Abstract

In yeast, the hexose assimilation is started at hexose phosphorylation. However, in Kluyveromyces marxianus, the hexokinase (HXK) and glucokinase (GLK) genes were not identified by experiments. Meanwhile, the glucose-free fructose product requires more cost-efficient method. In this study, the KmHXK1 and KmGLK1 genes were functionally identified through gene disruption, over-expression and recombinant enzymes characterization. Both glucose and fructose assimilation ability decreased significantly in KmHXK1 disrupted strain YLM001, however, this ability was not changed obviously in KmGLK1 disrupted strain YLM002. When over-expressing KmGLK1 in YLM001, only the glucose assimilation ability was recovered in obtained strain (YLM005). The kinetic constant analysis of recombinant enzymes also proved that KmHXK1 could phosphorylate glucose (Vmax 553.01 U/mg, Km 0.83 mM) and fructose (Vmax 609.82 U/mg, Km 0.52 mM), and KmGLK1 only phosphorylate glucose with a Vmax of 0.73 U/mg and a Km 4.09 mM. A thermo-tolerant strain YGR003 which produced glucose-free fructose from Jerusalem artichoke tuber in one step was constructed based on the obtained information. The highest production and fastest productivity were 234.44 g/L and 10.26 g/L/h, respectively, which were several folds of the results in previous reports.

Similar content being viewed by others

Introduction

In yeast the hexoses including glucose and fructose are phosphorylated by hexose-glucose kinase after uptake, then enter the glycolytic pathway. In Saccharomyces cerevisiae, three enzymes (encoded by HXK1, HXK2, and GLK1) can catalyze this reaction1. However, only one hexokinase (KmHXK1) and one glucokinase (KmGLK1) gene were found in the genome of Kluyveromyces marxianus based on theoretical translation and homology analysis2,3, and the functions of the two enzymes were not experimentally confirmed.

With the growing demand for natural, healthy and low-calorie food, a large number of alternative sugars has emerged since the early 1980 s4. Nutritive sweeteners (e.g., sucrose, fructose) are generally recognized as safe (GRAS) by the Food and Drug Administration (FDA)5. Other than as the highest sugar sweetener, fructose is also used as an excipient in pharmaceutical tablets, syrups and solutions. It makes medicines more palatable for the high sweetness and safety6,7. The ability to inhibit water crystallisation allows it to serve as a cryoprotectant8, The high solubility of fructose enables it to aid the solubility of therapeutic agents and adjusting osmolarity of solutions to make them compatible with parenteral administration7. Fructose is also used as lyoprotectants for its ability of protecting against the fundamentally different stresses of freezing and subsequent dehydration9. Also, fructose is metabolic in liver and does not require insulin, therefore it is beneficial to diabetics. Some studies showed that the consumption of high-fructose corn syrup (HFCS) or fructose may raise the risk of obesity and diabetes. However, most of them have a premise of excess consumption. Whether the fructose is the unique reason is still under contest, and more possibly, the overtake of calories overall led these epidemics10,11,12,13.

However, producing glucose-free fructose is still a costly and multistep procedure. Fructose is usually available in blends with other sugars, named as high-fructose corn syrup (HFCS)4 and is produced with glucose isomerase from corn starch hydrolysate. The demand of glucose-free fructose is expected to grow continually. As its commercial production expands and it requires more cost-effective to manufacture. To reduce the cost of manufacture, changing the source of the raw material to fructose-containing polysaccharides, such as inulin is a good choice. This would reduce the number of steps in the production of fructose and is more cost effective7.

Jerusalem artichoke can grow in marginal lands and is tolerant to drought and salt stresses14. The main carbohydrate in the Jerusalem artichoke tuber is inulin, a fructose-based polymer consisting of linear chains of β-2, 1-linked d-fructofuranose molecules terminated by a glucose residue15 that can be easily hydrolyzed into glucose and fructose by inulinase without expensive pretreatment. High fructose syrup (HFS) could be obtained through enzymatic hydrolysis of inulin16,17. However, it still contains glucose.

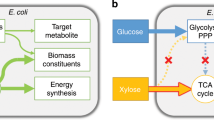

K. marxianus is a thermo-tolerant non-conventional yeast. It can assimilate some carbon source such as xylose and mannitol which S. cerevisiae cannot. Also, K. marxianus can directly utilize inulin from Jerusalem artichoke tubers (JAT) at elevated temperature without addition of inulinase and JAT pretreatment18,19,20. This ability makes K. marxianus a good candidate to use Jerusalem artichoke tubers at elevated temperatures. As mentioned above, the main mono-sugars in Jerusalem artichoke tubers hydrolysate were glucose and fructose. Glucose-free fructose syrup may be obtained through specific consumption of glucose.

In this study, we identified the genes of hexokinase (KmHXK1) and glucokinase (KmGLK1) through gene disruption and function analysis. Furthermore, with Jerusalem artichoke tubers, an efficient, thermo-tolerant and one step fructose producing strain was constructed through overexpression of the glucokinase gene in the KmHXK1 disrupted strain.

Results

KmHXK1 or KmGLK1 disruption

A hypothetical hexokinase and a hypothetical glucokinase gene were found in the genomic DNA sequence of K. marxianus. Through the alignment of amino acid sequences of KmHXK1 and KmGLK1 with other hexokinase (Fig. S1), KmHXK1 (GenBank KX270227) shares 89.4% identity with KlHXK1 (GenBank CAA43855) and 72.4% identity with ScHXK2 (GenBank AAA34699). KmGLK1 (GenBank KX270228) shares 59.6% identity with ScGLK1 (GenBank NP_009890). To identify the function of hypothetical KmHXK1 or KmGLK1, correspondent gene disrupted strains were constructed. After the disruption cassettes containing a ScURA3 gene were transformed into strain YHJ010 (Table 1) and screened on synthetic dropout (SD) medium without Uracil, the genomic DNA of obtained clones were extracted and used as PCR template. With primer pair KmHXK-F and KmHXK-R or KmGLK-F and KmGLK-R (Supplementary Table S1), a 3.2 Kb (KmHXK1) or 2.9 Kb (KmGLK1) fragment was amplified from genomic DNA of YHJ010, and a 4.2 kb or a 4.3 Kb fragment was amplified from genomic DNA of YLM001 and YLM002, respectively (Fig. 1). These results indicated a ScURA3 gene was inserted into KmHXK1 or KmGLK1 and proved that they were disrupted (Fig. 1).

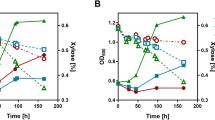

Genes functional evaluation through KmHXK1 or KmGLK1 disruption and KmGLK1 over-expression

The strains YLM001, YLM002 and control strain YWD016 which was URA3 complemented strain of YHJ010 (Table 1) were cultivated in SD medium with glucose or fructose as carbon source. The growth of YLM001 decreased significantly with both glucose and fructose (Fig. 2a and b), however, the growth of YLM002 showed little difference with YWD016 (Fig. 2a and b). Therefore, the KmHXK1 was the main enzyme involved in sugar metabolism and it may phosphorylates the hexose during sugar metabolism. However, the function of KmGLK1 was not clear. Then YLM005 which was constructed through over-expressing KmGLK1 gene in YLM001 was also cultivated with glucose or fructose as carbon source. As shown in Fig. 2c and d, the growth with glucose was recovered, but the growth with fructose was still very weak. These results indicated that KmGLK1 was an enzyme that preferred glucose as substrate.

Evaluation of the growth of KmHXK1 or KmGLK1 gene disrupted strains with glucose (a,c) or fructose (b,d) as carbon source. The growth of YLM001 (ΔKmHXK1), YLM002(ΔKmGLK1), YLM005 (YLM001 with KmGLK1 over-expression), YGR002 (YLM001 with TRP1 complemented) were compared. YWD016 and YGR001 (YHJ010 with URA3 and TRP1 complemented) in which auxtrophic markers were complemented were used as empty control (Table 1). The values are the means of three biological replicates ± standard deviation (n = 3).

Characterization of recombinant KmHXK1 and KmGLK1

To confirm the KmHXK1 and KmGLK1 were glucose or fructose kinase in the hexose metabolism, the recombinant enzymes were characterized. The KmHXK1 and KmGLK1 were over-expressed in Escherichia coli BL21 (DE3), the recombinant enzymes were purified through His-tag (Supplementary Fig. S2). The kinetic constant of recombinant KmHXK1 and KmGLK1 to glucose and fructose were determined. The Vmax and Km of KmHXK1 to fructose are 609.82 U/mg and 0.52 mM, and to glucose are 553.01 U/mg and 0.83 mM respectively. However, the Vmax and Km to glucose are 0.73 U/mg and 4.09 mM, and no obvious activity was detected with fructose as substrate.

Evaluate the sugar consumption of YLM005 strain with glucose-fructose mixture

YLM005, control strain YGR001 and YGR002 (Table 1) were cultivated with glucose-fructose mixture (10 g/L and 70 g/L, respectively). YLM005 grew well and reached OD600 3.59 in 10 h. During the growth, the glucose was consumed and decreased to 4.63 g/L in 22 h, however, the fructose was almost not consumed (Fig. 3a). The wild type control strain (YGR001) in which KmHXK1 and KmGLK1 was not modified also grew quickly and reached OD600 3.85 in 10 h. However, the glucose and fructose were consumed simultaneously (Fig. 3b). The glucose and fructose concentrations were decreased to 6.45 and 53.07 g/L, respectively. The growth of another strain YGR002, which was derived from YLM001 and TRP1 auxotrophy was complemented, was poor. It reached OD600 3.77 after 37 h cultivation and only consumed glucose (Fig. 3c). Therefore, in YLM005, the glucose assimilation ability was recovered, while fructose assimilation ability was still defective.

Hydrolysis inulin and selective consumption of produced glucose by strains YLM005 and YGR003

Because K. marxianus is a famous inulinase producing yeast, it is possible to obtain a strain which can hydrolyze inulin and produce glucose-free fructose by one step. To improve the inulin hydrolysis ability further, the LEU2 auxtrophy of YLM005 was complemented by transformation of plasmid pKmLEU21 to obtain a non-auxtrophic stain and named YGR003. Then the inulin hydrolysis and glucose consumption ability were evaluated through cultivating the strains with 100 g/L inulin. As shown in Fig. 4a, the growth of YGR003 was faster than YLM005 and could also reach higher cell density. Though the difference was not very large, the glucose consumption and fructose accumulation of YGR003 were stronger than YLM005 (Fig. 4b). Therefore, YGR003 was used in one step glucose-free fructose producing from Jerusalem artichoke tuber (JAT) powder.

One step producing glucose-free fructose from Jerusalem artichoke tuber powder

Because the pure inulin is relatively expensive material, JAT powder was used as substrate instead. To reduce the cost further, no nutrition except JAT powder and 0.2 M sodium phosphate buffer (pH 5.0) were used in reaction solution. The JAT was bought from the market of Yantai, China and contains 11.27% glucose and 71.10% fructose which were determined through mild acid hydrolysis.

Firstly, the production of glucose-free fructose from 100 g/L JAT powder under various temperatures with YGR003 was evaluated. As shown in Fig. 5a, about 70 g/L fructose was produced in 10 h with a productivity of about 7 g/L/h at 37 and 42 °C. However, at 45 °C, only 45.93 g/L fructose was produced in 10 h (Fig. 5a). Therefore, 42 °C was selected as the temperature for further evaluation with various concentration of JAT powder.

Evaluation of one step producing glucose -free fructose from JAT with strain YGR003. Glucose -free fructose from 100 g/L JAT under various temperature (a), with various concentration of JAT (b,c) at 42 °C, and the effect of heating (c) were determined. The values are the means of three biological replicates ± standard deviation (n = 3).

Secondly, the production of glucose-free fructose from JAT powder with various concentrations at 42 °C was evaluated. As shown in Fig. 5 and Table 2, 100, 200, 250, 300, 350 and 400 g/L JAT powder were used. With the JAT concentration increased, the production of fructose was also increased. However, longer time was required to reach glucose depletion. Therefore, the productivity first reached the peak (10.26 g/L/h), then decreased. Though in this study, the concentration of 350 g/L and 400 g/L JAT powder were also evaluated, the mixture of the yeast cells and JAT powder were like thick mud and the mixing efficiency was decreased which led to both the yield and the productivity decrease (Table 2).

Thirdly, producing glucose-free fructose with pre-heated JAT powder was evaluated. In previous reports, pre-heating improved the inulin extraction from JAT22. In this study, 350 g/L and 400 g/L pre-heated JAT (80 °C, 90 min) was used to evaluate if the fructose production could be improved further. As shown in Fig. 5c, the fructose produced with pre-heated JAT was not significantly improved. It is reasonable that the hydrolysis procedure took several days, and the release of inulin was not the limitation step.

Discussion

In this study, the KmHXK1 and KmGLK1 genes in K. marxianus were experimentally identified. HXK and GLK are the first enzymes in the hexose assimilation pathway after the sugar uptake into cell. After the genomic DNA of K. marxianus was sequenced, different to S. cerevisiae, only two genes (a HXK gene and a GLK gene) were found based on the sequence homology. In this study, we confirmed the function of these genes through gene disruption, hexose assimilation analysis and recombinant enzyme characterization. The deficient growth of KmHXK1 disrupted strain YLM001 with both glucose and fructose as carbon source and the enzymatic activity of recombinant KmHXK1 indicated that KmHXK1 is the main enzyme that catalyzes the hexose phosphorylation. On the other hand, no obvious growth reduction in KmGLK1 disruption strain YLM002, indicated that KmGLK1 is not essential in the step of hexose phosphorylation in K. marxianus. In our RNA-seq results, the KmHXK1 expression level was several hundred folds higher than KmGLK1 (data not shown) in YHJ010 when glucose was the substrate. This result is consistent with above conclusion that KmGLK1 is not the key enzyme in glucose metabolism. The recovered growth on glucose and deficient growth on fructose of KmGLK1 overexpression strain YLM005 indicated that KmGLK1 is really a glucose kinase. The hexokinase activities in crude lysate of YLM002 to glucose and fructose were 0.82 U/mg and 0.95 U/mg, respectively. The hexokinase activities in crude lysate of YLM005 to glucose and fructose were 0.093 U/mg and 0.067 U/mg. Though the hexokinase activities of YLM005 was very weak, it is strange that the fructose kinase activity in strain YLM005 almost cannot use fructose. Therefore, KmHXK1 and KmGLK1 genes were recombinant-expressed and the activities of pure enzymes were determined to avoid background interference. As shown in the results, recombinant KmGLK1 had no obvious fructose kinase activity. On the contrary, KmHXK1 phosphorylates glucose and fructose with relative high activity. The recombinant KmHXK1 has stronger activity to fructose than to glucose which is consistent with the activity in crude supernatant of YLM002. The fructose kinase of YLM005 is possible due to the NADH oxidation by other enzymes in the crude supernatant which was not completely inhibited and led a background. Hexokinase activity was also measured by another method which is through spectrophotometrically detecting optical density at 340 nm (OD340) by coupling the reaction to glucose-6-P dehydrogenase (data not shown)23. However, no fructose kinase activity could be detected with both KmHXK1 and KmGLK1. It is possible that the glucose-6-P dehydrogenase cannot use fructose-6-p as substrate.

A more convenient glucose-free fructose producing procedure is in great demand. HFCS 42 (42% fructose) is produced from corn starch hydrolysate with glucose isomerase, however HFCS with higher fructose i.e. HFCS 90 was obtained through large scale chromatographic processing of HFCS 42 to remove the glucose4,24. The preparation of glucose isomerase and large scale chromatography are relative high cost procedure. Inulin contains mainly fructose, it is excellent substrate for high fructose syrup production17,25,26,27,28,29,30,31. However, inulinase is required in inulin hydrolysis. Though inulinase is widely available, the cost need to be reduced further and preparing and stocking inulinase are also time- and labor-cost procedure in industrial application. There are a lot of microorganism expressing inulinase and hydrolyzing inulin, but the microorganism will utilize the glucose and fructose, leading a decreased yield of high fructose syrup. On other hand, glucose free fructose has a lot of excellent properties. A low cost and simple method for glucose free fructose is required in industrial application. Because YLM005 and YGR003 has strong glucose utilizing ability and very weak fructose utilizing ability, they can specifically consume the glucose in the inulin hydrolysate and the fructose are almost remained unchanged. YLM005 and YGR003 can be used to remove glucose and produce glucose-free fructose syrup from inulin.

Jerusalem artichoke tuber contain 60–80% inulin. Inulin as a reserve carbohydrate is a good feedstock for fructose production. Jerusalem artichoke is easily cultivated. It has high growth rate, good tolerance to frost, drought and poor soil, strong resistance to pests and plant diseases, with minimal to zero fertilizer requirements and the yield of tubers can reach up to 16–20 t/ha for tubers32. Furthermore, no nutrition addition is required by using JAT powder to produce fructose since there are some nutrition in JAT powder, and the cost is reduced further. Therefore, JAT is a good feed stock for glucose-free fructose production.

Using constructed yeast strain makes the fructose producing more convenient and efficient. In contrast to expensive enzyme preparation, yeast cell is easy to be stocked, propagated and prepared. Therefore, directly using yeast cell is more convenient than enzyme. Constructing a fructose assimilation deficient and inulin expressing yeast strain should enhance the fructose production from inulin or JAT. Fructose assimilation deficient strains were constructed in S. cerevisiae previously through which glucose-free fructose was produced with JAT29,33. A 8.5% of fructose syrup was obtained through fermentation by S. cerevisiae ATCC 36859 with high fructose corn syrup and hydrolyzed JAT juice with a yield of near 100% and a productivity of 1.33 g/L/h34. A HXK null and inulinase expression S. cerevisiae YBS618/INU was constructed. It consumed up to 10% inulin to produce glucose free-fructose. However, the yield and productivity was not indicated. Based on the Fig. 6 in that report, the productivity should be less than 3 g/L/h33. Finally, another HXK null and inulinase expression S. cerevisiae Y16/pHC-PinuT strain produced 9.2% (w/v) glucose free fructose in 24 h with a productivity of 3.83 g/L/h and the yield was not provided29. In this study, K. marxianus YGR003 used 400 g/L JAT and produced 234.44 g/L fructose with a productivity of 8.37 g/L/h. When 250 g/L JAT is used, the productivity reached 10.26 g/L/h.

Producing fructose with engineered K. marxianus has other advantages over S. cerevisiae. Because K. marxianus is an inulinase producing yeast, no recombinant inulinase expression is necessary. Furthermore, K. marxianus is a thermo-tolerant yeast, the fermentation can be conducted at as high as 42 °C. Other than reduction of cool cost, fermentation at elevated temperature can reduce the contamination. In this study, the non-sterilized JAT powder was directly used as substrate and the fructose was still produced efficiently (Fig. 5).

Pre-treating JAT powder is not necessary in this study. In previous report, heating improved the inulin extraction22, so the heated JAT powder was also used as substrate to produce glucose -free fructose in this study. However, there is no significant difference between the heated and no-heated JAT powder (Fig. 5c) as substrate. It is possible even without heating, the speed of inulin release matches the speed of hydrolysis already. Therefore, the heating and sterilization of the JAT powder are not necessary in this study.

Materials and Methods

Strains and reagents

K. marxianus NBRC 1777 was purchased from NITE Biological Resource Center (NBRC, Japan). K. marxianus YHJ010 is a TRP1, LEU2, and URA3 auxotrophic strain of NBRC 177721. Yeast Extract Peptone Dextrose (YPD) medium (20 g/L peptone, 10 g/L yeast extract, and 20 g/L d-glucose) was used to aerobically culture K. marxianus strains. Yeast Extract Peptone Inulin (YPI) medium (20 g/L peptone, 10 g/L yeast extract, and 20 g/L inulin) was used to grow the seed culture. Synthetic Dropout (SD) medium (6.7 g/L yeast nitrogen base [YNB] without amino acids and 20 g/L d-glucose) supplemented with the appropriate amino acids and/or Uracil was used for transformants selection. Agar plates of all media were prepared by adding 15 g/L agar. All chemical regents used were of analytical grade or higher. Inulin, YNB, d-fructose, d-glucose, and agar were purchased from Sangon Biotech Co. (Shanghai, China). Yeast extract and peptone were obtained from Oxoid (Hants, UK). All modifying enzymes and restriction enzymes were obtained from Thermo Fisher Scientific Co., Ltd. (Waltham, MA). Jerusalem artichoke tubers were purchased from the local market in Yantai, China.

Disruption of hexokinase and glucokinase gene

A hexokinase and a glucokinase which were named based on homology found in genome of K. marxianus. To disrupt hexokinase (KmHXK1, Genbank: KX270227) or glucokinase (KmGLK1, GenBank: KX270228) gene, the KmHXK1 and KmGLK1 gene were amplified from the genomic DNA of K. marxianus NBRC1777 with primer pairs KmHXK-F and KmHXK-R or KmGLK-F and KmGLK-R (Supplementary Table S1) respectively. A 3.2 Kb and a 2.9 Kb DNA fragment were obtained and inserted into pGEM-T easy. The resultant plasmid was named as pKmHXK-T and pKmGLK-T (Table 3). Then pKmHXK-T was digested by Hind III to remove 1.2 Kb sequence of KmHXK1 and blunted, pKmGLK-T was digested by EcoR V to remove a 0.8 Kb sequence of KmGLK1. A ScURA3 gene including promoter, open reading frame and terminator was amplified with primers ScURA3-SMAI-FULL-F and ScURA3-SMAI-FULL-R (Supplementary Table S1) using genomic DNA of S. cerevisiae W303 1A as temperate. The ScURA3 fragment was digested by Sma I and inserted into Hind III digested and blunted pKmHXK-T or EcoR V digested pKmGLK-T to obtain plasmid pKmHXK-ScURA3-T and pKmGLK-ScURA3-T respectively (Table 3). Then the KmHXK1 or KmGLK1 disruption cassette was amplified with primers KmHXK-F and KmHXK-R or KmGLK-F and KmGLK-R (Supplementary Table S1) and transformed into K. marxianus YHJ010 by using a modified lithium acetate method35,36. The transformants were screened on SD medium without Uracil. After the transformants were obtained, the KmHXK1 or KmGLK1 disruption was confirmed by PCR using primer pair KmHXK–F and KmHXK–R or KmGLK-F and KmGLK-R with genomic DNA as temperate. The clones with only one longer product amplified were positive and named YLM001 and YLM002 for KmHXK1 or KmGLK1 disruption respectively. ScURA3 fragment was also transformed into YHJ010 to complement the URA3 auxotrophic, and the obtained strain was named YWD016 as a non-disruption control (Table 1).

Over-expression of glucokinase gene

To overexpress KmGLK1, the ORF of KmGLK1 was amplified with primer pair KmGLK-F-EcoRI and KmGLK-R-NotI (Supplementary Table S1) with pKmGLK-T as template and inserted into YEGAP vector21 at EcoRI and NotI sites. The resultant plasmid was named as YEGAP-GLK (Table 3) which could express KmGLK1 under ScTDH3 promoter. Then YEGAP-GLK was transformed into the strain YLM001 in which KmHXK1 was disrupted and obtained strain was named YLM005. YEGAP was also transformed into YWD016 and YLM001, the resultant strain YGR001 and YGR002 (Table 1) were used as the empty vector control and non-disruption control, respectively. Finally, pKmLeu2 plasmid was transformed into YLM005 to obtain a non-auxotrophic strain YGR003.

Growth of the constructed K. marxianus strains on glucose, fructose and glucose-fructose mixture

To evaluate the sugar assimilation ability of constructed strains, YLM001, YLM002, YLM005 and control strains YWD016, YGR001 and YGR002 (Table 1) were cultivated with glucose or fructose as carbon source. After each strain was precultured in YP-glycerol medium overnight, they were inoculated into SD medium containing 20 g/L glucose or fructose with a starting OD600 of 0.2 and aerobically cultivated in a 250-ml flask containing 50 ml of medium at 42 °C with 200 rpm shaking. The growth was assessed by measuring the OD600. Furthermore, YLM005 and YGR001 and YGR002 were cultivated in a mixture of 10 g/L glucose and 70 g/L fructose as carbon source. When the strain cultivated on glucose-fructose mixture, other than growth, the sugar consumption was also determined.

Hydrolysis and utilization of pure inulin with constructed strains

To evaluate the inulin utilization ability of constructed strains, YLM005 and YGR003 were cultivated with SD medium containing 100 g/L inulin after each strain was precultured in YPI medium. Then they were inoculated into SD medium with a starting OD600 of 0.2 and aerobically cultivated in a 250-ml flask containing 50 ml of medium at 42 °C with 200 rpm shaking. Other than the growth was determined with OD600, the concentration of the glucose and the fructose were also measured.

One step producing fructose from JAT powder

After YGR003 was confirmed that it can hydrolyze inulin quickly and only utilize glucose, it was used in one step pure fructose production from JAT. The hydrolysis and utilization inulin in 100 g/L Jerusalem artichoke tuber with YGR003 was evaluated. Fifty milliliters fermentation medium containing 100 g/L Jerusalem artichoke tuber powder, 0.2 M sodium phosphate buffer (pH 5.0) was added into a 250-ml flask. Then 5 mL of pre-cultivated yeast cells which were cultivated in 50 ml of YPI and incubated at 37 °C with shaking at 200 rpm for 12 h were inoculated (10%, v/v) and cultivated with 200 rpm shaking. Cultivation temperature of 37, 42, and 45 °C were used to evaluate the effect of temperature on fructose production.

Other than 100, 200, 250, 300, 350 and 400 g/L JAT powder were used to evaluate the fructose production with various substrate concentrations, 80 °C, 90 min heated 350 and 400 g/L JAT powder were used to evaluate if the pre-heating would promote the fructose production. The inulin content in the powder was estimated as described previously37. The concentration of glucose and fructose in the culture supernatant during the cultivation were determined by HPLC. All fermentation samples were assayed in triplicate.

Recombinant expression KmHXK1 and KmGLK1 in E. coli

The NdeI site in KmGLK1 was removed by silent mutation. Using pKmGLK-T as template, a C- terminal fragment of KmGLK1 was first amplified by GLKdNdeI-F and KmGLK-XhoI-R (Supplementary Table S1) to eliminate the NdeI site. And the N-terminal fragment of KmGLK1 was amplified by KmGLK-NdeI-F and GLKdNdeI-R (Supplementary Table S1). Then the whole KmGLK1 with silent mutation was amplified with KmGLK-NdeI-F and KmGLK-XhoI-R through overlap PCR with above two fragments. The KmHXK1 gene was amplified from pKmHXK-T with primer pair KmHXK-NdeI-F and KmHXK-XhoI-R. Amplified KmGLK1 and KmHXK1 were digested by NdeI and XhoI and inserted into pET22b vector with a His-tag fused to the protein C-terminal. Resultant plasmids were named as pET22b-KmGLK and pET22b-KmHXK (Table 3), respectively. Then the plasmids were transformed into E. coli BL21(DE3) to express recombinant enzymes. The expression was induced with 1.0 mM IPTG in LB medium at 37 °C for 4 h when OD600 reach 0.5~0.8. After E. coli cells were recovered through centrifugation and lysed by sonication, the recombinant enzymes in supernatant of lysed E. coli cell were purified by Ni2+ charged Chelating Sepharose Fast Flow (GE Healthcare, Uppsala, Sweden) according the product instruction.

Enzyme activity assay

Hexokinase activity was measured as described previously38,39 with some modifications. Hexokinase activity to glucose or fructose was assayed in a 50 mM Tris–HCl (pH 7.5) buffered mixture containing glycine (50 mM), KCl (50 mM), ethylenediamine tetraacetic acid (EDTA) (1 mM), NaF (10 mM), phosphoenolpyruvate, tricyclohexylammonium (PEP-Tri) (1 mM), MgCl2 (5 mM), ATP (0.5 mM), NADH (0.3 mM), lactate dehydrogenase (LDH, E.C. 1.1.1.27, 25 U), pyruvate kinase (E.C. 2.7.1.40, 25 U), prepared hexokinase (100 μl), and glucose or fructose (10 mM), and adjusted to a volume of 500 μl with H2O. The reaction was initiated by adding 40 mM glucose or fructose, and the activity was determined by monitoring the decrease of absorbance at 340 nm using a spectrophotometer. One unit of D-hexkinase was defined as the amount of enzyme that phosphorylates 1 μmol D-glucose or fructose per min at 28 °C. Protein concentrations were determined via the Bradford method with bovine serum albumin (BSA) as the protein standard40.

Total fructose and glucose quantification

The total fructose and glucose was determined as described previously41. 0.2 g of JAT powder was hydrolyzed with 0.2 M HCl at 85 °C for 2 h, and then cooled on ice bath, neutralized with sodium hydroxide, filtered and adjusted to 100 mL with pure water. After 14000 × g centrifugation for 10 min and filtered through 0.2 μm polyethersulfone syringe filter, the samples were analyzed by HPLC.

HPLC analysis

Glucose and fructose concentrations during fermentation were analyzed by HPLC with a ROA-Organic Acid H+ (8%) column. 2.5 mM H2SO4 was used as the mobile phase with a flow rate of 0.3 ml/min. The column temperature was 75 °C.

Additional Information

How to cite this article: Guorong, Z. et al. Identification of hexose kinase genes in Kluyveromyces marxianus and thermo-tolerant one step producing glucose-free fructose strain construction. Sci. Rep. 7, 45104; doi: 10.1038/srep45104 (2017).

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

Santangelo, G. M. Glucose signaling in Saccharomyces cerevisiae . Microbiol Mol Biol R 70, 253–282, doi: 10.1128/Mmbr.70.1.253-282.2006 (2006).

Inokuma, K. et al. Complete genome sequence of Kluyveromyces marxianus NBRC1777, a nonconventional thermotolerant yeast. Genome Announc 3, e00389–00315, doi: 10.1128/genomeA.00389-15 (2015).

Lertwattanasakul, N. et al. Genetic basis of the highly efficient yeast Kluyveromyces marxianus: complete genome sequence and transcriptome analyses. Biotechnol Biofuels 8, doi: 10.1186/s13068-015-0227-x (2015).

Lima, D. M., Fernandes, P., Nascimento, D. S., Ribeiro, R. D. L. F. & de Assis, S. A. Fructose Syrup: A Biotechnology Asset. Food Technol Biotech 49, 424–434 (2011).

Duffy, V. B. & Sigman-Grant, M. Position of the american dietetic association: Use of nutritive and nonnutritive sweeteners. J Am Diet Assoc 104, 255–275, doi: 10.1016/j.jada.2003.12.001 (2004).

Bowe, M. K. Placebo evaluation of selected sugar-based excipients: in pharmaceutical and nutraceutical tableting. Pharm Technol 24, 34–44 (2000).

Barclay, T., Ginic-Markovic, M., Cooper, P. & Petrovsky, N. The chemistry and sources of fructose and their effect on functionality and health implications. J Excip Food Chem 3, 67–82 (2012).

Date, P. V., Samad, A. & Devarajan, P. V. Freeze thaw: a simple approach for prediction of optimal cryoprotectant for freeze drying. AAPS PharmSciTech 11, 304–313, doi: 10.1208/s12249-010-9382-3 (2010).

Crowe, J. H., Carpenter, J. F., Crowe, L. M. & Anchordoguy, T. J. Are freezing and dehydration similar stress vectors - a comparison of modes of interaction of stabilizing solutes with biomolecules. Cryobiology 27, 219–231, doi: 10.1016/0011-2240(90)90023-W (1990).

Kuzma, J. N. et al. No difference in ad libitum energy intake in healthy men and women consuming beverages sweetened with fructose, glucose, or high-fructose corn syrup: a randomized trial. Am J Clin Nutr 102, 1373–1380, doi: 10.3945/ajcn.115.116368 (2015).

Kmietowicz, Z. Sixty seconds on … high fructose corn syrup. BMJ-Brit Med J 351, doi: 10.1136/Bmj.H5693 (2015).

Sievenpiper, J. L. et al. Effect of fructose on body weight in controlled feeding trials a systematic review and meta-analysis. Ann Intern Med 156, 291–U291, doi: 10.7326/0003-4819-156-4-201202210-00007 (2012).

Forshee, R. A. et al. A critical examination of the evidence relating high fructose corn syrup and weight gain. Crit Rev Food Sci Nutr 47, 561–582, doi: 10.1080/10408390600846457 (2007).

Zhang, M. D., Chen, Q. A. & Shen, S. H. Physiological responses of two Jerusalem artichoke cultivars to drought stress induced by polyethylene glycol. Acta Physiol Plant 33, 313–318, doi: 10.1007/s11738-010-0549-z (2011).

Pandey, A. et al. Recent developments in microbial inulinases - Its production, properties, and industrial applications. Appl Biochem Biotech 81, 35–52, doi: 10.1385/Abab:81:1:35 (1999).

Singh, R. S., Dhaliwal, R. & Puri, M. Partial purification and characterization of exoinulinase from Kluyveromyces marxianus YS-1 for preparation of high-fructose syrup. J Microbiol Biotechn 17, 733–738 (2007).

Mutanda, T., Wilhelmi, B. & Whiteley, C. G. Controlled Production of Fructose by an Exoinulinase from Aspergillus Ficuum . Appl Biochem Biotechnol 159, 65–77, doi: 10.1007/s12010-008-8479-6 (2009).

Yuan, W. J. et al. Consolidated bioprocessing strategy for ethanol production from Jerusalem artichoke tubers by Kluyveromyces marxianus under high gravity conditions. J Appl Microbiol 112, 38–44, doi: 10.1111/j.1365-2672.2011.05171.x (2012).

Hu, N., Yuan, B., Sun, J., Wang, S. A. & Li, F. L. Thermotolerant Kluyveromyces marxianus and Saccharomyces cerevisiae strains representing potentials for bioethanol production from Jerusalem artichoke by consolidated bioprocessing. Appl Microbiol Biotechnol 95, 1359–1368, doi: 10.1007/s00253-012-4240-8 (2012).

Yuan, W. J., Zhao, X. Q., Ge, X. M. & Bai, F. W. Ethanol fermentation with Kluyveromyces marxianus from Jerusalem artichoke grown in salina and irrigated with a mixture of seawater and freshwater. Appl Microbiol Biotechnol 105, 2076–2083, doi: 10.1111/j.1365-2672.2008.03903.x (2008).

Hong, J., Wang, Y., Kumagai, H. & Tamaki, H. Construction of thermotolerant yeast expressing thermostable cellulase genes. J Biotechnol 130, 114–123, doi: 10.1016/j.jbiotec.2007.03.008 (2007).

Gaafar, A. M., Serag El-Din, M. F., Boudy, E. A. & El-Gazar, H. H. Extraction conditions of inulin from Jerusalem Artichoke tubers and its effects on blood glucose and lipid profile in diabetic rats. Am J Sci 6, 36–43 (2010).

Rose, M., Albig, W. & Entian, K. D. Glucose repression in Saccharomyces cerevisiae Is directly associated with hexose phosphorylation by hexokinase-Pi and hexokinase-Pii. Eur J Biochem 199, 511–518, doi: 10.1111/j.1432-1033.1991.tb16149.x (1991).

Liu, Z. Q. et al. Improvement and characterization of a hyperthermophilic glucose isomerase from Thermoanaerobacter ethanolicus and its application in production of high fructose corn syrup. J Ind Microbiol Biotechnol 42, 1091–1103, doi: 10.1007/s10295-015-1639-0 (2015).

Wei, W. L., Wan, W. G., Le, H. Y. & Wang, S. Y. Continuous preparation of fructose syrups from Jerusalem artichoke tuber using immobilized intracellular inulinase from Kluyveromyces sp Y-85. Process Biochem 34, 643–646 (1999).

Singh, R. S., Dhaliwal, R. & Puri, M. Production of high fructose syrup from Asparagus inulin using immobilized exoinulinase from Kluyveromyces marxianus YS-1. J Ind Microbiol Biotechnol 34, 649–655, doi: 10.1007/s10295-007-0237-1 (2007).

Kim, C. H. & Rhee, S. K. Fructose Production from Jerusalem Artichoke by Inulinase Immobilized on Chitin. Biotechnol Lett 11, 201–206, doi: 10.1007/Bf01026059 (1989).

Rawat, H. K., Ganaie, M. A. & Kango, N. Production of inulinase, fructosyltransferase and sucrase from fungi on low-value inulin-rich substrates and their use in generation of fructose and fructo-oligosaccharides. Anton Leeuw Int J G 107, 799–811, doi: 10.1007/s10482-014-0373-3 (2015).

Yu, J., Jiang, J., Ji, W., Li, Y. & Liu, J. Glucose-free fructose production from Jerusalem artichoke using a recombinant inulinase-secreting Saccharomyces cerevisiae strain. Biotechnol Lett 33, 147–152, doi: 10.1007/s10529-010-0414-6 (2011).

Santa, G. L. et al. From inulin to fructose syrups using sol-gel immobilized inulinase. Appl Biochem Biotechnol 165, 1–12, doi: 10.1007/s12010-011-9228-9 (2011).

Ricca, E. et al. Fructose production by inulinase covalently immobilized on sepabeads in batch and fluidized bed bioreactor. Int J Mol Sci 11, 1180–1189, doi: 10.3390/ijms11031180 (2010).

Yang, L., He, Q. S., Corscadden, K. & Udenigwe, C. C. The prospects of Jerusalem artichoke in functional food ingredients and bioenergy production. Biotechnol Rep 5, 77–88, doi: 10.1016/j.btre.2014.12.004 (2015).

Brevnova, E. E., Kozlov, D. G., Efremov, B. D. & Benevolensky, S. V. Inulase-secreting strain of Saccharomyces cerevisiae produces fructose. Biotechnol Bioeng 60, 492–497, doi: 10.1002/(Sici)1097-0290(19981120)60:4<492::Aid-Bit11>3.0.Co;2-K (1998).

Koren, D. W. & Duvnjak, Z. Pure Fructose Syrup and Ethanol-Production from High Fructose Corn Syrup Supplemented with Jerusalem Artichoke Juice. J Chem Technol Biot 47, 117–125 (1990).

Abdel-Banat, B. M. A., Nonklang, S., Hoshida, H. & Akada, R. Random and targeted gene integrations through the control of non-homologous end joining in the yeast Kluyveromyces marxianus . Yeast 27, 29–39, doi: 10.1002/Yea.1729 (2010).

Zhang, B. A. et al. Improving ethanol and xylitol fermentation at elevated temperature through substitution of xylose reductase in Kluyveromyces marxianus . J Ind Microbiol Biot 40, 305–316, doi: 10.1007/s10295-013-1230-5 (2013).

Baldini, M., Danuso, F., Turi, M. & Vannozzi, P. Evaluation of new clones of Jerusalem artichoke (Helianthus tuberosus L.) for inulin and sugar yield from stalks and tubers. Ind Crop Prod 19, 25–40, doi: 10.1016/S0926-6690(03)00078-5 (2004).

Wang, R. L., Zhang, L., Wang, D. M., Gao, X. L. & Hong, J. Identification of a xylulokinase catalyzing xylulose phosphorylation in the xylose metabolic pathway of Kluyveromyces marxianus NBRC1777. J Ind Microbiol Biotechnol 38, 1739–1746, doi: 10.1007/s10295-011-0963-2 (2011).

Akinterinwa, O. & Cirino, P. C. Heterologous expression of D-xylulokinase from Pichia stipitis enables high levels of xylitol production by engineered Escherichia coli growing on xylose. Metab Eng 11, 48–55, doi: 10.1016/j.ymben.2008.07.006 (2009).

Bradford, M. M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72, 248–254 (1976).

Matias, J., Gonzalez, J., Royano, L. & Barrena, R. A. Analysis of sugars by liquid chromatography-mass spectrometry in Jerusalem artichoke tubers for bioethanol production optimization. Biomass Bioenerg 35, 2006–2012, doi: 10.1016/j.biombioe.2011.01.056 (2011).

Hong, J., Tamaki, H., Akiba, S., Yamamoto, K. & Kumagai, H. Cloning of a gene encoding a highly stable endo-beta-1,4-glucanase from Aspergillus niger and its expression in yeast. J Biosci Bioeng 92, 434–441 (2001).

Acknowledgements

This work was supported by a Grant-in-Aid from the class General Financial Grant from National Natural Science Foundation of China (31570082), Anhui Provincial Natural Science Foundation (1608085MC47).

Author information

Authors and Affiliations

Contributions

J.H. conceived the study and wrote the manuscript; D.W. performed the data analysis and wrote the manuscript; X.L.G. reviewed this manuscript and supervised this study; G.R.Z., M.L. and J.C.W. performed the experiments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhang, G., Lu, M., Wang, J. et al. Identification of hexose kinase genes in Kluyveromyces marxianus and thermo-tolerant one step producing glucose-free fructose strain construction. Sci Rep 7, 45104 (2017). https://doi.org/10.1038/srep45104

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep45104

This article is cited by

-

The novel properties of Kluyveromyces marxianus glucose sensor/receptor repressor pathway and the construction of glucose repression-released strains

Microbial Cell Factories (2023)

-

Characterization of mating type on aroma production and metabolic properties wild Kluyveromyces marxianus yeasts

World Journal of Microbiology and Biotechnology (2023)

-

Integration of comprehensive data and biotechnological tools for industrial applications of Kluyveromyces marxianus

Applied Microbiology and Biotechnology (2020)

-

Release of glucose repression on xylose utilization in Kluyveromyces marxianus to enhance glucose-xylose co-utilization and xylitol production from corncob hydrolysate

Microbial Cell Factories (2019)

-

Functional analysis of Mig1 and Rag5 as expressional regulators in thermotolerant yeast Kluyveromyces marxianus

Applied Microbiology and Biotechnology (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.