Abstract

We report the first demonstration of operational InGaN-based thin-film transistors (TFTs) on glass substrates. The key to our success was coating the glass substrate with a thin amorphous layer of HfO2, which enabled a highly c-axis-oriented growth of InGaN films using pulsed sputtering deposition. The electrical characteristics of the thin films were controlled easily by varying their In content. The optimized InGaN-TFTs exhibited a high on/off ratio of ~108, a field-effect mobility of ~22 cm2 V−1 s−1 and a maximum current density of ~30 mA/mm. These results lay the foundation for developing high-performance electronic devices on glass substrates using group III nitride semiconductors.

Similar content being viewed by others

Introduction

Thin-film transistors (TFTs) are key devices in large-area electronics and are fabricated on various types of amorphous substrates, such as glass or plastic1,2,3. Although hydrogenated amorphous silicon (a-Si:H)4 and amorphous oxide semiconductors such as InGaZnO (IGZO)5,6,7 are widely used as channel materials in TFTs, the electron mobility of these materials falls short of realizing high-performance electronic systems fabricated on amorphous materials. Conversely, group III nitride semiconductors, which have already been used as commercial transistors in ultrafast communication systems8,9, are promising materials for high-performance TFTs if they can be successfully accommodated on large-area amorphous substrates. In industrial applications, however, film growth of nitride semiconductors is usually achieved using metal-organic vapor-phase epitaxy10,11 at approximately 1000 °C12,13,14 in order to enhance the chemical reactivity of the raw materials. This temperature is obviously incompatible with large-area flat glass substrates. In order to overcome this problem and fabricate TFTs on conventional glass substrates, a novel growth technique that allows us to obtain high-quality nitride semiconductors on glass at low temperatures must be developed. Recently, the use of a new growth technique called pulsed sputtering deposition (PSD) was proposed for the preparation of group III nitrides15. During growth with PSD, high-energy film precursors formed in a plasma help produce high-quality group III nitride materials even at low temperatures (e.g., lower than 500 °C); this enables us to obtain InGaN films without phase separation and/or to employ thermally unstable substrates such as glass. In fact, we fabricated InGaN-based full-color light emitting diodes on graphene-covered amorphous SiO2 surfaces16. In this process, graphene was utilized as a buffer layer to promote c-axis orientation of the InGaN layers. Unfortunately, this orienting buffer layer is so conductive that it also acts as a leakage pathway when used as a substrate for TFTs. Therefore, fabrication of nitride-based TFTs on glass substrates requires an alternative orienting buffer layer of a highly insulating nature. In this study, we investigated the use of HfO2 as an orienting layer for InGaN film growth on glass substrates. We also explored the feasibility of producing InGaN-based TFTs on large-area amorphous substrates using a low-temperature PSD growth technique.

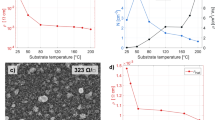

Figure 1 shows XRD patterns of the InGaN films grown on glass substrates in this study. An InxGa1−xN film with x = 0.5, directly grown on a glass substrate, did not show any diffraction peaks because of poor crystallinity. Conversely, the InGaN films grown on HfO2-coated glass substrates exhibited peaks attributed to 0002 diffraction. The appearance of a sole 0002 diffraction peak in the XRD patterns indicates that highly c-axis-oriented InGaN films grow on HfO2-coated glass substrates. The full width at half maximum values of rocking curves for 0002 diffraction were larger than 1° for all samples. It was impossible to detect asymmetric diffraction of the InGaN films due to poor in-plane alignment. The In contents of the InGaN films prepared on the HfO2 buffer indicated in Fig. 1 are derived from the peak positions of the diffractions assuming that Vegard’s law is valid. Reflection high-energy electron diffraction observations (not shown) revealed that the InGaN films grown on HfO2-coated glass substrates are polycrystalline. An atomic force microscopic image of an In0.30Ga0.70N film grown on a HfO2-coated glass substrate is shown in Fig. 2. Crystal grains with a size of ~10 nm are homogeneously grown on the substrate. The root-mean-square roughness of the InGaN surface was 1.8 nm, which is smooth enough to be used as a channel in a field-effect transistor. Coating glass substrates with HfO2 is also important for obtaining InGaN films with smooth surfaces and for suppressing electron scattering caused by rough interfaces between channel and gate dielectrics.

Herein, 50 μm × 50 μm square mesas of 80-nm-thick c-axis-oriented InGaN were formed using an inductively coupled plasma (ICP) dry etching technique. Ti/Al electrodes were deposited on the corners of the InGaN mesas to perform van der Pauw Hall-effect measurements. The In content of the InGaN was evaluated with energy-dispersive X-ray spectroscopy (EDS). Figure 3 summarizes the relationship between the In composition, electron concentration and electron mobility of the InGaN films. Note that since the Hall voltages for InGaN with In content x less than 0.6 were too low to be detected using our Hall-effect measurement setup, it was impossible to calculate the electron mobility and concentration of those InGaN. As the In composition decreases, the electron concentration of the InGaN monotonically decreases. An InGaN film with an In content of x = 0.60 has an electron concentration of ~1 × 1019 cm−3, whereas the electron concentration of a pure InN film is over 1 × 1020 cm−3. This result indicates that the electron concentration in InGaN films can be controlled by changing the In content. It is well known that as the In content in InGaN decreases, the Fermi-level stabilization energy drops from the conduction band into the forbidden gap17,18, which possibly explains the decrease in the electron concentration. Figure 3 also shows that the electron mobility of InGaN films decreases as the In content decreases. One of the reasons for this decrease is alloy scattering. Other possible explanations are the decrease in electron effective mass in InGaN with decreased In content and the formation of an energy barrier at the InGaN grain boundaries where the conduction band is possibly bent upward19.

TFTs with InGaN channels were fabricated by photolithography and Cl2 ICP dry etching technologies. First, InGaN films were etched into 200 μm × 50 μm mesa structures. Source and drain electrodes (Ti/Al: 10 nm/30 nm) were subsequently deposited by sputtering and a-HfO2 gate dielectrics were deposited on the InGaN films by atomic layer deposition (ALD) at 200 °C. Finally, gate electrodes (Au: 50 nm) were deposited by vacuum deposition. An optical microscope image and a schematic drawing of the transistor are shown in Fig. 4.

Figure 5 shows the field-effect mobility of the InGaN TFTs. It is clear that the mobility strongly depends on the In content of the InGaN channel layer. As the In composition decreases, the mobility decreases from 4 to 0.16 cm2 V−1 s−1 (indicated as Region I), but rapidly increases to 22 cm2 V−1 s−1 at an In composition of 0.45 (Region II), before again decreasing to <1 cm2 V−1 s−1 (Region III). The field-effect mobility of transistors is determined by several factors, such as the carrier mobility in the film, the electron concentration in the channel and the quality of the interfaces between the InGaN and the dielectrics. 20-nm-thick HfO2 (εr = 15) with a bias voltage of 5 V can potentially accumulate (or deplete) sheet electrons of ~2 × 1013 cm−2, which correspond to the electron density of 4 × 1019 cm−3 for 50-nm-thick InGaN. In Region I, the field-effect mobility is mainly affected by carrier mobility since the electron concentration is almost constant (Fig. 3). We speculate that the electron concentration rapidly decreased in Region II. (In fact, it cannot be measured due to the detection limit of our Hall-effect measurement). Figure S1 (Supplementary Information) shows the dependence of ON current in InGaN TFTs on In content. In Region II, the ON current falls ~10−2. If we assume that the carrier concentration closely tied with the ON current, we could conclude that carrier concentration of In0.45Ga0.55N is on the order of ~1017 cm−3, which can be adequately controlled with gating using the 20-nm-thick HfO2. We believe that the rapid decrease in electron concentration in this region strongly affected the field-effect mobility compared to decrease in the electron (Hall) mobility. In Region III, the carrier concentration decreases further and the contact resistance between InGaN and Ti/Al electrodes probably increases, which results in lowering the ON current (Fig. S1). The electron mobility also decreased. These factors lead to the lowered field-effect mobility in Region III. Figure 6 shows (a) the output and (b) the transfer characteristics of the In0.45Ga0.55N TFT, which exhibited the best performance in this study. The on/off ratio of the TFT was as high as ~108 and the field-effect mobility in the saturation region, μsat, was determined to be 22 cm2 V−1 s−1. Moreover, the current density in the on-state was as high as 30 mA/mm, which is obviously higher than in conventional TFTs employing a-Si:H or IGZO. Note that the surface of In0.45Ga0.55N film (Fig. S2) exhibiting the best TFT performance is as flat as that of In0.30Ga0.70N film.

In summary, we have succeeded in fabricating operational InGaN-based TFTs on glass substrates for the first time. We found that highly c-axis-oriented InGaN films can be grown by PSD on glass coated with amorphous HfO2 layers. Hall effect measurements have revealed that the electron concentration of the c-axis-oriented InGaN on glass can be controlled by varying their In content. An InGaN-based TFT with an In concentration of 0.45 exhibited the highest on/off ratio of ~108, a field-effect mobility of ~22 cm2 V−1 s−1 and a maximum current density of ~30 mA/mm. These excellent TFT characteristics prove that nitride semiconductors are promising materials for realizing high-performance electronic devices on glass substrates.

Methods

InGaN films were grown by PSD15,16,20,21 and their In content was modulated by changing the supply ratio of In and Ga. Before the growth, fused silica glass substrates were degreased by ultrasonic cleaning in ethanol for 5 min. InGaN films were grown on the glass substrates, with and without an amorphous HfO2 layer deposited by ALD at 200 °C. Tetrakis(dimethylamido)hafnium (Hf(NMe2)4) and O3 were used as precursors for the amorphous HfO2. The growth of InGaN was carried out at 300 °C. After the growth, metal droplets remaining on the surface of the InGaN films were immediately removed using HCl (~35%) solution. The InGaN samples were cut into specimens with a size of 10 mm × 10 mm and subjected to the XRD measurements.

Additional Information

How to cite this article: Itoh, T. et al. Fabrication of InGaN thin-film transistors using pulsed sputtering deposition. Sci. Rep. 6, 29500; doi: 10.1038/srep29500 (2016).

References

Street, R. A. Thin-Film Transistors. Adv. Mater. 21, 2007–2022 (2009).

Someya, T. et al. A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proc. Natl. Acad. Sci. 101, 9966–9970 (2004).

Klauk, H. Organic thin-film transistors. Chem. Soc. Rev. 39, 2643 (2010).

le Comber, P. G., Spear, W. E. & Ghaith, A. Amorphous-silicon field-effect device and possible application. Electron. Lett. 15, 179 (1979).

Nomura, K. et al. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 432, 488–92 (2004).

Nomura, K. et al. Amorphous Oxide Semiconductors for High-Performance Flexible Thin-Film Transistors. Jpn. J. Appl. Phys. 45, 4303–4308 (2006).

Frenzel, H. et al. Recent progress on ZnO-based metal-semiconductor field-effect transistors and their application in transparent integrated circuits. Adv. Mater. 22, 5332–49 (2010).

Mishra, U. K. & Parikh, P. AlGaN/GaN HEMTs-an overview of device operation and applications. Proc. IEEE 90, 1022–1031 (2002).

Ohno, Y. & Kuzuhara, M. Application of GaN-based heterojunction FETs for advanced wireless communication. IEEE Trans. Electron Devices 48, 517–523 (2001).

Amano, H., Sawaki, N., Akasaki, I. & Toyoda, Y. Metalorganic vapor phase epitaxial growth of a high quality GaN film using an AlN buffer layer. Appl. Phys. Lett. 48, 353 (1986).

Nakamura, S. GaN Growth Using GaN Buffer Layer. Jpn. J. Appl. Phys. 30, L1705–L1707 (1991).

Choi, J. H. et al. Nearly single-crystalline GaN light-emitting diodes on amorphous glass substrates. Nat. Photonics 5, 763–769 (2011).

Keller, S., Lu, J., Mishra, U. K., Denbaars, S. P. & Speck, J. S. Effect of indium on the conductivity of poly-crystalline GaN grown on high purity fused silica. Phys. Status Solidi A 209, 431–433 (2012).

Chung, K., Lee, C.-H. & Yi, G.-C. Transferable GaN layers grown on ZnO-coated graphene layers for optoelectronic devices. Science 330, 655–657 (2010).

Sato, K., Ohta, J., Inoue, S., Kobayashi, A. & Fujioka, H. Room-Temperature Epitaxial Growth of High Quality AlN on SiC by Pulsed Sputtering Deposition. Appl. Phys. Express 2, 011003 (2009).

Shon, J. W., Ohta, J., Ueno, K., Kobayashi, A. & Fujioka, H. Fabrication of full-color InGaN-based light-emitting diodes on amorphous substrates by pulsed sputtering. Sci. Rep. 4, 5325 (2014).

Li, S. X. et al. Fermi-level stabilization energy in group III nitrides. Phys. Rev. B 71, 161201(R) (2005).

Bailey, L. R. et al. Band bending at the surfaces of In-rich InGaN alloys. J. Appl. Phys. 104, 113716 (2008).

Fehrer, M., Einfeldt, S., Birkle, U., Gollnik, T. & Hommel, D. Impact of defects on the carrier transport in GaN. J. Cryst. Growth 189–190, 763–767 (1998).

Nakamura, E., Ueno, K., Ohta, J., Fujioka, H. & Oshima, M. Dramatic reduction in process temperature of InGaN-based light-emitting diodes by pulsed sputtering growth technique. Appl. Phys. Lett. 104, 051121 (2014).

Oseki, M., Okubo, K., Kobayashi, A., Ohta, J. & Fujioka, H. Field-effect transistors based on cubic indium nitride. Sci. Rep. 4, 3951 (2014).

Author information

Authors and Affiliations

Contributions

H.F. supervised the project. T.I. and A.K. performed the film growth, device fabrication and measurements. A.K., K.U. and J.O. designed the experimental procedure. T.I., A.K. and H.F. wrote the manuscript and all the authors interpreted the data and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Itoh, T., Kobayashi, A., Ueno, K. et al. Fabrication of InGaN thin-film transistors using pulsed sputtering deposition. Sci Rep 6, 29500 (2016). https://doi.org/10.1038/srep29500

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep29500

This article is cited by

-

A Rapid Method for Deposition of Sn-Doped GaN Thin Films on Glass and Polyethylene Terephthalate Substrates

Journal of Electronic Materials (2018)

-

Fabrication of full-color GaN-based light-emitting diodes on nearly lattice-matched flexible metal foils

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.