Abstract

Through in situ indentation of TiN in a high-resolution transmission electron microscope, the nucleation of full as well as partial dislocations has been observed from {001} and {111} surfaces, respectively. The critical elastic strains associated with the nucleation of the dislocations were analyzed from the recorded atomic displacements and the nucleation stresses corresponding to the measured critical strains were computed using density functional theory. The resolved shear stress was estimated to be 13.8 GPa for the partial dislocation 1/6 <110> {111} and 6.7 GPa for the full dislocation ½ <110> {110}. Such an approach of quantifying nucleation stresses for defects via in situ high-resolution experiment coupled with density functional theory calculation may be applied to other unit processes.

Similar content being viewed by others

Introduction

Understanding the mechanics of dislocation nucleation is a fundamental challenge due to the difficulty of direct experimental measurements at the atomic scale1,2,3,4,5,6,7,8,9. Under athermal conditions, the resolved shear stress required for dislocation nucleation is expected to be on the order of the theoretical limit of shear strength for perfect crystals. Owing to the inherent stochastic nature of dislocation nucleation at finite temperature10,11, the stresses for dislocation nucleation are below the athermal limit and correlated with test temperature12,13,14, deformation procedure (strain rate15,16 and stress state13) and nucleation sites (such as free surface, grain/interphase boundaries17,18,19,20,21 or cracks22,23,24,25). Nanoindentation experiments have been employed to explore nucleation phenomena from surfaces26,27. Using nanoindentation, Angstrom-level control on the displacement and nano-Newton-level control on the load, the onset of plastic behavior is characterized as a displacement excursion/burst or “pop-in” during load-controlled indentations28 or sudden force drop in displacement-controlled mode29. The stress field beneath the indenter tip is calculated using the Hertz contact model and the maximum shear stress is treated as the critical stress for dislocation nucleation30,31. However, ex situ studies cannot directly bridge the load-displacement curve with unit processes under the indenter. Molecular dynamics (MD)32 simulations have been employed to quantitatively study mechanics of dislocation nucleation, but are limited by the availability of reliable potentials and up to 10 orders of magnitude higher strain rate in simulations as compared to experiments.

In situ indentation in a TEM offers an excellent tool to unveil dislocation nucleation in various environments, such as free surfaces4,33, grain boundaries34, internal single-ended spiral sources1,35, twin boundaries36,37, interphase boundaries38,39,40 and cracks5. From quantitative load–displacement measurements in polycrystalline Al film using in situ indentation in a TEM2,26,33, Minor et al. estimated critical resolved shear stress for dislocation nucleation in both dislocation-free and deformed domains and found them close to the theoretical shear strength. In this Letter, we explored the nucleation mechanics at atomic scale by performing in situ indentation tests in a TEM at high-resolution mode. We characterized dislocation nucleation processes and computed the critical strains according to the recorded atomic displacements. The critical stresses are calculated by using first principles density functional theory to deal with non-linear elasticity of large strains.

TiN is one of most thoroughly investigated transition metal nitrides41,42,43,44,45,46,47,48,49,50 and chosen in this study. TiN with the rock-salt (B1) crystal structure has three possible slip systems {110} <110>, {001} <110> and {111} <110>. In order to reveal the nucleation behavior of dislocations on the three slip systems, we designed our experimental setup to selectively favor one or two slip systems. Table 1 shows the calculated Schmid factors for possible slip systems for the two cases of indentation direction along <111> and <001>, respectively. The Schmid factors exhibited in Table 1 show that the systems {111} <110> and {100} <110> will be primarily activated for the indentation along <111> and the systems {110} <110> and {111} <110> will be primarily activated for the indentation along <100>. We thus deposited TiN films epitaxially on single-crystal MgO (100) & (111) at 650 °C. In situ nanoindentation studies were conducted at room temperature with a Nanofactory scanning tunneling microscopy (STM) platform inside a Tecnai G(2) F30 transmission electron microscope. We performed indentation tests along two crystallographic directions <111> and <100>, as shown in Fig. S1 (also see movies in Supplementary Materials) and characterized two activated slip systems {111} <110> and {110} <110>.

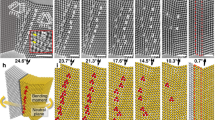

Figure 1a shows the HRTEM image of the TiN crystal under in situ straining by a tungsten indenter appearing in the lower right corner of the image (see Supplementary Movie 1). This image is one of a series of images collected at a rate of 3 frames per second during the test. A grain boundary separates the upper left grain from the lower right. The indenter is located at the surface of the upper grain away from the boundary. The loading direction is closely parallel to the  direction of the upper grain and the electron beam direction is along [110]. The region beneath the tip (marked as a square box in Fig. 1a) has been magnified in Fig. 1b. During an interval of 0.3 seconds, an offset along

direction of the upper grain and the electron beam direction is along [110]. The region beneath the tip (marked as a square box in Fig. 1a) has been magnified in Fig. 1b. During an interval of 0.3 seconds, an offset along  plane of 7.5 nm in magnitude is observed and is indicated by a dashed line in Fig. 1c, corresponding to the nucleation of a partial dislocation and the formation of a stacking fault. We further characterized the Burgers vector of the nucleated partial dislocation. A Burgers circuit starting at S and ending at F is shown in Fig. 1e and the Burgers vector is a0/6

plane of 7.5 nm in magnitude is observed and is indicated by a dashed line in Fig. 1c, corresponding to the nucleation of a partial dislocation and the formation of a stacking fault. We further characterized the Burgers vector of the nucleated partial dislocation. A Burgers circuit starting at S and ending at F is shown in Fig. 1e and the Burgers vector is a0/6 with the line sense ξ = [110]. To clearly show the offset associated with the partial dislocation during nucleation, we chose atoms in lower right corner (region I in Fig. S2) as a reference and remap atomic displacements in other regions. Supplementary Movie 2 reveals the collective shift of atoms in regions II, III and IV with respect to region I. This nucleated partial dislocation is observed for 1 second during the indentation. With continued compression, the offset region recovers (as shown in Fig. 1d), corresponding to the scenario that a trailing partial has been nucleated and combined with the leading partial to form a perfect lattice dislocation with Burgers vector ½ <110>, which has glided into the sample and is invisible in the frame in Fig. 1d.

with the line sense ξ = [110]. To clearly show the offset associated with the partial dislocation during nucleation, we chose atoms in lower right corner (region I in Fig. S2) as a reference and remap atomic displacements in other regions. Supplementary Movie 2 reveals the collective shift of atoms in regions II, III and IV with respect to region I. This nucleated partial dislocation is observed for 1 second during the indentation. With continued compression, the offset region recovers (as shown in Fig. 1d), corresponding to the scenario that a trailing partial has been nucleated and combined with the leading partial to form a perfect lattice dislocation with Burgers vector ½ <110>, which has glided into the sample and is invisible in the frame in Fig. 1d.

Nucleation of a partial dislocation loop in TiN under indentation along <111>.

(a) HRTEM snapshot from in situ indentation. (b) A magnified view of the region marked with the square box in (a). (c) After 0.3 s, an offset along  glide plane with a length of 7.5 nm, corresponding to a stacking fault, is observed. (d) After 1 s, The nucleated dislocation (including the trailing partial) glides into the crystal and out of the region of view. (e) A Burgers circuit (starting at S and ending at F) was drawn at one end by assuming the sense (direction) of the dislocation line is pointing into the plane of view. Scale bars: (b–d) 2 nm, (e) 1 nm.

glide plane with a length of 7.5 nm, corresponding to a stacking fault, is observed. (d) After 1 s, The nucleated dislocation (including the trailing partial) glides into the crystal and out of the region of view. (e) A Burgers circuit (starting at S and ending at F) was drawn at one end by assuming the sense (direction) of the dislocation line is pointing into the plane of view. Scale bars: (b–d) 2 nm, (e) 1 nm.

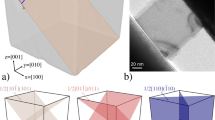

To quantify the critical strains corresponding to the nucleation of the partial dislocation, a lattice strain analysis was performed, based on the HRTEM image (Fig. 1b) acquired 0.3 s before the nucleation. The method is developed based on the least squares determination of the strain ellipse at a lattice site in the plane of a lattice image defined relative to a perfect reference lattice (see details in Supplementary Materials). Figure 2a–c show strains εyy, εxx and εxy in the nucleation region beneath the indenter, where the coordinate system is x =  , y =

, y =  and z =

and z =  . The presence of the scattered blank regions is due to image distortion under straining. The magnitude of compressive strains εyy decreases with distance from the indenter (Fig. 2a), roughly in agreement with Hertzian theory. Due to large strains beyond linear elasticity right beneath the indenter, stresses associated with such strains are calculated by using first principles density functional theory (DFT) (see Method for model details). Figure 2d shows the contour of the resolved shear stress on the

. The presence of the scattered blank regions is due to image distortion under straining. The magnitude of compressive strains εyy decreases with distance from the indenter (Fig. 2a), roughly in agreement with Hertzian theory. Due to large strains beyond linear elasticity right beneath the indenter, stresses associated with such strains are calculated by using first principles density functional theory (DFT) (see Method for model details). Figure 2d shows the contour of the resolved shear stress on the  plane. Superimposing the contour on the TEM micrograph helps identify the stress gradient beneath the indenter (in Fig. 2d), consistent with the trend in compressive strain εyy. There is a small region of large strains close to the indenter. The strain component εxx is predominantly tensile (Fig. 2b). With these data, the average strain tensor at the location of the dislocation nucleation is

plane. Superimposing the contour on the TEM micrograph helps identify the stress gradient beneath the indenter (in Fig. 2d), consistent with the trend in compressive strain εyy. There is a small region of large strains close to the indenter. The strain component εxx is predominantly tensile (Fig. 2b). With these data, the average strain tensor at the location of the dislocation nucleation is  . The corresponding DFT stress is

. The corresponding DFT stress is  (GPa) under the indenter, with the critical shear stress of 13.8 GPa for the nucleation of a partial dislocation on {111}.

(GPa) under the indenter, with the critical shear stress of 13.8 GPa for the nucleation of a partial dislocation on {111}.

The calculated strain and resolved shear stress components in a 2D density plot.

(a) εyy; (b) εxx; and (c) εxy. The strain tensors are obtained in the crystal system where x =  , y =

, y =  and z =

and z =  . (d), The contour of the resolved shear stress on

. (d), The contour of the resolved shear stress on  plane along y’ =

plane along y’ =  direction has been superimposed on the TEM micrograph.

direction has been superimposed on the TEM micrograph.

Figure 3a shows a TEM image when the e-beam direction is along [100] and the compressive loading direction is along [001]. Nucleation and glide of a full dislocation was observed (see Supplementary Movie 3). Figures 3b,c show, in two successive frames, the trajectory of a lattice dislocation on  plane. The dislocation is nucleated from the free surface in contact with the indenter and glides into the sample. The Burgers vector of the nucleated dislocation has been identified to be a0/2[110] with the line sense ξ =

plane. The dislocation is nucleated from the free surface in contact with the indenter and glides into the sample. The Burgers vector of the nucleated dislocation has been identified to be a0/2[110] with the line sense ξ =  . Lattice strain analysis based on HRTEM images determined the local strains under the indenter

. Lattice strain analysis based on HRTEM images determined the local strains under the indenter  and the corresponding DFT stresses

and the corresponding DFT stresses  (GPa). This corresponds to a resolved shear stress of 6.7 GPa, greater than the estimation made by Oden et al. based on the Hertz contact model47.

(GPa). This corresponds to a resolved shear stress of 6.7 GPa, greater than the estimation made by Oden et al. based on the Hertz contact model47.

{110} <110> has so far been commonly believed to be the room temperature slip system in TiN while the slip system {111} <110> has never been observed experimentally. Here we have for the first time confirmed two activated slip systems, {111} <110> and {110} <110>, with respect to indentation direction along <111> and <100>, respectively. Table 2 summarized the experimental results for the two indentation orientations.

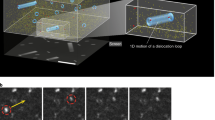

The possible reason for the higher nucleation stress for a partial dislocation on {111} plane than the full dislocation on {110} plane may be the larger Peierls stress for {111} <110>. To rationalize these observations, we calculated generalized stacking fault energies (GSFE) of {111}, {110} and {100} planes using DFT as a function of shear displacements along both <110> and <112> directions. Figure 4a shows variation of GSFE of {110} and {100} planes with shear displacements along <110> direction. The results suggest that dislocations a ½ <110> Burgers vector are energetically favored on {110} and {001} slip planes and {100} <110> experiences a higher unstable stacking energy of 2.5 J/m2. Figure 4b shows variation of GSFE of {111} plane with shear displacements along both <110> and <112> directions. The unstable stacking fault energy for a0/2 <110> shear is 2.5 J/m2. For the shear of a0/3 <112>, the unstable (γusf)51 and stable stacking fault energies (γsf) are 1.4 J/m2 and 1.1 J/m2 respectively. The results suggest that the partial dislocation with Burgers vector of a0/6 <112> prefers to nucleate and shear between two Ti layers. Following the notation of Frank and Nicholas52, we label planes of atoms containing Ti by Roman letters and planes of atoms containing N by Greek letters (in Fig. 4c,d). The stacking sequence of the {111} planes of TiN can be expressed as …AγBαCβAγBαCβ… In Fig. 4d, at displacement of a0/3 <112>, which corresponds to a Shockley partial vector, the stacking sequence is changed to …AγBαCβ|CβAγBα…, where “|” indicates the position of the fault plane. In this configuration, one Ti layer is displaced relative to the neighboring Ti layer in the “anti-twinning” sense. This corresponds to a high energy stacking fault structure in fcc metals. In Fig. 4b, at displacement of a0/6 <112>, which corresponds to the Shockley partial in the “twinning” sense, another type of stacking fault exists. However, formation of this type of stacking fault requires a cooperative motion of the interfacial nitrogen atoms within the slip plane, the so called “synchroshear mechanism”52, which is typically diffusion assisted. Since our experiments were not conducted at high temperatures, this type of stacking fault is not observed.

DFT calculated generalized stacking fault energies.

(a) Generalized stacking fault energies (GSFEs) as a function of shear displacement along <110> in {110} and {100} planes. (b) GSFEs as a function of shear displacements along both <110> and <112> directions on {111} plane. (c) The atomic structures (left) and associated electron localization functions (right) of perfect TiN. (d) The atomic structures (left) and associated electron localization functions (right) of stacking faulted TiN.

In summary, in situ indentation in a TEM under high-resolution coupled with image analysis has been successfully used to observe and quantify dislocation nucleation in TiN. For two different indentation orientations, <111> and <001>, we identified two slip systems in terms of dislocation characters and corresponding critical nucleation strains. Critical shear stresses were obtained using density functional theory to deal with non-linear elastic behavior of the high critical strains, ~13.8 GPa for nucleating a partial dislocation on {111} and ~6.7 GPa for nucleating a full dislocation on {110}. We believe that such approach can be applied to other unit phenomena, such as dislocation nucleation from boundaries or cracks, dislocation multiplication or interaction, etc.

Methods

In situ compression experiments

Our experiments were conducted inside a FEI Tecnai F30 field emission gun transmission electron microscope (TEM) equipped with a Nanofactory TEM-STM system. The TEM was operated at 300 kV, with a point-to-point resolution around 0.2 nm. The videos were recorded by a CCD (charge-coupled device) camera at 3 frames per second. TiN TEM foils were attached on a piezo-operated scanning tunneling microscope (STM) probe with silver paste. An etched W wire, with tip radius less than 100 nm, has been used as the indentation tool. And the compressive displacement rate is well controlled to be ~0.1 nm/s.

DFT simulations

The DFT calculations were performed using the Vienna Ab initio Simulation Package (VASP), employing the Perdew, Burke and Ernzerhof (PBE) exchange correlation functional and the projector-augmented wave (PAW) methodology. The calculated lattice parameters, bulk modulus and elastic constants of TiN in the rock salt crystal structure were in excellent agreement with other DFT calculations and experimental values44,45,52. For the dislocation structure calculations, a single partial dislocation was introduced into a TiN supercell. The supercell has  in x,

in x,  in y and

in y and  in z directions. The dislocation line direction is along z. The initial atomic structure of dislocation was created using anisotropic linear elasticity theory employing the Stroh solution. The supercell is periodic in z and has fixed boundaries in x and y, approx. 4.1 nm and 2.9 nm respectively. To get accurate atomic forces and stresses, a 1 × 1 × 7 Monkhorst−Pack mesh for k-point sampling and a planewave kinetic energy cutoff of 500 eV for the planewave expansion of the wave functions were used in the slab calculations. A thickness of 0.6–1.0 nm vacuum is applied to the fixed boundaries to avoid boundary-boundary interaction due to the periodic nature of the planewave based DFT calculations in a supercell. The nudged elastic band method calculations were used to calculate the Peierls barrier of the partial dislocations53,54.

in z directions. The dislocation line direction is along z. The initial atomic structure of dislocation was created using anisotropic linear elasticity theory employing the Stroh solution. The supercell is periodic in z and has fixed boundaries in x and y, approx. 4.1 nm and 2.9 nm respectively. To get accurate atomic forces and stresses, a 1 × 1 × 7 Monkhorst−Pack mesh for k-point sampling and a planewave kinetic energy cutoff of 500 eV for the planewave expansion of the wave functions were used in the slab calculations. A thickness of 0.6–1.0 nm vacuum is applied to the fixed boundaries to avoid boundary-boundary interaction due to the periodic nature of the planewave based DFT calculations in a supercell. The nudged elastic band method calculations were used to calculate the Peierls barrier of the partial dislocations53,54.

Additional Information

How to cite this article: Li, N. et al. Quantification of dislocation nucleation stress in TiN through high-resolution in situ indentation experiments and first principles calculations. Sci. Rep. 5, 15813; doi: 10.1038/srep15813 (2015).

References

Oh, S. H., Legros, M., Kiener, D. & Dehm, G. In situ observation of dislocation nucleation and escape in a submicrometre aluminium single crystal. Nat. Mater. 8, 95–100 (2009).

Minor, A. M. et al. A new view of the onset of plasticity during the nanoindentation of aluminium. Nat. Mater. 5, 697–702 (2006).

Li, J. The mechanics and physics of defect nucleation. MRS Bull. 32, 151–159 (2007).

Minor, A. M. et al. Room temperature dislocation plasticity in silicon. Philoso. Mag. 85, 323–330 (2005).

Zielinski, W., Lii, M. J. & Gerberich, W. W. Crack-tip dislocation emission arrangements for equilibrium–I. In situ TEM observations of Fe-2wt%Si. Acta Metall. Mater. 40, 2861–2871 (1992).

Van Vliet, K., Li, J., Zhu, T., Yip, S. & Suresh, S. Quantifying the early stages of plasticity through nanoscale experiments and simulations. Phys. Rev. B 67, 104105 (2003).

Zhu, T. et al. Predictive modeling of nanoindentation-induced homogeneous dislocation nucleation in copper. J. Mech. Phys. Solids 52, 691–724 (2004).

Li, J., Vliet, K. J. V., Zhu, T., Yip, S. & Suresh, S. Atomistic mechanisms governing elastic limit and incipient plasticity in crystals. Nature 418, 307–310 (2002).

Miller, R. E. & Acharya, A. A stress-gradient based criterion for dislocation nucleation in crystals. J. Mech. Phys. Solids 52, 1507–1525 (2004).

Chiu, Y. L. & Ngan, A. H. W. Time-dependent characteristics of incipient plasticity in nanoindentation of a Ni3Al single crystal. Acta Mater. 50, 1599–1611 (2002).

Zhu, T., Li, J., Samanta, A., Leach, A. & Gall, K. Temperature and Strain-Rate Dependence of Surface Dislocation Nucleation. Phys. Rev. Lett. 100, 025502 (2008).

Schuh, C. A., Mason, J. K. & Lund, A. C. Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat. Mater. 4, 617–621 (2005).

Mason, J., Lund, A. & Schuh, C. Determining the activation energy and volume for the onset of plasticity during nanoindentation. Phys. Rev. B 73, 054102 (2006).

Lund, A. C., Hodge, A. M. & Schuh, C. A. Incipient plasticity during nanoindentation at elevated temperatures. Appl. Phys. Lett. 85, 1362 (2004).

Schuh, C. A. & Lund, A. C. Application of nucleation theory to the rate dependence of incipient plasticity during nanoindentation. J. Mater. Res. 19, 2152–2158 (2011).

Wang, W., Jiang, C. B. & Lu, K. Deformation behavior of Ni3Al single crystals during nanoindentation. Acta Mater. 51, 6169–6180 (2003).

Tschopp, M. A., Spearot, D. E. & McDowell, D. L. Influence of Grain Boundary Structure on Dislocation Nucleation in FCC Metals. Dislocations in Solids 14, Chapter 82, 43–139 (2008).

Spearot, D., Jacob, K. & McDowell, D. Dislocation nucleation from bicrystal interfaces with dissociated structure. Int. J. Plast. 23, 143–160 (2007).

Wang, J., Zhang, R. F., Zhou, C. Z., Beyerlein, I. J. & Misra, A. Interface dislocation patterns and dislocation nucleation in face-centered-cubic and body-centered-cubic bicrystal interfaces. Int. J. Plast. 53, 40–55 (2014).

Beyerlein, I. J., Wang, J. & Zhang, R. Mapping dislocation nucleation behavior from bimetal interfaces. Acta Mater. 61, 7488–7499 (2013).

Zhang, R. F., Germann, T. C., Wang, J., Liu, X. Y. & Beyerlein, I. J. Role of interface structure on the plastic response of Cu/Nb nanolaminates under shock compression: Non-equilibrium molecular dynamics simulations. Scripta Mater. 68, 114–117 (2013).

Cleri, F., Yip, S., Wolf, D. & Phillpot, S. R. Atomic-Scale Mechanism of Crack-Tip Plasticity: Dislocation Nucleation and Crack-Tip Shielding. Phys. Rev. Lett. 79, 1309–1312 (1997).

Zhu, T., Li, J. & Yip, S. Atomistic Study of Dislocation Loop Emission from a Crack Tip. Phys. Rev. Lett. 93, 025503 (2004).

Rice, J. R. & Beltz, G. E. The activation energy for dislocation nucleation at a crack. J. Mech. Phys. Solids 42, 333–360 (1994).

Rice, J. R. Dislocation nucleation from a crack tip: an analysis based on the Peierls concept. J. Mech. Phys. Solids 40, 239–271 (1992).

Gouldstone, A. et al. Indentation across size scales and disciplines: Recent developments in experimentation and modeling. Acta Mater. 55, 4015–4039 (2007).

Bahr, D. F., Kramer, D. E. & Gerberich, W. W. Non-linear deformation mechanismis during nanoidentation. Acta Mater. 46, 3605–3617 (1998).

Lorenz, D. et al. Pop-in effect as homogeneous nucleation of dislocations during nanoindentation. Phys. Rev. B 67, 172101 (2003).

Hosson, J. T. M. et al. In situ TEM nanoindentation and dislocation-grain boundary interactions: a tribute to David Brandon. J. Mater. Sci. 41, 7704–7719 (2006).

Corcoran, S. G. & Colton, R. J. Anomalous plastic deformation at surfaces: Nanoindentation of gold single crystals. Phys. Rev. B 55, R16057–16060 (1997).

Lilleodden, E. T., Zimmerman, J. A., Foiles, S. M. & Nix, W. D. Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation. J. Mech. Phys. Solids 51, 901–920 (2003).

Szlufarska, I. Atomistic simulations of nanoindentation. Mater. Today 9, 42–50 (2006).

Minor, A. M., Lilleodden, E. T., Stach, E. A. & Morris, J. W. Direct observations of incipient plasticity during nanoindentation of Al. J. Mater. Res. 19, 176–182 (2004).

Lee, T. C., Robertson, I. M. & Birnbaum, H. K. TEM in situ deformation study of the interaction of lattice dislocations with grain boundaries in metals. Philos. Mag. A 62, 131–153 (1990).

Oh, S. H., Legros, M., Kiener, D., Gruber, P. & Dehm, G. In situ TEM straining of single crystal Au films on polyimide: Change of deformation mechanisms at the nanoscale. Acta Mater. 55, 5558–5571 (2007).

Li, N. et al. Twinning dislocation multiplication at a coherent twin boundary. Acta Mater. 59, 5989–5996 (2011).

Wang, Y. B., Sui, M. L. & Ma, E. In situ observation of twin boundary migration in copper with nanoscale twins during tensile deformation. Philos. Mag. Lett. 87, 935–942 (2007).

Li, N., Wang, J., Huang, J. Y., Misra, A. & Zhang, X. In situ TEM observations of room temperature dislocation climb at interfaces in nanolayered Al/Nb composites. Scripta Mater. 63, 363–366 (2010).

Zheng, S. J. et al. Deformation twinning mechanisms from bimetal interfaces as revealed by in situ straining in the TEM. Acta Mater. 60, 5858–5866 (2012).

Kumar, S., Wolfe, D. E. & Haque, M. A. Dislocation shielding and flaw tolerance in titanium nitride. Int. J. Plast. 27, 739–747 (2011).

Sundgren, J. E. & Hentzell, H. T. G. A review of the present state of art in hard coatings grown from the vapor phase. J. Vac. Sci. Technol., A 4, 2259 (1986).

Patsalas, P. & Logothetidis, S. Optical, electronic and transport properties of nanocrystalline titanium nitride thin films. J. Appl. Phys. 90, 4725 (2001).

Bès, R., Pipon, Y., Millard-Pinard, N., Gavarini, S. & Freyss, M. First-principles study of rare gas incorporation in titanium nitride. Phys. Rev. B 87, 024104 (2013).

Yadav, S. K., Ramprasad, R., Misra, A. & Liu, X. Y. First-principles study of shear behavior of Al, TiN and coherent Al/TiN interfaces. J. Appl. Phys. 111, 083505 (2012).

Yadav, S. K., Ramprasad, R., Misra, A. & Liu, X. Y. Core structure and Peierls stress of edge and screw dislocations in TiN: A density functional theory study. Acta Mater. 74, 268–277 (2014).

Jang, D., Meza, L. R., Greer, F. & Greer, J. R. Fabrication and deformation of three-dimentsional hollow ceramic nanostructures. Nat. Mater. 12, 893–898 (2013).

Oden, M., Ljungcrantz, H. & Hultman, L. Characterization of the induced plastic zone in a single crystal TiN(001) film by nanoindentation and transmission electron microscopy. J. Mater. Res. 12, 2134–2142 (1997).

Minor, A. M., Stach, E. A., Morris, J. W. Jr. & Petrov, I. In-situ nanoindentation of epitaxial TiN/MgO (001) in a transmission electron microscope. J. Elec. Mater. 32, 1023–1027 (2003).

Bhattacharyya, D., Mara, N. A., Dickerson, P., Hoagland, R. G. & Misra, A. Compressive flow behavior of Al-TiN multilayers at nanometer scale layer thickness. Acta Mater. 59, 3804–3816 (2011).

Li, N., Wang, H., Misra, A. & Wang, J. In situ nanoindentation study of plastic co-deformation in Al-TiN nanocomposites. Sci. Rep. 4, 6633 (2014).

Van Swygenhoven, H., Derlet, P. M. & Froseth, A. G. Stacking fault energies and slip in nanocrystalline metals. Nat. Mater. 3, 399–403 (2004).

Yadav, S. K. et al. First-principles density functional theory study of generalized stacking faults in TiN and MgO. Philoso. Mag. 94, 464–475 (2013).

Henkelman, G. & Jonsson, H. Improved tangent estimate in the nudged elastic band method for finding minimum energy paths and saddle points. J. Chem. Phys. 113, 9978–9985 (2000).

Henkelman, G., Uberuaga, B. P. & Jonsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Acknowledgements

The authors thank insightful discussions with Prof. J.P. Hirth. This work was supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences. LANL is operated by Los Alamos National Security, LLC, for the National Nuclear Security Administration of the U.S. Department of Energy under Contract No. DE-AC52-06NA25396. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy (DOE) Office of Science by Los Alamos National Laboratory (Contract DE-AC52-06NA25396) and Sandia National Laboratories (Contract DE-AC04-94AL85000).

Author information

Authors and Affiliations

Contributions

N.L. conducted experiments. S.K.Y. and X.Y.L. carried out DFT simulations. J.W., R.G.H. and A.M. conceived of the research and provided guidance. All authors analysed the data, discussed the results and wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Li, N., Yadav, S., Liu, XY. et al. Quantification of dislocation nucleation stress in TiN through high-resolution in situ indentation experiments and first principles calculations. Sci Rep 5, 15813 (2015). https://doi.org/10.1038/srep15813

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep15813

This article is cited by

-

Large mechanical properties enhancement in ceramics through vacancy-mediated unit cell disturbance

Nature Communications (2023)

-

Review: mechanical behavior of metal/ceramic interfaces in nanolayered composites—experiments and modeling

Journal of Materials Science (2018)

-

Micro-scale modeling of interface-dominated mechanical behavior

Journal of Materials Science (2018)

-

In-plane anisotropy and twin boundary effects in vanadium nitride under nanoindentation

Scientific Reports (2017)

-

Understanding dislocation slip in stoichiometric rocksalt transition metal carbides and nitrides

Journal of Materials Science (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.