Abstract

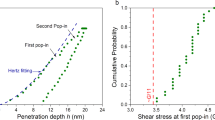

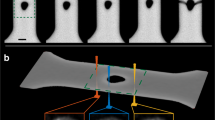

The amorphous nature of metallic glasses and their mechanical properties make them interesting for structural applications. However, the interplay between the nature of atomic structures in metallic glasses and mechanical properties remains poorly understood. In this study, high-frequency dynamic micropillar tests have been used to probe both atomic clusters and flow defects in metallic glasses. We show that loosely bonded atomistic free-volume zones that are enveloped elastically by tightly bonded atomic clusters show a deformation character similar to supercooled liquids. At room temperature, the effective viscosity of these free-volume zones is of the order of 1×108 Pa s before the occurrence of shear banding. The confined liquid-like deformation of free-volume zones leads to significant mechanical hysteresis in micropillars under dynamic loading, providing important insight into how atomistic structural features affect the deformation behaviours in metallic glasses in the apparent elastic regime. The inelastic behaviour also serves as the basis for the superior damping resistance of metallic glasses.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Klement, K., Willens, R. H. & Duwez, P. Non-crystalline structure in solidified gold–silicon alloys. Nature 187, 869–870 (1960).

Pampillo, C. A. Review: Flow and fracture in amorphous alloys. J. Mater. Sci. 10, 1194–1227 (1975).

Spaepen, F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses. Acta Metall. 23, 407–415 (1977).

Argon, A. S. Plastic deformation in metallic glasses. Acta Metall. 27, 47–58 (1979).

Miracle, D. B. A structural model for metallic glasses. Nature Mater. 3, 697–702 (2004).

Sheng, H. W. et al. Polyamorphism in a metallic glass. Nature 6, 192–197 (2007).

Miracle, D. B., Egami, T., Flores, K. M. & Kelton, F. K. Structural aspects of metallic glasses. MRS Bull. 32, 629–634 (2007).

Fan, C., Liaw, P. K. & Liu, C. T. Atomistic model of amorphous materials. Intermetallics 17, 86–87 (2009).

Ma, D., Stoica, A. D. & Wang, X-L. Power-law scaling and fractal nature of medium-range order in metallic glasses. Nature Mater. 8, 30–34 (2009).

Johnson, W. L. & Samwer, K. A universal criterion for plastic yielding of metallic glasses with a (T/Tg)2/3 temperature dependence. Phys. Rev. Lett. 95, 195501 (2005).

Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004).

Yang, Y., Ye, J. C., Lu, J., Liu, F. X. & Liaw, P. K. Effects of specimen geometry and base material on the mechanical behavior of focused-ion-beam-fabricated metallic-glass micropillars. Acta Mater. 57, 1613–1623 (2009).

Lee, C. J., Huang, J. C. & Nieh, T. G. Sample size effect and microcompression of Mg65Cu25Gd10 metallic glass. Appl. Phys. Lett. 91, 161913 (2007).

Volkert, C. A., Donohue, A. & Spaepen, F. Effect of sample size on deformation in amorphous metals. J. Appl. Phys. 103, 083539 (2008).

Schuster, B. E., Wei, Q., Hufnagel, T. C. & Ramesh, K. T. Size-independent strength and deformation mode in compression of a Pd-based metallic glass. Acta Mater. 56, 5091–5100 (2008).

Greer, J. R., Oliver, W. C. & Nix, W. D. Size dependence of mechanical properties of gold at the micron scale in the absence of strain gradients. Acta Mater. 53, 1821–1830 (2005).

Lunkenheimer, P., Schneider, U., Brand, R. & Loidl, A. Glassy dynamics. Contemp. Phys. 41, 15–36 (2000).

Johnson, W. L., Demetriou, M. D., Harmon, J. S., Lind, M. L. & Samwer, K. Rheology and ultrasonic properties of metallic glass-forming liquids: A potential energy landscape perspective. MRS Bull. 32, 644–650 (2007).

Harmon, J. S., Demetriou, M. D., Johnson, W. L. & Samwer, K. Anelastic to plastic transition in metallic glass-forming liquids. Phys. Rev. Lett. 99, 135502 (2007).

Busch, R., Bakke, E. & Johnson, W. L. Viscosity of the supercooled liquid and relaxation at the glass transition of the Zr46.75Ti8.25Cu7.5Ni10Be27.5 bulk metallic glass forming alloy. Acta Mater. 46, 4725–4732 (1998).

Egami, T. in Bulk Metallic Glasses (eds Miller, M. & Liaw, P. K.) 27–52 (Springer, 2008).

Ye, J. C., Lu, J., Yang, Y. & Liaw, P. K. Extraction of bulk metallic-glass yield strengths using tapered micropillars in micro-compression experiments. Intermetallics 18, 385–393 (2010).

Acknowledgements

Y.Y. acknowledges financial support provided by the Research Grant Council (RGC), the Hong Kong Government, with grant number PolyU5203/08E. J.L. is also grateful to RGC for the financial support of grant number PolyU7/CRF/08. C.T.L. is supported by PolyU internal financial support.

Author information

Authors and Affiliations

Contributions

C.T.L., J.L. and Y.Y. designed experiments, analysed data and wrote the Letter. J.C.Y. carried out all dynamical microcompression experiments and analysed data. Q.W. carried out all transmission electron microscopy imaging experiments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Information (PDF 1652 kb)

Rights and permissions

About this article

Cite this article

Ye, J., Lu, J., Liu, C. et al. Atomistic free-volume zones and inelastic deformation of metallic glasses. Nature Mater 9, 619–623 (2010). https://doi.org/10.1038/nmat2802

Issue Date:

DOI: https://doi.org/10.1038/nmat2802

This article is cited by

-

Anomalous temperature dependence of elastic limit in metallic glasses

Nature Communications (2024)

-

Ripples in the bottom of the potential energy landscape of metallic glass

Nature Communications (2024)

-

Oxidation-induced superelasticity in metallic glass nanotubes

Nature Materials (2024)

-

Non-affine atomic rearrangement of glasses through stress-induced structural anisotropy

Nature Physics (2023)

-

Influence of oscillation strain on the dynamic mechanical relaxation of a La-based metallic glass

Science China Technological Sciences (2023)