Abstract

The ability to observe chemical reactions at the molecular level convincingly demonstrates the physical and chemical phenomena occurring throughout a reaction mechanism. Videos obtained through in situ transmission electron microscopy (TEM) revealed the oxidation of catalytic soot under practical reaction conditions. Carbon oxidation reactions using Ag/SiO2 or Cs2CO3/nepheline catalysts were performed at 330 °C under an O2 flow of 0.5 Pa in the TEM measurement chamber. Ag/SiO2 catalyzed the reaction at the interface of the mobile Ag species and carbon, while the Cs species was fixed on the nepheline surface during the reaction. In the latter case, carbon particles moved, remained attached to the Cs2CO3/nepheline surface and were consumed at the interface by the oxidation reaction. Using this technique, we were able to visualize such mobile and immobile catalysis according to different mechanisms.

Similar content being viewed by others

Introduction

Recently, diesel-engine automobiles have been attracting significant attention relative to gasoline-engine automobiles as they emit relatively low amounts of carbon dioxide (CO2) per unit driving distance. However, the particulate matter (PM) that is released with the diesel exhaust is harmful to the environment and human health1. To reduce the PM emitted to the surrounding environment, a diesel particulate filter (DPF) can be installed and it is currently the most widely-accepted approach for trapping the PM. Regeneration of the DPF is frequently required to remove PM accumulation for minimizing pressure loss.

The emitted PM is mainly comprised of carbonaceous soot. The oxidation of PM by gaseous oxygen occurs at around 600 °C, which cannot be accomplished by the diesel exhaust, approximately 200 °C–400 °C2. Generally, the filtered PM is oxidized by increasing the exhaust temperature either via combustion of additional fuel or addition of external energy such as an electric source, resulting in decreased fuel efficiency. Physical damage to the DPF structure by the high temperature has also been reported3; therefore, an alternative solution for DPF regeneration at lower temperatures would be advantageous.

The oxidation of PM at a decreased temperature using a catalyst has been investigated. Oxygen and nitrogen dioxide already present in the exhaust can be utilized as oxidizing reagents for carbonaceous materials. Although NO2 has a higher oxidizing reactivity, it is generated only on platinum-group catalysts via NO oxidation at low temperatures in wet atmosphere. Therefore, the diesel oxidation catalyst would require a large quantity of Pt metal. Furthermore, the concentration of O2 in diesel exhaust is thousand times higher than that of NO24. Therefore, O2 is the preferred oxidizing agent for PM oxidation.

Currently, effective catalysts for carbon oxidation by O2 are alkali metal oxides5,6,7, Ag8,9, CeO2-based mixed oxides10,11,12,13 and perovskites14,15. These catalysts are classified into two categories: “mobile catalyst” or “mobile oxygen”16,17. The mobile catalyst, including metal and alkali compounds, has a low melting point. In the reaction atmosphere, the catalyst undergoes solid–liquid phase transformation, leading to an increase in the contact area of the liquefied catalyst with the reactant (PM). Catalysts involving mobile oxygen species such as CeO2 show high intrinsic activity for PM oxidation, as the active mobile oxygen is easily produced at the catalytic surface/interface with carbon from inside the bulk oxide.

Catalytic PM oxidation occurs under solid (PM, carbon)–solid (catalyst)–gas (O2) triphasic conditions when using mobile species. Unlike other catalytic reactions under heterogeneous conditions (e.g., gas reactant–solid catalyst or liquid reactant–solid catalyst), the solid–solid–gas triphasic reaction proceeds with some difficulty depending on the contact between the two solids. The contact between the PM and catalyst is crucial in promoting the reaction18. However, this triphasic reaction and its mechanism in relation to a solid–solid reaction are still unclear; few investigations have been conducted toward a detailed analysis of this process. A catalytic reaction mechanism has been speculated on the basis of the information about the surface before and after the reaction. Real-time investigation of the reaction mechanism on solid catalysts under operating conditions and in the presence of reactants at high temperatures remains a challenge; however, recent studies have used in situ and operando analyses (XRD19, IR20. To understand the practical reaction mechanism, we focus on in situ analysis by TEM through which we can observe and investigate the actual surface in real time under operating conditions. Several experiments using in situ TEM have been reported: observation of catalytic reactions with gas and solid catalysts21, crystal growth processes22,23 and investigations of supported metal behavior (e.g., melting point)24,25. Herein, we assume a very simple reaction for PM oxidation on solid catalyst, C(s)+O2(g)→CO2(g), where the reaction is triphasic. We report in situ observation of catalytic PM oxidation using TEM and demonstrate how PM oxidation proceeds, as well as catalysts’ behavior during oxidation.

Experimental

We initially focused on alkali carbonate catalysts loaded on nepheline, an aluminosilicate that showed high tolerance for hydration and leaching of alkali species26,27,28,29. Furthermore, Ag catalysts have been reported and recognized worldwide to show high performance for PM oxidation. In this study, Cs2CO3-loaded nepheline and Ag supported on SiO2 were chosen as representative mobile catalysts. Here we have chosen cesium compound rather than potassium or sodium ones because the former showed higher catalytic performance than the latter ones29, meaning that lower temperature is expected to be required for the TEM analysis. Also, cesium could be analyzed more clearly than potassium or sodium because of the difference in their atomic weights from the other components such as aluminosilicate nepheline and carbon.

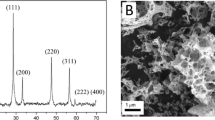

Silica-supported Ag catalyst containing 10 wt% of Ag was prepared with the incipient wetness method using an aqueous AgNO3 solution (Wako Pure Chemical) and powder SiO2 (fumed, Aldrich). After heating till complete evaporation of the aqueous phase, the precipitated product was calcined at 500 °C for 3 h in air.

The nepheline-loaded Cs2CO3 catalyst was prepared as follows. A Na form Lind-type A zeolite with Si/Al molar ratio of 1 (Wako Pure Chemical) was sintered at 1000 °C for 4 h in air to give Na-nepheline through solid–solid phase transformation26,27,28. Cs2CO3 (Wako Pure Chemical) was then loaded on the Na-nepheline support by impregnation (10 wt%). This was immersed in distilled water and the solvent was evaporated at 100 °C under vigorous stirring. The precipitated product was calcined at 800 °C for 3 h in air.

The catalytic activity test for PM oxidation was performed using temperature-programmed oxidation on a thermogravimetric–differential thermal analyzer (TG-DTA, Rigaku Thermo Plus TG8120). Carbon black #2600 (Mitsubishi Chemical) of diameter 13 nm was used as the reference for PM particles. The prepared catalyst and carbon were mixed in an agate motor for 10 min, generally called a “tight contact”. The catalytic activity test was normally conducted by two types of contacts; one is “loose contact”, for which the soot is mixed with the catalyst by using a spatula and the other is “tight contact”, for which the soot and catalyst are mixed in an agate motor. It has long been recognized that the “tight-contact” scenario is more reflective of the intrinsic catalytic performance. Catalyst/carbon weight ratio was set at 10. The mixture was then heated to 800 °C at 10 K min−1 under a flow of dried air. The catalytic activity for the carbon oxidation was evaluated by the temperature Tig, the point at which a distinct exothermic DTA curve derived from the heat of the carbon oxidation starts to appear.

Carbon oxidation on a Cu-microgrid was observed at an accelerating voltage of 1 MeV, under 0.5 Pa O2 atmosphere at 330 °C on a TEM (JEM-1000K RS; JEOL). A small amount of the tight-contact-mode catalyst and carbon was placed on the Cu-microgrid. This was placed in the sample holder, which equips with the furnace and temperature controller and inserted in the TEM. First, O2 gas was introduced into the environmental cell chamber by gradually increasing the pressure surrounding the Cu-microgrid to 0.5 Pa and then heated to 330 °C. Details of the image recording system for the JEM-1000K RS TEM are described in a previous study30.

Results and Discussion

The catalytic performance of carbon oxidation is shown in Fig. 1. Nepheline and SiO2 (not shown in the figure) showed next to no catalytic activity for the oxidation because their DTA curves closely resemble those of the noncatalytic reaction of carbon with gaseous oxygen. The carbon oxidation using Ag/SiO2 and Cs2CO3/nepheline occurred at 255 °C and 311 °C, respectively, indicating that the Ag catalyst shows a higher oxidation activity than the Cs2CO3 catalyst.

Figures 2 and SI_2 display a series of TEM images obtained during the carbon oxidation using Ag/SiO2 at 330 °C with a 0.5 Pa O2 supply. Images (A)–(G) were acquired over 48 s, with one image captured every 8 s. As shown in image (A), Ag particles can be observed as black dots with their diameters ranging from 5 to 25 nm. During the carbon oxidation, two Ag species were observed: mobile Ag particles on SiO2 (Ag1 in (A)) and silent Ag particles on SiO2 (Ag2 in (A)). The C–O–Ag interaction may be slightly stronger than the Si–O–Ag one. The mobile Ag on SiO2 transferred to carbon particles and oxidation appeared to occur at the active interface of Ag and carbon. As the reaction proceeded, the mobile Ag agglomerated into larger particles. Finally, the mobile, agglomerated Ag terminated the reaction by becoming silent, without any contact with the carbon around the Ag particle. In the case of the silent Ag, from the first reaction stage, the carbon particles around Ag seemed to transfer to the active interface while maintaining contact with Ag during the reaction. To identify the reason for Ag mobility, the behavior of Ag/SiO2 without the carbon was investigated. By comparing the TEM images before (H) and after (I) the reaction, the morphology and interface/surface of the Ag particle was changed from a crystal-like faceted plane to a spherical shape. Furthermore, the contrast of the Ag particles in image (I) decreased from the surface to the inside, indicating that the particle surface melted and became spherical because of the surface tension.

These results implied that liquefaction may be occurring at the Ag/SiO2 interface according to the definition of Tammann temperature31. Surface premelting of Ag began at 550 °C–650 °C in vacuum depending on the Ag particle size32. Coalescence of Ag particles was also observed at 150 °C33. In this study, during the carbon oxidation, Ag particles on carbon easily agglomerated, which might be due to the heat of the carbon oxidation at the interface and partial liquefaction of the Ag surface at 330 °C. The mobile range of Ag transferred from the SiO2 surface onto the carbon particles became limited as carbon was consumed. Consequently, we can deduce that Ag/SiO2 can be used as a mobile catalyst for PM oxidation.

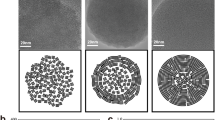

Figures 3(A) and SI_3 show the TEM image of Cs2CO3/nepheline physically mixed with carbon at 330 °C in vacuum. Images (B) and (C) demonstrate the time course of carbon oxidation at 330 °C, with O2 flowing at 0.5 Pa, acquired over 28 min. In image (A), the dark spheres correspond to Cs2CO3/nepheline and the gray shadows are the agglomerated carbon particles. As explained above, the nepheline itself did not catalyze carbon oxidation at 330 °C; therefore, the oxidation activity derives from the Cs species. Images (A)–(C) led us to conclude that carbon oxidation occurs at the whole surface of the Cs2CO3/nepheline. This also indicates that the Cs species was highly dispersed on the nepheline surface. During the reaction, carbon particles continuously moved toward the Cs2CO3/nepheline surface, where carbon was oxidized.

In situ TEM images of Cs2CO3/nepheline catalyst. (A)–(C) show TEM time course images for carbon oxidation using Cs2CO3/nepheline at 330 °C with an O2 gas flow of 0.5 Pa. (D) shows the TEM image of Cs2CO3/nepheline and (E) and (F) show EELS mapping on Cs2CO3/nepheline for Cs M-core at RT and 400 °C, respectively. (G)–(I) show TEM time course images during carbon oxidation using only Cs2CO3 at 330 °C with an O2 gas flow of 0.5 Pa.

Image (D) shows a TEM image of Cs2CO3/nepheline and images (E) and (F) display electron energy loss spectroscopy (EELS) mapping images of the Cs M-core at RT and 400 °C, respectively. The Cs species on nepheline was in a high dispersion state at RT, which was maintained even at 400 °C, revealing a specific interaction between the Cs species and nepheline. Images (G)–(I) summarize the TEM time course during the carbon oxidation using Cs2CO3 at 330 °C with an O2 flow of 0.5 Pa. Black dots derived from Cs cationic species became distinct as carbon oxidation proceeded. Notably, such black dots did not appear on the carbon in the TEM images (A)–(C). This result also indicates the specific interaction between the Cs cationic species and negatively-charged nepheline surface (Coulomb attraction). Alkali metal catalysts are currently categorized as mobile catalysts under PM oxidation conditions owing to their low melting point. However, this study clearly suggests that the Cs species on nepheline maintains its high dispersion state and is silent on the support during the carbon oxidation. Such high stability of alkali metals on nepheline has been demonstrated in our previous study26,27,28. Thus, we emphasize that the properties of the supported metals significantly depend on the nature of and interaction with, the substrate. Therefore, it is evident that Cs2CO3/nepheline has potential application as a mobile oxygen catalyst for PM oxidation.

Note that the TEM analyses of the PM oxidation performance investigated herein are not simply minor phenomena occurring within the very limited field of view being observed. As indicated in the Supplementary Materials, we compared the kinetics observed by the TEM views and detected by the TG-DTA measurements and the reaction rate of the carbon oxidation under the same conditions, which showed a comparable order, suggesting that the views by TEM can be recognized as the intrinsic performance of the catalysts reported in this study.

Conclusions

In situ TEM was successfully applied for the elucidation of the PM oxidation mechanism for two catalyst types: Ag/SiO2 and Cs2CO3/nepheline. The Ag particles were mobile during the carbon oxidation at 330 °C in an O2 atmosphere at 0.5 Pa. The carbon was consumed by the mobile Ag particles, causing the Ag particles to agglomerate. The reaction was finalized when all the carbon was consumed from the Ag–C islands. The Cs species were fixed silently on nepheline during the reaction even at 400 °C, which was indicated via EELS mapping. Interestingly, the interface of carbon and nepheline particles was continuously generated where carbon was oxidized. Finally, we show how, by visualizing these reactions at the TEM level, we were able to not only demonstrate the catalytic mechanism but also explain some physical and chemical characteristics of these catalysts. Seeing is not only believing, but also realizing and seizing an actual phenomenon in catalysis.

Additional Information

How to cite this article: Kamatani, K. et al. Direct observation of catalytic oxidation of particulate matter using in situ TEM. Sci. Rep. 5, 10161; doi: 10.1038/srep10161 (2015).

References

Sydbom, A. et al. Health effects of diesel exhaust emissions, Eur. Repair. J. 17, 733 (2001).

Mul, G., Kapteijn, F., Moulijn, J. A. Catalytic oxidation of model soot by metal chlorides, Appl. Catal. B 12, 33 (1997).

van Setten, B. A. A. L., Makkee, M., Moulijn, J. A. Science and technology of catalytic diesel particulate filters, Catal. Rev. Sci. Eng. 43, 489 (2001).

Görsmann, C. Catalytic Coatings for Active and Passive Diesel Particulate Filter Regeneration, Mon. Chem. 136, 91 (2005).

Neri, G. et al. K- and Cs-FeV/Al2O3 soot combustion catalysts for diesel exhaust treatment, Appl. Chem. B 42, 381 (2003).

An, H., McGinn, P. J. Catalytic behavior of potassium containing compounds for diesel soot combustion, Appl. Catal. B 62, 46 (2006).

Zhang, Z., Zhang, Y., Wang, Z., Gao, X. Catalytic performance and mechanism of potassium-supported Mg-Al hydrotalcite mixed oxides for soot combustion with O2, J. Catal. 271, 12 (2010).

Corro, G., Pal, U., Ayala, E., Vidal, E. Diesel soot oxidation over silver-loaded SiO2 catalysts, Catal. Today 212, 63 (2013).

Aneggi, E. et al. Soot combustion over silver-supported catalysts, Appl. Catal. B 91, 489 (2009).

Machida, M. et al. On the Reasons for High Activity of CeO2 Catalyst for Soot Oxidation, Chem. Mater. 20, 4489 (2008).

Yeqin, S. et al. Soot combustion performance and H2-TPR study on ceria-based mixed oxides, Chin. J. Catal. 34, 567 (2013).

Yamazaki, K., Kayama, T., Dong, F., Shinjoh, H. A mechanistic study on soot oxidation over CeO2-Ag catalyst with ‘rice-ball’ morphology, J. Catal. 282, 289 (2011).

Shimizu, K., Kawachi, H., Satsuma, A. Study of active sites and mechanism for soot oxidation by silver-loaded ceria catalyst, Appl. Catal. B 96, 169 (2010).

Shimokawa, H., Kusaba, H., Einaga, H., Teraoka, Y. Effect of surface area of La-K-Mn-O perovskite catalysts on diesel particulate oxidation, Catal. Today 139, 8 (2008).

Fino, D., Russo, N., Saracco, G., Specchia, V. The role of suprafacial oxygen in some perovskites for the catalytic combustion of soot, J. Catal. 217, 367 (2003).

Fino, D. Diesel emission control: Catalytic filters for particulate removal, Sci. Tech. Adv. Mater. 8, 93 (2007).

Uchisawa, J., Obuchi, A., Nanba, T. in HANDBOOK OF ADVANCED METOHDS AND PROCESSES IN OXIDATION CATALYSIS (eds Duprez, D. & Cavani, F. ) Ch. 2, 25–50 Imperial College Press 2014).

Neeft, J. P. A., van Pruissen, O. P., Makkee, M., Moulijn, J. A. Catalysts for the oxidation of soot from diesel exhaust gases ІІ. Contact between soot and catalyst under practical conditions, Appl. Catal. B 12, 21 (1997).

Grunwaldt, J. D. et al. In Situ Investigations of Structural Changes in Cu/ZnO Catalysts, J. Catal. 194, 452 (2000).

Vigier, F. et al. On the mechanism of ethanol electro-oxidation on Pt and PtSn catalysts: electrochemical and in situ IR reflectance spectroscopy studies, J. Electroanal. Chem. 563, 81 (2004).

Chenna, S., Banerjee, R., Crozier, P. Atomic-Scale Observation of the Ni Activation Process for Partial oxidation of Methane Using In Situ Environmental TEM, Chem. Cat. Chem. 3, 1051 (2011).

Simões, S. et al. In situ TEM study of grain growth in nanocrystalline copper thin films, Nanotechnology 21, 145701 (2010).

Ghatak, J., Guan, W., Möbus, G. In situ TEM observation of lithium nanoparticle growth and morphological cycling, Nanoscale 4, 1754 (2012).

Narui, K. et al. Effects of addition of Pt to PdO/Al2O3 catalyst on catalytic activity for methane combustion and TEM observations of supported particles, Appl. Catal. A 179, 165 (1999).

Lee, J., Lee, J., Tanaka, T., Mori, H. In situ atomic-scale observation of melting point suppression in nanometer-sized gold particles, Nanotechnology, 20, 475706 (2009).

Ogura, M. et al. Potassium-doped sodalite: A tectoaluminosilicate for the catalytic material towards continuous combustion of carbonaceous matters, Appl. Catal. B 77, 294 (2008);

Kimura, R. et al. Nepheline from K2CO3/Nanosized Sodalite as a Perspective Candidate for Diesel Soot Combustion, J. Am. Chem. Soc. 130, 12844 (2008);

Kimura, R. et al. Alkali Carbonate Stabilized on Aluminosilicate via Solid Ion Exchange as a Catalyst for Diesel Soot Combustion, J. Phys. Chem. C 115, 14892 (2011).

Ogura, M. et al. Carbonate-Promoted Catalytic Activity of Potassium Cations for Soot Combustion by Gaseous Oxygen, Chem. Cat. Chem. 6, 479 (2014).

Tanaka, N. et al. Development of an environmental high-voltage electron microscope for reaction science, Microscopy 62, 205 (2013).

Moulijn, J. A., van Diepen, A. E., Kapteijn, F. Catalyst deactivation: is it predictable? What to do?, Appl. Catal. A 212, 3 (2001).

Tang, S., Zhu, S., Lu, H., Meng, X. Shape evolution and thermal stability of Ag nanoparticles on spherical SiO2 substrates, J. Solid State Chem. 181, 587 (2008).

Moon, K. S. et al. Thermal Behavior of Silver Nanoparticles for Low-Temperature Interconnect Applications, J. Electron. Mater. 34, 168 (2005).

Acknowledgements

A part of this work was performed under a management of “Elements Strategy Initiative for Catalysts & Batteries (ESICB)” supported by MEXT program “Elements Strategy Initiative to Form Core Research Center” since 2012, MEXT; Ministry of Education, Culture, Sports, Science and Technology, Japan. MO would like to express appreciation to Enago for providing editorial assistance.

Author information

Authors and Affiliations

Contributions

M.O. and K.K. wrote the main manuscript text and K.H., Y.Y., S.A. and N.T. prepared Figs. 1–3. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kamatani, K., Higuchi, K., Yamamoto, Y. et al. Direct observation of catalytic oxidation of particulate matter using in situ TEM. Sci Rep 5, 10161 (2015). https://doi.org/10.1038/srep10161

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep10161

This article is cited by

-

Triglyceride methanolysis in the presence of KOH immobilized on seashells-based anorthite and coal fly ash: a comparative study

Reaction Kinetics, Mechanisms and Catalysis (2023)

-

On-Filter Integration of Soot Oxidation and Selective Catalytic Reduction of NOx with NH3 by Selective Two Component Catalysts

Catalysis Letters (2020)

-

Real-Time Observation of Carbon Oxidation by Driven Motion of Catalytic Ceria Nanoparticles within Low Pressure Oxygen

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.