Abstract

Nanometer-scale ferroelectric dots and tubes have received a great deal of attention owing to their potential applications to nonvolatile memories and multi-functional devices. As for the size effect of 180° stripe domains in ferroelectric thin films, there have been numerous reports on the thickness-dependent domain periodicity. All these studies have revealed that the domain periodicity (w) of 180° stripe domains scales with the film thickness (d) according to the classical Landau-Lifshitz-Kittel (LLK) scaling law (w ∝ d1/2) down to the thickness of ~2 nm. In the case of PbTiO3 nanodots, however, we obtained a striking correlation that for the thickness less than a certain critical value, dc (~35 nm), the domain width even increases with decreasing thickness of the nanodot, which surprisingly indicates a negative value in the LLK scaling-law exponent. On the basis of theoretical considerations of dc, we attributed this anomalous domain periodicity to the finite lateral-size effect of a ferroelectric nanodot with an additional effect possibly coming from the existence of a thin non-ferroelectric surface layer.

Similar content being viewed by others

Introduction

Ferroelectrics are receiving a great deal of attention because of their technological promise in leading toward miniaturized and efficient memory devices1. Like other ferroics, ferroelectrics are characterized by domain structures. Various forms of ferroelectric materials, such as ceramics, single crystals and thin films, exhibit a variety of different domain structures which include a stripe, mosaic, or vortex to minimize the total free energy which is composed of competing depolarization and domain-wall energy terms2,3,4,5,6,7,8,9,10. Ferroic domains that are ordered along one unique direction but with opposite polarity or magnetic moment are called 180° domains. It has long been known that the width of 180° stripe magnetic domains closely follows the so-called Landau-Lifshitz-Kittel (LLK) scaling law11. This law was later extended to ferroelectric domains by Mitsui and Furuichi2. According to the scaling law, the domain width (w) is directly proportional to the square root of the crystal thickness (d), namely, w = Adγ, where A is a proportionality constant and γ is the scaling-law exponent (=1/2).

Extensive theoretical studies3,12,13,14,15,16 have been carried out to examine the validity of the LLK scaling law on ferroelectric multiple domains, in conjunction with a variety of experimental studies done by employing various methods that include x-ray scattering5,6, piezoelectric force microscopy10, and scanning transmission electron microscopy12. Until now, all the experimental studies for 180° stripe domains reveal that the LLK scaling law with the exponent around 1/2 is valid down to the thickness of ~2 nm5,14,15. However, there appears one interesting study done by Catalan et al.10. According to their study, the domain size of multiferroic BiFeO3 thin films having irregular domain walls is noticeably larger than those of other ferroelectrics having the same thickness and the observed scaling-law exponent (γ) of 0.59 deviates quite substantially from its normal value of 1/2. They correlated the former with a strong magneto-electric coupling at domain walls while attributing the latter to a fractal-like Hausdorff dimension10.

Among numerous ferroelectrics, lead titanate (PbTiO3; PTO hereafter) has been most extensively studied and is known as a prototype of displacive ferroelectrics without exhibiting any over-damping of the resonance-type soft phonons17,18. Currently, PTO-based nano-scale dots and tubes have received a great deal of attention owing to their potential applications to high-density nonvolatile memories and multi-functional devices19,20. As for the size effect of 180° stripe domains in PTO thin films, there have been numerous reports on the thickness-dependent domain periodicity5,6,13,14,15. All these studies reveal that the domain periodicity of 180° stripe domains scales with the film thickness (d) according to the classical LLK scaling law down to the thickness of ~2 nm5,14,15.

Contrary to the experimentally observed LLK scaling behavior, a theoretical solution of the Laplace equation for rigorously evaluating the depolarizing-field energy of a normal ferroelectric suggests that the LLK scaling law does break for the thickness less than a certain critical size, dc :21 the domain width (w) even increases with decreasing thickness below dc. Unlike 180° stripe domains, the experimental w of the (101)-type 71° domains in rhombohedral BiFeO3 indeed follows this anomalous behavior with dc as large as ~200 nm22. Huang et al.22 were able to qualitatively account for the observed thickness-dependent domain width for the (101)-type 71° domains by theoretically considering the sum of the elastic and domain-wall energies in (101) boundary22. Similarly, the domain width of a pseudo-proper ferroelectric is predicted to be inversely proportional to the film thickness (i.e., w ~ λ2/d) for a very thin film23, where d ≪ λ and λ is the characteristic length associated with the linear coupling between the polarization (secondary order parameter) and the primary order parameter (e.g., λ = ~15 nm for TbMnO3)23.

In view of the above discrepancy between the theoretical prediction21,23 and the experimental observations5,14,15, it is of great scientific importance to experimentally clarify whether there exists any critical thickness (dc) for the validity of the LLK scaling law or not. Until now, however, the LLK scaling law for 180° stripe ferroelectric domains has been experimentally tested using thin films5,6,10,12,13,14,15 where the lateral dimension (L) is practically infinite. Considering this, we have critically examined the effect of the lateral dimension on the validity of the LLK scaling law using ferroelectric PTO nanodots having a variety of different lateral sizes.

Herein we present a quite striking experimental result that the thickness-dependent domain width of the PTO nanodot having 180° stripe domains does not obey the LLK scaling law but is characterized by a negative exponent (γ < 0) below a certain critical thickness, dc. On the basis of theoretical considerations of dc, we have come to the conclusion that the finite lateral-size effect, in addition to the possible existence of a ferroelectrically inactive surface layer, should be taken into account to properly explain the difference in the scaling behavior between ferroelectric films and dots.

Experimental Results

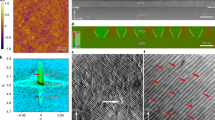

A ferroelectric PTO nanodot array was fabricated on an Nb-doped SrTiO3 (STO) substrate using the dip-pen nanolithography (DPN) method [Fig. 1(a)]. This method had been successfully applied to the fabrication of PTO nanodots having a variety of different lateral sizes20. Figure 1(b) shows atomic force microscopy (AFM) images of PTO nanodots with several different size classes. These DPN-formed nanodots are rectangle-shaped, indicating a high degree of crystallinity. From the high-resolution transmission electron microscopy image, we confirmed that these PTO nanodots are characterized by the tetragonal 4 mm (C4v) symmetry with the polar c-axis perpendicular to the substrate plane20. The dimension (thickness, side length) of the nanodot can be controlled by adjusting the dip-pen deposition time [Fig. 1(c)]. For a short deposition time (<1 sec), the lateral dimension (side length L) increases rapidly while the thickness (d) increases rather steadily with increasing deposition time. As shown in Fig. 1(d), d33 value decreases while the coercive electric field increases with the lateral size, which presumably reflects size-dependent depolarization effects20.

(a) Dip-pen nanolithography (DPN) of PbTiO3 nanodots. (b) An AFM image for PbTiO3 nanodot array having four different size classes. The array was formed by the DPN method. (c) Side length and thickness of PbTiO3 nanodots as a function of the dip-pen deposition time. (d) d33 value and the coercive electric field (Ec) plotted as a function of the nanodot size, where A, B, C, and D indicate the dot size in (b).

To examine the effect of the lateral dimension (L) on the validity of the LLK scaling law, PFM (piezoelectric force microscopy) measurements were carried out for a series of PTO nanodots having a variety of different lateral sizes ranging from 45 nm to 500 nm. Figure 2(a) presents PFM images of the five selected PTO nanodots with different lateral sizes. The PFM images indicate that regardless of the lateral dimension, the PTO nanodots grown on an Nb-doped STO substrate are characterized by ferroelectric 180° stripe domains. The PFM line profile of the PTO nanodot having a lateral dimension of 185 nm [∵ (197-12 nm)] is shown in Fig. 2(b) as an example. This line profile demonstrates that the nanodot is composed of nine 180° stripe domains. Figure 2(c) presents the AFM line profiles of the four selected nanodots [A, B, C, and D in Fig. 1(b)] showing that the thickness (d) of the nanodot increases with the lateral dimension (L). In the below, we summarize the four characteristic geometric parameters of the five 180° stripe domains presented in Fig. 2(a) in the ascending order of the dot thickness, d: (i) dot A (L = 45 nm, n = 2, d = 21.5 nm, w = 22.5 nm), (ii) dot B (L = 60 nm, n = 3, d = 25 nm, w = 20.0 nm), (iii) dot C (L = 100 nm, n = 6, d = 35 nm, w = 16.7 nm), (iv) dot E (L = 185 nm, n = 9, d = 40.7 nm, w = 20.6 nm), and (v) dot D (L = 150 nm, n = 7, d = 42 nm, w = 21.4 nm), where the AFM line profile of the dot E having L = 185 nm is not presented in Fig. 2(c) since its height is very close to that of the dot D, and n denotes the number of 180° stripe domains in a given nanodot. Thus, L = nw. Similar to the present nanodots, 180° stripe-domain structures were also observed in epitaxially grown PTO films (on STO substrates) for the film thickness down to ~2 nm5.

(a) PFM images of the five selected nanodots with different lateral sizes. (b) A PFM line profile of the PbTiO3 nanodot having a lateral dimension of 185 nm as an example. (c) AFM line profiles of the four selected nanodots with different lateral sizes, where A, B, C, and D denote the lateral size (i.e., side length) of 45, 60, 100, and 150 nm, respectively.

We now focus on the correlation between the domain width (w) and the dot thickness (d). In the case of PTO thin films, there is a good linear correlation between log w and log d with the scaling exponent (λ) of 1/2 [Fig. 3], which closely follows the LLK scaling law5. In contrast, the PTO nanodots exhibit a quite striking correlation. For d > 35 nm, the PTO nanodots also follow the scaling law with the estimated exponent of 0.52. However, the domain width even increases with decreasing thickness for d < 35 nm [Fig. 3]. This kind of surprising results has never been observed in ferroelectric thin films.

Data for the thin films (blue color triangles) were taken from the published result5.

Theoretical Analysis and Discussion

Gibbs free-energy function of a ferroelectric nanodot

To clarify the main cause of the observed striking result in the PTO nanodots, we have theoretically considered the effect of the lateral dimension on the difference in the scaling behavior between a nanodot and a thin film and consequently examined the possibility of occurrence of the anomalous domain periodicity for the dot thickness less than a certain critical value (dc). For this purpose, we first formulated the Gibbs free-energy of a ferroelectric nanodot (having a finite lateral dimension) as a function of the domain width and obtained a modified LLK scaling law that accounts for, at least qualitatively, the observed anomalous domain periodicity for d < 35 nm.

Let us consider a ferroelectric nanodot (i.e., nano-rectangle) having a dimension of L × L × d with the domain width of w, as schematically depicted in Fig. 4. Then, the Gibbs free-energy function of a ferroelectric nanodot (having the volume of L2d) with respect to that of a paraelectric nanodot (at given T and P) can be written in terms of w, d, and L as

where Δμ denotes the difference in the bulk free energy per unit volume between the paraelectric and ferroelectric phases at given T and P, namely,  and ΔGdep designates the depolarization-field energy per unit area. On the other hand, σw in Eq. (1) denotes the domain-wall energy per unit area whereas σs represents the surface tension of four side faces of a retangular nanodot having the area of L × d per face. Here σs can be viewed as the excess surface free energy (per unit area) of the ferroelectric rectangle [σ(T, P)] with respect to the surface tension of the paraelectric rectangle (σp) having the same dimension, i.e., σs ≡ σ(T, P)−σp. Thus, the last term takes care of the excess surace free energy of a nano-rectangle having six mutually orthogonal faces. For mathematical simplicity, we assume that

and ΔGdep designates the depolarization-field energy per unit area. On the other hand, σw in Eq. (1) denotes the domain-wall energy per unit area whereas σs represents the surface tension of four side faces of a retangular nanodot having the area of L × d per face. Here σs can be viewed as the excess surface free energy (per unit area) of the ferroelectric rectangle [σ(T, P)] with respect to the surface tension of the paraelectric rectangle (σp) having the same dimension, i.e., σs ≡ σ(T, P)−σp. Thus, the last term takes care of the excess surace free energy of a nano-rectangle having six mutually orthogonal faces. For mathematical simplicity, we assume that  where

where  denotes the excess surface free energy of top (or bottom) surface of a retangular nanodot. It can be shown, however, that this simplification does not alter our interpretation of the anomalous domain periodicity. In addition, it is theoretically shown that 180° stripe domains under an external electric field behave as elastic domains due to the converse piezoelectric effect24. Under this condition, the interatomic elastic-interaction between 180° ferroelectric domains is an important factor in determining the effective dielectric and piezoelectric responses of thin film constrained by a substrate24. Since we are examining the domain periodicity in the absence of an external electric field, we neglect this interatomic elastic-interaction term in our theoretical analysis.

denotes the excess surface free energy of top (or bottom) surface of a retangular nanodot. It can be shown, however, that this simplification does not alter our interpretation of the anomalous domain periodicity. In addition, it is theoretically shown that 180° stripe domains under an external electric field behave as elastic domains due to the converse piezoelectric effect24. Under this condition, the interatomic elastic-interaction between 180° ferroelectric domains is an important factor in determining the effective dielectric and piezoelectric responses of thin film constrained by a substrate24. Since we are examining the domain periodicity in the absence of an external electric field, we neglect this interatomic elastic-interaction term in our theoretical analysis.

According to the Landau-Ginzburg theory, the difference in the free energy between ferroelectric and paraelectric states can be written in terms of P (polarization order-parameter) and its gradient as

where κ denotes the Ginzburg gradient-energy coefficient. In Eq. (2) χ (below the Curie temperature) and ξ are negative while ζ is positive for a displacive ferroelectric that undergoes a discontinuous first-order phase transition25. From Eq. (2), one can deduce the following expression for the equilibrium bulk polarization  under the condition of zero gradient:

under the condition of zero gradient:

Substituting Eq. (3) into Eq. (2) yields the following expression that relates Δμ with the Landau expansion coefficients (i.e., dielectric stiffness coefficients):

Considering Eq. (2), one can evaluate the domain-wall energy, σw, by carrying out the following integration if the polarization profile across the domain wall, P(x), is established:

The second expression of Eq. (5) is valid for a symmetrical domain boundary.

Let us now return to Eq. (1). Substituting nw for L (Fig. 4) and dividing ΔGdot by L2, one obtains the following expression for the Gibbs free-energy function of a ferroelectric nanodot per unit area (ΔG):

where the first two terms in the right-hand-side of Eq. (6) represent the free energy of the single-domain state per unit area (ΔGsd) whereas the last term denotes the domain-wall energy (ΔGw) of a nano-rectangle having the dimension of L × L × d. ΔGdep in Eq. (6) represents the depolarization-field energy per unit area. Let us now define the following parameter for future convenience:

εz in Eq. (7) denotes the relative dielectric permittivity along the unique polarization axis, i.e., εc for PTO. Then, ΔGw can be rewritten in terms of R and c as

Similarly, ΔGsd can be rewritten using R and c as

On the other hand, the following complicated expression of ΔGdep can be obtained by solving the Laplace equation under suitable continuity conditions for the electric field ( E ) and the dielectric displacement vector ( D ):21

where g is defined by g ≡ (εxεz) = cεz. The term,  , represents the energy of a plate condenser per unit area having thickness d, filled by a dielectric with the permittivity εz and carrying surface charges ± Po. On the other hand, f(R, g) is a dimensionless function which is equal to the terms inside the parenthesis of Eq. (10).

, represents the energy of a plate condenser per unit area having thickness d, filled by a dielectric with the permittivity εz and carrying surface charges ± Po. On the other hand, f(R, g) is a dimensionless function which is equal to the terms inside the parenthesis of Eq. (10).

According to Kopal, Bahnik, and Fousek21, there exists a certain critical film thickness above which the electrostatic interaction of the domain surfaces can be neglected. This thickness is given by

For d > dc, ΔGdep can be simplified by the following well known expression2,14,21,26, instead of the complicated expression presented in Eq. (10):

where ζ(3) is the Riemann zeta function and is equal to  .

.

A modified scaling law for ferroelectric nanodots

Under the condition of d > dc (i.e., “thick” plates approximation), Eq. (6) can be written explicitly using Eq. (12) as

Then, one can obtain the following expression for the equilibrium domain width of a ferroelectric rectangle (dot) by setting (∂ΔG/∂w)d = 0:

The last expression of Eq. (14) represents an asymptotic scaling law under the condition of n → ∞ and, thus, corresponds to a thin film having an infinite lateral dimension. As expected, this asymptotic law correctly reproduces the classical w2−d scaling law. In contrast, the first expression indicates that the w2−d scaling law may not be valid for a nanodot where n is a small integer and depends on d.

One cannot neglect the mutual electrostatic interaction between the domain (plate) surfaces for the dot thickness smaller than dc. In this case, Eq. (12) should not be used to evaluate ΔGdep. Instead, one can derive a modified scaling law by exploiting Eqs (8), (9), and (10) and subsequently by setting (∂ΔG/∂R)g = 0. To do this, let us first evaluate (∂ΔGdep/∂R)g. In doing this, one has to consider the following two obvious relations: sin2(mπ/2) = 1 for m = 1, 3, 5.… (odd integers) and sin2(mπ/2) = 0 for m = 2, 4, 6.… (even integers). Incorporating this result into Eq. (10), one obtains the following expression of (∂ΔGdep/∂R)g:

As defined in Eq. (7), R is proportional to (d/w). Substituting Eq. (15) into the requirement that  , one can eventually obtain the following non-classical relation between w and d for d < dc:

, one can eventually obtain the following non-classical relation between w and d for d < dc:

where

Eq. (16) clearly indicates that the simple w2−d scaling law is no more valid for d < dc. According to Eq. (16), the domain width even increases with decreasing d, which successfully accounts for the observed anomalous domain periodicity (Fig. 3) for d < 35 nm (dc). It is interesting to note that the last expression of Eq. (16) which is asymptotically valid for n → ∞ (infinite lateral dimension) exactly coincides with the modified scaling equation for thin films as proposed by Kopal et al.21.

Effect of the lateral dimension on the critical thickness

Though the anomalous behavior of the domain periodicity (for d < dc) in the PTO nanodots can be qualitatively explained by adopting Eq. (16), we still have one important question to be resolved in the case of thin films: Why does the classical w2−d scaling law describe the domain periodicity well down to the thickness of ~2 nm? In other words, why is the critical thickness (dc) not observed down to ~2 nm in the case of thin films? To answer this question, we have considered the most prominent difference between a nanodot and a thin film, which is the lateral dimension (L), thus, the number of domains, n.

In the case of thin films where the lateral dimension (L) is practically infinite, the critical thickness (dc) for neglecting the electrostatic interaction of the domain surfaces is given by Eq. (11). According to Eq. (11), the critical film thickness can be rewritten as  . Since the right-hand side of this relation is constant for fixed values of εz, εx, σw, and Po, the critical film thickness is proportional to

. Since the right-hand side of this relation is constant for fixed values of εz, εx, σw, and Po, the critical film thickness is proportional to  For σw = 5 × 10−3 J•m−2, Po = 0.2 C•m−2, and c = 5, dc(film) is approximately given by g ×2.2 × 10−13 (m). Combining this result with the observation that dc(film) <2 nm one can deduce that g ≤ ~1 × 10+13. Numerical calculations of the thickness-dependent (w/g) using Eqs (16) and (17) further indicate that regardless of the value of g-parameter used, the domain width (w) increases rapidly with decreasing film thickness (dfilm) for dfilm < dc.

For σw = 5 × 10−3 J•m−2, Po = 0.2 C•m−2, and c = 5, dc(film) is approximately given by g ×2.2 × 10−13 (m). Combining this result with the observation that dc(film) <2 nm one can deduce that g ≤ ~1 × 10+13. Numerical calculations of the thickness-dependent (w/g) using Eqs (16) and (17) further indicate that regardless of the value of g-parameter used, the domain width (w) increases rapidly with decreasing film thickness (dfilm) for dfilm < dc.

We will then deduce the corresponding expression of the critical thickness for a ferroelectric nanodot (dc(dot)) where L or n is finite. To do this, we first assume that the domain width at dc is proportional to dc(dot) itself. Thus, one can establish that wc(dot) = kdc(dot), where k is a proportionality constant. By exploiting this proportionality and Eq. (14) in the vicinity of dc, one can eliminate wc(dot) from this relation and obtain the following expression for dc(dot):

where nc denotes the number of distinct domains in the nanodot having the critical thickness of dc(dot). k2-term appeared in the first expression of the above equation was eliminated in the second expression by comparing Eq. (11) with the first expression in the asymptotic thin-film limit where n → ∞. It is worth noting that the last expression of Eq. (18), which corresponds to the asymptotic thin-film limit, does coincide with Eq. (11) which had been deduced by Kopal and co-workers for thin films21.

Comparing the second expression of Eq. (18) with Eq. (11), one obtains the following ratio of the critical thickness for a nanodot having n distinct 180° domains (dc(dot)) to that for a thin-film having an infinite lateral dimension (dc(film)):

This equation predicts that the asymptotic value of the above ratio in the limit of nc → ∞ (i.e., thin film) is 1 as expected. One can qualitatively estimate dc(film) by taking a suitable value of (σs/σw). Assuming (σs/σw) ≈ 5 and plugging nc = 6 and dc(dot) ≈ 35 nm into Eq. (19), one predicts that dc(film) = 8.4 nm which is in direct disagreement with the observation that dc(film) ≤ 2 nm5,14,15. Herein, ncand dc(dot) values were taken from those of the dot C (see “Experimental Results” section). One can immediately obtain the following expressions from Eq. (19):

In obtaining the last expression of Eq. (20), we used the observation that dc(dot) ≈ 35 nm (Fig. 3) and dc(film) <2 nm5,14,15. This indicates that the ratio of σs to σw should be greater than a certain critical value which, in turn, is linearly proportional to nc with the intercept being 1/4. The allowed region of nc-dependent (σs/σw) is shown in Fig. 5 using a shaded mark. According to this theoretical prediction, the minimum value of (σs/σw) that satisfies the above inequality for nc = 6 is 25.0 which seems to be unrealistically high to be accepted. This suggests that the critical thickness, dc, is actually determined not only by the lateral-size effect but also by some other factor. In other words, the lateral-size effect alone cannot account for the observation that Ro ≡ dc(dot)/dc(film) >17.5(=35/2).

As shown in the figure, the minimum allowed value depends sensitively on the thickness of a non-ferroelectric surface layer, δ. Among the four lines, the black line which corresponds to (δ/w) = 0 denotes the minimum allowed value of (σs/σw) in the absence of a thin non-ferroelectric surface layer. The shaded region represents the allowed region of nc-dependent (σs/σw) for δ = 0.

Possible existence of a non-ferroelectric surface layer

It is now clear that the lateral-size effect alone cannot satisfactorily explain the observed difference in the w2-d scaling behavior between a film and a nanodot [Fig. 3]. To resolve this puzzling situation, we postulate the presence of a ferroelectrically inactive thin surface layer. This postulation is supported by the experimental observations of thin non-ferroelectric surface layers in perovskite-based ferroelectrics such as BaTiO327,28,29. According to the experimental estimate by transmission electron microscopy, the thickness of this surface layer is around 10 nm28. First-principles calculations30,31 and phase-field simulations32 also support the existence of a surface relaxation layer. The size-dependent depolarization effects on d33 and Ec, as shown in Fig. 1(d), also suggest a non-ferroelectric surface layer. The most important effect of this postulation is considered to be the compensation of the depolarizing field33 by the lateral surfaces of a nanodot.

We have examined the possible existence of a non-ferroelectric surface layer and its effect on the optimized surface structure. For this purpose, we performed first-principles density-functional theory (DFT) calculations on the basis of the generalized gradient approximation (GGA) method implemented with the projector augmented wave (PAW)34 pseudopotential using the Vienna ab initio Simulation Package (VASP)35. All of the DFT calculations were performed using the plane wave cutoff energy of 500 eV. We have considered the stacking of PbTiO3 along [001], which consists of alternating TiO2 and PbO layers. For actual calculations, we adopted slabs of 11 atomic layers of the in-plane polarized c(2 × 2) surface unit cell for the PbO termination31. For polarized films (within in-plane ferroelectric (FE) distortion), we found that in-plane FE and anti-ferrodistortive (AFD) distortions are concurrently enhanced at the PbO-terminated surface region, which leads to the formation of a structural surface phase with coexisting [100]-oriented FE and AFD distortions. However, this surface phase does not possess any FE polarization component along the principal [001] polar direction.

Having examined the possible existence of a surface phase by ab initio DFT calculations, we have thermodynamically considered this issue by suitably modifying the Gibbs free-energy function of a ferroelectric nanodot having surface layers36. We eventually obtained the following approximation for the critical-thickness ratio in the presence of a non-ferroelectric surface layer with the thickness δ:36

where Lc is the lateral dimension of a nanodot at the critical dot-thickness, Rδ denotes the ratio of the two critical thicknesses in the presence of a non-ferroelectric surface layer of the thickness δ. σfp appeared in Eq. (21) denotes the interfacial tension between the ferroelectric nanodot and the paraelectric surface layer. The most prominent difference between Eq. (19) and Eq. (21) is the introduction of a geometry term, {Lc/(Lc−2δ)}2, in Eq. (21), which always enhances Rδ. More importantly, Eq. (21) tells us that both the existence of a non-ferroelectric surface layer of the thickness δ and the finite lateral-size effect determine Rδ, thus dc(dot). Assuming (σfp/σw) = 10, δ ≈ 15 nm and plugging nc = 6, Lc ≈ 100 nm into Eq. (21), one obtains dc(film) of ~2.3 nm which qualitatively agrees with the observation that dc(film) ≤ ~2 nm.

Similar to the derivation of Eq. (20), one can obtain the following expression of (σfp/σw) directly from Eq. (21):

Again, we used the observation that dc(dot) ≈ 35 nm (Fig. 3) and dc(film) <2 nm in obtaining the last expression of Eq. (22). Unlike Eq. (20), however, there is no linear correlation between (σfp/σw) and nc. Notice that the right-hand side of Eq. (22) exactly coincides with that of Eq. (20) when δ = 0. The boundary between the allowed and prohibited regions of the nc-dependent (σfp/σw) is plotted in Fig. 5 for four selected values of (δ/w) including 0. The minimum allowed value of (σfp/σw) decreases significantly with increasing value of δ at a given nc, suggesting that the formation of a thin non-ferroelectric surface layer substantially reduces the minimum allowed value of (σfp/σw). However, our derivation of Eq. (21) adopts a couple of unjustified assumptions36. We thus leave this problem (i.e., a rigorous theoretical treatment of the LLK scaling law for a nanodot having a non-ferroelectric surface layer) as a future challenging task. On the basis of all these results, we have come to the conclusion that the finite lateral-size effect (n), in addition to the possible existence of a ferroelectrically inactive surface layer, should be taken into account to properly explain the difference in the scaling behavior between ferroelectric films and nanodots.

Conclusion

For the dot thickness larger than the critical value (dc) of ~35 nm, the width of 180° stripe domains scales with the thickness of the PTO nanodot according to the classical LLK scaling law. For the dot thickness smaller than dc, however, we obtain a quite striking correlation that the thickness-dependent domain width is experimentally represented by a negative exponent. On the basis of theoretical considerations of dc, we attribute this anomalous domain periodicity to the finite lateral-size effect of a ferroelectric nanodot with an additional effect possibly coming from the existence of a non-ferroelectric surface layer. Ab initio DFT calculations support the existence of a structural surface phase but with the absence of a FE polarization component along the principal [001] polar direction.

Experimental Methods

Dip-pen nanolithography (DPN) method was used to fabricate a ferroelectric PTO nanodot array20. DPN, which enables us to form nanopatterns with various molecules at desired places, is one of noble atomic force microscopy (AFM) techniques that utilize both electric force microscopy (EFM) and piezo-response force microscopy (PFM). Unlike DPN involving polymers, we adopted sequential drying and annealing processes for the fabrication of PTO nanodots. We used a PbO-excess precursor sol modified with a low-viscosity alcohol. We first formed PTO-precursor sol on an Nb-doped SrTiO3 (STO) substrate. To elaborate the DPN process, we used an Nb-doped STO substrate that had an atomically flat surface with well-aligned terraces formed by HF treatment and annealing. After the deposition, we slowly dried these precursor sol nanodots at room temperature. For the crystallization of ferroelectric perovskite PTO, we annealed these nanodots under an oxygen atmosphere at 650 °C for 1 min by rapid thermal annealing. The size of the PTO nanodots was controlled by suitably adjusting the dip-pen deposition time. Piezoelectric hysteresis loops were measured by employing piezoelectric force microscopy (PFM) at a frequency of 10 kHz. PFM images of the PTO nanodots were observed using a high-resolution electric force mode of the PFM, where a platinum-coated Si3N4 cantilever tip was employed.

Additional Information

How to cite this article: Son, J. Y. et al. Anomalous domain periodicity observed in ferroelectric PbTiO3 nanodots having 180° stripe domains. Sci. Rep. 6, 26644; doi: 10.1038/srep26644 (2016).

References

Scott, J. F. Ferroelectric Memories (Springer-Verlag, Berlin, 2000).

Mitsui, T. & Furuichi, J. Domain structure of Rochelle salt and KH2PO4 . Phys. Rev. 90, 193–202 (1953).

Shih, W. Y., Shih, W.-H. & Aksay, I. A. Size dependence of the ferroelectric transition of small BaTiO3 particles: effect of depolarization. Phys. Rev. B 50, 15575–15585 (1994).

Bratkovsky, A. M. & Levanyuk, A. P. Abrupt appearance of the domain pattern and fatigue of thin ferroelectric films. Phys. Rev. Lett. 84, 3177–3180 (2000).

Streiffer, S. K. et al. Observation of nanoscale 180° stripe domains in ferroelectric PbTiO3 thin films. Phys. Rev. Lett. 89, 067601 (2002).

Fong, D. D. et al. Ferroelectricity in ultrathin perovskite films. Science 304, 1650–1653 (2004).

Lai, B.-K. et al. Electric-field-induced domain evolution in ferroelectric ultrathin films. Phys. Rev. Lett. 96, 137602 (2006).

Naumov, I. & Bratkovsky, A. M. Unusual polarization patterns in flat epitaxial ferroelectric nanoparticles. Phys. Rev. Lett. 101, 107601 (2008).

Schilling, A. et al. Domains in ferroelectric nanodots. Nano Lett. 9, 3359–3364 (2009).

Catalan, G. et al. Fractal dimension and size scaling of domains in thin films of multiferroic BiFeO3 . Phys. Rev. Lett. 100, 027602 (2008).

Kittel, C. Theory of the structure of ferromagnetic domains in films and small particles. Phys. Rev. 70, 965–971 (1946).

Schilling, A. et al. Scaling of domain periodicity with thickness measured in BaTiO3 single crystal lamellae and comparison with other ferroics. Phys. Rev. B 74, 024115 (2006).

Scott, J. F. Nanoferroelectrics: statics and dynamics. J. Phys.: Condens. Matter 18, R361–R386 (2006).

Catalan, G., Scott, J. F., Schilling, A. & Gregg, J. M. Wall thickness dependence of the scaling law for ferroic stripe domains. J. Phys.: Condens. Matter 19, 022201 (2007).

Zhao, G.-P., Chen, L. & Wang, J. A modified scaling law for 180° stripe domains in ferroelectric thin films. J. Appl. Phys. 105, 061601 (2009).

Prosandeev, S., Lisenkov, S. & Bellaiche, L. Kittel law in BiFeO3 ultrathin films: a first-principles-based study. Phys. Rev. Lett. 105, 147603 (2010).

Burns, G. & Scott, B. A. Raman studies of under damped soft modes in PbTiO3 . Phys. Rev. Lett. 25, 167 (1970).

Cho, S. M., Jang, H. M. & Kim, T. Y. Origin of anomalous line shape of the lowest-frequency A1(TO) phonon in PbTiO3 . Phys. Rev. B 64, 014103 (2001).

Scott, J. F. Applications of modern ferroelectrics. Science 315, 954–959 (2007).

Son, J. Y., Shin, Y.-H., Ryu, S., Kim, H. & Jang, H. M. Dip-pen lithography of ferroelectric PbTiO3 nanodots. J. Am. Chem. Soc. 131, 14676–14678 (2009).

Kopal, A., Bahnik, T. & Fousek, J. Domain formation in thin ferroelectric thin films: the role of depolarization energy. Ferroelectrics 202, 267–274 (1997).

Huang, C. W. et al. Phenomenological analysis of domain width in rhombohedral BiFeO3 films. Phys. Rev. B 80, 140101(R) (2009).

Cano, A. & Levanyuk, A. P. Pseudoproper ferroelectricity in thin films. Phys. Rev. B 81, 172105 (2010).

Chen, L. & Roytburd, A. L. 180° ferroelectric domains as elastic domains. Appl. Phys. Lett. 90, 102903 (2007).

Mitsui, T. An Introduction to the Physics of Ferroelectrics (Gordon and Breach Publishers, London, 1976), pp.59–77.

Bjorkstam, J. L. & Oettel, R. E. 180° domain formation in ferroelectrics with shorted electrodes. Phys. Rev. 159, 427–430 (1967).

Känzig, W. Space charge layer near the surface of a ferroelectric. Phys. Rev. 98, 549–550 (1955).

Tsai, F. & Cowley, J. M. Thickness dependence of ferroelectric domains in thin crystalline films. Appl. Phys. Lett. 65, 1906–1908 (1994).

Kolpak, A. M., Li, D., Shao, R., Rappe, A. M. & Bonnell, D. A. Evolution of the structure and thermodynamic stability of the BaTiO3 (001) surface. Phys. Rev. Lett. 101, 036102 (2008).

Padilla, J. & Vanderbilt, D. Ab initio study of BaTiO3 surfaces. Phys. Rev. B 56, 1625–1631 (1997).

Bungaro, C. & Rabe, K. M. Coexistence of antiferrodistortive and ferroelectric distortions at the PbTiO3 (001) surface. Phys. Rev. B 71, 035420 (2005).

Slutsker, J., Artemev, A. & Roytburd, A. Phase-field modeling of domain structure of confined nanoferroelectrics. Phys. Rev. Lett. 100, 087602 (2008).

Fong, D. D. et al. Stabilization of monodomain polarization in ultrathin PbTiO3 films. Phys. Rev. Lett. 96, 127601 (2006).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Son, J. Y., Lee, J.-H., Shin, Y.-H. & Jang, H. M. Anomalous domain periodicity observed in ferroelectric PbTiO3 nanodots with 180° stripe domains. arXiv:1301.3293v1 [cond-mat.mtrl-sci] (15 Jan 2013).

Acknowledgements

This work was financially supported by the Basic Science Research Program (Grant No. 2015R1A2A2A 0502795 & Grant No. 2013R1A2A2A 01068274) through the National Research Foundation (NRF) funded by the Korea Government (MAIP).

Author information

Authors and Affiliations

Contributions

J.Y.S. discovered the anomalous domain periodicity and conducted experiments. S.S. helped J.Y.S. do experimental characterizations, J.-H.L. carried out DFT calculations. H.M.J. did theoretical analysis and wrote the manuscript. All authors discussed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Son, J., Song, S., Lee, JH. et al. Anomalous domain periodicity observed in ferroelectric PbTiO3 nanodots having 180° stripe domains. Sci Rep 6, 26644 (2016). https://doi.org/10.1038/srep26644

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep26644

This article is cited by

-

Multiferroic and energy-storage characteristics of polycrystalline Ca-doped BiFeO3 thin films on Si substrates

Journal of the Korean Ceramic Society (2023)

-

Multiferroic and photovoltaic current properties of tetragonally strained BiFeO3 thin films

Journal of Electroceramics (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.