Abstract

Interface engineering has become an important strategy for designing radiation-resistant materials. Critical to its success is fundamental understanding of the interactions between interfaces and radiation-induced defects, such as voids. Using transmission electron microscopy, here we report an interesting phenomenon in their interaction, wherein voids adhere to only one side of the bimetal interfaces rather than overlapping them. We show that this asymmetrical void-interface interaction is a consequence of differing surface energies of the two metals and non-uniformity in their interface formation energy. Specifically, voids grow within the phase of lower surface energy and wet only the high-interface energy regions. Furthermore, because this outcome cannot be accounted for by wetting of interfaces with uniform internal energy, our report provides experimental evidence that bimetal interfaces contain non-uniform internal energy distributions. This work also indicates that to design irradiation-resistant materials, we can avoid void-interface overlap via tuning the configurations of interfaces.

Similar content being viewed by others

Introduction

Recently, high strength, outstanding thermal stability and exceptional irradiation resistance have been achieved simultaneously by virtue of interface engineering in nanolayered materials1,2,3,4,5,6,7. It has also been established that interfaces can act as efficient sinks for point defects8,9. However, other radiation-induced defects, such as voids within the phases, can interact with the interfaces, reducing their cohesion. To effectively design bimetal interfaces to be simultaneously radiation resistant and mechanically strong, an understanding of interface interactions with voids at a fine scale is needed.

Generally, interfaces formed by joining two unlike solids are surfaces with characteristic energies, expressed in units of J/m2. The procedure for computing these energies, originally proposed by Gibbs10, yields a single average value for flat interfaces. However, many flat, solid-state interfaces have non-uniform internal structures. For example, semi-coherent interfaces consist of alternating regions of coherency separated by networks of inherent defects known as misfit dislocations11,12,13. Recent modeling investigations have shown that this structural non-uniformity leads to corresponding non-uniformity in interface energies, which are highest near misfit dislocation intersections (MDIs) and lowest within regions of coherency14,15,16. Precipitates forming at interfaces with location-dependent energies preferentially wet regions of high energy while regions with low energy might not be wetted at all16,17,18.

Because solid-state interfaces are buried within composite materials, their internal energy distributions are difficult to assess experimentally, especially when they vary over nanometer-scale distances. In this report, we show experimentally that interfaces between Cu and Ag lamellae contain non-uniform internal energy distributions. We find that, unlike with grain boundaries19,20,21, irradiation-induced voids do not overlap with bimetal interfaces. Instead, voids adhere to specific regions of these interfaces. They are also distributed asymmetrically, lying on the side of the phase with the lower surface energy, which is the Ag side at the Ag-Cu interfaces. This finding is consistent with predictions of non-uniform internal interface energy, which allows voids to wet some parts of the interface from one side of the interface, but not other parts. As we show here, atomistic molecular dynamics (MD) simulations support this interpretation.

Results

Adhesion of voids to Cu-Ag interfaces

We begin with examination of the Cu-Ag nanolayered composite, where Ag has the lower surface energy than Cu. The Cu-Ag nanolayered composite with an eutectic composition (40–60 at.% Cu-Ag) was synthesized by a flux-melting technique22 and has about 30 nm and 65 nm thick Cu and Ag layers, respectively. Voids were induced via He irradiation on TEM foils of the Cu-Ag nanolayered composite (see Method and Supplementary information). Figure 1 shows a typical over-focus bright field transmission electron microscopy (TEM) image of voids within the Cu-Ag nanolayered composite after 200 KeV He-ion irradiation at 450 °C to a fluence of 2 ×1017. As shown, we find that the voids adhere to Cu-Ag interfaces from the Ag side. We also observe that the contact areas between the voids and the Cu-Ag interfaces are of nanometer-scale dimensions. This observation is unexpected since voids in single-phase polycrystalline metals normally overlap with the grain boundaries19,20,21.

Surface wetting of interfaces with uniform energies

To explain why the voids adhere to a small interface area on one side of the interface rather than overlapping the interface, we use arguments based on surface wetting23. As shown in Fig. 2a, when three adjacent phases (A, B and C) are in equilibrium, their surfaces meet at angles, α, β and θ, determined by ratios of their interface energies: γAB, γAC and γBC. The interface energies obey the geometrical constraint of  , meaning no one interface energy can be larger than the sum of the other two. For this reason, when a precipitate forms at an interface, its equilibrium shape is usually lenticular and bulges slightly in the direction of the constituent with which it has a lower surface energy. This scenario assumes the interface energy γAB is uniform, i.e., it does not depend on location within the interface plane. For example, consider a void wetting a coherent (111)Ag twin boundary. In this case, A and B are the same phase and the boundary has uniform energy. As shown in Fig. 2b, acquired from the same He-irradiated TEM sample as displayed in Fig. 1, a void overlaps symmetrically the twin boundary. However, semicoherent interfaces such as Cu-Ag and Cu-Nb are known to have non-uniform internal structure24,25,26. We therefore expect that they also have a non-uniform energy.

, meaning no one interface energy can be larger than the sum of the other two. For this reason, when a precipitate forms at an interface, its equilibrium shape is usually lenticular and bulges slightly in the direction of the constituent with which it has a lower surface energy. This scenario assumes the interface energy γAB is uniform, i.e., it does not depend on location within the interface plane. For example, consider a void wetting a coherent (111)Ag twin boundary. In this case, A and B are the same phase and the boundary has uniform energy. As shown in Fig. 2b, acquired from the same He-irradiated TEM sample as displayed in Fig. 1, a void overlaps symmetrically the twin boundary. However, semicoherent interfaces such as Cu-Ag and Cu-Nb are known to have non-uniform internal structure24,25,26. We therefore expect that they also have a non-uniform energy.

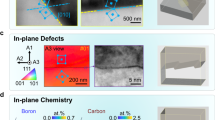

Cu-Ag interface structures characterized by TEM

To investigate the location-dependent energy distribution in bimetal interfaces we will use atomistic modelling. However, building accurate atomic-scale models of interfaces requires first knowing the complete interfacial crystallography, i.e., misorientation and interface plane orientation27. For this reason, we perform high resolution TEM (HRTEM) analysis of individual interfaces. Figure 3a shows a typical TEM image of the as-prepared Cu-Ag composite. The Cu-Ag composite exhibits two types of interfaces, both possessing {111} interface planes. Type I interfaces have a cube-on-cube orientation relationship, where Cu and Ag have the same orientation across the interface, as illustrated in Fig. 3b. In type II interfaces, however, Cu and Ag exhibit a twin-like symmetry about the interface, as shown in Fig. 3c and hence we refer to type II interfaces as “hetero-twins”. This observation is consistent with previous studies on Cu-Ag interfaces via electron backscattered diffraction (EBSD)28 and TEM29. We also observe that the internal structures of the type I and type II interfaces are identical. This equivalence is consistent with our observation that both Cu-Ag interface types exhibit the same asymmetric void distribution.

Direct observation of adhesion of voids to MDIs at Cu-Ag interfaces

Imaging under a two-beam condition has been used to identify voids at MDIs at Cu-Ag interfaces. Figure 4a,c are bright field TEM and dark field TEM images of the Cu-Ag interface under the two-beam condition shown in Fig. 4b. To perform the two-beam imaging, the sample was tilted so that the Cu-Ag interface overlapped and showed misfit dislocation patterns that are clear in the dark field TEM image in Fig. 4c. Voids located at MDIs are indicated by the arrows. These images provide direct evidence of adhesion of voids to MDIs.

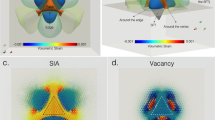

Non-uniform structures and energies of Cu-Ag interfaces studied by MD simulations

To explain our experimental findings, we characterize the internal structure of the Ag-Cu interface using MD simulations. By examining the coordination of interfacial atoms, we find that this interface contains three sets of misfit dislocations along the <110> directions, indicated by light-green atoms in Fig. 5a. The dislocation lines are Shockley partials with edge character30. All three sets of misfit dislocations intersect at periodic locations, shown by blue atoms in Fig. 5a. The misfit dislocation lines and intersections separate the coherent interface regions (orange atoms in Fig. 5a) containing perfect FCC stacking and intrinsic stacking faults (ISF). The coherent regions are associated with low potential energy and moderate coherency strain energy, while the dislocation lines and intersections have much higher energy density due to the cores of interface dislocations24. Therefore, a highly non-uniform interface energy landscape is expected. We computed the location-dependent interface energy on the Cu-Ag interface. As shown in Fig. 5b, the interface energy exhibits significant variations with location and these variations correlate to the misfit dislocation pattern of the interface. The coherent FCC stacking regions correspond to minima of the energy contour: they have energy of −0.02 J/m2. The energy of the coherent ISF regions is also low, having a slightly higher energy of 0.03 J/m2. The interface energy at dislocation lines is comparatively higher 0.06 J/m2. The MDIs correspond to maxima of the energy landscape and have a substantially higher energy of 0.47 J/m2. Such regular variations in interface energy have been predicted in other semi-coherent bimetal interfaces as well25,31.

Void wetting of Cu-Ag interfaces with non-uniform structures and energies.

(a) Misfit dislocation network in the cube-on-cube Cu-Ag interface. Atoms shown are on the Cu side of the interface and colored by coordination number. (b) Contour plot of the location-dependent interface energy of a Cu-Ag interface. Black contours correspond to zero wetting energy. (c) Schematic of a void wetting a single MDI where W > 0 at a Cu-Ag interface.

Void wetting of Cu-Ag interfaces with non-uniform energies

To explain void interactions with Cu-Ag interfaces, we use a wetting energy parameter, W = γA + γA-B − γB, where γA and γB are the surface energies of phases A and B and it is assumed that γA < γB. γA-B is the A-B interface energy23. When W > 0, thermodynamics favors wetting, meaning that the void will stay in A phase and touch the interface. In contrast, when W < 0, wetting is not favored and the void has minimum energy when it is entirely contained within the phase with the lowest free surface energy (the A phase). To calculate the surface energy associated with the formation of a void, we need to know the shape of the void. As discussed in the Supplementary information, voids in Cu and Ag assume the same truncated octahedron shape composed of {111} and {100} planes. We find that γAg111 = 0.92 J/m2, γCu111 = 1.06 J/m2, γAg100 = 0.99 J/m2 and γCu100 = 1.13 J/m2 32. Consequently, with all else being the same, the void will have a smaller surface energy in Ag than Cu. If the void wets the {111}Cu-{111}Ag interface from the Ag (A phase) side, the wetting results in a {111}Cu surface replacing an equal area of {111}Cu-{111}Ag interface and {111}Ag surface. In this case, the wetting parameter is calculated as: W = γAg111 + γCu-Ag − γCu111. Because γCu-Ag varies from location to location within the interface, therefore so does W and the likelihood for void touching.

Figure 5b shows regions with W > 0, which occur at MDIs and W < 0, located at coherent patches. The black contour denotes W = 0. Voids completely wet regions where W > 0. Beyond the black contours, however, where W < 0, the voids do not wet the interface at all. Within the wetting area, W > 0 is consistent with the geometrical constraint  , given by Neumann’s triangle33. Since the regions where W > 0 are small, the curvature deviation from {111}Cu surface is too small to be observed by TEM. However, once a void has grown large enough to cover an entire MDI, it is not thermodynamically favorable for it to continue to wet the interface as it grows. Instead, it extends into the side with lower surface energy, i.e., the Ag phase, as illustrated in Fig. 5c. Then it can become visible in the TEM. This growth process results in a different equilibrium void shape than that expected on an interface with uniform energies. The notion of non-uniform interface energies explains the asymmetric void distribution about bimetal interfaces reported here.

, given by Neumann’s triangle33. Since the regions where W > 0 are small, the curvature deviation from {111}Cu surface is too small to be observed by TEM. However, once a void has grown large enough to cover an entire MDI, it is not thermodynamically favorable for it to continue to wet the interface as it grows. Instead, it extends into the side with lower surface energy, i.e., the Ag phase, as illustrated in Fig. 5c. Then it can become visible in the TEM. This growth process results in a different equilibrium void shape than that expected on an interface with uniform energies. The notion of non-uniform interface energies explains the asymmetric void distribution about bimetal interfaces reported here.

Discussion

Previous simulations have found that similar wetting arguments to those given above may also be used to explain the formation of He precipitates at Cu-Nb interfaces with a Kurdjumov-Sachs orientation relationship (KS Cu-Nb)16. Our investigation is consistent with this previous simulation work. However, no direct experimental validation of this prediction was previously available. The present work provides such validation through the TEM observations of Cu-Ag interfaces shown in Fig. 1. Although the Cu-Ag and KS Cu-Nb interfaces have different interface structures and orientations29, they show the same void distribution phenomenon indicating the wetting controlled void distribution is universal at bimetal interfaces. The conditions governing interface void formation are important since the configuration of voids and bubbles significantly influence the properties of irradiated materials17,34. Moreover, by controlling the internal structure of bimetal interfaces, it may be possible to tailor the way they interact with voids and other precipitates35. For example, interfaces may be used as precipitation templates for implanted impurities, reducing the damage caused by such impurities36.

In summary, using TEM we have demonstrated that voids distribute at hetero-interfaces asymmetrically. The asymmetric void distribution can be rationalized based on the phase with the lower surface energy and wetting of interfaces with heterogeneous formation energies. These findings can provide insight into designing irradiation-resistant materials. Voids that just touch the interfaces may be less harmful to cohesion than those that overlap the interfaces because the former will give rise to a smaller reduction of interface bonded area than the latter. Optimization could include choosing proper constituents of the composites and tuning their interface energies by adjusting their crystallography such that void-interface overlap or even touching is hindered.

Methods

Materials fabrication

The bulk nanolayered Cu-Ag composite with an eutectic composition (40–60 at.% Cu-Ag) was fabricated via a flux-melting technique22. The starting materials used for the eutectic preparation are Ag (99.999% pure) and Cu (99.999% pure) fragments. Mixtures of the starting materials were placed in fused silica tubes together with pieces of B2O3 flux. The tubes were then heated slowly to above 1200 °C to melt the B2O3, Ag and Cu. When the flux melting was completed, the fused silica tubes containing the melt and the B2O3 flux were quenched into water. The diameter and length of the ingots are about 8 mm 50 mm, respectively.

TEM characterization

TEM samples were prepared by a conventional cross-sectioning method, consisting of low-speed saw cutting, mechanical polishing, dimpling and ion milling on a Gatan precision ion polishing system (PIPS) operated at 3.5 kV. TEM was performed on a Cs-corrected Titan 80–300 (FEI) operated at 300 kV.

He ion irradiation

He ion irradiation was conducted using a Danfysik 200 kV ion implanter at Los Alamos National Laboratory. The TEM samples were mounted with silver paste onto a large Cu holder, through which the irradiation temperatures were controlled. Additionally, the He ion beam was perpendicular to the TEM samples. To generate voids in the TEM observation available regions of TEM samples (generally with thickness ), high enough energy (200 keV) and fluence (2 × 1017 ions/cm2) according to SRIM calculation37, as well as high temperature 450 °C were selected2. In this setting, a damage level of ~3 displacements per atom (dpa) was produced in Cu, Ag and Nb. Moreover, to confirm that these cavities are voids, the distribution of He concentration in the TEM samples have been calculated by SRIM37 and low-temperature irradiation experiments with the same He ion energy and fluence were performed (Supplementary information).

), high enough energy (200 keV) and fluence (2 × 1017 ions/cm2) according to SRIM calculation37, as well as high temperature 450 °C were selected2. In this setting, a damage level of ~3 displacements per atom (dpa) was produced in Cu, Ag and Nb. Moreover, to confirm that these cavities are voids, the distribution of He concentration in the TEM samples have been calculated by SRIM37 and low-temperature irradiation experiments with the same He ion energy and fluence were performed (Supplementary information).

Atomistic modelling and analyses of the Cu-Ag interface

We use molecular dynamics simulations to obtain the Cu-Ag (111) interface structure. The Cu-Ag (111) bilayer model with cube-on-cube orientation relation is first constructed by joining two rectangular single crystals of Cu and Ag together. The orientations for both crystals are the same: x-axis along  , y-axis along [111] and z-axis along

, y-axis along [111] and z-axis along  . The interface is perpendicular to the y direction. Periodic boundary condition (PBC) are applied in the x and z directions and a semi-fixed boundary condition is applied in the y direction14. To minimize the internal stress created by the imposition of PBCs, model dimensions are chosen to be 19 nm, 10 nm and 11 nm in the x, y and z directions. We modelled interatomic interactions using embedded-atom method (EAM) potentials for Cu, Ag and their cross pair30,38. Such potentials have been shown to produce reliable interface properties14,24,39. The structure is then relaxed using quenching molecular dynamics40. Each layer of the equilibrium structure has zero stress in the y direction and less than 10 MPa in the x and z directions.

. The interface is perpendicular to the y direction. Periodic boundary condition (PBC) are applied in the x and z directions and a semi-fixed boundary condition is applied in the y direction14. To minimize the internal stress created by the imposition of PBCs, model dimensions are chosen to be 19 nm, 10 nm and 11 nm in the x, y and z directions. We modelled interatomic interactions using embedded-atom method (EAM) potentials for Cu, Ag and their cross pair30,38. Such potentials have been shown to produce reliable interface properties14,24,39. The structure is then relaxed using quenching molecular dynamics40. Each layer of the equilibrium structure has zero stress in the y direction and less than 10 MPa in the x and z directions.

We analysed the relaxed Cu-Ag interface model by performing coordination number and energy calculations at the interface. The coordination number of an interfacial atom is the number of atoms within a cut-off radius (rcut). The cut-off radius is chosen as the average of the first and second nearest neighbour distances in bulk conditions. For instance, the cut-off radii used for Cu and Ag atoms are 0.309 nm and 0.349 nm, respectively. We computed the location-dependent interface energy on an array consisting of 91 and 51 points along the x and z directions of the interface, respectively. For each sampling point, local interface energy is calculated within a cylinder straddling on the interface with radius r = 0.5 nm and height h = 7 nm. The axis of the cylinder is parallel to the interface normal; the geometric center of the cylinder coincides with the sampling point on the interface. The local interface energy is calculated according to  , where nCu and nAg are the number of Cu and Ag atoms in the cylinder.

, where nCu and nAg are the number of Cu and Ag atoms in the cylinder.  and

and  are the cohesive energies per atom of Cu and Ag.

are the cohesive energies per atom of Cu and Ag.

Additional Information

How to cite this article: Zheng, S. et al. Adhesion of voids to bimetal interfaces with non-uniform energies. Sci. Rep. 5, 15428; doi: 10.1038/srep15428 (2015).

References

Zheng, S. et al. High-strength and thermally stable bulk nanolayered composites due to twin-induced interfaces. Nature Communications 4, 1696 (2013).

Han, W. Z. et al. Design of Radiation Tolerant Materials Via Interface Engineering. Adv Mater 25, 6975–6979 (2013).

Beyerlein, I. J., Caro, A., Demkowicz, M. J., Mara, N. A., Misra, A. & Uberuaga, B. P. Radiation damage tolerant nanomaterials. Mater Today 16, 443–449 (2013).

Liu, X. C., Zhang, H. W. & Lu, K. Strain-Induced Ultrahard and Ultrastable Nanolaminated Structure in Nickel. Science 342, 337–340 (2013).

Misra, A., Hirth, J. P. & Hoagland, R. G. Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites. Acta Mater 53, 4817–4824 (2005).

Anderson, P. M., Foecke, T. & Hazzledine, P. M. Dislocation-based deformation mechanisms in metallic nanolaminates. Mrs Bulletin 24, 27–33 (1999).

Phillips, M. A., Clemens, B. M. & Nix, W. D. A model for dislocation behavior during deformation of Al/Al3SC (fcc/L1(2))metallic multilayers. Acta Mater 51, 3157–3170 (2003).

Singh, B. N. Effect of grain-size on void formation during high-energy electron-irradiation of austenitic stainless-steel. Philos Mag 29, 25–42 (1974).

Bai, X. M., Voter, A. F., Hoagland, R. G., Nastasi, M. & Uberuaga, B. P. Efficient Annealing of Radiation Damage Near Grain Boundaries via Interstitial Emission. Science 327, 1631–1634 (2010).

Gibbs, J. W. A Method of Geometrical Representation of the Thermodynamic Properties of Substances by Means of Surfaces. Transactions of the Connecticut Academy 2, 382–404 (1871).

Amelinckx, S. The direct observation of dislocations. Academic Press (1964).

Laird, C. & Aaronson, H. I. Dislocation structures of broad faces of widmanstatten gamma plates in an a1-15 percent ag alloy. Acta Metall 15, 73–103 (1967).

Sutton, A. P. & Balluffi, R. W. Interfaces in Crystalline Materials. OUP (2006).

Shao, S., Wang J. & Misra, A. Energy minimization mechanisms of semi-coherent interfaces. J Appl Phys 116, 023508 (2014).

Demkowicz, M. J., Hoagland, R. G. & Hirth, J. P. Interface structure and radiation damage resistance in Cu-Nb multilayer nanocomposites. Phys Rev Lett 100, 136102 (2008).

Kashinath, A., Misra, A. & Demkowicz, M. J. Stable Storage of Helium in Nanoscale Platelets at Semicoherent Interfaces. Phys Rev Lett 110, 086101 (2013).

Demkowicz, M. J., Misra, A. & Caro, A. The role of interface structure in controlling high helium concentrations. Curr Opin Solid State Mat Sci 16, 101–108 (2012).

Di, Z. et al. Tunable helium bubble superlattice ordered by screw dislocation network. Phys Rev B 84, 052101 (2011).

Braski, D. N., Schroeder, H. & Ullmaier, H. Effect of tensile-stress on the growth of helium bubbles in an austenitic stainless-steel. J Nucl Mater 83, 265–277 (1979).

Lane, P. L. & Goodhew, P. J. Helium bubble nucleation at grain-boundaries. Philos Mag A-Phys Condens Matter Struct Defect Mech Prop 48, 965–986 (1983).

Han, W. Z., Demkowicz, M. J., Fu, E. G., Wang, Y. Q. & Misra, A. Effect of grain boundary character on sink efficiency. Acta Mater 60, 6341–6351 (2012).

Shen, T. D., Schwarz, R. B. & Zhang, X. Bulk nanostructured alloys prepared by flux melting and melt solidification. Appl Phys Lett 87, 141906 (2005).

de Gennes, P.-G., Brochard-Wyart, F. & Quere, D. Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves. Springer (2004).

Shao, S., Wang, J., Misra, A. & Hoagland, R. G. Spiral Patterns of Dislocations at Nodes in (111) Semi-coherent FCC Interfaces. Sci Rep 3, 02448 (2013).

Wang, J., Kang, K., Zhang, R. F., Zheng, S. J., Beyerlein, I. J. & Mara, N. A. Structure and Property of Interfaces in ARB Cu/Nb Laminated Composites. JOM 64, 1208–1217 (2012).

Demkowicz, M. J. & Thilly, L. Structure, shear resistance and interaction with point defects of interfaces in Cu-Nb nanocomposites synthesized by severe plastic deformation. Acta Mater 59, 7744–7756 (2011).

Sutton, A. P. & Balluffi, R. W. Overview .61. on geometric criteria for low interfacial energy. Acta Metall 35, 2177–2201 (1987).

Tian, Y. Z. & Zhang, Z. F. Bulk eutectic Cu–Ag alloys with abundant twin boundaries. Scr Mater 66, 65–68 (2012).

Zheng, S. J. et al. Plastic instability mechanisms in bimetallic nanolayered composites. Acta Mater 79, 282–291 (2014).

Mishin, Y., Mehl, M. J., Papaconstantopoulos, D. A., Voter, A. F. & Kress, J. D. Structural stability and lattice defects in copper: Ab initio, tight-binding and embedded-atom calculations. Phys Rev B 63, 224106 (2001).

Beyerlein, I. J., Wang, J. & Zhang, R. F. Mapping dislocation nucleation behavior from bimetal interfaces. Acta Mater 61, 7488–7499 (2013).

Todd B. D., Lyndenbell R. M. Surface and bulk properties of metals modeled with sutton-chen potentials. Surf Sci 281, 191–206 (1993).

Rowlinson, J. S. & Widom, B. Molecular Theory of Capillarity. Clarendon Press (1982).

Li, N., Nastasi, M. & Misra, A. Defect structures and hardening mechanisms in high dose helium ion implanted Cu and Cu/Nb multilayer thin films. Int J Plast 32–33, 1–16 (2012).

Vattre, A. J., Abdolrahim, N., Kolluri, K. & Demkowicz, M. J. Computational design of patterned interfaces using reduced order models. Sci Rep 4, 06231 (2014).

Yuryev, D. V. & Demkowicz, M. J. Computational design of solid-state interfaces using O-lattice theory: An application to mitigating helium-induced damage. Appl Phys Lett 105, 221601 (2014).

Ziegler, J., Biersack, J. & Littmark, U. The stopping and range of ions in solids. Pergamon Press (1985).

Williams, P. L., Mishin, Y. & Hamilton, J. C. An embedded-atom potential for the Cu-Ag system. Model Simul Mater Sc Eng 14, 817–833 (2006).

Mara, N. A., Beyerlein, I. J., Carpenter, J. S. & Wang, J. Interfacially Driven Deformation Twinning in Bulk Ag-Cu Composites. JOM 64, 1218–1226 (2012).

Demkowicz, M. J., Wang, J. & Hoagland, R. G. Interfaces between Dissimilar Crystalline Solids. In: Dislocations in Solids (ed^(eds Hirth, J.P. ). Elsevier (2008).

Acknowledgements

This work is supported by the Center for Materials at Irradiation and Mechanical Extremes, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Office of Basic Energy Sciences under Award Number 2008LANL1026. This work was performed, in part, at the Center for Integrated Nanotechnologies, an Office of Science User Facility operated for the U.S. Department of Energy, Office of Science. S. Z. gratefully acknowledges support for this research by “Hundred Talents Project” of Chinese Academy of Sciences, National Natural Science Foundation of China (grant number 51401208) and Shenyang National Laboratory for Materials Science (grant number 2015RP18).

Author information

Authors and Affiliations

Contributions

S.Z., N.A.M. and I.J.B. designed the experiments, S.Z. did the TEM and HRTEM characterization, S.S. and M.J.D. performed the MD simulations, J.Z. and Y.W. carried out He ion irradiation and S.Z., M.J.D. and I.J.B. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zheng, S., Shao, S., Zhang, J. et al. Adhesion of voids to bimetal interfaces with non-uniform energies. Sci Rep 5, 15428 (2015). https://doi.org/10.1038/srep15428

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep15428

This article is cited by

-

Metal-matrix nanocomposites under compressive loading: Towards an understanding of how twinning formation can enhance their plastic deformation

Scientific Reports (2020)

-

Faceted He-Filled “Pancakes” Confined within Nanoscale Metal Layers

JOM (2020)

-

Micro-scale modeling of interface-dominated mechanical behavior

Journal of Materials Science (2018)

-

Microstructure Evolution and Mechanical Response of Nanolaminate Composites Irradiated with Helium at Elevated Temperatures

JOM (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.