Abstract

We demonstrate the electro-thermal control of aluminum-doped zinc oxide (Al:ZnO) /vanadium dioxide (VO2) multilayered thin films, where the application of a small electric field enables precise control of the applied heat to the VO2 thin film to induce its semiconductor-metal transition (SMT). The transparent conducting oxide nature of the top Al:ZnO film can be tuned to facilitate the fine control of the SMT of the VO2 thin film and its associated properties. In addition, the Al:ZnO film provides a capping layer to the VO2 thin film, which inhibits oxidation to a more energetically favorable and stable V2O5 phase. It also decreases the SMT of the VO2 thin film by approximately 5–10 °C because of an additional stress induced on the VO2 thin film and/or an alteration of the oxygen vacancy concentration in the VO2 thin film. These results have significant impacts on technological applications for both passive and active devices by exploiting this near-room-temperature SMT.

Similar content being viewed by others

Introduction

Vanadium dioxide (VO2) in thin-film and nanostructured forms has been intensely studied in recent years because of the presence of a metal-insulator (MIT) or semiconductor-metal transition (SMT) near room temperature (RT) at ~68 °C in bulk form, which is also accompanied by a structural phase transition1,2,3,4,5,6,7. The crystal symmetry of VO2 changes from a P21/c (monoclinic semiconducting phase) to a P42/mnm (rutile metallic phase) space symmetry when VO2 traverses from below to above the SMT. This transition can be temperature-1, voltage-8,9,10 and photo-induced11 in this strongly electron-correlated material. The successful growth and study of VO2 thin films has been demonstrated using several deposition techniques, including reactive sputtering12, atomic layer deposition (ALD)13, pulsed laser deposition (PLD)14, chemical vapor deposition15, electron beam evaporation16, the sol-gel process17 and thermal evaporation18. These and many other studies have provided a better understanding of the SMT and VO2 properties; the oxygen vacancy concentration19 and strain20 play important roles, but many aspects remain unclear. A more thorough understanding of the SMT and VO2 properties will aid in the fine-tuning and control of the SMT so that it can be more reliably used for applications.

Technological applications in various passive and active devices have been developed based on this near-RT SMT. The most notable applications include low-loss plasmonics21, smart window coatings22, ultrafast optical switches and sensors11, new electronic devices such as Mott field effect transistors23 and uncooled bolometers for infrared imaging24. Smart devices, which use the large optical and electrical property changes of VO2, appear to be at the forefront of this field and are of particular interest here. For example, a smart energy-efficient window must satisfy a number of criteria, including high transmittance in the visible range (400–700 nm), low transmittance in the infrared range (3–50 μm) and variable transmittance in the near-infrared range (700–3,000 nm). This variable transmittance depends on whether the building interior must be heated or cooled, i.e., the window transmits (reflects) the near-infrared light if there is a heating (cooling) demand25 and it must be actively or passively modulated. In this paper, we discuss a possible thin-film platform in which to electro-thermally control the VO2 phase across its SMT, which enables modulation for smart window thin-film coatings and/or other technological devices.

Results

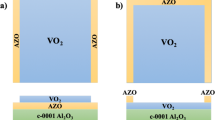

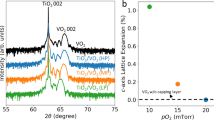

Epitaxial VO2 thin films were grown on c-plane (0001) sapphire (Al2O3) substrates using oxygen plasma-assisted pulsed laser deposition (PA-PLD). The SMT occurs near 50 °C, as confirmed with Raman spectroscopy and four-point probe electrical measurements, which are not shown here but can be found elsewhere in the literature26. The near-RT SMT of these VO2 thin films can be induced using the aforementioned techniques, most of which are external to the VO2 thin film and device. For example, the SMT is typically thermally induced using an external heater in contact with the VO2. However, the direct incorporation of a thin-film heater into a multilayered thin-film device has spatial and temporal advantages, low power requirements and fast response times27,28. Therefore, a thick film of Al:ZnO, which has unique transparent heater qualities29, was grown on top of the VO2 thin films using atomic layer deposition (ALD). Details on these Al:ZnO films can be found in the literature29,30,31. The ALD-grown Al:ZnO film is polycrystalline and the VO2 thin film has an epitaxial relationship with the sapphire substrate of (010)[100]VO2  (0001)[10-10]Al2O3 as confirmed via symmetric [Fig. 1(a)] and asymmetric [Fig. 1(b)] x-ray diffraction (XRD) scans.

(0001)[10-10]Al2O3 as confirmed via symmetric [Fig. 1(a)] and asymmetric [Fig. 1(b)] x-ray diffraction (XRD) scans.

(a) Symmetric θ-2θ and (b) asymmetric ϕ scans of the multilayered thin-film samples revealing the epitaxial relationship between the film layers and substrate. (c) Schematic and (d) cross-sectional SEM image of the multilayered thin-film samples composed of Au/Ti electrodes on Al:ZnO (370 nm)/VO2 (50 nm)/Al2O3 (0001) substrate.

Electrical contacts were fabricated on top of the Al:ZnO film along opposite edges of the 10 mm × 10 mm sample [see the multilayered thin-film sample schematic in Fig. 1(c)], such that the transparent heating properties of the Al:ZnO film could be used to induce the SMT in the underlying VO2 thin film. In addition to their transparency, the Al:ZnO films (with an Al:Zn ALD cycle ratio of 1:20) have a moderate thermal conductivity (4.2–4.3 W m−1 K−1), which facilitates heat transport to the VO2 thin film29. An infrared (IR) camera was used to measure the temperature distribution over the 1 cm2 area of the Al:ZnO/VO2 multilayered thin-film samples at different applied voltages and these measurements were corroborated via thermocouple measurements. Figure 2 shows the steady-state IR thermal images of the multilayered thin-film samples at applied voltages of 1–5 V. These steady-state temperatures were achieved within 2–5 minutes after applying the voltages, where the time rates of temperature increase are shown in Fig. 3(a); the final steady-state temperatures are plotted versus the applied voltage in Fig. 3(b). The temperature was measured at the center of the samples, where there is a fairly uniform temperature distribution across the entire surface, particularly at or below the SMT. Figure 4 shows this temperature gradient across the multilayered thin-film samples, which was measured between the electrodes from the upper left to the lower right [see Figs 1(c) and 2]. The SMT in these multilayered thin-film samples occurs at just under 3 V (discussed later), where the temperature gradient is ±1 °C across the sample. Smaller temperature gradients are expected by improving the electrodes because of the noticeable defects in the upper and lower left corners of the sample (see Fig. 2), which cause the temperature to decrease at the 0 mm end (see Fig. 4).

(a) Temperature versus time plots for the applied voltages in Fig. 2, where the steady-state final temperatures are achieved within 2–5 minutes. (b) Steady-state temperature versus the applied voltage, which shows the expected parabolic relationship between temperature and applied voltage. Measurements were taken with an IR thermal camera using the temperature at the center of the samples.

Temperature distribution across the sample images in Fig. 2, which are taken along the diagonal between the electrodes from the upper left to the lower right (12.8 mm in length).

A fairly uniform temperature distribution (±1 °C below 3 V) is found for the applied voltages studied: (a) 1.0 V, (b) 1.9 V, (c) 2.7 V, (d) 3.7 V, (e) 4.2 V and (f) 4.7 V.

The Al:ZnO film is heated because of the Joule heating effect, where the power converted to heat (and consequently the steady-state temperature) is proportional to the square of the applied voltage as shown in Fig. 3(b)9. This Joule heating effect can be reproducibly controlled using the Al:ZnO film properties, particularly the film thickness and amount of Al-doping (i.e., Al:Zn ALD cycle ratio), which govern the metallic behavior of the films based on the carrier concentration as we recently demonstrated29. These two parameters enable one to precisely tailor the amount of heat and temperature, where both thicker and more metallic-like films produce higher temperatures at lower applied voltages, an approach that has considerable advantages in device fabrication and operation.

The SMT of the VO2 thin film below the Al:ZnO film layer was tracked using various characterization techniques. Micro-Raman spectroscopy is suitable to distinguish the SMT in VO2. Below the transition, sharp Raman peaks (modes) are observed, which signifies the monoclinic semiconducting phase, whereas only a broadband emission is observed for the rutile metallic phase above the transition26,32. Many, but not all, of the possible Raman modes for the monoclinic semiconducting phase of VO2 were resolved in the RT spectra26,32,33,34,35. The inset of Fig. 5 shows the Raman spectra, which highlights the 196 and 224 cm−1 modes, for both VO2 phases: the semiconducting phase below the transition and the metallic phase above the transition. These two Raman modes were used to track the SMT in the VO2 thin film to determine the transition temperature of the Al:ZnO/VO2 device, which was found to be between 42 and 46 °C (see Fig. 5). Similar and corroborating results were obtained using an external heater below the sapphire substrate to increase the temperature of the VO2 thin film (not shown).

The 196 cm−1 and 224 cm−1 Raman modes of the VO2 monoclinic phase were tracked with respect to the temperature by applying voltage to the Al:ZnO/VO2 multilayered thin-film samples.

An SMT temperature between 42 and 46 °C was found, where the red dashed line is a guide to the eye, which indicates a T−5 power law dependence. (Inset) Raman spectra of the multilayered thin-film samples below (red line) and above the SMT (blue line), which show that only the modes of the monoclinic semiconducting phase are present below the SMT.

XRD was also used to track the SMT in the VO2 thin film as shown in Fig. 6 when voltages were applied to the Al:ZnO/VO2 multilayered thin-film device. The XRD results show that there is a sudden shift in the VO2 unit cell parameters at an SMT temperature of 43.5 °C, thus corroborating the Raman spectroscopy results. Below this temperature, the monoclinic VO2 (020) reflection is centered at 2θ = 39.962° and yields a lattice parameter of 0.2254 nm. The VO2 reflection suddenly shifts to a lower angle (2θ = 39.924°) above this temperature and yields an expanded lattice parameter of 0.2256 nm. These results are consistent with the bulk VO2 x-ray powder diffraction files (PDFs) for the monoclinic (01-082-0661) and rutile (03-065-9786) phases from the International Centre for Diffraction Data (ICDD) and published XRD studies in the literature36. The shift in the bulk VO2 structures amounts to ∆2θ = 0.09°, whereas only a shift of ∆2θ = 0.04° is observed in the multilayered thin-film device. This result is not surprising because the VO2 thin film is under stress due to the mismatch with the sapphire substrate and the Al:ZnO film on top of it. Furthermore, thermal expansion of the VO2 lattice cannot account for this shift. First, the peak shift is sudden and not gradual with increasing temperature. Second, the average thermal expansion of VO2 is αave = 5.70 × 10−6 K−1 (monoclinic structure) and 13.35 × 10−6 K−1 (rutile structure) at these temperatures37, which can only account for approximately 10% of the exhibited lattice expansion (i.e., αave must be an order of magnitude larger to be responsible for the observed XRD peak shift in the data).

Electrical transport measurements in the form of electrical resistance versus temperature plots are typically used to study the SMT of VO2 films. In this case, the VO2 thin film in the Al:ZnO/VO2 multilayered thin-film device is buried beneath the Al:ZnO film and therefore cannot be measured directly. However, the electrical resistance of the Al:ZnO film can be measured versus temperature using a four-point probe in the van der Pauw configuration and a resistive heater below the sapphire substrate. Figure 7 shows that indeed the SMT of the underlying VO2 thin film is manifest in the measurements of the Al:ZnO resistance, with the expected hysteresis during heating and cooling. Furthermore, an identical Al:ZnO film without the underlying VO2 thin film was measured for comparison and shows no hysteretic behavior.

Resistance versus temperature plots obtained from four-point probe electrical (I–V) measurements in the van der Pauw configuration.

The Al:ZnO/VO2 multilayered thin-film device shows the expected hysteresis of the VO2 SMT during heating (red) and cooling (blue). Measurements for an identical Al:ZnO film on sapphire without the VO2 thin film shows no hysteresis (green).

Interestingly, the growth of an Al:ZnO film on top of the VO2 thin film provides several advantages in addition to placing a thin-film heater in direct contact with the VO2 (previously mentioned), which creates a mechanism to finely control the heat applied to VO2 to induce the SMT. The thick Al:ZnO film also acts as a capping layer to the VO2 thin film and prevents the oxidation of VO2 to V2O5, which is the most energetically favorable and stable phase. Otherwise, over the lifetime of a device, the VO2 thin film will oxidize to become V2O5 and degrade the SMT and its associated properties. Another advantage of the thick Al:ZnO film is its ability to decrease the SMT of the VO2 thin film by approximately 5–10 °C compared to a VO2 thin film without an Al:ZnO capping film26. This phenomenon is thought to occur because of the additional stress on the VO2 thin film and/or an alteration of the oxygen vacancy concentration, which pushes the SMT to a lower temperature38.

In summary, the electro-thermal control of a multilayered Al:ZnO/VO2 thin-film device was demonstrated, where the SMT of the VO2 thin film was induced by applying a small potential (<3 V) across the Al:ZnO film. This electro-thermal energy provided by the Al:ZnO film can be finely tuned using its transparent conducting oxide properties to significantly control the VO2 SMT and its associated electrical and optical properties. The Al:ZnO film acts as a transparent window and heater, serves as a protective capping layer to the VO2 thin film and aids in decreasing the VO2 transition temperature. These results have important implications for the use of VO2 and Al:ZnO in technological applications, particularly active smart devices.

Methods

Fabrication of the samples

Epitaxial vanadium dioxide (VO2) thin films were grown on non-annealed c-plane (0001) sapphire (Al2O3) substrates (10 mm × 10 mm) at 550 °C using a Neocera pulsed laser deposition (PLD) system, which operated at a base pressure of 10−8 Torr. The V2O5 target material was ablated with a KrF excimer laser (λ = 248 nm, pulse width = 25 ns, energy = 220 mJ/pulse) at an angle of 45° with a repetition rate of 3 Hz and a spot size of approximately 2 mm × 4 mm, which resulted in an energy density of ~3 J cm−2. These 50 nm thick VO2 thin films, confirmed with x-ray reflectivity and cross-sectional scanning electron microscopy (SEM) [Fig. 1(d)], were grown at a rate of ~0.4 nm/min under a 150 W oxygen (O2) radio frequency plasma using ultra-high purity (99.994%) O2 gas at a working pressure of 3.0 × 10−5 Torr (i.e., plasma-assisted PLD). Further details on these VO2 thin films are discussed elsewhere26.

Aluminum-doped zinc oxide (Al:ZnO) thin films were grown on top of the epitaxial VO2 (020)m thin films using a Cambridge NanoTech Ultratech atomic layer deposition (ALD) system, which operated at a base pressure in the mid-10−3 Torr range. Ultra-high purity (99.999%) nitrogen (N2) gas, which constantly flowed at 20 sccm, was used to purge the chamber and as the carrier gas for the precursors: diethyl zinc [DEZ, Zn(C2H5)2], water (H2O) and trimethylaluminum [TMA, Al(CH3)3]. The Al:ZnO films were grown at 250 °C by alternating between 15 ms pulses of DEZ and H2O (with 5 s purges in between each) for 20 times (cycles) to obtain a zinc oxide film. After the 20th DEZ pulse, a 15 ms pulse of TMA was used for the aluminum dopant, which was followed by the 20th H2O pulse. This 20 cycle sequence defines a 1:20 Al:Zn ratio and consequently constitutes the Al:ZnO film used herein. In total, 3000 cycles were performed, which yielded a growth rate of ~0.12 nm per cycle and thus a total thickness of 370 nm [Fig. 1(d)]. Further details on these ALD pulsing sequences and Al:ZnO thin films are discussed elsewhere30,31.

Fabrication of the electrical contacts

45 nm gold (Au)/10 nm titanium (Ti) electrical contacts (1 mm × 10 mm) were deposited on top of the Al:ZnO/VO2 multilayered thin film on opposing sides of the 10 mm × 10 mm sample [Fig. 1(c)]. These contacts were deposited at RT with a growth rate of ~0.12 nm/sec in an AJA International electron beam evaporation system, which operated at a base pressure of 10−8 Torr.

SEM imaging techniques

A Hitachi SU8010 field-emission scanning electron microscope (FE-SEM) was used to obtain cross-sectional images of the multilayered Al:ZnO/VO2 thin-film device after cleaving it in half.

Raman spectroscopy characterization techniques

A Horiba LabRAM HR Evolution Raman spectrometer with a laser excitation wavelength (λ = 785 nm) in the near-infrared range was used because it has been shown to produce the clearest spectrum of Raman active modes for VO2 on sapphire compared to shorter wavelengths in the visible range35. This clearer spectrum is achieved because resonance fluorescence at these shorter visible wavelengths increases the background and overwhelms the signal from the VO2 thin film. The spectra were acquired for the Al:ZnO/VO2 thin-film device at various steady-state temperatures by applying a voltage across the electrical contacts on the Al:ZnO film and using an external resistive heater below the sapphire substrate to increase the temperature.

XRD characterization techniques

A standard high-resolution (0.0001°) four-circle x-ray diffractometer (XRD) with Cu Kα radiation and thin-film optics was used to characterize the microstructure of the Al:ZnO/VO2 thin-film device. Diffraction scans were acquired for the Al:ZnO/VO2 thin-film device at various steady-state temperatures by applying a voltage across the electrical contacts on the Al:ZnO film and using an external resistive heater below the sapphire substrate to increase the temperature.

Electrical transport characterization techniques

The temperature dependence of the electrical resistance of the multilayered Al:ZnO/VO2 thin-film device was measured using a four-point probe in the van der Pauw configuration, where the SMT of the VO2 was thermally induced with a resistive heater below the sapphire substrate. The four, 50 μm diameter probes contacted the Al:ZnO film surface, where current-voltage (I–V) measurements were acquired versus temperature using a Keithley 6220 Current Source applying 21 mA of direct current along one edge of the sample and a Keithley 2182A Nanovoltmeter measuring the potential across the other edge.

Additional Information

How to cite this article: Skuza, J. R. et al. Electro-thermal control of aluminum-doped zinc oxide/vanadium dioxide multilayered thin films for smart-device applications. Sci. Rep. 6, 21040; doi: 10.1038/srep21040 (2016).

References

Morin, F. J. Oxides which show a metal-to-insulator transition at the Neel temperature. Phys. Rev. Lett. 3, 34–36 (1959).

Berglund, C. & Jayaraman, A. Hydrostatic-pressure dependence of the electronic properties of VO2 near the semiconductor-metal transition temperature. Phys. Rev. 185, 1034–1039 (1969).

Dernier, P. D. & Marezio, M. Crystal structure of the low-temperature antiferromagnetic phase of V2O3 . Phys. Rev. B 2, 3771–3776 (1970).

Zylbersztejn, A. & Mott, N. F. Metal-insulator transition in vanadium dioxide. Phys. Rev. B 11, 4383–4395 (1975).

Mott, N. F. Metal-Insulator Transitions (Taylor & Francis, 1990).

Imada, M., Fujimori, A. & Tokura, Y. Metal-insulator transitions. Rev. Mod. Phys. 70, 1039–1263 (1998).

Qazilbash, M. M. et al. Correlated metallic state of vanadium dioxide. Phys. Rev. B 74, 205118 (2006).

Kim, H.-T. et al. Raman study of electric-field-induced first-order metal-insulator transition in VO2-based devices. Appl. Phys. Lett. 86, 242101 (2005).

Mun, B. S. et al. Role of Joule heating effect and bulk-surface phases in voltage-driven metal-insulator transition in VO2 crystal. Appl. Phys. Lett. 103, 061902 (2013).

Goldflam, M. D. et al. Voltage switching of a VO2 memory metasurface using ionic gel. Appl. Phys. Lett. 105, 041117 (2014).

Cavalleri, A. et al. Femtosecond structural dynamics in VO2 during an ultrafast solid-solid phase transition. Phys. Rev. Lett. 87, 237401 (2001).

Fuls, E. N., Hensler, D. H. & Ross, A. R. Reactively sputtered vanadium dioxide thin films. Appl. Phys. Lett. 10, 199–201 (1967).

Rampelberg, G. et al. Semiconductor-metal transition in thin VO2 films grown by ozone based atomic layer deposition. Appl. Phys. Lett. 98, 162902 (2011).

Borek, M., Qian, F., Nagabushnam, V. & Singh, R. K. Pulsed laser deposition of oriented VO2 thin films on R-cut sapphire substrates. Appl. Phys. Lett. 63, 3288–3290 (1993).

Takei, H. & Koide, S. Growth and electrical properties of vanadium-oxide single crystals by oxychloride decomposition method. J. Phys. Soc. Jpn. 21, 1010 (1966).

Leroy, J., Bessaudou, A., Cosset, F. & Crunteanu, A. Structural, electrical and optical properties of thermochromic VO2 thin films obtained by reactive electron beam evaporation. Thin Solid Films 520, 4823–4825 (2012).

Partlow, D. P., Gurkovich, S. R., Radford, K. C. & Denes, L. J. Switchable vanadium oxide films by a sol-gel process. J. Appl. Phys. 70, 443–452 (1991).

Cheng, C., Liu, K., Xiang, B., Suh, J. & Wu, J. Ultra-long, free-standing, single-crystalline vanadium dioxide micro/nanowires grown by simple thermal evaporation. Appl. Phys. Lett. 100, 103111 (2012).

Ruzmetov, D., Senanayake, S. D., Narayanamurti, V. & Ramanathan, S. Correlation between metal-insulator transition characteristics and electronic structure changes in vanadium oxide thin films. Phys. Rev. B 77, 195442 (2008).

Aetukuri, N. B. et al. Control of the metal-insulator transition in vanadium dioxide by modifying orbital occupancy. Nature Physics 9, 661–666 (2013).

Wang, L. et al. Surface plasmon polaritons in VO2 thin films for tunable low-loss plasmonic applications. Opt. Lett. 37, 4335–4337 (2012).

Granqvist, C. G. Transparent conductors as solar energy materials: A panoramic review. Sol. Energy Mater. Sol. Cells 91, 1529–1598 (2007).

Kittiwatanakul, S. et al. Transport behavior and electronic structure of phase pure VO2 thin films grown on c-plane sapphire under different O2 partial pressure. J. Appl. Phys. 114, 053703 (2013).

Jin, Y. O., Ozcelik, A., Horn, M. W. & Jackson, T. N. Potential for reactive pulsed-dc magnetron sputtering of nanocomposite VOx microbolometer thin films. J. Vac. Sci. Technol. A 32, 061501 (2014).

Li, S.-Y., Niklasson, G. A. & Granqvist, C. G. A thermochromic low-emittance coating: Calculations for nanocomposites of In2O3:Sn and VO2 . Appl. Phys. Lett. 99, 131907 (2011).

Skuza, J. R., Scott, D. W. & Pradhan, A. K. Sapphire substrate-induced effects in VO2 thin films grown by oxygen plasma-assisted pulsed laser deposition. J. Appl. Phys. 118, 195303 (2015).

Ingvarsson, S., Klein, L. J., Au, Y.-Y., Lacey, J. A. & Hamann, H. F. Enhanced thermal emission from individual antenna-like nanoheaters. Opt. Express 15, 11249–11254 (2007).

Renoux, P., Jónsson, S. Æ., Klein, L. J., Hamann, H. F. & Ingvarsson, S. Sub-wavelength bolometers: Uncooled platinum wires as infrared sensors. Opt. Express 19, 8721–8727 (2014).

Pradhan, A. K. et al. Extreme tunability in aluminum doped zinc oxide plasmonic materials for near-infrared applications. Sci. Rep. 4, 6415 (2014).

Mundle, R. M. et al. Electrical conductivity and photoresistance of atomic layer deposited Al-doped ZnO films. J. Vac. Sci. Technol. A 31, 01A146 (2013).

Mundle, R. & Pradhan, A. K. Electrical response in atomic layer deposited Al:ZnO with varying stack thickness. J. Appl. Phys. 115, 183503 (2014).

Schilbe, P. Raman scattering in VO2 . Physica B 316–317, 600–602 (2002).

Pan, M. et al. Raman study of the phase transition in VO2 thin films. J. Cryst. Growth 268, 178–183 (2004).

Chen, X.-B. Assignment of the Raman modes of VO2 in the monoclinic insulating phase. J. Korean Phys. Soc. 58, 100–104 (2011).

Radue, E. et al. Effect of a substrate-induced microstructure on the optical properties of the insulator-metal transition temperature in VO2 thin films. J. Appl. Phys. 113, 233104 (2013).

Okimura, K., Sakai, J. & Ramanathan, S. In situ x-ray diffraction studies on epitaxial VO2 films grown on c-Al2O3 during thermally induced insulator-metal transition. J. Appl. Phys. 107, 063503 (2010).

Kucharczyk, D. & Niklewski, T. Accurate x-ray determination of the lattice parameters and the thermal expansion coefficients of VO2 near the transition temperature. J. Appl. Cryst. 12, 370–373 (1979).

Kang, L. et al. Thermochromic properties and low emissivity of ZnO:Al/VO2 double-layered films with a lowered phase transition temperature. Solar Energy Mat. & Solar Cells 95, 3189–3194 (2011).

Acknowledgements

The authors would like to thank S. K. Pradhan and K. D. Song for their assistance. This work was supported by the Department of Defense (DoD) Center of Excellence in Advanced Nanomaterials and Devices (CEAND) Grant Numbers W911NF-11-1-0209 and W911NF-11-1-0133 (US Army Research Office), as well as the National Science Foundation Centers of Research Excellence in Science and Technology (NSF-CREST) Center for Nano- and Bio-inspired Materials and Devices (CNBMD) Grant Number HRD 1036494.

Author information

Authors and Affiliations

Contributions

J.R.S., R.M.M. and A.K.P. conceived the ideas and experiments. J.R.S., D.W.S. and R.M.M. conducted the experiments. J.R.S. and D.W.S. analyzed the data and all authors participated in the discussion of the results. J.R.S. wrote the manuscript and all authors reviewed and revised the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Skuza, J., Scott, D., Mundle, R. et al. Electro-thermal control of aluminum-doped zinc oxide/vanadium dioxide multilayered thin films for smart-device applications. Sci Rep 6, 21040 (2016). https://doi.org/10.1038/srep21040

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep21040

This article is cited by

-

Effect of thickness and annealing on electrical characteristics of cerium oxide-doped vanadium oxide (CeO2:V2O5) thin film for sensor application

Journal of Materials Science: Materials in Electronics (2024)

-

Reduced Transition Temperature in Al:ZnO/VO2 Based Multi-Layered Device for low Powered Smart Window Application

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.