Abstract

A general strategy involving a novel and highly efficient aerobic benzylic oxidation promoted by cheap, reusable activated carbon in water is developed. Application of this method has been demonstrated in the benign synthesis of bioactive 2-benzoylbenzimidazoles and 2-benzoylbenzoxazoles derivatives. Furthermore, the activated carbon catalyst could be recovered and reused at least three times without significantly losing its activity. Preliminary research suggests that the oxidation mechanism may involve intermediate hydroperoxidation and that a portion of the final carbonyl product is obtained through a secondary benzylic alcohol intermediate. Finally, theoretical calculations reveal that the oxidation yield is closely associated with the electric density at the benzylic position of the substrate.

Similar content being viewed by others

Introduction

Benzylic oxidation is of considerable importance in both laboratory and industrial syntheses. Large quantities of oxidants including MnVII, CrVI and IV have traditionally been used for benzylic oxidation, but each results in large amounts of unwanted waste1,2,3. Molecular oxygen is a safe, inexpensive and environmentally friendly oxidant. Typically, benzylic oxidation with O2 is carried out under extreme conditions, such as high temperature or irradiation, thus forming a free radical or singlet oxygen4,5. However, most of aerobic benzylic oxidations that involve milder conditions may use expensive and/or toxic transition metals, such as Pd, Ru and Rh6,7,8,9.

Carbon chemistry is one of the most active and promising research fields in organic synthesis and catalyst research. Recent reports have shown an outstanding performance of nanoscaled carbon catalysts in several important reactions and related chemical industrial processes10,11,12,13,14. On the other hand, activated carbon (AC) is widely used as a low-cost adsorbent in the chemical industry. A new promising method has been reported using AC/O2 system for oxidation of benzylic alcohols or alkylarenes (fluorenes, xanthenes and anthrones) to the corresponding carbonyl compounds15,16. It is worth noting that using nonpolar m-xylene at relative high temperature is recommended in these methods.

The use of water as the reaction solvent becomes an attractive research area in green chemistry17,18,19,20. Although much progress has been made in the field of aqueous organic oxidations, only a few examples of benzylic oxidation performed in water by stoichiometric hypervalent iodine or photocatalysis have been described so far21,22,23. Herein, we wish to report an activated carbon-promoted aerobic benzylic oxidation in water as a green synthetic approach to 2-benzoylbenzimidazoles and 2-benzoylbenzoxazoles.

Results and Discussion

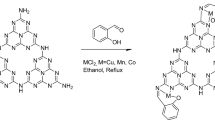

During the intended preparation of 5-methyl-2-(4-azylbenzyl)benzo[d]imidazole via catalytic hydrogenation for the evaluation of its bioactivity, 5-methyl-2-(4-nitrobenzyl)benzo[d]imidazole (1) was inadvertently placed in a mixture of 10% Pd/C in ethanol under air at room temperature for approximately 12 h. The majority of the starting material remained unreacted, however, two unexpected products, 5-methyl-2-(4-nitrohydroxybenzyl)benzo[d]imidazole (2) and 5-methyl-2-(4-nitrobenzoyl)benzo[d]imidazole (3), were detected. This reaction was checked using 2-(4-chlorobenzyl)benzo[d]imidazole (4) as the substrate and two oxidation products, 5 and 6, were obtained (Fig. 1). These results showed that the benzylic methylenes of 2-benzoylbenzo[d]imidazoles could be oxidized in air in the presence of Pd/C.

To explore the role of Pd/C in this reaction, compound 1 and 4 were treated in ethanol in the absence of Pd/C under air at room temperature for 24 h respectively and no oxidation products were observed. The reactions were then carried out utilizing various Pd0 or PdII species, including Pd black, Pd[PPh3]4, Pd(OAc)2, PdCl2 and [Ph3P]2PdCl2, as the catalysts. However, no desired product could be detected in the reaction mixture after 24 h. On the other hand, the Pd leaching from 10% Pd/C during the oxidation of 4 was measured and no leached palladium species was detected after the phase separation of the reaction mixture (Shimadzu, Kyoto, Japan, AA-7000, <1 ppm detection limit)24. These unexpected results prompted us to examine the effectiveness of activated carbon in the oxidation.

Using commercially available AC to replace Pd/C, the reaction was repeated and the benzylic oxidation products were clearly achieved after 6 h. Three types of AC were tested and the desired products were obtained respectively, supporting the effectivity of AC in these reactions. The results indicated that activated carbon, instead of palladium, was crucial for the aerobic benzylic oxidation of 2-benzylbenzo[d]imidazoles.

2-(4-Chlorobenzoyl)benzo[d]imidazole (4) was then chosen as the model substrate to examine the influence of atmosphere, temperature and solvent on the yields of the oxidation products (5 and 6). The results are summarized in Table 1. As expected, the oxidation rate under O2 was higher than that under air (entries 1 and 2). An increase of temperature from room temperature to 50 °C led to the increase of the yields (entry 3). Generally, nonpolar m-xylene at 95 °C or higher was the standard reaction condition in the reported AC/O2 radical oxidation system15,16. In our work, various organic solvents were examined and polar solvents, especially acetonitrile, showed more improvement than nonpolar solvents (entries 4–10). In order to optimize the environmental properties and to achieve the minimal toxicity, the oxidation of 4 was carried out in water or under solvent-free conditions. Although the substrate 4 and the oxidation products have relatively low solubility in water, the on-water reaction gave the expected products smoothly (entry 11)20. The effect of temperature on these on-water reactions was further investigated and increasing the reaction temperature from 50 °C to 85 °C led to an increase of the yields of both 5 and 6 (entries 12 and 13).

It should be noted that the pressure of the oxygen inside the reaction tube could also affect the yield. When the mode reaction of 4 was carried under oxygen atmosphere without sealing, the reaction speed was lower than that under the sealed condition and the final yield of 6 was only about 60% at 24 h.

During the reaction optimization, three types of AC, I, II and III and graphite powder IV were used to examine the influence of the surface area and the content of Fe on the yields. As shown in Table 2, II and III having more surface area than I, exhibited higher activity. While III contained much lower Fe than II, they showed almost the same reactivity (entries 1–3). In contrast, using IV with less surface area but more Fe content than the three types AC, no oxidation product was yielded after the reaction (entry 8). Thus, we believe that the surface area of AC plays a more critical role than Fe in the reaction. The yield of the oxidation product was also affected by the amount of AC. The amount of AC III was reduced from 40 to 30 mg/mmol without affecting the yields of 5 and 6 and the yields decreased significantly when 20, 10 or 5 mg/mmol of AC was used (entries 3–7).

Figure 2 shows the effect of time on the reaction. Substrate 4 was gradually consumed till undetectable by hour 20. The amount of 5 increased to 31.6% by hour 4 and then slowly decreased to less than 1% by hour 24. On the other hand, product 6 increased consistently from the start and reached at 98.8% at the end. Extending the reaction time to 26 hours did not improve the yield of the reaction.

The observation suggested that 5 was generated during the aerobic oxidation process and it could be converted to the corresponding carbonyl compound (6). It is noteworthy that benzylic alcohol (compound 5) has never been documented before in the oxidation of alkylarenes to the corresponding carbonyl compounds in the AC/O2 system. To confirm the oxidized conversion of 5 to 6, compound 5, which was prepared via reduction of 6 with NaBH4 in ethanol, was treated with AC III in H2O under O2 at 85 °C for 12 h, to give 6 in a nearly quantitative yield.

The recycling of AC was subsequently tested in the reaction utilizing of 4 under the aforementioned conditions. In each cycle, AC III was separated by filtration and washed with EtOAc and then used directly in the next cycle without further treatment. The second reaction produced excellent yields (85%) and the third reaction gave a slightly lower yield (81%).

Generally, the mechanism of aerobic oxidation with O2 involves a free radical or singlet oxygen4,5. To evaluate the presence of free radical species in this oxidation, 1.5 equivalents of radical scavenger 2,6-di-tert-butyl-4-methylphenol (BHT) or 2,2,6,6-tetramethyl-1-piperidinyloxy (TEMPO), was added to the reaction mixture in water or water/acetonitrile (1/1, v/v). It was found that the oxidation was unaffected. In addition, the reaction was shown to be unaffected when adding 1.5 equivalents of singlet oxygen quencher (diazabicyclooctane, DABCO) or protecting from the light.

The detailed mechanism requires further study, however, based on the available data we have and the base-mediated aerobic oxidation involving deprotonation at the carbonyl position described25,26,27, a possible mechanism of the oxidation is proposed in Fig. 3. The starting material (a) absorbed on AC could be assumed to exist in form (b) with an electric rich centre on the benzyl sp2 carbon. The electric density of the benzylic position could be evaluated using computational modeling (Fig. S1). The electrophilic addition of molecular oxygen absorbed on AC to the enamine tautomer b formed an intermediate zwitterionic peroxide (c), which is subsequently converted to the hydroperoxide (d) via intra or intermolecular abstraction of a proton. A portion of d is dehydrated to give 2-benzoylbenzo[d]imidazole (e), while the other d is converted into 2-hydroxybenzylbenzo[d]imidazole (f). Through a similar process, the secondary benzylic alcohol f was oxidized to the corresponding carbonyl compound e.

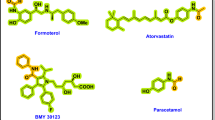

To extend the scope of the procedure and further understand the relationship between the oxidation yield and electric density of the benzylic position, the optimized reaction conditions were applied to a number of 2-benzylbenzimidazoles that are analogues of potential CB2 agonists28. As shown in Table 3, 2-benzylbenzo[d]imidazoles bearing electron-withdrawing groups on the benzene ring (entries 4, 8 and 12) generally afforded the higher yield than substrates with electron-donating groups (entries 5, 9 and 13).

Computational electric density of the benzylic position of the substrates was performed with the Jaguar 4.0 software utilizing the B3LYP hybrid density functional method. Table 3 shows that the oxidation yield is closely associated with the benzylic electric density. The substrates carrying three OCH3 (entries 5, 9 and 13) generally have lower yields due to the low electric density. For the substrates in entries 3, 7 and 11 that have higher electric density at the benzylic position, the reactions were slightly blocked by the steric hindrance from the chloro group at the ortho position of the benzene ring.

Encouraged by the above results, this method was tested for the synthesis of 2-benzoylbenzo[d]oxazoles that are analogues of fatty acid amide hydrolase inhibitors29. Table 4 revealed that 2-benzylbenzo[d]oxazoles are good substrates for the oxidation process. The electronic and steric effects of the substituents are similar with those of 2-benzylbenzo[d]imidazoles. The substrates carrying three OCH3 (entries 4 and 13) have low yields due to the low benzylic electric density. In addition, we believe that the relatively lower benzylic electric density of the benzoxazoles caused their lower yields compared with the benzimidazoles in Table 3.

To understand the efficiency of our protocol with respect to others for benzylic oxidation of the 2-benzylbenzimidazoles, the E Factor (cost and environmental impact of the process) and mass intensity of each method are summarized in Table S1 of the Supporting Information. Comparing the oxidants, solvents and yields, it is clear to see that the present conditions are more efficient, clean and comparatively more sustainable.

In summary, an aerobic benzylic oxidation promoted by commercially available, inexpensive, reusable activated carbon in the green solvent water has been developed. It leads to an environmentally friendly and efficient approach to the synthesis of potential bioactive molecules including 2-benzoylbenzimidazoles and 2-benzoylbenzoxazoles. For the first time, secondary benzylic alcohol (5) was found during the activated carbon catalyzed aerobic benzylic oxidation and it could be converted to the corresponding carbonyl compound (6) under the standard conditions. The reusable AC maintains a high efficiency including the 3rd run without further treatment. Available evidences indicate that the rate of this oxidation is unaffected by radical scavengers, singlet oxygen quenchers and light irradiation. Preliminary research suggests that the oxidation mechanism may involve the intermediate hydroperoxide and that a portion of the final carbonyl product is obtained through a secondary benzylic alcohol intermediate. In addition, the oxidation yield is closely associated with the benzylic electric density that was calculated by using the Schrödinger software. Efforts to further apply this method to the construction of other potentially valuable organic molecules are currently underway.

Methods

Reagents and equipments

Unless otherwise noted, all the materials were obtained from commercially available sources and were used without purification. Thin-layer chromatography was performed on GF254 silica gel plates to monitor the reaction and the plates were examined under UV light. The purification of the products was performed using column chromatography (60 Å, 200–300 mesh, Qingdao Ocean Chemicals or 120 Å, S-50mm, YMC Co., Ltd.), or silica gel plates (0.25 mm layer, Qingdao Ocean Chemicals) with the designated solvents. IR spectra were obtained using a JASCO FT/IR-480 plus spectrometer. 1H and 13C NMR spectra were taken in CDCl3 solution on Bruker ARX-300 and Bruker AV-600 spectrometers with TMS as the internal reference. Chemical shifts were reported in ppm downfield from tetramethylsilane and proton–proton coupling constants (J) in Hz. ESI-MS spectrawere performed on a Finigan LCQ Advantage MAX mass spectrometer.

General experimental section

A mixture of substrate (2 mmol) and activated carbon III (60 mg) in water (5 mL) was placed in a sealed tube (100 mL). The system was purged with molecular oxygen and sealed. The reaction mixture was heated to 85 °C and stirred for 24 h. Upon completion, the reaction mixture was cooled to room temperature and filtered. After the filtrate was concentrated, the product was isolated by silica gel column chromatography and analyzed by MS, 1H-NMR and 13C-NMR. See the supporting information for the characterization details.

Additional Information

How to cite this article: Bao, K. et al. Activated carbon for aerobic oxidation: Benign approach toward 2-benzoylbenzimidazoles and 2-benzoylbenzoxazoles synthesis. Sci. Rep. 5, 10360; doi: 10.1038/srep10360 (2015).

References

Shaabani, A., Mirzaei, P., Naderi, S. & Lee, D. G. Green oxidations. The use of potassium permanganate supported on manganese dioxide. Tetrahedron. 60, 11415–11420 (2004).

Lee, S. & Fuchs, P. L. Chemospecific chromium[VI] catalyzed oxidation of C-H bonds at −40 degrees C1. J. Am. Chem. Soc. 124, 13978–13979 (2002).

Yusubov, M. S., Nemykin, V. N. & Zhadankin, V. V. Transition metal-mediated oxidations utilizing monomeric iodosyl- and iodylarene species. Tetrahedron. 66, 5745–5752 (2010).

Moriyama, K., Takemura, M., & Togo, H. Direct and selective benzylic oxidation of alkylarenes via C-H abstraction using alkali metal bromides. Org. Lett. 14, 2414–2417 (2012).

Martin, N. H. & Jefford, C. W. Synthesis and photo-oxygenation of some substituted 1-benzyl-3,4-dihydroisoquinolines. Mechanism of enamine photo-oxygenation. Helvetica. Chimica. Acta. 65, 762–774 (1982).

Zhou, M., Schley, N. D. & Crabtree, R. H. Cp* iridium complexes give catalytic alkane hydroxylation with retention of stereochemistry. J. Am. Chem. Soc. 132, 12550–12551 (2010).

Urgoitia, G., SanMartin, R., Herrero, M. T. & Domínguez, E. Palladium NCN and CNC pincer complexes as exceptionally active catalysts for aerobic oxidation in sustainable media. Green Chem. 13, 2161–2166 (2011).

Yang, X. L., et al. Porous metalloporphyrinic frameworks constructed from metal 5,10,15,20-tetrakis(3,5-biscarboxylphenyl)porphyrin for highly efficient and selective catalytic oxidation of alkylbenzenes. J. Am. Chem. Soc. 134, 10638–10645 (2012).

Recupero, F. & Punta, C. Free radical functionalization of organic compounds catalyzed by N-hydroxyphthalimide. Chem. Rev. 107, 3800–3844 (2007).

Qi, W., et al. Oxidative dehydrogenation on nanocarbon: identification and quantification of active sites by chemical titration. Angew. Chem. Int. Ed. 52, 14224–14228 (2013).

Frank, B., Zhang, J., Blume, R., Schlogl, R. & Su, D. Heteroatoms increase the selectivity in oxidative dehydrogenation reactions on nanocarbons. Angew. Chem. Int. Ed. 48, 6913–6917(2009).

Keller, N., et al. Zwiebelförmige kohlenstoffe als katalysatoren in der styrolsynthese durch oxidative dehydrierung von ethylbenzol. Angew. Chem. 114, 1962–1966 (2002).

Nasir Baig, R. B. & Varma, R. S. Magnetic carbon-supported palladium nanoparticles: an efficient and sustainable catalyst for hydrogenation reactions. ACS Sustainable Chem. Eng. 2, 2155–2158 (2014).

Nasir Baig, R. B., Nadagouda, M. N. & Varma, R. S. Carbon-coated magnetic palladium: applications in partial oxidation of alcohols and coupling reactions. Green Chem. 16, 4333–4338 (2014).

Sano, Y., Tanaka, T. & Hayashi, M. Oxidation of secondary benzylic alcohols to ketones by activated carbon–molecular oxygen system. Chem. Lett. 36, 1414–1415 (2007).

Nishida, S. & Hayashi, M. Oxidation of secondary benzylic alcohols to ketones and benzylic oxygenation of alkylarenes with hydrogen peroxide in the presence of activated carbon. Synlett. 11, 1683–1685 (2012).

Li, C. J. Organic reactions in aqueous media with a focus on carbon-carbon bond formations: a decade update. Chem. Rev. 105, 3095–3165 (2005).

Breslow, R. “The principles and reasons for using water as a solvent for green chemistry,” in Handbook of green chemistry, Vol. 5 (eds Anastas, P. & Li, C. J. ) Ch. 1, 1–29 (Wiley-VCH, 2010).

Gawande, M. B. & Branco, P. S. An efficient and expeditious Fmoc protection of amines and amino acids in aqueous media. Green Chem. 13, 3355–3359 (2011).

Gawande, M. B., Bonifa´cio, V. D. B., Luque, R., Branco, P. S. & Varma, R. S. Benign by design: catalyst-free in-water, on-water green chemical methodologies in organic synthesis. Chem. Soc. Rev. 42, 5522–5551 (2013).

Dohi, T., Takenaga, N., Goto, A., Fujioka, H. & Kita, Y. Clean and efficient benzylic C-H oxidation in water using a hypervalent iodine reagent: activation of polymeric iodosobenzene with KBr in the presence of montmorillonite-K10. J. Org. Chem. 73, 7365–7368 (2008).

Xu, Y., Hu J. T. & Yan, J. An environmentally benign benzylic oxidation catalyzed by hypervalent iodine intermediate in water. Chinese Chem. Lett. 23, 891–894 (2012).

Gonzalez, M. A., Howell S. G. & Sikdar, S. K. Photocatalytic selective oxidation of hydrocarbons in the aqueous phase. J. Catal. 183, 159–162 (1999).

Biffis, A., Zecca, M. & Basato, M. Palladium metal catalysts in Heck C–C coupling reactions. J. Mol. Catal. A: Chem. 173, 249–274 (2001).

Pattabiraman, V. R., Padakanti, S. V., Veeramaneni, R., Pal, M. & Yeleswarapu, K. R. Synthesis of 3,4-diarylsubstituted maleic anhydride/maleimide via unusual oxidative cyclization of phenacyl ester/amide. Synlett. 6, 947–951 (2002).

Park, K. K., Tsou, L. K. & Hamilton, A. D. Facile and selective aerobic oxidation of arylalkanes to aryl ketones using cesium carbonate. Synthesis. 21, 3617–3620 (2006).

Zhao, J., Zhang, X., Wang, Liu, S. B. & Xu, B. A straightforward synthesis of N-monosubstituted α-keto amides via aerobic benzylic oxidation of amides. Tetrahedron. 68, 573–577 (2012).

Pagé, D., et al. Novel benzimidazole derivatives as selective CB2 agonists. Bioorg. Med. Chem. Lett. 18, 3695–3700 (2008).

Myllymaki, M. J., et al. Design, synthesis and in vitro evaluation of carbamate derivatives of 2-benzoxazolyl- and 2-benzothiazolyl- (3-hydroxyphenyl)-methanones as novel fatty acid amide hydrolase inhibitors. J. Med. Chem. 50, 4236–4242 (2007).

Acknowledgements

We gratefully acknowledge the National S&T Major Project (2012ZX09103101-060), the National Natural Science Foundation of China (Grant No. 30973614) and the Shenyang Science & Technology Bureau Item (No. F12-277-1-23) for generous financial support.

Author information

Authors and Affiliations

Contributions

K.B., F.L., H.L., Z.W., Q.S. and J.W. performed the experiments. K.B., F.L. and W.Z. reviewed, analyzed and interpreted the data. K.B. and W.Z. wrote the paper. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0

About this article

Cite this article

Bao, K., Li, F., Liu, H. et al. Activated carbon for aerobic oxidation: Benign approach toward 2-benzoylbenzimidazoles and 2-benzoylbenzoxazoles synthesis. Sci Rep 5, 10360 (2015). https://doi.org/10.1038/srep10360

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep10360

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.