Abstract

Currently, finding high capacity adsorbents with large selectivity to capture Xe is still a great challenge. In this work, nitrogen-doped porous carbons were prepared by programmable temperature carbonization of zeolitic imidazolate framework-8 (ZIF-8) and ZIF-8/xylitol composite precursors and the resultant samples are marked as Carbon-Z and Carbon-ZX, respectively. Further adsorption measurements indicate that ZIF-derived nitrogen-doped Carbon-ZX exhibits extremely high Xe capacity of 4.42 mmol g−1 at 298 K and 1 bar, which is higher than almost all other pristine MOFs such as CuBTC, Ni/DOBDC, MOF-5 and Al-MIL-53, and even more than three times of the matrix ZIF-8 at similar conditions. Moreover, Carbon-ZX also shows the highest Xe/N2 selectivity about ~120, which is much larger than all other reported MOFs. These remarkable features illustrate that ZIF-derived nitrogen-doped porous carbon is an excellent adsorbent for Xe adsorption and separation at room temperature.

Similar content being viewed by others

Introduction

Noble gas xenon plays an important role in human industrial development and has increasingly extensive applications in aspects of lighting1, medicine2,3, nuclear magnetic resonance4 and so on. In order to obtain pure Xe for further utilization, the energy-intensive cryogenic fractional distillation was often used to concentrate the noble gas Xe from air. Alternatively, researchers have also made great efforts to adopt various kinds of absorbents to study Xe adsorption5,6,7,8. However, Xe has a very low concentration (0.086 ppmv) in air, and the traditional adsorbents like zeolites hold only very low Xe uptake9, which leads to a great challenge for Xe adsorption and separation. Therefore, finding high capacity adsorbents with large selectivity to capture Xe (including adsorption and separation) is very important and significant.

Recently, metal-organic frameworks (MOFs) and covalent-organic polymers (COPs), as a new class of porous materials, have attracted enormous attention in the field of gas adsorption and separation owing to their tunable pore structures, modified functional groups, multidimensional networks and high porosity & BET surface areas etc10,11,12,13. Thallapally et al.14,15,16,17 carried out a series of experiments to explore Xe adsorption capacity on MOFs, and found that Ni/DOBDC with high surface area, uniform porosity and polarization of metal cations exhibits a large Xe uptake of 4.16 mol kg−1 at 1 bar and 298 K, which is higher than that of activated charcoal17. Besides, Greathouse et al.5,18 used computational methods to study Xe adsorption/separation from air on several kinds of MOFs, and explored the effects of pore size and framework topology on noble gas selectivity. Similarly, Snurr et al.19 performed grand canonical Monte Carlo (GCMC) simulations to predict Xe uptake and Xe/Kr separation, and further screened the promising MOFs for Xe/Kr adsorption and separation among 137000 hypothetical MOFs20. Moreover, some other groups6,21 also investigated Xe adsorption and separation on MOFs containing open metal sites. It is still a great challenge to search for this kind of absorbent with both high capacity and excellent selectivity.

Nevertheless, Ben et al.22,23 found that the fully carbonized PAF-1-450 shows not only high CO2 capacity of 4.5 mmol g−1 at 273 K and 1 bar, but also large selectivity of 209 for a 15/85 CO2/N2 mixture, which was greatly better than the matrix PAF-1, because the carbonization approach can achieve dehydrogenation of phenyl rings in PAF-1, and efficiently decrease the excluded effects of hydrogen atoms of phenyl rings on the gas molecules adsorbed. Interestingly, the recently reported MOF-derived nitrogen-doped porous carbons not only demonstrate excellent electrochemical performance as electrode materials24,25,26, but also exhibit the improved gas adsorption capacity for H2 and CO227,28.

In this work, we adopted zeolitic imidazolate framework-8 (ZIF-8) and ZIF-8/xylitol composite as precursors to prepare nitrogen-doped porous carbons and further investigated the Xe adsorption and separation in the nitrogen-doped carbons. For comparison, we also explored the Xe adsorption and separation in the matrix ZIF-8. In addition, our previous GCMC simulations suggest that CuBTC among several representative MOFs and COFs shows the highest Xe uptake of 3.60 mmol g−1 at 1 bar and 298 K29. Therefore, we also experimentally synthesized the CuBTC material for Xe adsorption and separation30. On the one hand, we can confirm the rationality and accuracy of the GCMC prediction of Xe adsorption on CuBTC. On the other hand, we can demonstrate if the ZIF-derived nitrogen-doped porous carbon is better than CuBTC material for Xe adsorption or not. For discrimination, we marked the ZIF-8 derived nitrogen-doped carbon as Carbon-Z and the ZIF-8/xylitol composite derived nitrogen-doped carbon as Carbon-ZX. The detailed synthesis process was presented in elsewhere24,26,30 and also in Supporting Information.

Results and Discussion

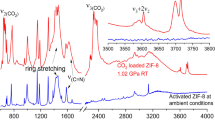

Figure 1(a,b) displays the SEM images of Cu-BTC and ZIF-8 with their specific crystal appearance, which can be confirmed by the PXRD in Figure S1. It can be seen that the patterns agree well with the simulation peaks, meaning no impurity and a high purity phase. Figure 1(c,d) shows amorphous morphology of Carbon-Z and Carbon-ZX which coincides with their PXRD in Figure S2 with two typical peaks 2 θ ≈ 23° and 43° ascribed to the (002) and (101) planes of graphitic carbon31. Raman results in Figure S3 indicate the typical G band and D band, which originate from ideal sp2 carbons vibration in plane and defected carbons, respectively. Then, IG/ID values of both Carbon-Z and Carbon-ZX are ~1.02, revealing the existence of graphitic and disordered structures in ZIF-derived porous carbons32,33. Besides, 2D peak also demonstrates the stack of graphite layer to some extent33,34,35. X-ray photoelectron spectroscopy (XPS) was also used to determine nitrogen content and found that the nitrogen contents of Carbon-Z and Carbon-ZX are 2.99% and 4.06%, respectively (Figure S4). Besides, Figure S4 also shows tthree different nitrogen types in Carbon-Z and Carbon-ZX, including pyridinic nitrogen, quaternary nitrogen and pyrrolic nitrogen27, implying the different bonding configurations in ZIF-derived nitrogen-doped porous carbons. Although there is no nitrogen element in xylitol, Carbon-ZX shows a higher nitrogen content than Carbon-Z, probably because the premelting and polymerization of xylitol molecules around ZIF-8 surface can protect the nitrogen losing in process of carbonization26.

Adsorption–desorption isotherms of nitrogen at 77 K were used to further study the BET surface area and total pore volume by ASAP 2020 analyzer, and shown in Fig. 2. The porosity parameters are listed in Table 1. Obviously, Cu-BTC, Carbon-Z and Carbon-ZX exhibit type-I isotherm with almost all micropores (see Fig. 2b), while ZIF-8 displays type-IV isotherm with clear hysteresis hoop according to IUPAC classification36. Pore size distributions in Fig. 2 indicate that ZIF-8 possesses hierarchical pore structure including micropores less than 2 nm and meso- & macropores larger than 10 nm, while Cu-BTC only holds the micropore less than 1 nm, and both Carbon-Z and Carbon-ZX have micropores less than 2 nm. ZIF-8 holds the high surface area of 1321 m2g−1, while ZIF-8 derived Carbon-Z shows the smaller BET of 603 m2g−1, possibly owing to the partial collapse of skeleton in the process of heating. Surprisingly, compared with Carbon-Z, introducing additional carbon source ‘xylitol’ apparently improves the BET and pore volumes of Carbon-ZX (see Table 1). This possible reason is that in carbonization process, xylitol absorbed on ZIF-8 forms a premelting layer around ZIF-8 surface to keep skeletal integrity of product, which causes that Carbon-ZX possesses larger BET of 1470 m2g−1 and pore volume of 0.68 cm3g−1, compared to Carbon-Z. The observation is in good agreement with literature25,37.

Xe adsorption measurements at low pressure and 298 K were conducted using ASAP 2020 equipped with a constant temperature device by circulating water and glycol at 1:1 ratio, and the Xe adsorption isotherms are shown in Fig. 3, where all adsorption isotherms increase with pressure with no saturation. Interestingly, experimental uptake of Xe in Cu-BTC excellently matches with the GCMC simulation data29, suggesting that GCMC simulation is a powerful tool to predict the gas adsorption with high accuracy and rationality to some extent. However, Xe adsorption capacity of ZIF-8 was over-predicted in simulation way, which is largely higher than experimental results. This over-prediction phenomenon for gas capture on ZIF-8 also occurred in literature5, possibly owing to the crystal defects or marcopores existence of experimental product which are unfavorable for adsorption in practice. Compared to ZIF-8, Cu-BTC possesses higher Xe capacity of 3.39 mmol g−1 at 1 bar and 298 K, which is ascribed to open metal sites with polarity in Cu-BTC16,20.

It is noteworthy that Xe capacity of Carbon-ZX reaches 4.42 mmol g−1 at 1 bar and 298 K, which is a triple improvement compared to its matrix ZIF-8 (see in Table 1), although ZIF-8 and Carbon-ZX hold the similar BET surface area. This observation sufficiently indicates that the carbonization approach can efficiently achieve dehydrogenation of ZIF materials, and enhance the affinity of samples for Xe molecules by eliminating the excluded effects from hydrogen atoms of aromatic rings23,28. On the other hand, nitrogen-doping would lead to the asymmetrical distribution of charges on the carbon surface38,39, which also further enhances the electrostatic attraction between the charges on nitrogen-doped porous carbon surfaces and polarizable Xe molecules22,40. The synergistic effects of two reasons above result in the excellent performance of Carbon-ZX for Xe adsorption22,41.

Actually, Xe adsorption capacity of 4.42 mmol g−1 at 298 K and 1 bar for Carbon-ZX is not only higher than Cu-BTC, but also larger than almost all other pristine MOFs, including Ni/DOBDC of 4.16 mmol g−1, MOF-5 of 1.97 mmol g−1 under the same conditions17, monohalogenated IRMOF-2 series of 1.5–2.0 mmol g−1 at 292 K and 1 bar42, Al-MIL-53 of 2.0 mmol g−1 at 308 K and 1 bar5, CC3 of 2.69 mmol g−1 at 298 K and 1 bar7. However, Xe capacity of Carbon-ZX is slightly smaller than the value of 4.88 mmol g−1 for Ag-modified Ag@MOF-74Ni15. In short, ZIF-derived nitrogen-doped porous Carbon-ZX is an excellent candidate for Xe adsorption at low pressure and room temperature.

Besides Xe adsorption, separation of Xe from mixtures is another important issue. Accordingly, we used ideal adsorption solution theory (IAST) as a credible tool to predict the gas selectivity43,44,45,46. Considering the fact that Xe has a very small concentration in air, therefore we plan to explore the selectivity for Xe/CO2 and Xe/N2 at the small ratio 1/99. Due to the requirement of IAST calculation, we also measured adsorption of CO2 and N2 adsorption in four samples at 298 K and their isotherms were shown in Fig. 4. The calculated selectivities for Xe/CO2 and Xe/N2 at the ratio of 1/99 were demonstrated in Fig. 5.

Figure 4 shows that ZIF-8 possesses the lowest adsorption for both CO2 and N2. Actually, the CO2 adsorption capacity of ZIF-8 at 1 bar coincides with the data reported in literature47. It is noted that Cu-BTC shows the highest CO2 adsorption at p > 0.5 bar compared with others, primarily attributed to the interactions between quadrupolar CO2 molecules and positive charges in unsaturated metal sites48. Furthermore, except Cu-BTC, both CO2 and N2 adsorption capacity follows the order of Carbon-ZX > Carbon-Z > ZIF-8, which means that ZIF-derived nitrogen-doped porous carbons hold remarkable property of gas adsorption.

Figure 5 shows the selectivity of four samples for Xe/CO2 and Xe/N2 at the same ratio 1/99. Clearly, Carbon-ZX exhibits the highest selectivity for both Xe/CO2 and Xe/N2 mixtures. With the increase of pressure, Sads(Xe/CO2) of Carbon-ZX gradually drops, while Sads(Xe/N2) almost keeps the same value about ~120.0 which is much higher than almost all other MOFs, for example, S = 11.7 ~ 32.0 of NOTT series, S = 5.3 ~ 18.2 of MOF-74 series, S = 44.0 of PCN-1421, and S < 10.0 of other MOFs including IRMOF-1 and UMCM-129. Moreover, the selectivity trends for Xe/N2 follow the order of Carbon-ZX > Carbon-Z > CuBTC > ZIF-8 just like gas adsorption capacity ranking. Actually, Carbon-ZX possesses not only the highest Xe capacity but also the highest selectivities for both Xe/CO2 and Xe/N2 mixtures among four samples studied, which indicates that the ZIF-derived nitrogen-doped porous carbon is an excellent candidate in potential noble gas adsorption and separation from the air.

In summary, we have successfully synthesized nitrogen-doped porous carbons (Carbon-Z and Carbon-ZX) by using ZIF-8 and ZIF-8/xylitol composite as matrix. It is found that the prepared nitrogen-doped Carbon-ZX shows much better Xe adsorption properties, compared to matrix ZIF-8. Actually, the nitrogen-doped Carbon-ZX exhibits not only extremely high Xe adsorption capacity of 4.42 mmol g−1 at room temperature and 1 bar, which is larger than almost all other MOFs, but also excellent selectivity of ~120 for Xe/N2 at the same ratio 1/99, which is mainly attributed to the asymmetrical charge distribution on the nitrogen-doped porous carbon network and elimination of the excluded effects of H atoms on aromatic rings for the guests via carbonization. In previous reports, ZIF-derived nitrogen-doped porous carbons have shown excellent performance in supercapacitors and oxygen reduction reaction of fuel cells, while this work demonstrates that ZIF-derived nitrogen-doped carbon is also an excellent candidate for gas adsorption and separation, especially for noble gas Xe.

Additional Information

How to cite this article: Zhong, S. et al. ZIF-Derived Nitrogen-Doped Porous Carbons for Xe Adsorption and Separation. Sci. Rep. 6, 21295; doi: 10.1038/srep21295 (2016).

References

Bussiahn, R., Gortchakov, S., Lange, H. & Uhrlandt, D. Experimental and theoretical investigations of a low-pressure He–Xe discharge for lighting purpose. J. Appl. Phys. 95, 4627–4634 (2004).

Salerno, M. et al. Hyperpolarized noble gas MR imaging of the lung: potential clinical applications. Eur. J. Radiol. 40, 33–44 (2001).

Liu, L., Xu, Y. & Tang, P. Mechanistic insights into xenon inhibition of NMDA receptors from MD simulations. J. Phys. Chem. B. 114, 9010–9016 (2010).

Raftery, D., MacNamara, E., Fisher, G., Rice, C. V. & Smith, J. Optical pumping and magic angle spinning: Sensitivity and resolution enhancement for surface NMR obtained with laser-polarized xenon. J. Am. Chem. Soc. 119, 8746–8747(1997).

Parkes, M. V., Staiger, C. L., Perry, I. V., Allendorf, M. D. & Greathouse, J. A. Screening metal–organic frameworks for selective noble gas adsorption in air: effect of pore size and framework topology. Phys. Chem. Chem. Phys. 15, 9093–9106 (2013).

Hulvey, Z. et al. Noble gas adsorption in copper trimesate, HKUST-1: an experimental and computational study. J. Phys. Chem. C. 117, 20116–20126 (2013).

Chen, L. et al. Separation of rare gases and chiral molecules by selective binding in porous organic cages. Nat. Mater. 13, 954–960 (2014).

Banerjee, D. et al. Potential of metal–organic frameworks for separation of xenon and krypton. Acc. Chem. Res. 48, 211–219 (2014).

Bazan, R. E., Bastos-Neto, M., Moeller, A., Dreisbach, F. & Staudt, R. Adsorption equilibria of O2, Ar, Kr and Xe on activated carbon and zeolites: single component and mixture data. Adsorption. 17, 371–383 (2011).

Millward, A. R. & Yaghi, O. M. Metal-organic frameworks with exceptionally high capacity for storage of carbon dioxide at room temperature. J. Am. Chem. Soc. 127, 17998–17999(2005).

Banerjee, R. et al. Control of pore size and functionality in isoreticular zeolitic imidazolate frameworks and their carbon dioxide selective capture properties. J. Am. Chem. Soc. 131, 3875–3877 (2009).

Xiang, Z. & Cao, D. Porous covalent–organic materials: synthesis, clean energy application and design. J. Mater. Chem. A. 1, 2691–2718 (2013).

Xiang, Z. et al. Covalent-organic polymers for carbon dioxide capture. J. Mater. Chem. 22, 22663–22669 (2012).

Fernandez, C. A., Liu, J., Thallapally, P. K. & Strachan, D. M. Switching Kr/Xe selectivity with temperature in a metal–organic framework. J. Am. Chem. Soc. 134, 9046–9049 (2013).

Liu, J., Strachan, D. M. & Thallapally, P. K. Enhanced noble gas adsorption in Ag@ MOF-74Ni. Chem. Commun. 50, 466–468 (2014).

Liu, J., Thallapally, P. K. & Strachan, D. Metal–organic frameworks for removal of Xe and Kr from nuclear fuel reprocessing plants. Langmuir. 28, 11584–11589 (2012).

Thallapally, P. K., Grate, J. W. & Motkuri, R. K. Facile xenon capture and release at room temperature using a metal–organic framework: a comparison with activated charcoal. Chem. Commun. 48, 347–349 (2012).

Greathouse, J. A., Kinnibrugh, T. L. & Allendorf, M. D. Adsorption and separation of noble gases by IRMOF-1: grand canonical monte carlo simulations. Ind. Eng. Chem. Res. 48, 3425–3431 (2009).

Ryan, P., Farha, O. K., Broadbelt, L. J. & Snurr, R. Q. Computational screening of metal‐organic frameworks for xenon/krypton separation. AIChE J. 57, 1759–1766 (2011).

Sikora, B. J., Wilmer, C. E., Greenfield, M. L. & Snurr, R. Q. Thermodynamic analysis of Xe/Kr selectivity in over 137000 hypothetical metal–organic frameworks. Chem. Sci. 3, 2217–2223 (2012).

Perry, I. V. et al. Noble gas adsorption in metal–organic frameworks containing open metal sites. J. Phys. Chem. C. 118, 11685–11698 (2014).

Ben, T. et al. Selective adsorption of carbon dioxide by carbonized porous aromatic framework (PAF). Energy Environ. Sci. 5, 8370–8376 (2012).

Ben, T. et al. Gas storage in porous aromatic frameworks (PAFs). Energy Environ. Sci. 4, 3991–3999 (2011).

Zhang, L. et al. Highly graphitized nitrogen-doped porous carbon nanopolyhedra derived from ZIF-8 nanocrystals as efficient electrocatalysts for oxygen reduction reactions. Nanoscale. 6, 6590–6602 (2014).

Zhang, P. et al. ZIF-derived in situ nitrogen-doped porous carbons as efficient metal-free electrocatalysts for oxygen reduction reaction. Energy Environ. Sci. 7, 442–450 (2014).

Zhong, S., Zhan, C. & Cao, D. Zeolitic imidazolate framework-derived nitrogen-doped porous carbons as high performance supercapacitor electrode materials. Carbon. 85, 51–59 (2015).

Aijaz, A., Fujiwara, N. & Xu, Q. From metal–organic framework to nitrogen-decorated nanoporous carbons: high CO2 uptake and efficient catalytic oxygen reduction. J. Am. Chem. Soc. 136, 6790–6793 (2014).

Jiang, H. et al. From metal–organic framework to nanoporous carbon: toward a very high surface area and hydrogen uptake. J. Am. Chem. Soc. 133, 11854–11857 (2011).

Wang, Q., Wang, H., Peng, S., Peng, X. & Cao, D. Adsorption and separation of Xe in metal–organic frameworks and covalent–organic Materials. J. Phys. Chem. C. 118, 10221–10229 (2014).

Küsgens, P. et al. Characterization of metal-organic frameworks by water adsorption. Micropor. Mesopor. Mater. 120, 325–330 (2009).

Belin, T. & Epron, F. Characterization methods of carbon nanotubes: a review. Mater. Sci. Eng. B. 119, 105–118 (2005).

Pimenta, M. et al. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 9, 1276–1290 (2007).

Ferrari, A. C. et al. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 97, 187401 (2006).

Pachfule, P., Dhavale, V. M., Kandambeth, S., Kurungot, S. & Banerjee, R. Porous‐organic‐framework‐templated nitrogen‐rich porous carbon as a more proficient electrocatalyst than Pt/C for the electrochemical reduction of oxygen. Chem. Eur. J. 19, 974–980 (2013).

Pachfule, P., Biswal, B. P. & Banerjee, R. Control of porosity by using isoreticular zeolitic imidazolate frameworks (IRZIFs) as a template for porous carbon synthesis. Chem. Eur. J. 18, 11399–11408 (2012).

Sing, K. S. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 57, 603–619 (1985).

Zhang, P., Sun, F., Shen, Z. & Cao, D. ZIF-derived porous carbon: a promising supercapacitor electrode material. J. Mater. Chem. A. 2, 12873–12880 (2014).

Ma, C. C., Shao, X. H. & Cao, D. P. Nitrogen-doped graphene nanosheets as anode materials for lithium ion batteries: A first principles study. J. Mater. Chem. 22, 8911–8915 (2012).

Xiang, Z. H. et al. Nitrogen-doped holey graphitic carbon from 2D covalent organic polymers for oxygen reduction. Adv. Mater. 26, 3315–3320 (2014).

Minemoto, S. & Sakai, H. Measuring polarizability anisotropies of rare gas diatomic molecules by laser-induced molecular alignment technique. J. Chem. Phys. 134, 214305 (2011).

Huang, L., Xiang, Z. & Cao, D. A porous diamond carbon framework: a new carbon allotrope with extremely high gas adsorption and mechanical properties. J. Mater. Chem. A. 1, 3851–3855 (2013).

Meek, S. T., Teich-McGoldrick, S. L., Perry, J. J., Greathouse, J. A. & Allendorf, M. D. Effects of polarizability on the adsorption of noble gases at low pressures in monohalogenated isoreticular metal–organic frameworks. J. Phys. Chem. C. 116, 19765–19772 (2012).

Zhang, Z. et al. Enhancement of CO2 adsorption and CO2/N2 selectivity on ZIF‐8 via postsynthetic modification. AIChE J. 59, 2195–2206 (2013).

Myers, A. & Prausnitz, J. M. Thermodynamics of mixed‐gas adsorption. AIChE J. 11, 121–127 (1965).

Xiang, Z., Peng, X., Cheng, X., Li, X. & Cao, D. CNT@ Cu3 (BTC)2 and metal–organic frameworks for separation of CO2/CH4 mixture. J. Phys. Chem. C. 115, 19864–19871 (2011).

Xiang, Z. et al., Systematic tuning and multifunctionalization of covalent organic polymers for enhanced carbon capture. J. Am. Chem. Soc., 137, 13301–13307 (2015).

Pérez-Pellitero, J. et al. Adsorption of CO2, CH4 and N2 on zeolitic imidazolate frameworks: experiments and simulations. Chem. Eur. J. 16, 1560–1571 (2010).

Liang, Z., Marshall, M. & Chaffee, A. L. CO2 adsorption-based separation by metal organic framework (Cu-BTC) versus zeolite (13X). Energy Fuels. 23, 2785–2789 (2009).

Acknowledgements

This work is supported by NSF of China (No. 91334203, 21274011), National 863 Program (2013AA031901) and Outstanding Talents Plan from BUCT.

Author information

Authors and Affiliations

Contributions

D.C. produced the original idea, designed experiments, analysed the data and wrote the manuscript. S.Z. performed all experiemts and wrote the manuscript, Q.W. analysed the data and revised the manuscript. All authors have reviewed, discussed and approved the results and conclusions of this article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhong, S., Wang, Q. & Cao, D. ZIF-Derived Nitrogen-Doped Porous Carbons for Xe Adsorption and Separation. Sci Rep 6, 21295 (2016). https://doi.org/10.1038/srep21295

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep21295

This article is cited by

-

Kinetic, equilibrium, adsorption mechanisms of cationic and anionic dyes on N-doped porous carbons produced from zeolitic-imidazolate framework

International Journal of Environmental Science and Technology (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.