Eng Chem Res. 2014;53:12819–29.

Zhou G, Byun JH, Oh Y, Jung BM, Cha HJ, Seong DG, et al. Highly sensitive wearable textile-based humidity sensor made of high-strength, single-walled carbon nanotube/poly(vinyl alcohol) filaments. ACS Appl Mater Interfaces. 2017;9:4788–97.

Abudabbus MM, Jevremović I, Nešović K, Perić-Grujić A, Rhee KY, Mišković-Stanković V. In situ electrochemical synthesis of silver-doped poly(vinyl alcohol)/graphene composite hydrogels and their physico-chemical and thermal properties. Compos B Eng. 2018;140:99–107.

Morimune S, Nishino T, Goto T. Poly(vinyl alcohol)/graphene oxide nanocomposites prepared by a simple eco-process. Polym J. 2012;44:1056–63.

Morimune S, Kotera M, Goto T, Nishino T. Uniaxial drawing of poly(vinyl alcohol)/graphene oxide nanocomposites. Carbon. 2014;70:38–45.

Morimune-Moriya S, Goto T, Nishino T. Effect of aspect ratio of graphene oxide on properties of poly (vinyl alcohol) nanocomposites. Nanocomposites. 2019;5:84–93.

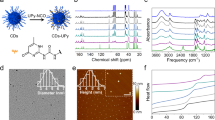

Morimune S, Kotera M, Nishino T, Hata K, Goto K. Poly(vinyl alcohol) nanocomposites with nanodiamond. Macromolecules. 2011;44:4415–21.

Morimune S, Nishino T. Strong, tough, transparent and highly heat-resistant acrylic glass based on nanodiamond. Polymer. 2021;222:123661.

Morimune S, Nishino T, Goto T. An ecological approach to graphene oxide reinforced poly(methyl methacrylate) nanocomposites. ACS Appl Mater Interfaces. 2012;4:3596–601.

Morimune-Moriya S, Yada S, Kuroki N, Ito S, Hashimoto T, Nishino T. Strong reinforcement effects of nanodiamond on mechanical and thermal properties of polyamide 66. Comp Sci Technol. 2020;199:108356.

Tohgo K, Fukuhara D, Hadano A. The influence of debonding damage on fracture toughness and crack-tip field in glass-particle-reinforced Nylon 66 composites. Comp Sci Technol. 2001;61:1005–16.

Li L, Li CY, Ni C, Rong L, Hsiao B. Structure and crystallization behavior of Nylon 66/multiwalled carbon nanotube nanocomposites at low carbon nanotube contents. Polymer. 2007;48:3452–60.

Hartikainen J, Lehtonen O, Harmia T, Lindner M, Valkama, Ruokolainen J, et al. Structure and morphology of polyamide 66 and oligomeric phenolic resin blends: molecular modeling and experimental investigations. Chem Mater. 2004;16:3032–9.

Viswanathan G, Chakrapani N, Yang H, Wei B, Chung H, Cho K, et al. Single-step in situ synthesis of polymer-grafted single-wall nanotube composites. J Am Chem Soc. 2003;125:9258–9.

Zille A, Fernandes MM, Francesko A, Tzanov T, Fernandes M, Oliveira FR, et al. Size and aging effects on antimicrobial efficiency of silver nanoparticles coated on polyamide fabrics activated by atmospheric DBD plasma. ACS Appl Mater Interfaces. 2015;7:13731–44.

Zou H, Wang K, Zhang Q, Fu Q. A change of phase morphology in poly (p-phenylene sulfide)/polyamide 66 blends induced by adding multiwalled carbon nanotubes. Polymer. 2006;47:7821–6.

Linggawati A, Mohammad AW, Ghazali Z. Effect of electron beam irradiation on morphology and sieving characteristics of nylon-66 membranes. Eur Polym J. 2009;45:2797–804.

Wu Y, Xu Y, Wang D, Zhao Y, Weng S, Xu D, et al. FT-IR spectroscopic investigation on the interaction between nylon 66 and lithium salts. J Appl Polym Sci. 2004;91:2869–75.

Jovic B, Nikolic A, Petrovic S. FTIR spectroscopic study of hydrogen bonding and solvent induced frequency shifts of N-tert-butylacetamide. J Mol Struct. 2013;1044:140–3.

Guo L, Sato H, Hashimoto T, Ozaki Y. FTIR study on hydrogen-bonding interactions in biodegradable polymer blends of poly(3-hydroxybutyrate) and poly(4-vinylphenol). Macromolecules. 2010;43:3897–902.

Morimune-Moriya S, Obara K, Fuseya M, Katanosaka M. Development and characterization of strong, heat-resistant and thermally conductive polyimide/nanodiamond nanocomposites. Polymer. 2021;230:124098.

Chen J, Yan L, Song W, Xu D. Interfacial characteristics of carbon nanotube-polymer composites: a review. Comp Part A: Appl Sci Manuf. 2018;114:149–69.

Chazot CAC, Hart AJ. Understanding and control of interactions between carbon nanotubes and polymers for manufacturing of high-performance composite materials. Comp Sci Technol. 2019;183:107795.

Pramanik C, Nepal D, Nathanson M, Gissinger JR, Garley A, Berry RJ, et al. Molecular engineering of interphases in polymer/carbon nanotube composites to reach the limits of mechanical performance. Comp Sci Technol. 2018;166:86–94.

Georgakilas V, Otyepka M, Bourlinos AB, Chandra V, Kim N, Kemp KC, et al. Functionalization of graphene: covalent and non-covalent approaches, derivatives and applications. Chem Rev. 2012;112:6156–214.

Abdou JP, Reynolds KJ, Pfau MR, Staden J, Braggin GA, Tajaddod N, et al. Interfacial crystallization of isotactic polypropylene surrounding macroscopic carbon nanotube and graphene fibers. Polymer. 2016;91:136–45.

Han JT, Kim JS, Kim SH, Lim HS, Jeong HJ, Jeong SY, et al. Nanocarbon-induced rapid transformation of polymer surfaces into superhydrophobic surfaces. ACS Appl Mater Interfaces. 2010;2:3378–83.

Zhang Z, Qu J, Feng Y, Feng W. Assembly of graphene-aligned polymer composites for thermal conductive applications. Compos Commun. 2018;9:33–41.

Chan CM, Wu J, Li JX, Cheung YK. Polypropylene/calcium carbonate nanocomposites. Polymer. 2002;43:2981–2992.

Zhang F, Feng Y, Feng W. Three-dimensional interconnected networks for thermally conductive polymer composites: design, preparation, properties, and mechanisms. Mater Sci Eng. 2020;142:100580.

Chen J, Wei H, Bao H, Jiang P, Huang X. Millefeuille-inspired thermally conductive polymer nanocomposites with overlapping BN nanosheets for thermal management applications. ACS Appl Mater Interfaces. 2019;11:31402–10.

Sun J, Zhang X, Du Q, Murugadoss V, Wu D, Guo Z. The contribution of conductive network conversion in thermal conductivity enhancement of polymer composite: a theoretical and experimental study. ES Mater Manuf. 2021;13:53–65.

Zhao Y, Niu M, Yang F, Jia Y, Cheng Y. Ultrafast electro-thermal responsive heating film fabricated from graphene modified conductive. Mater Eng Sci. 2019;8:33–38.

Li J, Zhang P, He H, Zhai S, Xian Y, Ma W, et al. Enhanced thermal transport properties of epoxy resin thermal interface materials. ES Energy Environ. 2019;4:41–47.

Wu S, Xiao C, Kong S, Li B, Yang Z, Tang Z, et al. Carbon nanodots as an eco-friendly activator of sulfur vulcanization in diene-rubber composites. Compos Commun. 2021;25:100755.

Mochalin VN, Neitzel I, Etzold BJM, Peterson A, Palmese G, Gogotsi Y. Covalent incorporation of aminated nanodiamond into an epoxy polymer network. ACS Nano. 2011;5:7494–502.

Neitzel I, Mochalin VN, Niu J, Cuadra J, Kontsos A, Palmese GR, et al. Maximizing Young’s modulus of aminated nanodiamond-epoxy composites measured in compression. Polymer. 2012;53:5965–71.

Morimune-Moriya S, Kato T, Haga R, Hashimoto T, Tanahashi H. Reinforcement effects of nanodiamond on natural rubber nanocomposites. J Soc Rubber Sci Technol, Jpn. 2019;92:253–9.

Sobani M, Soucek MD. Low temperature fracture toughness of polysulfide modified BPA-epoxide primers. Prog Org Coat. 2022;163:106626.

Li X, Nie W, Xu Y, Zhou Y, Chen P, Zhang C. Functionalized GO/polysulfide rubber composites with excellent comprehensive properties based interfacial optimum design. Compos, Part B. 2020;198:108234.

Vinayan BP, Zhao-Karger Z, Diemant T, Chakravadhanula VSK, Schwarzburger NI, Cambaz MA, et al. Performance study of magnesium–sulfur battery using a graphene based sulfur composite cathode electrode and a nonnucleophilic Mg electrolyte. Nanoscale. 2016;8:3296–306.

Wang D, Tang Z, Fang S, Wu S, Zeng H, Wang A, et al. The use of inverse vulcanized polysulfide as an intelligent interfacial modifier in rubber/carbon black composites. Carbon. 2021;184:409–17.

Gannoruwa A, Sumita A, Kawahara S. Highly enhanced mechanical properties in natural rubber prepared with a nanodiamond nanomatrix structure. Polymer. 2017;126:40–47.

Wu J, Xang W, Huang G, Li H, Tang M, Wu S, et al. Vulcanization kinetics of graphene/natural rubber nanocomposites. Polymer. 2013;54:3314–23.

Morimune-Moriya S. Mechanical properties of polymer nanocomposites reinforced with high aspect ratio fillers. J Adhes Soc Jpn. 2017;53:348–54.

Acknowledgements

The author expresses gratitude to all of her colleagues for their valuable contributions to this focused review. The author is also sincerely grateful to Prof. Takashi Nishino from Kobe University for technical help and fruitful discussions. This research was supported by KAKENHI grants for Young Scientists 20K15043 from the Japan Society for the Promotion of Science (JSPS), 11th Shiseido Female Researcher Science Grant from Shiseido Co., Ltd., and Tokuyama Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Morimune-Moriya, S. Polymer/nanocarbon nanocomposites with enhanced properties. Polym J 54, 977–984 (2022). https://doi.org/10.1038/s41428-022-00644-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-022-00644-w

This article is cited by

-

Conformational relaxation of ethylene-propylene-diene terpolymer at a solid interface

Polymer Journal (2023)