Abstract

The magnetostructural coupling between structural and magnetic transitions leads to magneto-multifunctionalities of phase-transition alloys. Due to the increasing demands of multifunctional applications, to search for the new materials with tunable magnetostructural transformations in a large operating temperature range is important. In this work, we demonstrate that by chemically alloying MnNiSi with CoNiGe, the structural transformation temperature of MnNiSi (1200 K) is remarkably decreased by almost 1000 K. A tunable magnetostructural transformation between the paramagnetic hexagonal and ferromagnetic orthorhombic phase over a wide temperature window from 425 to 125 K is realized in (MnNiSi)1−x(CoNiGe)x system. The magnetic-field-induced magnetostructural transformation is accompanied by the high-performance magnetocaloric effect, proving that MnNiSi-CoNiGe system is a promising candidate for magnetic cooling refrigerant.

Similar content being viewed by others

Introduction

Magnetostructural transformation (MST), a coupling between the structural and magnetic transition, attracts considerable attention due to various associated interesting magnetoresponsive effects, such as magnetic shape memory effect1, magnetic field-induced strain2,3, magnetoresistance4,5 and magnetocaloric effect6,7,8,9. These effects show potential applications in sensors10, magneto-mechanical devices11,12, energy-harvesting devices13, magnetic cooling refrigeration14,15 and so on. In order to realize MST in a phase-transition material, a large magnetization difference (ΔM) between the two structural phases is essential and is always pursued to increase the magnetic field-driving capacity1. If MST in a given system is tuned to occur between a paramagnetic (PM)/antiferromagnetic (AFM) state and a ferromagnetic (FM) state1,16, rather than between two FM states17, a large ΔM will be gained. As an example, MST is widely observed in Heusler-type magnetic shape memory alloys, which show ferromagnetic martensitic transitions18,19.

Based on this viewpoint, another type of magnetic shape memory material, the hexagonal MnM′X compound (M′ = Co or Ni, X = Si or Ge) is designed to obtain MST20,21,22,23. In stoichiometric MnM′X compounds, the structural transformation takes place from a martensitic-like hexagonal Ni2In to an orthorhombic TiNiSi structure during the cooling process24. The main challenge in MnM′X compounds is that the structural transformation temperature (Tt) is usually much higher than the magnetic-ordering temperatures of both hexagonal and orthorhombic phases25,26,27 and the transformation occurs between two PM states25,26,27, resulting in a low ΔM and low magnetic field-driving capacity17.

It is known that, in MnM′X compounds, the stability of Ni2In and TiNiSi structures is highly dependent on the covalent bonds between M′ and X atoms28,29 and that between the neighbouring Mn and Mn atoms16. The stoichiometric tuning20,23, foreign-atoms-substituting16,21,22,30,31 and applied stress32 may alter the strength of covalent bonds, thus influence Tt. For example, by introducing interstitial B atoms or substituting Cu for Mn atoms, Tt of MnCoGe can be reduced from 420 K to below Curie temperature of the orthorhombic phase (TC) and MST from PM hexagonal to FM orthorhombic phase is realized during cooling22,31. In the case of MnNiGe system, the stoichiometric tuning can reduce Tt from 470 K to below than 200 K and obtain MST from FM hexagonal to AFM orthorhombic phase with decreasing temperature20. Moreover, it is reported that if Tt lies in the Curie-temperature window (CTW), which is the range between Curie temperatures of the hexagonal and orthorhombic phases16,33,34, the structural transition will couple with magnetic state changes, bringing a large ΔM. The CTW is expected to be broad enough, so that MST and the coupled magnetoresponsive effects can be freely tailored in a large temperature range. However, in MnM′Ge-based compounds, the relatively low magnetic ordering temperatures restrict the further enlargement of CTW.

Aimed at the potential applications with magnetoresponsive effects, a good candidate of MnM′X compound with MST should have both a large ΔM and a wide CTW. As a member of MnM′X family, MnNiSi has a high TC of 622 K35, indicating a potential large CTW. However, Tt in stoichiometric MnNiSi alloy is as high as 1200 K24, which is almost two times higher than those in MnCoGe and MnNiGe24,25,26,27. Compared to the previously mentioned alloy systems, to effectively tune down Tt to below TC is a big obstacle in MnNiSi system before the realization of MST36,37. Recently, the isostructural alloying opens up a new feasibility to realize the magnetostructural coupling in MnNiSi-based compounds16,33,34,38,39,40,41. By applying this method, the wide CTW can be further obtained. In this work, by Co and Ge co-substitution, we perform the isostructural alloying of MnNiSi and CoNiGe. In this (MnNiSi)1−x(CoNiGe)x system, Tt is successfully tuned down to below than TC and the tunable MST between PM hexagonal and FM orthorhombic phase can be obtained in a large CTW by altering the CoNiGe-content. Due to the large ΔM between two phases, the observed MST can be induced by the external magnetic field at room temperature (RT). The effect is accompanied by a large magnetocaloric effect, indicating the potential applications in magnetic cooling refrigerator.

Results

Structural characterization

Figure 1(a) shows X-ray diffraction (XRD) patterns of (MnNiSi)1−x(CoNiGe)x (x = 0.32, 0.33, 0.34, 0.35, 0.36, 0.37, 0.38, 0.39, 0.40, 0.41, 0.42, 0.43 and 0.44) alloys measured at RT. It is reported that the stoichiometric MnNiSi exhibits the orthorhombic TiNiSi structure at RT24, while CoNiGe possesses the stable hexagonal Ni2In structure42. With the increase of CoNiGe-content, the structure of (MnNiSi)1−x(CoNiGe)x samples at RT changes from the orthorhombic TiNiSi to hexagonal Ni2In phase and no other impurity phase is found. For the samples with x ≤ 0.36, TiNiSi structure dominates at RT; while for x = 0.37, the XRD pattern indicates the coexistence of TiNiSi and Ni2In structures; when x ≥ 0.38, the single Ni2In structure is observed. XRD results suggest that the introduction of CoNiGe will stabilize Ni2In structure and lower down Tt from 1200 K to below RT24. From the crystallographic point of view, TiNiSi structure can be understood as the distortion of Ni2In structure and the axes of the two structures are related as aortho = chex, bortho = ahex and cortho =  ahex25. It is known that the stability of Ni2In structure is associated with the low chex/ahex (aortho/bortho)39,43. In (MnNiSi)1−x(CoNiGe)x system, the value of aortho/bortho (chex/ahex) decreases with increasing CoNiGe-content, especially at the range of x ≤ 0.36, shown in the inset of Fig. 1(a). It further supports that Co and Ge co-substitution can reduce Tt.

ahex25. It is known that the stability of Ni2In structure is associated with the low chex/ahex (aortho/bortho)39,43. In (MnNiSi)1−x(CoNiGe)x system, the value of aortho/bortho (chex/ahex) decreases with increasing CoNiGe-content, especially at the range of x ≤ 0.36, shown in the inset of Fig. 1(a). It further supports that Co and Ge co-substitution can reduce Tt.

Structural analysis of the phase transitions.

(a) Composition dependent XRD patterns of (MnNiSi)1−x(CoNiGe)x measured at RT. Inset: aortho/bortho and chex/ahex ratios. (b) Temperature-dependent XRD of (MnNiSi)0.66(CoNiGe)0.34 from 353 to 493 K. Inset: cell volumes from 353 to 493 K for (MnNiSi)0.66(CoNiGe)0.34.

To further investigate the thermo-induced structural transformation in (MnNiSi)1−x(CoNiGe)x system, the temperature-dependent XRD measurement during heating is performed on (MnNiSi)0.66(CoNiGe)0.34. As shown in Fig. 1(b), (MnNiSi)0.66(CoNiGe)0.34 exhibits TiNiSi structure at below 390 K, while becomes pure Ni2In structure at above 433 K. When the temperature is 413 K, two structures coexist, suggesting that TiNiSi structure transits to Ni2In structure with increasing temperature. According to XRD analysis, the temperature-dependent unit-cell volume is calculated, shown in the inset of Fig. 1(b). A large decrease of 2.5% in unit-cell volume is observed during the structural transformation on heating, indicating a remarkable atomic displacement during the structural reconstruction.

MST and magnetic phase diagram

In order to confirm the CoNiGe-content dependent Tt, DSC measurements of (MnNiSi)1−x(CoNiGe)x (x = 0.32, 0.33, 0.34, 0.35, 0.36, 0.37, 0.38, 0.39, 0.40, 0.41, 0.42) were carried out upon cooling and heating with a ramp rate of 10 K/min, which are shown in Fig. 2. The observed large endothermic/exothermic peaks during heating/cooling cycles are associated with the latent heat of the first-order structural transitions between TiNiSi and Ni2In structures. The thermal hysteresis between heating and cooling cycles signifies the first-order nature of structural transformation. For the sample with x = 0.34, the endothermic peak appears at 410 K, which agrees well with the temperature-dependent XRD analysis. It is also found that the endothermic and exothermic peaks shift towards lower temperatures with the increase of CoNiGe-content. This phenomenon verifies that the introduction of CoNiGe can reduce Tt of MnNiSi from 1200 K to be below RT.

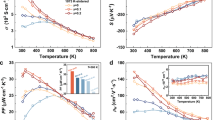

Since the magnetic properties of MnM′X alloys are sensitive to the Mn-Mn distances44, the large distortion of unit-cell during the structure transformation may bring about considerable changes of magnetic states. The temperature dependences of magnetization (M-T) for (MnNiSi)1−x(CoNiGe)x (x = 0.36, 0.38 and 0.41) measured during heating and cooling with a ramp rate of 2 K/min at a magnetic field of 0.1 T are shown in Fig. 3(a) (some other representative M-T curves are shown in the supporting information). A sharp magnetic transition from the high-temperature PM to low-temperature FM state is observed during cooling. The transition shifts to the lower temperatures with the increase of CoNiGe-content. The obvious thermal hysteresis, reflecting the irreversibility between cooling and heating cycles, suggests the first-order nature of the transition. Tt, here defined as the temperature where |dM/dT| is the maximum, agrees well with the DSC measurement. These results prove that the studied samples experience MST between FM orthorhombic and PM hexagonal phase as the temperature changes. While it is worth noting that Mn atoms carry the majority of magnetic moments in MnNiSi alloys35. To investigate the saturated magnetization, Ms, of MnNiSi-CoNiGe system, M-B curves of some samples are measured at 4.2 K in Fig. 3(b). As shown in the inset, Ms decreases with increasing CoNiGe-content and it is lower than that of stoichiometric MnNiSi (2.62 μB/f.u.)35. It indicates that the substitution of large-moment Mn atoms by small-moment Co atoms modifies the exchange interactions between Mn-Mn atoms37.

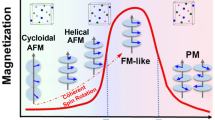

According to DSC and magnetic measurements, the structural and magnetic phase diagram of (MnNiSi)1−x(CoNiGe)x system is obtained, as shown in Fig. 4. The sample with x = 0.32 transits from PM hexagonal to PM orthorhombic phase at 450 K, then to FM orthorhombic phase at 425 K during cooling. Upon the further increase of CoNiGe-content to 0.43, Tt continuously decreases to 125 K. When x is higher than 0.43, MST disappears and a weak magnetic spin-glass-like state is found, similar as Mn1−xFexNiGe16. Thus, a CTW ranged from 425 to 125 K is established in (MnNiSi)1−x(CoNiGe)x system, where alloys undergo a tunable MST coupled with a magnetic transition from PM to FM state.

Magnetic-field-inducing MST and magnetocaloric effect

In the case of Ni-Mn based ferromagnetic shape memory alloys, due to the large ΔM between FM austenite and weak magnetic martensite, the austenite is energetically more favorable in the magnetic field, giving rise to the decrease of Tt and the magnetic-field-inducing MST from the martensite to austenite1. Similarly, in (MnNiSi)1−x(CoNiGe)x system with a first-order PM-FM transition, the magnetic field will stabilize FM TiNiSi structure and lead to a MST from the hexagonal to orthorhombic phase. For the sample with x = 0.38, Tt increases 4.8 K under a magnetic field of 5 T, indicating that MST can be induced by the magnetic field (Fig. 5(a)). Due to the discontinuities of spin and lattice, MST is associated with a large magnetic entropy change (ΔS). It is known that the maximum value of ΔS can be estimated from M-T curves measured at different constant fields (here, B = 0.1 and 5 T, respectively) using the Clausius-Clapeyron equation:

(a) M-T curves of (MnNiSi)0.62(CoNiGe)0.38 for applied fields B = 0.1 T and 5 T. (b) Isothermal M-B curves measured around Tt for the sample with x = 0.38 (c) Temperature dependence of ΔS in the field changes of 0–2 T and 0–5 T for the samples x = 0.38, 0.39 and 0.40. Inset: magnetic hysteresis loss of sample with x = 0.38.

For (MnNiSi)0.62(CoNiGe)0.38, the calculated maximum value of ΔS is −41.8 J/(kg·K), where ΔM = 41 A·m2/kg, ΔB = 4.9 T and ΔT = 4.8 K (Fig. 5(a)). To further confirm the magnetocaloric effect during the transition, ΔS in the heating process is also calculated from the isothermal magnetization curves (M-B curves in Fig. 5(b)) using the Maxwell relation. As shown in Fig. 5(c), the maximum value of ΔS is −40.3 J/(kg·K) at 295 K, which agrees with the value obtained by Clausius-Clapeyron equation. In (MnNiSi)1−x(CoNiGe)x system, the large CTW offers the possibility to obtain large ΔS values in the temperature range of nearly 300 K. As an example, the substitution levels of x = 0.40 and 0.39 give rise to ΔS of −31.7 and −30.5 J/(kg·K) for ΔB = 5 T at 245 and 270 K, respectively (Fig. 5(c)). The observed maximum ΔS is larger than some promising magnetocaloric systems, such as some MnM′Ge-based systems16,30,33, Ni-Mn based alloys7,8 and rare earth-transition metal intermetallic compounds45. The effective refrigeration capacity (RCeff), which is calculated by subtracting the average hysteresis loss (HL) from the refrigeration capacity (RC) value, is commonly adopted to evaluate magnetocaloric effect46. For sample with x = 0.38, RC value is 170.1 J/kg around room temperature, numerically calculated by integrating the area under ΔS-T curves, using the temperatures at half-maximum of the peak as the integration limits. And HL, calculated from the area surrounded by hysteresis loops (M-B curves), is negligible, as shown in the inset of Fig. 5(c). Therefore, RCeff is about 169.8 J/kg for this sample under the field change of 0–5 T. These indicate the potential applications for the RT magnetic cooling refrigerator. Besides, as mentioned above, the MnNiSi-CoNiGe system undergoes large changes of lattice parameters and unit volume during the transition (Fig. 1(a)), which can be induced by the applied magnetic field. This may be utilized for the strain-based applications16.

Discussion

The observed MST between FM orthorhombic and PM hexagonal phase is achieved by adjusting Tt into the CTW. However, as mentioned above, Tt of MnNiSi is as high as 1200 K and cannot be efficiently decreased by the conventional methods36,37. Here, the question is why Co and Ge co-substitution can sharply reduce Tt to below TC, leading to the observed MST. In MnM′X alloys, covalent bonds form between M′ and X atoms and between the neighbouring Mn and Mn atoms both in TiNiSi and Ni2In structures16,28,29. These covalent bonds act as skeletons, stabilizing the crystalline structure16,29,47. The structure transformation can be understood as a competition between the strengths of covalent bonds in TiNiSi and Ni2In structures16,34,47. Thus, altering the strength of covalent bonds can influence Tt. For the system with M′ = Ni, Tt of MnNiGe lies around 470 K24,25, which is 730 K lower than that of MnNiSi24. This suggests that altering the main-group elements can influence the strength of covalent bond, leading to the change of Tt. Similar phenomenon is found in Al substituted MnNiGe alloy48. Except for altering elements which form M′-X covalent bond, the decrease of Tt is also observed when Mn is replaced by other 3d-atoms, such as Mn1−xFexCoGe alloy49. Based on the site-preference rule50, Fe atoms occupy Mn sites and induce lattice change in c axis. This change will influence the separation of Mn atoms, leading to the enhancement of the strength of Mn-Mn covalent bonds, which is helpful to stabilizing the Ni2In structure. For MnNiSi, Tt cannot be efficiently reduced by the single-element substitution36,37. However, when CoNiGe is introduced, Co atoms occupy 3d-atom Mn sites, Ge atoms occupy main-group Si sites and Tt decreases by almost 1000 K with increasing CoNiGe-content.

From the view of applications, a large CTW enables tunable magnetoresponsive effects in a wide temperature range. In this (MnNiSi)1−x(CoNiGe)x system, the CTW is as large as 300 K, which is comparable to the previously reported systems, such as MnCoGe-based system23, Mn1−xCoxNiGe33, MnNiGe:Fe system16, (Mn, Fe)Ni(Ge, Si)34 and Gd-Si-Ge alloys51. It is known that the realization of PM-FM-type MST should meet the condition that Tt can be tuned into the temperature window between the magnetic-ordering temperatures of orthorhombic and hexagonal phases. In (MnNiSi)1−x(CoNiGe)x system, TC of orthorhombic phase is around 425 K (shown in Fig. S1). However, with the increase of CoNiGe-content, a spin-glass-like state appears and the magnetic order-disorder transition of hexagonal phase is still not observed (Fig. S1). This phenomenon indicates that the magnetic ordering temperature of hexagonal phase is lower than 125 K. Therefore, a large CTW between 425 and 125 K is established in (MnNiSi)1−x(CoNiGe)x system.

Conclusions

To summarize, we have successfully realized a PM-FM magnetostructural coupling in (MnNiSi)1−x(CoNiGe)x system. By introducing CoNiGe which possesses a stable Ni2In structure, Tt decreases sharply, resulting in the first-order MST between FM orthorhombic and PM hexagonal phase. This is due to the enhancement of covalent bonds which modifies the relative stability of two structures. Besides, a large CTW of 300 K is established, which will benefit the multifunctional applications of the materials over a wide temperature range. Due to the large ΔM during the transition, MST can not only be induced by temperature, but also by magnetic field. Large, tunable magnetocaloric effect generated from MST is obtained. The magnetic entropy change of (MnNiSi)0.62(CoNiGe)0.38 reaches −40.3 J/(kg·K) under the field change of 0–5 T around RT, suggesting the potential applications in magnetic cooling refrigerator.

Methods

The samples with nominal compositions of (MnNiSi)1−x(CoNiGe)x (x = 0.32, 0.33, 0.34, 0.35, 0.36, 0.37, 0.38, 0.39, 0.40, 0.41, 0.42, 0.43 and 0.44) were prepared by arc-melting the appropriate amounts of raw materials in a water-cooled copper crucible under a high purity argon atmosphere for three times. As-cast ingots were annealed in vacuumed quartz tubes at 1073 K for four days before quenched into the cold water.

The crystal structures of the specimens were identified by X-ray diffraction (XRD, Bruker, D8 Advance) analysis with Cu-Kα radiation. The structural transitions were investigated by differential scanning calorimetry (DSC, Mettler Toledo, DSC 3).

Magnetic measurements were performed with vibrating sample magnetometer (VSM, LakeShore, 7407) and Physical Property Measurement System (PPMS, Quantum Design, Dynacool). Isothermal magnetic entropy change (ΔS) was calculated from the isothermal magnetization curves using Maxwell equation (2):

To avoid the irreversibility in the magnetic-field-induced first-order MST, isothermal magnetization curves were measured using a so-called loop process52: in the heating process, the isothermal magnetization were measured with a temperature interval of 2 K in the magnetic field variation from 0 to 5 T. For each M-B curve, the samples were initially cooled down to complete orthorhombic region (for our samples, it’s around 150 K) at 5 K/min. Then the samples were heated slowly to the measuring temperature at 3 K/min. To guarantee the temperature stability of measurement, a waiting time of 300 s was hold at the initial and targeted temperatures. Besides, for the samples with x = 0.38, 0.39 and 0.40, the highest loop temperatures were 301, 288 and 261 K, respectively.

Additional Information

How to cite this article: Liu, J. et al. Realization of magnetostructural coupling by modifying structural transitions in MnNiSi-CoNiGe system with a wide Curie-temperature window. Sci. Rep. 6, 23386; doi: 10.1038/srep23386 (2016).

References

Kainuma, R. et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 439, 957–960 (2006).

Ullakko, K., Huang, J. K., Kantner, C., O’Handley, R. C. & Kokorin, V. V. Large magnetic-field-induced strains in Ni2MnGa single crystal. Appl. Phys. Lett. 69, 1966–1968 (1996).

Chmielus, M., Zhang, X. X., Witherspoon, C., Dunand, D. C. & Mullner, P. Giant magnetic-field-induced strains in polycrystalline Ni-Mn-Ga foams. Nat. Mater. 8, 863–866 (2009).

Sharma, V. K., Chattopadhyay, M. K., Shaeb, K. H. B., Chouhan, A. S. & Roy, B. Large magnetoresistance in Ni50Mn34In16 alloy. Appl. Phys. Lett. 89, 222509 (2006).

Ma, S. C. et al. Peculiarity of magnetoresistance in high pressure annealed Ni43Mn41Co5Sn11 alloy. Appl. Phys. Lett. 102, 032407 (2013).

Pecharsky, V. K. & Gschneidner, K. A. Jr. Giant magnetocaloric effect in Gd5(Si2Ge2). Phys. Rev. Lett. 78, 4494 (1997).

Krenke, T. et al. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys. Nat. Mater. 4, 450–454 (2005).

Liu, J., Gottschall, T., Skokov, K. P., Moore, J. D. & Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 11, 620–626 (2012).

Zhang, Y. et al. Enhanced magnetic refrigeration properties in Mn-rich Ni-Mn-Sn ribbons by optimal annealing. Sci. Rep. 5, 11010 (2015).

Sarawate, N. & Dapino, M. Experimental characterization of the sensor effect in ferromagnetic shape memory Ni-Mn-Ga. Appl. Phys. Lett. 88, 121923 (2006).

Karaca, H. E. et al. Magnetic field-induced phase transformation in NiMnCoIn magnetic shape-memory alloys—a new actuation mechanism with large work output. Adv. Funct. Mater. 19, 983–998 (2009).

Liu, J., Scheerbaum, N., Weiss, S. K. & Gutfleisch, O. NiMn-Based alloys and composites for magnetically controlled dampers and actuators. Adv. Eng. Mater. 14, 653–667 (2012).

Karaman, I., Basaran, B., Karaca, H. E., Karsilayan, A. I. & Chumlyakov, Y. I. Energy harvesting using martensite variant reorientation mechanism in a NiMnGa magnetic shape memory alloy. Appl. Phys. Lett. 90, 172505 (2007).

Gschneidner, K. A. Jr., Pecharsky, V. K. & Tsokol, A. O. Recent developments in magnetocaloric materials. Rep. Progr. Phys. 68, 1479–1539 (2005).

Gutfleisch, O. et al. Magnetic materials and devices for the 21st century: stronger, lighter and more energy efficient. Adv. Mater. 23, 821–842 (2011).

Liu, E. K. et al. Stable magnetostructural coupling with tunable magnetoresponsive effects in hexagonal ferromagnets. Nat. Commun. 3, 873 (2012).

Koyama, K., Sakai, M., Kanomata, T. & Watanabe, K. Field-induced martensitic transformation in new ferromagnetic shape memory compound Mn1.07Co0.92Ge. Jpn. J. Appl. Phys. 43, 8036–8039 (2004).

Krenke, T. et al. Ferromagnetism in the austenitic and martensitic states of Ni-Mn-In alloys. Phys. Rev. B 73, 174413 (2006).

Mañosa, L. et al. Giant solid-state barocaloric effect in the Ni-Mn-In magnetic shape-memory alloy. Nat. Mater. 9, 478–481 (2010).

Zhang, C. L. et al. Magnetostructural phase transition and magnetocaloric effect in off-stoichiometric Mn1.9-xNixGe alloys. Appl. Phys. Lett. 93, 122505 (2008).

Trung, N. T. et al. From single- to double-first-order magnetic phase transition in magnetocaloric Mn1−xCrxCoGe compounds. Appl. Phys. Lett. 96, 162507 (2010).

Trung, N. T., Zhang, L., Caron, L., Buschow, K. H. J. & Brück, E. Giant magnetocaloric effects by tailoring the phase transitions. Appl. Phys. Lett. 96, 172504 (2010).

Liu, E. K. et al. Vacancy-tuned paramagnetic/ferromagnetic martensitic transformation in Mn-poor Mn1−xCoGe alloys. Europhys. Lett. 91, 17003 (2010).

Johnson, V. Diffusionless orthorhombic to hexagonal transitions in ternary silicides and germanides. Inorg. Chem. 14, 1117–1120 (1975).

Bażela, W., Szytuła, A., Todorovć, J., Tomkowicz, Z. & Zięba, A. Crystal and magnetic structure of NiMnGe. Phys. Status Solidi A 38, 721–729 (1976).

Fjellvåg, H. & Andresen, A. F. On the crystal structure and magnetic properties of MnNiGe. J. Magn. Magn. Mater. 50, 291–297 (1985).

Kanomata, T. et al. Magneto-volume effect of MnCo1−xGe (00.2). J. Magn. Magn. Mater. 131, 140–144 (1995).

Kanematsu, K. Covalent bond and spin scheme in the intermetallic compound with B82 type. Jpn. J. Appl. Phys. 17, 85–93 (1962).

Austin, A. E. & Adelson, E. X-ray spectroscopic studies of bonding in transition metal germanides. J. Solid State Chem. 1, 229–236 (1970).

Choudhury, D., Suzuki, T., Tokura, Y. & Taguchi, Y. Tuning structural instability toward enhanced magnetocaloric effect around room temperature in MnCo1−xZnxGe. Sci. Rep. 4, 7544 (2014).

Samanta, T., Dubenko, I., Quetz, A., Stadler, S. & Ali, N. Giant magnetocaloric effects near room temperature in Mn1−xCuxCoGe. Appl. Phys. Lett. 101, 242405 (2012).

Caron, L., Trung, N. T. & Brück, E. Pressure-tuned magnetocaloric effect in Mn0.93Cr0.07CoGe. Phys. Rev. B 84, 020414(R) (2011).

Liu, E. K. et al. Giant magnetocaloric effect in isostructural MnNiGe-CoNiGe system by establishing a Curie-temperature window. Appl. Phys. Lett. 102, 122405 (2013).

Wei, Z. Y. et al. Unprecedentedly wide Curie-temperature windows as phase-transition design platform for tunable magneto-multifunctional materials. Adv. Electron. Mater. 1, 1500076 (2015).

Johnson, V. & Fredbrick, C. G. Magnetic and crystallographic properties of ternary manganese silicides with ordered Co2P structure. Phys. Status Solidi A 20, 331 (1973).

Duraj, R. & Zach, R. Magnetic phase transitions in NiMnSinGe1-n and NiMn1-tTitGe systems under pressure. J. Magn. Magn. Mater. 73, 69–78 (1988).

Li, Y. et al. Structural transitions, magnetic properties and electronic structures of Co(Fe)-doped MnNiSi compounds. J. Appl. Phys. 117, 17C117 (2015).

Zhang, C. L. et al. The tunable magnetostructural transition in MnNiSi-FeNiGe system. Appl. Phys. Lett. 103, 132411 (2013).

Samanta, T. et al. Hydrostatic pressure-induced modifications of structural transitions lead to large enhancements of magnetocaloric effects in MnNiSi-based systems. Phys. Rev. B 91, 020401(R) (2015).

Samanta, T. et al. Effects of hydrostatic pressure on magnetostructural transitions and magnetocaloric properties in (MnNiSi)1−x(FeCoGe)x . J. Appl. Phys. 117, 123911 (2015).

Zhang, C. L. et al. Magnetostructural transition and magnetocaloric effect in MnNiSi-Fe2Ge system. Appl. Phys. Lett. 107, 212403 (2015).

Kanematsu, K., Ohoyama, T. & Yasukochi, K. Magnetic property of (Co, Ni)1.67Ge. J. Phys. Soc. Jpn. 17, 932 (1962).

Samanta, T. et al. Mn1−xFexCoGe: A strongly correlated metal in the proximity of a noncollinear ferromagnetic state. Appl. Phys. Lett. 103, 042408 (2013).

Barcza, A., Gercsi, Z., Knight, K. S. & Sandeman, K. G. Giant magnetoelastic coupling in a metallic helical metamagnet. Phys. Rev. Lett. 104, 247202 (2010).

Zhang, H. et al. Giant rotating magnetocaloric effect induced by highly texturing in polycrystalline DyNiSi compound. Sci. Rep. 5, 11929 (2015).

Huang, L., Cong, D. Y., Suo, H. L. & Wang, Y. D. Giant magnetic refrigeration capacity near room temperature in Ni40Co10Mn40Sn10 multifunctional alloy. Appl. Phys. Lett. 104, 132407 (2014).

Wei, Z. Y. et al. Realization of multifunctional shape-memory ferromagnets in all-d-metal Heusler phases. Appl. Phys. Lett. 107, 022406 (2015).

Samanta, T. et al. Magnetostructural phase transitions and magnetocaloric effects in MnNiGe1−xAlx . Appl. Phys. Lett. 100, 052404 (2012).

Wang, Z. L. et al. First-order magnetostructural transformation in Fe doped Mn-Co-Ge alloys. J. Alloys Comp. 577, 486–490 (2013).

Szytuła, A. et al. Crystal and magnetic structure of CoMnGe, CoFeGe, FeMnGe and NiFeGe. J. Magn. Magn. Mater. 25, 176–186 (1981).

Pecharsky, V. K. & Gschneidner, K. A. Jr. Tunable magnetic regenerator alloys with a giant magnetocaloric effect for magnetic refrigeration from ~20 to ~290 K. Appl. Phys. Lett. 70, 3299 (1997).

Caron, L. et al. On the determination of the magnetic entropy change in materials with first-order transitions. J. Magn. Magn. Mater. 321, 3559–3566 (2009).

Acknowledgements

This work is sponsored by National Natural Science Foundation of China (Grant No: 51271093, 51571121), Fundamental Research Funds for the Central Universities (Grant No: 30920140111010), Jiangsu Natural Science Foundation for Distinguished Young Scholars (Grant No: BK20140035), Cooperative Innovation Fund of Jiangsu Province (Grant No: BY2014004-01) and Qing Lan Project of Jiangsu Province. It is also funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Contributions

J.L. and F.X. proposed the idea, J.L. prepared the samples, G.P. carried out the magnetic measurement, I.A.S. and N.U.H. performed the DSC measurement, J.L. and Y.Y.G. analyzed the data, Y.Y.G. and G.Z.X. provided fruitful discussions.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Liu, J., Gong, Y., Xu, G. et al. Realization of magnetostructural coupling by modifying structural transitions in MnNiSi-CoNiGe system with a wide Curie-temperature window. Sci Rep 6, 23386 (2016). https://doi.org/10.1038/srep23386

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep23386

This article is cited by

-

Realization of Magnetostructural Transition and Magnetocaloric Properties of Ni–Mn–Mo–Sn Heusler Alloys

Journal of Superconductivity and Novel Magnetism (2019)

-

Magnetostructural transformation and magnetocaloric effect of Sn-bonded Mn0.66Fe0.34Ni0.66Fe0.34Si0.66Ge0.34 composite

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.