Abstract

Authors reported an effective path to decrease the thermal conductivity while to increase the coefficient of thermal expansion, thus enhancing the thermo-physical properties of the LnMeA11O19-type magnetoplumbite LaMgAl11O19 by simultaneously substituting La3+, Mg2+ and Al3+ ions with large ionic radius Ba2+, Zn2+ and Ti4+, respectively. The mechanism behind the lowered thermal conductivity was mainly due to the multi-enhanced-phonon scattering modes in Ln-Me-A sites co-substituted LnMeA11O19 ceramics. These modes involve the following four aspects, namely, point defect mechanism, the intrinsic scattering in the complex crystal cell and materials with stepped surface to localize phonon vibrational modes, as well as nano-platelet-like structure to incorporate additional grain boundary scattering. This study provides novel thoughts for promising candidate materials of even lower thermal conductivity for the next generation thermal barrier coatings.

Similar content being viewed by others

Introduction

Thermal barrier coatings (TBCs) have attracted extensive interest owing to their wide applications in the areas of coat transition pieces, combustion lines, first stage blades and vanes, as well as hot-path components of gas turbines. In addition to high melting points, absence of phase transformation from room temperature to the operating temperature, chemical inertness, low sintering rate and thermal expansion perfectly matching the substrate, low thermal conductivity is the most valuable characteristics to be considered. The total theoretical thermal conductivity of polycrystalline ceramics is simply the sum of the followed two terms1,2,3:

where κp and κr are the thermal conductivities contributed by vibrations and radiation, respectively, Cv is the specific heat capacity at constant volume, ρ is the density of the material,  is the mean velocity of phonons in the material, lp is the phonon mean free path, σ is Stefan Boltzmann's constant (5.67 × 10−8 W·m−2·K−1), n is the refractive index of the material, T and lr are the thermodynamic temperature (K) and photon mean free path, respectively. The specific heat capacity at constant volume for any crystalline solids at a value of 3NkB ≈ 25 J·mol−1·K−1 above the Debye temperature. Therefore to lower the thermal conductivity in TBCs ceramics, the main approaches are to lower ρ, vm or lp. The total phonon mean free path, in TBCs ceramics, is primarily defined by:

is the mean velocity of phonons in the material, lp is the phonon mean free path, σ is Stefan Boltzmann's constant (5.67 × 10−8 W·m−2·K−1), n is the refractive index of the material, T and lr are the thermodynamic temperature (K) and photon mean free path, respectively. The specific heat capacity at constant volume for any crystalline solids at a value of 3NkB ≈ 25 J·mol−1·K−1 above the Debye temperature. Therefore to lower the thermal conductivity in TBCs ceramics, the main approaches are to lower ρ, vm or lp. The total phonon mean free path, in TBCs ceramics, is primarily defined by:

where li is the intrinsic mean free path of phonons due to the difference among ion masses, lvac, lgb, lpoint and lls are the mean free path of phonons contributed by vacancies, grain boundaries, point defects and layered microstructures, respectively. The designs to reduce lp has been engineered on several types of oxide ceramics, intermetallic compounds or metal chalcogenides (e.g. La2Zr2O74, 7-8YSZ5,6, LaMgAl11O197,8, W/Al2O39, PbTe–PbSnS210) by separately introducing point defects, vacancies, complex crystal structures, nanosized grains and layered microstructures. However, there is insufficient research into realizing above-mentioned scattering mechanisms jointly working in one TBCs material system and materials meeting these requirements are not easily synthesized in the laboratory.

Recently, some researchers have reported experimentally that nano-grain boundaries11,12, point defects13 and layered microstructure10,14 play important roles in enhancing the phonon scattering. Focusing on the role of combined phonon scattering mechanisms on the thermal conductivity, we note that LnMeA11O1915,16,17 (Figure S1, Supplementary information) has been proposed as one of promising candidates for the next generation thermal barrier coatings18. However, doping-free LaMgAl11O19 still shows relatively high thermal conductivity, rendering it harder to achieve smaller phonon mean free path. While introducing point defects has been proved to be an effective approach to reduce thermal conductivity of materials with exeptionally low κ. Furthermore, multi-sites-doping is a successful strategy to introduce multi-sites distortion and disorder with mass and strain fluctuations. In addition, smaller grain size resulting in a higher number of grain boundaries in the heat path adds additional thermal resistance to the polycrystalline solid phase. Therefore, it is significantly attractive to evaluate and characterize the thermo-physical properties of Ln-Me-A sites co-substituted LnMeA11O19 ceramics with nanosized grains and thereby to seek a novel thought to further lower thermal conductivity.

In this study, we optimized the κ of the LnMeA11O19-type magnetoplumbite LaMgAl11O19 by simultaneously substituting La3+, Mg2+ and Al3+ ions with large ionic radius Ba2+, Zn2+ and Ti4+ (Table S1, Supplementary information), respectively and introducing nanostructure and layered microstructures through citric acid sol-gel route19 and spark plasma sintering technique20. A better understanding of the influences of point defects, nano-grain boundaries and layered structures on thermo-physical properties is obtained by combining experimental results with the calculated minimum thermal conductivity using Clarke's model21,22. The results demonstrate that the thermal conductivities of La1−xBaxMg1−xZnxAl11−xTixO19 (LBMZATO, x = 0.0, 0.1, 0.2, 0.3, 0.4, 0.5) ceramics are exceptionally low, close to the predicated minimum thermal conductivities, which verifies that the inter-atomic spacing-sized phonon mean free paths are responsible for the point-defect scattering, high-denstiy grain-boundary scattering and localized phonon vibrational modes by layered crystal structure. More importantly, the coefficients of thermal expansion of LBMZATO ceramics at 1073–1273 K also show a remarkable improvement with the increased Ba2+, Zn2+ and Ti4+ content fraction, reaching the maximal value of 11.39 × 10−6 K−1 at 1273 K, which is close to the CTE of 7 ~ 8 wt.% yttria stabilized zirconia (YSZ) system at the elevated temperature23. These conclusions suggest that LBMZATO ceramics are promising candidates for advanced thermal barrier coatings applications.

Results

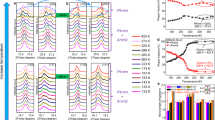

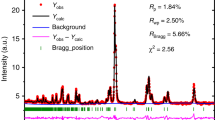

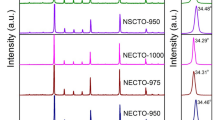

According to the XRD patterns (Fig. S2), all the obtained LBMZATO ceramics were comprised of pure magnetoplumbite LaMgAl11O19 phase. Increasing Ba2+ + Zn2+ + Ti4+ doping fraction leads to a shift of the X-ray spectra to lower 2θ values (Fig. S3). The refined cell parameters of LBMZATO (with 0.0 ≤ x ≤ 0.5) are reported in Table S2. The sites formation energy calculation of invasion ions and host ions in La1−xBaxMg1−xZnxAl11−xTixO19 series were calculated by material stuido (Tab. S3). The exact composition of the materials were determined by X-ray fluorescence spectrometry (XRF, Tab. S4) and X-ray photoelectron spectroscopy (XPS, Tab. S5 and Fig. S4). It can be concluded that Ba2+, Zn2+ and Ti4+ have completely entered the sites of La3+, Mg2+ and Al3+, respectively and finite solid solutions have formed. For the magnetoplumbite LaMgAl11O19, the dependence between parameters of LBMZATO and Ba2+, Zn2+ and Ti4+ doping fraction was approximately consistent with the Vegard's law24, which displays a linear relationship between crystal structural parameters and composition variation. The smallest platelike crystallites in this material were 35 nm in thickness, as clearly evidenced in the typical SEM image of LaMgAl11O19 without doping (Figure 1a). Figure 1b is the typical TEM morphology of LaMgAl11O19 showing uniformity of phase composition. The selected area electron diffraction (SAED) pattern (Figure 1c) confirms that LaMgAl11O19 possesses a magnetoplumbite-type hexagonal crystal structure. High resolution TEM (HRTEM) image (Figure 1d) with electron beam parallel to  direction also revealed the crystalline structure and the smooth surface with a

direction also revealed the crystalline structure and the smooth surface with a  plane.

plane.

(a) The scanning electron microscope (SEM image) for mother material LaMgAl11O19, sintered by spark plasma sintering(SPS) technique at 1500°C for 10 min. (b) TEM characterizations of the mother material LaMgAl11O19.(c) The corresponding selected area electron diffraction (SAED) patterns taken from the red circle region A in (b). (d) The HRTEM image taken from the middle region A in (b).

As observed in the high-magnification SEM and TEM (Figure 2a,b), stepped crystal grains with ~50 nm height and ~100 nm width exist in the sample. Figure 2 (c) is a high-magnification atomic resolution image in [0001] direction, which reveals two parts that are separated by one dashed line. Figure 2d is the reduced FFT(Fast Fourier Transform) from region B in Figure 2c, including two clear step-like surfaces. The electron diffraction patterns of the upper and lower parts show identical magnetoplumbite-type hexagonal crystal structure. Detailed analysis showed that the lower and upper parts were well matched with each other because both include (004) and (006) lattice planes, which indicates that the borderline between the lower and upper parts is coherent interface.

(a) The high-magnification SEM image for LBMZATO with Ba2+, Zn2+ and Ti4+ dopant content fraction x = 0.3. (b) The high-magnification transmission electron microscope (TEM) image of (a). (c) The HRTEM image taken from the red circle region A in (b). (d) The reduced FFT from region B in image (c) includes two clear step-like surfaces.

The thermal diffusivities and specific heat capacities in the range 293–1273 K are illustrated in Fig. S5 and Fig. S6 (Tab. S6), respectively. The thermal conductivities initially decrease with increasing x, reaching their lowest values at x = 0.5. The thermal conductivity of LBMZATO decreases with increasing temperature from room temperature to 800°C (Figure 3). Due to thermal radiation at high temperatures, thermal conductivity becomes less sensitive to composition variation, instead, it rises slightly. The T−1 temperature-dependent thermal conductivity for LBMZATO suggests a dominant phonon conduction behavior in most inorganic non-metallic materials. Thermal conductivities of LBMATO ceramics are obviously lower than 8YSZ, especially for La0.5Ba0.5Mg0.5Zn0.5Al10.5Ti0.5O19, whose thermal conductivity values are 1.51 ~ 1.67 W·m−1·K−1 from room temperature to 1000°C. The coefficients of thermal expansion of LBMZATO (with 0.0 ≤ x ≤ 0.5) solid solution are plotted in Figs. S7–8. CTE rises with the increasing Ba2+, Zn2+ and Ti4+ fraction, which exhibits a composition dependence similar to the reverse composition dependence of the thermal conductivity.

Discussion

An inter-atomic spacing-sized phonon mean free path means that the strongest scattering occurs in the crystal cell and corresponds to the minimum thermal conductivity as reported by Clarke21. In light of Debye's phonon gas theory, thermal conduction in dielectric solids can be considered as the transport of phonons carrying energy and the thermal conductivity of materials is then represented in another form equivalent to κ = α · Cp · ρ, by the relation25:

where CV, vm and l represent the heat capacity per unit volum, the average speed of sound in the materials and the phonon mean free path, repectively. By combining Eqs (3) and the relation CV = Cp · ρ, the phonon mean free path can be expressed as:

where α is characterized by the laser flash system (Netzsch LFA 427, Germany) from room temperature up to 1273 K in an argon atmosphere. For each temperature, three measurements were made to obtain the mean value of thermal diffusivity. The average speed of sound vm is determined by the relation:

Combining Eqs.(4) and (5), the phonon mean free path can be obtained:

where vl and vt represent longitudinal and transverse sound speed, repectively.

The phonon mean free path of LBMZATO solid solutions as a function of temperature is plotted in Fig. 4. The phonon mean free paths of LBMZATO are nearly temperature-independent above 873 K (equal to Debye temperature of LBMZATO), which agrees with the typical behavior of inorganic materials. The phonon mean free paths of LBMZATO ceramics vary between 0.18 and 0.34 nm in the range from room temperature to 1000°C. This confirms that the phonon mean free path is smaller than parameters (a = b = 5.5920 Å, c = 21.9650 Å) and approaches the inter-atomic spacing. The distance between the Al3+ cation and O2− anion in AlO5 hexahedron is 1.74 Å26.

Clarke evaluated a formula based on the minimum thermal conductivity according to the phonon mean free path equal to the inter-atomic spacing20:

where kB is Boltzmann's constant, NA is the Avogadro number, m is number of atoms per molecule, ρ is the density, M is the molecular mass and E is the Young's modulus. Values of kmin were calculated by Eq.(7) and the relationship between kmin and composition was also plotted in Fig. 3. The measured thermal conductivity of LBMZATO was close to the calculated minimum thermal conductivity, which means that the phonon mean free path may be as small as the inter-atomic spacing.

With the aid of the Debye model, the mechanism behind the such low thermal conductivities in LBMZATO solid solution can be well understood. The thermal conductivity in the form of the Debye model could be given by27,28:

where  is a dimensionless quantity and τC is the phonon scattering relaxation time. The following processes are assumed to limit the flow of phonons: grain-boundary scattering, point-defect scattering, phonon-phonon Umklapp scattering, stacking faults and dislocation. Therefore the combined resistive

is a dimensionless quantity and τC is the phonon scattering relaxation time. The following processes are assumed to limit the flow of phonons: grain-boundary scattering, point-defect scattering, phonon-phonon Umklapp scattering, stacking faults and dislocation. Therefore the combined resistive  (reciprocal of relaxation time) can be defined29,30:

(reciprocal of relaxation time) can be defined29,30:

where  ,

,  ,

,  ,

,  ,

,  and

and  are the resistives contributed by grain-boundary scattering, point-defect scattering, phonon-phonon Umklapp scattering and grain-boundary scattering, stacking faults, dislocation and stepped surface, respectively. L is the typical grain size and A, B, C, D and E are adjustable parameters for phonon scattering from point-defect, Umklapp phonon-phonon interactions, stacking faults, dislocation and displacement layers respectively. In this work, authors suppose that the main sources of thermal resistance are represented by plate-like grain boundary31,32 and point-defect33 as well as stepped surface10,34 in the crystal. The grain boundary term has the least effect on the phonon mean free path in conventional coarser-grained materials. However, the phonon mean-free-path may be strongly affected by the additional phonon scattering at interfaces that is induced by grain-size reduction35,36. In our study, it is hypothesized that nanocrystalline materials offer the potential of limiting thermal conductivity by incorporating plate-like grain boundary scattering as an extrinsic phonon-scattering phenomenon. The expression for relaxation time due to grain boundary scattering process has been given by Casimir37:

are the resistives contributed by grain-boundary scattering, point-defect scattering, phonon-phonon Umklapp scattering and grain-boundary scattering, stacking faults, dislocation and stepped surface, respectively. L is the typical grain size and A, B, C, D and E are adjustable parameters for phonon scattering from point-defect, Umklapp phonon-phonon interactions, stacking faults, dislocation and displacement layers respectively. In this work, authors suppose that the main sources of thermal resistance are represented by plate-like grain boundary31,32 and point-defect33 as well as stepped surface10,34 in the crystal. The grain boundary term has the least effect on the phonon mean free path in conventional coarser-grained materials. However, the phonon mean-free-path may be strongly affected by the additional phonon scattering at interfaces that is induced by grain-size reduction35,36. In our study, it is hypothesized that nanocrystalline materials offer the potential of limiting thermal conductivity by incorporating plate-like grain boundary scattering as an extrinsic phonon-scattering phenomenon. The expression for relaxation time due to grain boundary scattering process has been given by Casimir37:

where  is the mean velocity of phonons in the material, L mean grain size. Due to enhanced phonon scattering at high-density grain boundaries (Fig. 5a), the specimens synthesized by citric acid sol-gel technique showed a reduction (~13%) in thermal conductivity compared with the conventional solid-state with microscale grains (Fig. 5b).

is the mean velocity of phonons in the material, L mean grain size. Due to enhanced phonon scattering at high-density grain boundaries (Fig. 5a), the specimens synthesized by citric acid sol-gel technique showed a reduction (~13%) in thermal conductivity compared with the conventional solid-state with microscale grains (Fig. 5b).

The comparison of thermal conductivity for fully dense LaMgAl11O19 ceramics synthesized by conventional solid-state reaction and citric acid sol-gel technique.

The standard deviation of thermal conductivity values is within ±2% based on three independent laser flash measurements, which is smaller than the symbol in the figure.

The resistive contributed by point-defect scattering can be given by Klemens as38:

where Γ is the total imperfection parameter, which is given in Eqs.(S1–3, Supporting Information). Debye frequency ωD is given by  , where Ω is given by MA/ρ, MA is the average atomic mass and MA of LaMgAl11O19 is 3.96 × 10−23 g.

, where Ω is given by MA/ρ, MA is the average atomic mass and MA of LaMgAl11O19 is 3.96 × 10−23 g.

In addition, authors consider another process of phonon scattering in LBMZATO samples to account for the resistive contributed by stepped surface  39:

39:

where GN is the number of stepped surface in a crystal, a is the constant. Vibrations of stepped surfaces have been studied by P. Knipp40,41. In the proximity of a step, further reduction of atomic coordination induces even more charge-density redistribution and a more substantially altered interatomic potential than for a flat surface. Numerical studies show that the characteristics of surface modes depend strongly on the surface interatomic potential. The main difference between the phonon structures of the vicinal surfaces and the unstepped surface lies in the shape of their Brillouin zones. The polarizations of the step phonons change from row to row, but a stepped phonon is strictly longitudinal and the other two are strictly transverse at the step edge, where the amplitudes are maximum42. P. Knipp40 reported the existence and characteristics of edge-localized vibrational modes for the simplest model by fcc surface dynamics. Though somehow speculative, authors consider the number of stepped surfaces in a crystal is proportional to the Ba + Zn + Ti concentration (Fig. 6). Authors consider the mechanism behind morphology change is due to the two dimensional nucleationstep mechanism of crystal growth in Ln-Me-A sites co-substituted LnMeA11O19 ceramics. The nucleation type is determined by the thermal roughness of crystal surface, which is determined by the relation43:

where ϕff, ϕss and ϕsf represent the interaction energy between the average contents of two neighboring blocks of fluid, the potential energy of a solid-solid nearest-neighbor pair and the average potential energy of a solid-fluid pair, repectively, kB is Boltzmann's constant. The thermal roughness of crystal surface γ rises with the increasing Ba2+, Zn2+ and Ti4+ fraction in La1−xBaxMg1−xZnxAl11−xTixO19 system. When γ is greater than the critical value of 4, the nucleation mechanism is transformed from normal growth to two dimensional nucleation growth. Therefore, the number of stepped surfaces in Ba-Zn-Ti co-doped LaMgAl11O19 system increases with the increasing dopant fraction.

The calculated relaxation times due to grain boundaries, point defects and stepped surfaces in LBMZATO based on Eqs. (10–12) are plotted in Fig. 7. It can be seen from Fig. 7 that both the τD and τStepped contributed by point-defects and stepped surfaces, respectively, decrease with the Ba + Zn + Ti concentration varying from x = 0.1 to 0.5. It is evident that by forming solid solutions of LBMZATO substantial additional resistive of the phonons flow is introduced in suppressing the thermal conductivity. Here the current authors provided a novel thought to find some new microstructure optimization processes to further lower thermal conductivity for thermal barrier coatings, such as materials with stepped surface to localize phonon vibrational modes or nano-platelet-like structure to incorporate additional grain boundary scattering.

In summary, this study on Ba2+, Zn2+ and Ti4+ co-doped Lanthanum magnesium aluminate LaMgAl11O19 ceramics displays increased CTE and reduced thermal conductivity, which is contributed by the substantial additional point-defect scattering, plate-like grain-boundary scattering and stepped surfaces. Point defects are effective at scattering short wavelength phonons, while plate-like nano-grains are required to scatter mid- and long-wavelength phonons effectively, highl-density grain boundaries and layered microstructures can play an effective role in scattering longer-wavelength phonons. A novel thought to further lower thermal conductivity was provided by introducing multi-enhanced-phonon scattering modes in Ln-Me-A sites co-substituted LnMeA11O19 ceramics, namely, materials with stepped surface to localize phonon vibrational modes and point defect mechanism, as well as nano-platelet-like structure to incorporate additional grain boundary scattering. A low thermal conductivity of 1.44 ~ 1.65 W·m−1·K−1 at 1027 K qualifies the LaMgAl11O19 based-bulk ceramics with high CTE (~11.2 × 10−6 K−1, T = 1027 K) as a promising candidate for advanced thermal barrier coatings.

Methods

The series of samples were synthesized through citric acid sol-gel route over the solid solution range according to the formula La1−xBaxMg1−xZnxAl11−xTixO19 (LBMZATO, x = 0.0, 0.1, 0.2, 0.3, 0.4, 0.5). Details of powder processing approach used in citric acid sol-gel route are described elsewhere44. The acquired powders were isostatically cool pressed and sintered at 1500°C for 6 h in air to obtain LBMZATO ceramics. The LBMZATO ceramics were machined into samples of 5.0 × 5.0 × 20.0 mm for CTE characterization. Finally, full dense LBMZATO ceramics were prepared by spark plasma sintering under an applied pressure of 50 MPa at 1500°C with a constant heating rate 100°C min−1 to mold into pellets of ~12.7 mm in diameter and ~1.2 mm in thickness. The temperature remained at 1500°C for 15 min and a constant vacuum pressure of 4.5 Pa was maintained throughout the entire sintering process. As the specimens were loaded into a graphite die with an internal diameter of 13.1 mm, the LBMZATO changed into black disks due to the presence of excess graphite so all of the specimens were further heated in air at 950°C for 8 h. The phase compositions of the sintered pellets were identified by X-ray diffraction (XRD) (Bruker-D8 Advance Da Vinci) with CuKα radiation (40 mA, 40 kV) with 2θ angle range from 10 to 90°. The phase structure were identified using a Raman spectrometer (Raman, LabRAM HR800, HORIBA Jobin Yvon, France) using an argon ion laser with radiation at 633 nm and collected across wavenumbers 400 ~ 2000 cm−1. The signal was collected at a rate of 600 cm−1/30 s and accumulated by triple scanning. The sound speed in each of the solid solutions was measured by an ultrasonic reflection method with a computer controlled ultrasonic pulser-receiver (Olympus Model 5073PR, Waltham, MA, USA). The morphology and crystal structure in LBMZATO phases upon Ba2+ + Zn2+ + Ti4+ co-substitution were evaluated by field emission scanning electron microscopy (SEM, JSM-7001F, JEOL, Japan) and high resolution transmission electron microscopy/electron diffraction (HRTEM/ED, JEM-2010F, JEOL, Japan) techniques.

The thermal diffusivities of the samples were characterized by the laser flash system (Netzsch LFA 427, Germany) from room temperature up to 1273 K exposed to air and the temperature rise at the back side is measured as a function of time with an In-Sb infrared detector. The front and the back surfaces of each specimen were coated with two thin layers of carbon, approximately 10 μm thick, both to ensure the laser absorption at the front surface and to standardize the absorptance of the front surface and the emissivity of the back surface of the specimen. For each temperature three measurements were made to obtain the mean value of thermal diffusivity. The error in thermal diffusivity tests is within ±2%. The specific heat capacitances of the solid solutions at various temperatures were calculated according to the Neumann-Kopp rule based on the reference specific heat values of La2O3, BaO, MgO, ZnO, Al2O3 and TiO2. The real densities of the LBMZATO ceramics were measured by Archimedes' method. The thermal conductivity (κ) was calculated from the measured diffusivity (a/mm2·s−1), the specific heat (Cp/J·g−1·K−1) and the density (ρ/g·cm−3) using the relationship:

The thermal conductivity of the full dense solid, κf, was further normalized by the formula45:

where Φ is the porosity of the sintered specimen.

References

Slack, G. A. Nonmetallic crystals with high thermal conductivity. J. Phys. Chem. Solids. 34, 321–335 (1973).

Kim, W. et al. Thermal conductivity reduction and thermoelectric figure of merit increase by embedding nanoparticles in crystalline semiconductors. Phys. Revi. Lett. 96, 045901–4 (2006).

Peterson, R. B. Direct simulation of phonon-mediated heat transfer in a Debye crystal. J. Heat Transfer. 116, 815–822 (1994).

Lehmann, H., Pitzer, D., Pracht, G., Vassen, R. & Stöver, D. Thermal Conductivity and Thermal Expansion Coefficients of the Lanthanum Rare-Earth-Element Zirconate System. J. Am. Ceram. Soc. 86, 1338–1344 (2003).

Clarke, D. R. & Phillpot, S. R. Thermal barrier coating materials. Mater. Today 8, 22–29 (2005).

Schlichting, K. W., Padture, N. P. & Klemens, P. G. Thermal conductivity of dense and porous yttria-stabilized zirconia. J. Mater. Sci. 36, 3003–3010 (2001).

Bansal, N. P. & Zhu, D. M. Thermal properties of oxides with magnetoplumbite structure for advanced thermal barrier coatings. Surf. Coat. Technol. 202, 2698–2703 (2008).

Pracht, G., Vafien, R. & Stover, D. Lanthanum-Lithium Hexaaluminate—A New Material for Thermal Barrier Coatings in Magnetoplumbite Structure—Material and Process Development. Adv. Ceram. Coat. Interfaces:Ceram. Eng. Sci. Proc. 27, 87–99 (2008).

Costescu, R. M. et al. Ultra-low thermal conductivity in W/Al2O3 nanolaminates. Sci. 303, 989–990 (2004).

He, J. Q. et al. Strong Phonon Scattering by Layer Structured PbSnS2 in PbTe Based Thermoelectric Materials. Adv. Mater. 24, 4440–4444 (2012).

Feser, J. P. et al. Ultralow Thermal Conductivity in Polycrystalline CdSe Thin Films with Controlled Grain Size. Nano Lett. 13, 2122–2127 (2013).

Vineis, C. J. et al. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 22, 3970–3980 (2010).

Lan, J. L. et al. Enhanced Thermoelectric Properties of Pb-doped BiCuSeO Ceramics. Adv. Mater. 25, 5086–5090 (2013).

Zhao, L. Y. et al. Peierls distortion as a route to high thermoelectric performance in In4Se3−δ crystals. Nature 459, 965–968 (2009).

Park, J. G. & Cormack, A. N. Defect structures and nonstoichiometry in lanthanum hexa-aluminate. J. Eur. Ceram. Soc. 19, 2249–2256 (1999).

Iyi, N., Inoue, Z., Takekawa, S. & Kimura, S. The Crystal Structure of Lanthanum Hexaaluminate. J. Solid. State. Chem. 54, 70–77 (1984).

Gasperin, M., Saine, M. C., Kahn, A., Laville, F. & Lejus, A. M. Influence of M2+ Ions Substitution on the Structure of Lanthanum Hexa-aluminates with Magnetoplumbite Structure. J. Solid State Chem. 54, 61–69 (1984).

Cao, X. Q., Vassen, R. & Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 24, 1–10 (2004).

Mali, A. & Ataie, A. Structural characterization of nano-crystalline BaFe12O19 powders synthesized by sol–gel combustion route. Scripta Mater. 53, 1065–1070 (2005).

Hungrí, T., Galy, J. & Castro, A. Spark plasma sintering as a useful technique to the nanostructuration of piezo-ferroelectric materials. Adv. Eng. Mater. 11, 615–631 (2009).

David, R. Clarke. Materials selection guidelines for low thermal conductivity thermal barrier coatings. Surf. Coat. Technol. 163–164, 67–74 (2003).

Clarke, D. R. & Phillpot, S. R. Thermal barrier coating materials. Mater. Today 8, 22–29 (2005).

Hayashi, H. et al. Thermal Expansion Coefficient of Yttria Stabilized Zirconia for Various Yttria Contents. Solid State Ionics 176, 613–619 (2005).

Mitsui, T. & Westphal, W. B. Dielectric and X-Ray Studies of CaxBa1−xTiO3 and CaxBa1−xTiO3 . Phys. Rev. 124, 1354–1359 (1961).

Jackson, H. E. & Walker, C. T. Thermal Conductivity, Second Sound and Phonon-Phonon Interactions in NaF. Phys. Rev. B 3, 1428–39 (1971).

Smith, J. V. A review of the Al-O and Si-O distances. Acta Cryst. 7, 479–481 (1954).

Holland, M. G. Analysis of thermal conductivity. Phys. Rev. 132, 2461–2471 (1963).

Callaway, J. Model for thermal conductivity at low temperatures. Phys. Rev. 113, 1046–1051 (1959).

Callaway, J. & von Baeyer, H. C. Effect of point imperfections on thermal conductivity. Phys. Rev. 120, 1149–1154 (1960).

Zhou, Z., Uher, C., Jewell, A. & Caillat, T. Influence of point-defect scattering on the thermal conductivity of solid solution Co (Sb1−xAsx)3 . Phys. Rev. B 71, 235209–6 (2005).

Nicholls, J. R., Lawson, K. J., Johnstone, A. & Rickerby, D. S. Methods to reduce the thermal conductivity of EB-PVD TBCs. Surf. Coat. Tech. 151, 383–391 (2002).

Rowe, D. M., Shukla, V. S. & Savvides, N. Phonon scattering at grain boundaries in heavily doped fine-grained silicon–germanium alloys. Nature 290, 765–766 (1981).

Lu, H. R., Wang, C. A. & Zhang, C. G. Influence of Ln3+ and B3+ Ions Co-Substitution on Thermophysical Properties ofLnMB11O19-type Magnetoplumbite LaMgAl11O19 for Advanced Thermal Barrier Coatings. J. Am. Ceram. Soc. 96, 1063–1066 (2013).

Niu, L., Gaspar, D. J. & Sibene, S. J. Phonons localized at step edges: A route to understanding forces at extended surface defects. Sci. 268, 847–847 (1995).

Biswas, K. et al. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 489, 414–418 (2012).

Biswas, K. et al. Strained endotaxial nanostructures with high thermoelectric figure of merit. Nat. Chem. 3, 160–166 (2011).

Casimir, H. B. G. & Du Pré, F. K. Note on the thermodynamic interpretation of paramagnetic relaxation phenomena. Physica 5, 507–511 (1938).

Klemens, P. G. Thermal resistance due to point defects at high temperatures. Phys. Rev. 119, 507–509 (1960).

Klemens, P. G. Some Scattering Problems in Conduction Theory. Can. J. Phys. 35, 441–450 (1957).

Knipp, P. Phonons on stepped surfaces. Phys. Rev. B 43, 6908–6923 (1991).

Knipp, P. Surface phonons localized at step edges. Phys. Rev. B 40, 7993–7995 (1989).

Dong, J., Sankey, O. F. & Myles, C. W. Theoretical study of the thermal conductivity in Ge framework semiconductors. Phys. Rev. Lett. 86, 2361–2364 (2001).

Gilmer, G. H. & Bennema, P. Simulation of crystal growth with surface diffusion. J. Appl. Phys. 43, 1347–1360 (2003).

Narottam, P. B., Zhu, D. M. & Maryam, E. G. Corrigendum to Effects of doping on thermal conductivity of pyrochlore oxides for advanced thermal barrier coatings. Mater. Sci. Eng. A 459, 192–195 (2007).

Schlichting, K. W., Padture, N. P. & Klemens, P. G. Thermal conductivity of dense and porous yttria-stabilized zirconia. J. Mater. Sci. 36, 3003–3010 (2001).

Acknowledgements

The authors would like to thank the financial support from the National Natural Science Foundation of China (NSFC–Nos.11232008 and 51221291) and Tsinghua University Initiative Scientific Research Program(No.2012THZ0).

Author information

Authors and Affiliations

Contributions

H.R.L. and C.A.W. designed the experiments. H.R.L. carried out the fabrication of materials and characterization/measurement of thermo-physical properties. Y.H. contributed to microstructural characterizations. Y.H. and H.M.X. provided help in the experiments. The paper was written by H.R.L. and C.A.W. and all authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Lu, H., Wang, CA., Huang, Y. et al. Multi-Enhanced-Phonon Scattering Modes in Ln-Me-A Sites co-substituted LnMeA11O19 Ceramics. Sci Rep 4, 6823 (2014). https://doi.org/10.1038/srep06823

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep06823

This article is cited by

-

A Review of the Mg2(Si,Sn) Alloy System as Emerging Thermoelectric Material: Experimental and Modeling Aspects

Journal of Electronic Materials (2021)

-

Novel Al2O3–SiO2 aerogel/porous zirconia composite with ultra-low thermal conductivity

Journal of Porous Materials (2018)

-

Can litter addition mediate plant productivity responses to increased precipitation and nitrogen deposition in a typical steppe?

Ecological Research (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.