Abstract

We report the preparation of novel quasi-one-dimensional (quasi-1D) C60 nanostructures on rippled graphene. Through careful control of the subtle balance between the linear periodic potential of rippled graphene and the C60 surface mobility, we demonstrate that C60 molecules can be arranged into a quasi-1D C60 chain structure with widths of two to three molecules. At a higher annealing temperature, the quasi-1D chain structure transitions to a more compact hexagonal close packed quasi-1D stripe structure. This first experimental realization of quasi-1D C60 structures on graphene may pave a way for fabricating new C60/graphene hybrid structures for future applications in electronics, spintronics and quantum information.

Similar content being viewed by others

Introduction

Graphene, a single atom thick layer of sp2 hybridized carbon atoms, is a unique two-dimensional (2D) material that exhibits fascinating physical properties and has numerous potential applications1,2,3. To understand the physical and chemical properties of graphene and explore its potential applications, significant research efforts have recently been devoted to investigate the adsorption and desorption of various molecules on graphene and to further optimize and control the molecule/graphene hybrid structures. For these studies, graphene grown by chemical vapor deposition (CVD) on metals is emerging as an ideal platform, which is also one of the most promising candidates for practical applications of graphene that require scalable production of graphene4,5.

Buckminsterfullerene, C60, is a closed-cage structure composed of 60 carbon atoms linked by single and double bonds to form a hollow sphere. Due to its many exciting chemical and physical properties, numerous applications have been demonstrated in single-electron transistors, superconductivity and photovoltaics6,7. Due to its single element composition and highly symmetrical shape, C60 often serves as a model system for understanding molecule-surface interactions. C60 on epitaxial graphene, a system exclusively formed of elemental carbon, provides an ideal model system to study interactions at the molecular level, electromigration, molecular electronics and spintronics. On most metal or graphite surfaces, C60 molecules self-assemble into isotropic thermodynamically favorable hexagonal close-packed monolayers8,9,10,11.

A particularly interesting arrangement of C60 molecules is quasi-one-dimensional (quasi-1D) structures. Highly ordered quasi-1D molecular configurations are excellent model systems and prototypes of 1D quantum confinement of electronic states and thus have potential importance in electronic nanodevices, spintronics and solid-state quantum computation12,13,14,15. However, quasi-1D C60 nanostructures have been rarely realized experimentally due to their highly anisotropic configuration. A few previously reported experimental results include C60 peapods by embedding C60 molecules in carbon nanotubes, 1D C60 structures aligned along step edges on vicinal surfaces of metal single crystals and C60 chains on self-assembled molecular layers16,17,18,19,20,21,22,23,24,25,26. For CVD graphene, periodically linear rippled structures have been previously observed on various growth substrates27,28. Here we experimentally realize quasi-1D C60 nanostructures on rippled graphene by utilizing the linear periodic potential in graphene as a template. Through carefully controlling the subtle balance between the weak periodic potential and the surface mobility of C60, C60 molecules on rippled graphene are arranged into a novel quasi-1D C60 chain structure with widths ranging from two to three molecules wide. At a higher annealing temperature, the quasi-1D chain structure transitions to a more compact hexagonal close packed quasi-1D stripe structure. To the best of our knowledge, this is the first experimental realization of quasi-1D C60 structures on graphene. Our experimental results may pave a way for fabricating new C60/graphene hybrid structures for future applications in electronics, spintronics (e.g. endohedral fullerenes with magnetic spins can be aligned in quasi-1D configurations) and quantum information.

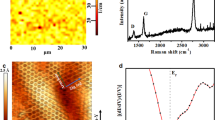

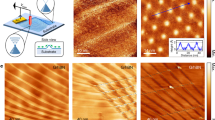

C60 molecules were deposited onto graphene grown by the CVD method on Cu foil at the background pressure below 2.0 × 10−8 mbar (more details are in the Method section). After post-deposition annealing at 423 K, we observed small atomically flat facets with typical sizes ranging from 50 nm to 200 nm on the surface. These facets can be classified into two predominant types based on the distinguishable surface characteristics, labeled as type A and type B (see the Supporting Information Figs. S1a and S1b). On type A facets, C60 molecules form hexagonal close packed monolayers and islands (see the Supporting Information Fig. S3a). On type B facets we observed a characteristic quasi-1D feature of C60 molecules as shown in the large-area overview STM image in Fig. 1a. A closer inspection of the high-resolution STM images reveals the details of this quasi-1D structure featured in Fig. 1b, in which each bright protrusion represents a C60 molecule. Typically, the quasi-1D chains consist of two or three C60 rows, referred to as bimolecular and trimolecular C60 chains, respectively. Within a chain, the C60-C60 intermolecular spacing is 1.00 ± 0.01 nm, indicating that C60 molecules arrange in a close packed manner. From the line profile shown in Fig. 1c that corresponds to the dashed line marked in Fig. 1b, the isolation between adjacent C60 chains can be clearly seen from the gap between the second and the third peaks. Here, the second and the third peaks represent the C60 molecules belonging to neighboring chains. The measured average interchain distance, defined as the distance between the centers of adjacent C60 rows belonging to neighboring chains, is 1.23 ± 0.02 nm, as schematically shown in Fig. 3a. In our measurements, we observed that the chains consist exclusively of two or three C60 rows. From statistical analysis, the bimolecular chains are shown to be more numerous, with a ratio of number of bimolecular to trimolecular chains of about 2.0. As observed in large-scale STM images, the chains are usually arranged in a 3-2-2 or 2-3-2 manner. In our measurements, we observed that the orientation of these C60 chains was exclusively along the same direction, nearly parallel to the bending axis. In the chain structure we also observed some junctions where a bimolecular segment transitions into a trimolecular segment, or vice versa.

Quasi-1D bimolecular and trimolecular C60 chains after annealing at 423 K.

(a) Large scale STM image of C60 on graphene showing well ordered quasi-1D structure on Cu facets (Vs = 1.90 V, I = 0.40 nA). (b) High-resolution image of bimolecular and trimolecular C60 chains. Within the chains, the C60-C60 intermolecular spacing is ~1.0 nm and the interchain distance, defined as the distance between the centers of adjacent C60 rows belonging to neighboring chains, is 1.23 nm (Vs = 1.95 V, I = 0.50 nA). (c) A line profile along the close packed orientation as marked with the dashed blue line in (b).

Schematic models of the C60 chain and stripe structures showing the graphene layer (small dark green balls) and the C60 layer (dark blue space filling spheres) on top of the graphene layer.

(a) and (c) Bimolecular and trimolecular C60 chains on graphene after annealing at 423 K. (b,d) C60 stripe structure with 6-row width after annealing at 487 K.

In order to investigate the temperature evolution of the C60 nanostructures on graphene, we performed subsequent annealing at a higher temperature, 487 K, for 2 hours. After annealing at this temperature, the C60 chain structure disappeared and a new more compact hexagonal close packed quasi-1D stripe structure emerged, as shown in Fig. 2a. The zoom in topographic STM image in Fig. 2b reveals hexagonal close packed quasi-1D stripes with widths of three to six C60 rows. A noticeable difference from the C60 chain structure is that these quasi-1D stripes are formed on staggered narrow terraces, which are between nearly straight and parallel step edges (Fig. 2b,d). In the stripe structure there is no spacing between neighboring stripes. In contrast, the quasi-1D stripe structure appears more crowded than the close packed structure. The lateral inter-row distance between the two rows adjacent to the step edges, on the upper and lower terraces respectively, is 0.75 ± 0.01 nm, as schematically shown in the ball models in Fig. 3b,d. This high-density arrangement seems to accommodate the underlying narrow terraces that formed after annealing at 487 K. On the narrow terraces, C60 molecules are arranged in a close packed manner with a characteristic C60-C60 intermolecular spacing of 1.00 ± 0.02 nm. We also noticed that the C60 row near the step edge on the upper terrace is with a measured height higher than the other rows on the same terrace as shown in Fig. 2b,d. Different from the dominance of C60 chains with widths of two or three C60 rows, the width of the stripes varies from three to eight rows of C60 (see Fig. 2a,b and Fig S2c). The most common stripes have a width of 6 C60 rows. Figure 2c is the normalized distribution of the C60 stripe width in terms of the number of C60 rows. The 6-row stripes are the most common stripe structure, with a probability of 45% and 5-row stripes are the second most likely stripe structure. The 8-row and 3-row stripes are minority groups. The lateral periodicity of these typical 6-row stripes is 5.08 ± 0.02 nm, almost exactly the same as the lateral spacing of a bimolecular chain plus a neighboring trimolecular chain in the chain structure, which is also 5.08 ± 0.02 nm. The stripes are nearly parallel to each other and the orientation of the stripes is along the same orientation with the C60 chains. Similar to the chain structure, there are junction regions in these quasi-1D stripes. Another detail worth noticing is that the down hill direction of the stripes is determined by the boundaries of the facets. The protrusion boundaries are the downhill side while the depression boundaries correspond to the uphill side (see Figs. S2a and S2b in the Supporting Information).

Self-assembled hexagonal close packed quasi-1D C60 stripe structure on rippled graphene after annealing at 487 K.

(a) Large-scale STM image of C60 on graphene showing hexagonal close packed quasi-1D stripe structure (Vs = 2.20 V, I = 0.20 nA). (b) High-resolution image of the hexagonal close packed quasi-1D stripes (Vs = 2.40 V, I = 0.20 nA). (c) Normalized distribution of C60 stripe widths in terms of the number of rows. (d) A line profile along the close packed orientation as marked with the dashed blue line in (b).

To compare the chain structure and the stripe structure more clearly and visually, we try to use a 3D model to explain it. Figure 3a,c is the schematic model for the bimolecular and trimolecular C60 chains with dark blue spheres representing C60 molecules and green spheres representing carbon atoms of underlying graphene. The single C60 row on the left side is the adjacent row in the next bimolecular or trimolecular chain. The width of a bimolecular cell (chain plus the interchain spacing) plus a trimolecular cell is 5.08 ± 0.02 nm. From these models, we can clearly see the large spacing (1.23 nm) between adjacent chains (Fig. 3a). In the stripe structures, the inter-row spacing between the C60 rows adjacent to step edges from both sides is 0.75 nm, narrower than the other C60 rows arrange in a hexagonal close packed manner (Fig. 3b,d).

To gain detailed insight into the growth mechanisms of the quasi-1D C60 chain and stripe structures, we used STM to characterize the underlying graphene of the empty areas adjacent to the C60 quasi-1D structures and the bare graphene surface before and after C60 desorption. After the annealing temperature up to 578 K, all C60 molecules were desorbed from the surface and the surface was restored to bare graphene on Cu. The desorption temperature is close to the desorption temperature of C60 molecules on highly ordered pyrolytic graphite (HOPG)29. The similar deposition temperature indicates a similar activation energy, which is 1.69 eV for C60 on graphite based on the thermal desorption spectroscopy study29. Atomic-resolution images taken on small flat facets of the substrates, where the quasi-1D C60 chains and stripes are grown, show a well-defined linear periodic graphene rippled superstructure with an orientation close to the chain and stripe orientation. Figure 4a shows the typical linear periodic modulation of graphene with the periodicity of 0.75 ± 0.01 nm and with the same orientation of the observed C60 chains and stripes, as indicated by the blue arrow in Fig. 4b. The linear periodic structure shown in Fig. 4a,b is attributed to the case where the underlying Cu facet is Cu(100). To confirm that, we checked two characteristic surface features. The step edges have a height of ~0.18 nm, which is the characteristic step height of monoatomic steps on Cu (100) surface30,31. This kind of linear modulation of graphene due to the square lattice symmetry of the Cu(100) surface has been experimentally observed before27,28,30. The superposition of a graphene lattice on a Cu(100) surface with various angles produces linear rippled patterns with different periodicity27,28,30. At some certain angle, there will be maze-like reconstruction of graphene on Cu(100)32. However, superstructures of graphene on Cu(111) surface have characteristic six-fold symmetry33,34,35,36,37,38, which can be distinguished easily from the linear periodic ripple structure in our experiments. In a few cases, linear superstructures of graphene on Cu(111) were also observed, but they usually have a much larger periodicity and disappear after annealing to 500 K39. The graphene ripples in our experiments survived after annealing to 693 K. From all these observations, it is reasonable to conclude that the Cu surface underneath rippled graphene is Cu(100). Based on the periodicity of the ripples, we are able to calculate the relative angle between graphene and the underlying Cu(100) surface. Figure 4c is a suggested atomic model for the rippled graphene. The zigzag direction of graphene has an angle of 13.0° relative to the  direction of the underlying Cu(100). The calculated periodicity is 0.80 nm and the orientation of ripples is with a relative angle of 15.2° to the zigzag direction of graphene, consistent with the measured angle of 15.0° ± 0.5°. The calculated periodicity is slightly larger than the measured periodicity of 0.75 nm. This difference may attribute to the out of plane distortion of graphene ripples, as shown in the line profile in Fig. 4d.

direction of the underlying Cu(100). The calculated periodicity is 0.80 nm and the orientation of ripples is with a relative angle of 15.2° to the zigzag direction of graphene, consistent with the measured angle of 15.0° ± 0.5°. The calculated periodicity is slightly larger than the measured periodicity of 0.75 nm. This difference may attribute to the out of plane distortion of graphene ripples, as shown in the line profile in Fig. 4d.

STM topography images of rippled graphene on Cu.

(a) Large area STM topographic image of the rippled graphene showing well-defined linear periodic modulation with a 0.75 nm spatial modulation frequency (Vs = 0.80 V, I = 1.0 nA). (b) Magnified STM image of the rippled graphene with the ball model of C60 molecules in the arrangement of a bimolecular (right) and trimolecular (left) chain with the orientation along the ripples. The blue arrow indicates the orientation of the linear graphene ripples and the C60 chains, with a measured angle of 15.0° ± 0.5° relative to the zigzag direction of graphene, indicated by the black arrow. The periodicity of the linear modulation is 0.75 ± 0.01 nm (Vs = 0.80 V, I = 1.0 nA). (c) Suggested ball and stick model of the overlay of graphene on Cu(100). The zigzag direction of graphene is rotated by 13.0° with respect to the  direction of the Cu(100) underneath. The green balls represent carbon atoms of graphene and the yellow balls represent Cu atoms of the underlying Cu surface. The blue arrow indicates the orientation of the linear moiré pattern and the black arrow indicates the zigzag direction of graphene. (d) Line profile along the zigzag orientation of graphene (marked as a dashed white line in (a)) showing the periodic modulation.

direction of the Cu(100) underneath. The green balls represent carbon atoms of graphene and the yellow balls represent Cu atoms of the underlying Cu surface. The blue arrow indicates the orientation of the linear moiré pattern and the black arrow indicates the zigzag direction of graphene. (d) Line profile along the zigzag orientation of graphene (marked as a dashed white line in (a)) showing the periodic modulation.

The orientation of the graphene ripples is fully consistent with that of the C60 chain structure. Based on the rippled graphene structure, it is possible for us to explain the formation of the chain structure from the point of view of mechanical stability40. The most common morphology for the C60 on flat graphene is the hexagonal close-packed structure due to the weak diffusion barrier on flat graphene and the much stronger C60-C60 interaction41,42. On rippled graphene, the linear periodic potential provides a template for C60 to arrange into more stable quasi-1D configurations. The linear periodicity of rippled graphene, 0.75 ± 0.01 nm, is smaller than the typical inter-row distance of 0.87 nm in the C60 closed packed arrangement. C60 molecules randomly occupy the valley sites of the linear periodic potential at the initial stage of growth. It is possible for C60 molecules to settle down in the adjacent ripples at a less stable state because C60 molecules are forced to stay slightly off the valley sites. In this way, two or three adjacent linear graphene ripples are filled up. This is consistent with the observation that almost all C60 chains consist of two or three rows. Based on a geometrical and energetic argument, it is easy to see that chains with 4 or more rows are less likely to form. Compared with the formation of the bimolecular chains, the possibility to form trimolecular chains (both sides need a C60 molecule sitting down around the middle C60 molecule) is about half the probability of the formation of the bimolecular chains, which only need one side to be occupied with C60 molecules. From a Monte Carlo statistical approach, C60 molecules adsorbed on such a linear graphene sheet will be stabilized in one of the valleys40 and if a second or a third molecular row packs closely to the stabilized molecular row, the chain structure consequently forms. We expect that C60 molecules with less thermal energy can form monomolecular chains. That is one of the possible directions to further tune and control the formation of these quasi-1D structures.

In order to understand how the bimolecular and trimolecular chains transform into the C60 stripe structure after annealing at 487 K, we will start by considering the diffusion of Cu atoms underneath graphene and the arrangement of C60 molecules on graphene. When annealing at a higher temperature of 487 K, C60 molecules have a higher probability to overcome the potential energy difference between the hilltop and the valley sites of rippled graphene and rearrange into chains with larger width due to the higher thermal excitation. The junction structure in the bimolecular and trimolecular chains probably provides diffusion channels for C60 molecules to transfer between adjacent chains resulting in emergent chains with larger widths. Considering that the arrangement of bimolecular and trimolecular chains is usually 2-3-2 or 3-2-2 as described above, it is reasonable to assume that the emergent chains with width of five C60 rows are the configuration with highest probability to form, compared with chains of other widths. The distribution of chain widths and stripe widths may imply that at the annealing temperature of 487 K, the thermal excitation can only drive C60 molecules to cross over one or two energy barriers, but not more. When adjacent bimolecular and trimolecular chains merge into a 5-row chain, the interchain spacing between the merged 5-row chain to its neighboring chains can be generated from the initial interchain spacing in the chain configuration (1.23 nm), which is 1.59 nm. This spacing is slightly smaller than the interchain spacing of 1.73 nm required for a new C60 row to fill in the empty space. It has been previously reported that Cu atoms can easily diffuse underneath a graphene sheet even at room temperature. These detailed observations suggest that copper atoms can diffuse along smooth step edges and kinked sites and even dissociate from step edges, indicating a weak interaction between the graphene sheet and the underlying copper atoms30. Here the surface reconstruction due to diffusion of underlying copper atoms provides the possibility for another C60 row to form along the straight step edges and results in hexagonal close packed quasi-1D C60 stripes with the typical width of six rows. The origin of C60 stripes with other number of rows can be attributed to the emergence of different combinations of C60 chains, such as two bimolecular chains emerging into a stripe with five C60 rows.

In both C60 chain and stripe structures (Figs 1 and 2), we notice that a few C60 molecules appear higher than others and the relative height shows bias dependence. The difference is possibly due to the defect sites in the underlying graphene that appear as bright sites in the STM images of graphene (Fig. 4a).

In summary, our results demonstrate that novel quasi-1D C60 structures can be realized on rippled graphene. These quasi-1D structures are controllable by tuning the temperature, from a chain structure with widths of two or three C60 molecules and then to a hexagonal close packed quasi-1D stripe structure. In our experiments, temperature is the main tunable parameter. Based on the subtle balance between the C60-C60 intermolecular and the C60-graphene interactions, as well as the size of the graphene ripples due to the moiré patterns, we expect that the quasi-1D C60 structures on rippled graphene can be further tuned and controlled by varying the size of the ripples, the coverage of adsorbed C60 molecules and the temperature.

Methods

All experiments were carried out in an ultra-high vacuum (UHV) scanning tunneling microscope system (Omicron LT-STM). Before C60 deposition, the graphene grown by the CVD method on Cu foil was annealed for 12 hours at 673 K in a preparation chamber with a base pressure of low 10−10 mbar. C60 powder (MER Corporation, 99.5% purity) was loaded into the homemade Knudsen cell mounted on the load lock of the LT-STM system. The C60 source was degassed at a pressure of low 10−8 mbar before deposition. C60 molecules were then sublimated at a deposition rate of ~0.9 ML/min with the background pressure below 2.0 × 10−8 mbar. During the deposition process, the substrate was kept at room temperature. The samples were then subsequently annealed at 423 K, 487 K and 578 K respectively in the preparation chamber of the STM system with the base pressure at low 10−10 mbar. All the STM measurements were performed at room temperature in the STM characterization chamber with a base pressure of about 3.0 × 10−11 mbar.

Additional Information

How to cite this article: Chen, C. et al. Temperature Evolution of Quasi-one-dimensional C60 Nanostructures on Rippled Graphene. Sci. Rep. 5, 14336; doi: 10.1038/srep14336 (2015).

References

Novoselov, K. S. et al. Two-dimensional gas of massless Dirac fermions in graphene. Nature 438, 197 (2005).

Zhang, Y. B., Tan, Y. W., Stormer, H. L. & Kim, P. Experimental observation of the quantum Hall effect and Berry’s phase in graphene. Nature 438, 201 (2005).

Castro Neto, A. H., Guinea, F., Peres, N. M. R., Novoselov, K. S. & Geim, A. K. The electronic properties of graphene. Rev Mod Phys 81, 109 (2009).

Li, X. S. et al. Large-Area Synthesis of High-Quality and Uniform Graphene Films on Copper Foils. Science 324, 1312 (2009).

Mattevi, C., Kim, H. & Chhowalla, M. A review of chemical vapour deposition of graphene on copper. J Mater Chem 21, 3324 (2011).

Kadish, K. M. & Ruoff, R. S. Fullerenes: Chemistry, Physics and Technology. (Wiley, New York, 2000).

Dresselhaus, M. S., Dresselhaus, G. & Eklund, P. C. Science of Fullerenes and Carbon Nanotubes. (Academic Press, 1996).

Liu, H. & Reinke, P. C60 thin film growth on graphite: Coexistence of spherical and fractal-dendritic islands. J Chem Phys 124, 164707 (2006).

Yu, H. B. et al. Scanning Tunneling Microscopy of C60 on Graphite. Surf Sci 286, 116 (1993).

Kenny, D. J. & Palmer, R. E. Nucleation and growth of C60 thin films on graphite. Surf Sci 447, 126 (2000).

Hashizume, T. et al. Intramolecular Structures of C60 Molecules Adsorbed on the Cu(111)-(1×1) Surface. Phys Rev Lett 71, 2959 (1993).

Harneit, W. Fullerene-based electron-spin quantum computer. Phys Rev A 65, 032322 (2002).

Burkard, G., Loss, D. & DiVincenzo, D. P. Coupled quantum dots as quantum gates. Phys Rev B 59, 2070 (1999).

Joachim, C. & Ratner, M. A. Molecular electronics: Some views on transport junctions and beyond. P Natl Acad Sci USA 102, 8801 (2005).

Hornbaker, D. J. et al. Mapping the one-dimensional electronic states of nanotube peapod structures. Science 295, 828 (2002).

Smith, B. W., Monthioux, M. & Luzzi, D. E. Encapsulated C60 in carbon nanotubes. Nature 396, 323 (1998).

Zhang, H. L. et al. C60 molecular chains on a-sexithiophene nanostripes. Small 3, 2015 (2007).

Tamai, A. et al. One-dimensional chains of C60 molecules on Cu(221). Surf Sci 566, 633 (2004).

Zeng, C. G., Wang, B., Li, B., Wang, H. Q. & Hou, J. G. Self-assembly of one-dimensional molecular and atomic chains using striped alkanethiol structures as templates. Appl Phys Lett 79, 1685 (2001).

Chen, L. et al. Tunable arrays of C-60 molecular chains. Advanced Materials 20, 484 (2008).

Zhang, H. L., Chen, W., Huang, H., Chen, L. & Wee, A. T. S. Preferential trapping of C60 in nanomesh voids. Journal of the American Chemical Society 130, 2720 (2008).

Chen, W., Zhang, H., Huang, H., Chen, L. & Wee, A. T. S. Orientationally ordered C60 on p-sexiphenyl nanostripes on Ag(111). Acs Nano 2, 693 (2008).

Huang, H. et al. “Zigzag” C60 chain arrays. Applied Physics Letters 92, 023105 (2008).

Feng, M., Lee, J., Zhao, J., Yates, J. T. & Petek, H. Nanoscale templating of close-packed C60 nanowires. Journal of the American Chemical Society 129, 12394 (2007).

Murray, P. W., Brookes, I. M., Haycock, S. A. & Thornton, G. Nanoscale templating of one-dimensional surface molecular structures. Physical Review Letters 80, 988 (1998).

Klitgaard, S. K. et al. Self-assembly of C60 into highly ordered chain-like structures on HOPG observed at ambient conditions. Surf Sci 601, L35 (2007).

Rasool, H. I. et al. Continuity of Graphene on Polycrystalline Copper. Nano Lett 11, 251 (2011).

Cho, J. et al. Atomic-Scale Investigation of Graphene Grown on Cu Foil and the Effects of Thermal Annealing. Acs Nano 5, 3607 (2011).

Ulbricht, H., Moos, G. & Hertel, T. Interaction of C60 with carbon nanotubes and graphite. Phys Rev Lett 90, 095501 (2003).

Rasool, H. I. et al. Atomic-scale characterization of graphene grown on copper (100) single crystals. J Am Chem Soc 133, 12536 (2011).

Wong, S. S., Pai, W. W., Chen, C. H. & Lin, M. T. Coverage-dependent adsorption superstructure transition of C60/Cu(001). Phys Rev B 82, 125442 (2010).

Xie, N. et al. Visualization of a Maze-Like Reconstruction of Graphene on a Copper Surface at the Atomic Scale. Chinese Phys Lett 30, 056802 (2013).

Zhao, L. et al. Influence of copper crystal surface on the CVD growth of large area monolayer graphene. Solid State Commun 151, 509 (2011).

Reckinger, N. et al. Anomalous moir, pattern of graphene investigated by scanning tunneling microscopy: Evidence of graphene growth on oxidized Cu(111). Nano Res 7, 154 (2014).

Gao, L., Guest, J. R. & Guisinger, N. P. Epitaxial Graphene on Cu(111). Nano Lett 10, 3512 (2010).

Niu, T. C., Zhou, M., Zhang, J. L., Feng, Y. P. & Chen, W. Growth Intermediates for CVD Graphene on Cu(111): Carbon Clusters and Defective Graphene. J Am Chem Soc 135, 8409 (2013).

Sule, P., Szendro, M., Hwang, C. & Tapaszto, L. Rotation misorientated graphene moire superlattices on Cu (111): Classical molecular dynamics simulations and scanning tunneling microscopy studies. Carbon 77, 1082 (2014).

Kim, W., Yoo, K., Seo, E. K., Kim, S. J. & Hwang, C. Scanning Tunneling Microscopy Study on a Graphene Layer Grown on a Single-crystal Cu(111) Surface by Using Chemical Vapor Deposition. J Korean Phys Soc 59, 71 (2011).

Jeon, I. et al. Passivation of Metal Surface States: Microscopic Origin for Uniform Mono layer Graphene by Low Temperature Chemical Vapor Deposition. Acs Nano 5, 1915 (2011).

Kim, S. Y., Hwang, H. J. & Kang, J. W. One-dimensional self-assembly of C60 molecules on periodically wrinkled graphene sheet: A Monte Carlo approach. Phys Lett A 377, 3136 (2013).

Cho, J. et al. Structural and Electronic Decoupling of C60 from Epitaxial Graphene on SiC. Nano Lett 12, 3018 (2012).

Jung, M. et al. Atomically resolved orientational ordering of C60 molecules on epitaxial graphene on Cu(111). Nanoscale 6, 11835 (2014).

Acknowledgements

We would like to thank Professor Ted Einstein for helpful discussions. C.C., H.Z. and C.T. acknowledge the financial support provided for this work by the U.S. Army Research Office under the grant W911NF-15-1-0414.

Author information

Authors and Affiliations

Contributions

C.T. designed the experiment. C.C., H.Z., A.M. and C.T. prepared the samples, performed the measurements and carried out the analysis. C.C., H.Z., A.M., J.R.H. and C.T. discussed the results and wrote the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Chen, C., Zheng, H., Mills, A. et al. Temperature Evolution of Quasi-one-dimensional C60 Nanostructures on Rippled Graphene. Sci Rep 5, 14336 (2015). https://doi.org/10.1038/srep14336

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep14336

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.