Abstract

An all-solid Yb3+/Er3+ co-doped single-mode phosphate photonic crystal fiber (PCF) with Watt-level output power and 20 μm core diameter is demonstrated for the first time. A PCF whose refractivity of the active core is lower than that of the background glass is suggested and theoretically confirmed to be in single-mode operation at 40 μm core diameter.

Similar content being viewed by others

Fibers with short length and large mode area (LMA) are some of the most extensively investigated subjects in high-power fiber lasers and amplifiers1. On one hand, LMA fibers can withstand considerably higher energy without end-face damage and can effectively increase the threshold of nonlinear effects. Many solutions have been suggested to overcome the limitation of the core diameter in a traditional step-index fiber, including chirally-coupled-core (CCC) fibers2, leaky channel fibers3, gain-guiding fibers4, all-solid photonic bandgap fibers5 and so forth. Among them, photonic crystal fibers (PCFs)6,7 are some of the most promising designs for extending the core diameter of a single-mode LMA fiber. In fact, LMA-PCFs with core sizes approaching 100 μm have already been demonstrated8, thereby indicating the scalability of the core diameter in this kind of design. However, the presence of hollows in a traditional LMA-PCF causes difficulty in splicing PCFs to commercially available fiber-coupled devices and thus realizing an all-fiber laser system. Consequently, the industrial applications of LMA-PCFs are limited. To address this problem, a PCF with an all-solid (AS) microstructure has been suggested and realized9. The hollows of this PCF are replaced by another kind of glass, making the all-fiber laser system possible. After then, an Nd-doped silicate AS-PCF10 and a single-mode Nd-doped phosphate AS-PCF with up to 40 μm core diameter are realized11.

On the other hand, a short-length fiber can weaken the nonlinear effects and make a laser system more compact. A straightforward method of shortening fiber length is to heavily dope the active core. However, for the extensively used silica PCFs12,13, the solubility of rare-earth ions such as Yb2O3 cannot be substantially increased prior to the onset of other deleterious effects, such as quenching, phase separation and devitrification14,15. In addition, when the core is highly doped, matching the refractive indexes between the photonic crystal cladding and the active core is difficult for silica glass, which decreases the core diameter scalability of the PCF. By contrast, soft glass can be very heavily doped without exerting any other detrimental effect16 and its refractive indices can be easily adjusted. Thus, soft glass is a promising medium for PCF17,18.

In this paper, we demonstrate for the first time a phosphate Yb/Er co-doped single-mode AS-PCF with Watt-level output power and 20 μm core diameter. Using the finite-difference time-domain method, we also confirm that a single-mode AS-PCF with up to 40 μm core diameter can be realized using an index-depressed active core based on the concept of higher-order-mode (HOM) delocalization.

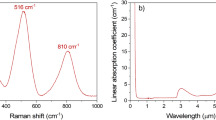

Our fiber consists of three kinds of phosphate glasses (P2O5-Al2O3-K2O-BaO-Sb2O3-La2O3) and the end face is shown in Figure 1. The refractive indexes of G0, G1 and G2 are 1.5398, 1.5393 and 1.5124 respectively at 1.55 μm, measured by the V prism method with accuracy of 5 × 10−5. The glass forming region is remarkably large in phosphate glasses, so the proportions of the components and thus the refractive indexes in the glass can be adjusted in a large range without adding any other dopants. The one-cell core is composed of Yb/Er co-doped phosphate glass (G0) with active dopant levels of 6 wt.% for Yb3+ ions and 0.5 wt.% for Er3+ ions. The inner cladding is composed of glasses G1 (bright area inside the black hexagon) and G2 (black dots). The outer cladding (black hexagon) consists of glasses G2. We use G1 glasses as the jacket of our fiber. These glasses are all provided by the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences. The fiber is featured by a center-to-center distance between two nearest rods, Λ and the rod diameter, d, with d/Λ = 0.26.

We used a fiber with a length of 60 cm and an outer diameter of 350 μm to build the laser. The numerical aperture (NA) and the normalized diameter of the inner cladding are 0.32 and ~200 μm, respectively. The doped core of the fiber is 20 μm in diameter, with a calculated effective NA of ~0.05 at around 1.55 μm. Moreover, the doped part has a loss of 2.6 dB/m at ~1330 nm and a pumping absorption coefficient of ~7 dB/m at 927 nm. Both properties are measured using the cutback method11. A fiber-coupled laser diode operated at 927 nm is used as the pumping source. A collimating lens is used to align the pumping beam and a coupling lens with NA = 0.3 serves as the laser input couple. The cavity comprises a butt-coupled dichroic mirror with high reflectivity (~1535 nm) and a cleaved fiber end with ~5% Fresnel reflectivity.

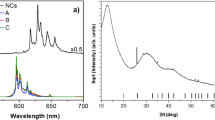

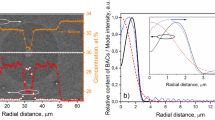

The laser performance is shown in Figure 2 and the laser spectrum is shown in Figure 3. A maximum output power of ~1.6 W is extracted with a lasing threshold of ~150 mW for absorbed pump power and the slope efficiency is 21%. No rollover is found at the highest output power, indicating that the maximum power of our laser is limited only by the maximum available pump power. The laser spectrum has a full-width at half-maximum (FWHM) of ~1 nm with the central wavelength at 1534.5 nm. We also measured the beam quality factor (M2) of the laser to be 1.05. M2 and the far-field intensity profile of the laser are shown in Figure 4.

Notably, the core diameter here is still relatively small, given the core extension ability of the PCF. To further exploit the potential of our PCF, a design with the refractivity of the active core being a little lower than that of the background material is more desirable because of the delocalization function of the HOMs of this structure, which originates from the leaky nature of PCFs19. Moreover, the possibility of quantifying the delocalization nature of the modes using the overlap factor (OF) has been well demonstrated10,11,19,20.

A high gain and single-mode operation are both important for a PCF, so the OF between the fundamental mode (FM) and the doped core should be as large as possible. Simultaneously, the OF between HOMs and the core should be as low as possible. The former guarantees a large OF of the FM, which contributes to ensure adequate gain of the fiber laser. The latter leads to a large overlap difference (ΔOF; ΔOF = OFFM − OFHOM) between the FM and HOMs, thereby enabling single-mode operation. Figure 5 shows the delocalization behavior of the modes, where all modes can be seen to “leak” from the doped core but at different degrees to result in distinctive OFs. Consequently, optimizing the parameters d and Λ of the fiber enables a PCF with large OF for FM and low OF for HOMs to be obtained, leading to a high-gain PCF with single-mode operation.

A ΔOF of 30% between the FM and HOM with the largest OF (referred to as HOMmax) is proven adequate to ensure a single-mode operation. Therefore, we fixed the value of ΔOF to be higher than 30% in our simulation and then identified the fiber parameters, the core diameter dc (dc = Λ here) and d, with the largest OF for FM. Additionally, considering that the refractivity of undoped background material is more convenient and easier to be lowered than that of doped glass when increasing the doping level, we chose to increase the refractive index of the background material and keep the refractivity of the active core unchanged, yielding Δn = −2 × 10−4. We chose this index step because of its accessibility in our laboratory.

After numerous calculations, an AS-PCF having three rings of photonic crystal cladding with d = 24 μm, dc = Λ = 40 μm and thus d/Λ = 0.6 was established. The calculated OFs of the FM and HOMmax, as well as of the corresponding ΔOFs, are 74% and 43%, respectively. Consequently, ΔOF = 31% can be acquired and a single-mode operation can be expected. Notably, for a set of glasses with a certain refractivity relationship, the available optimal parameters including the largest fiber core and the corresponding d and Λ are definite. If the parameters diverge from the optimal values, the fiber either has poor pump absorption efficiency and slope efficiency, or it will have a too low differential overlap to support single-mode laser operation. This trend has been theoretically and experimentally investigated in Ref. [16] and is not expatiated here.

In conclusion, we report a phosphate single-mode Yb/Er-doped AS-PCF with 1.6 W output power and 20 μm core diameter. In addition, a single-mode AS-PCF with up to 40 μm core diameter is theoretically investigated and confirmed.

References

Jauregui, Limpert & Tuennermann High-power fibre lasers. Nat.Photonics 7, 861 (2013).

Ma et al. Single-mode chirally-coupled-core fibers with larger than 50 μm diameter cores. Opt Express 22, 9206 (2014).

Kong et al. Flat-top mode from a 50 μm-core Yb-doped leakage channel fiber. Opt Express 21, 32371 (2013).

Sudesh, V. et al. Diode-pumped 200 μm diameter core, gain-guided, index-antiguided single mode fiber laser. Appl. Phys. B 90, 369 (2008).

Baz, A., Bigot, L., Bouwmans, G. & Quiquempois, Y. Single-Mode, Large Mode Area, Solid-Core Photonic BandGap Fiber With Hetero-Structured Cladding. J. Lightwave Technol. 31, 830 (2013).

Knight, J. C. Photonic crystal fibres. Nature 424, 847 (2003).

Wang et al. Hollow-core photonic crystal fibre for high power laser beam delivery. High Power Laser Sci. Eng. 1, 17 (2013).

Brooks, C. D. & Di Teodoro, F. Multimegawatt peak-power, single-transverse-mode operation of a 100 μm core diameter, Yb-doped rodlike photonic crystal fiber amplifier. Appl. Phys. Lett. 89, 111119 (2006).

Zhang, G. et al. Neodymium-doped phosphate fiber lasers with an all-solid microstructured inner cladding. Opt. Lett. 37, 2259 (2012).

Wang et al. All-Solid Silicate Photonic Crystal Fiber Laser With 13.1 W Output Power and 64.5% Slope Efficiency. J. Lightwave Technol. 32, 1116 (2014).

Wang, L. F. et al. Phosphate single mode large mode area all-solid photonic crystal fiber with multi-watt output power. Appl. Phys. Lett. 104, 131111 (2014).

Wang et al. Spectral evolution of NIR luminescence in a Yb3+-doped photonic crystal fiber prepared bynon-chemical vapor deposition. Chin. Opt. Lett. 11, 61601 (2013).

Zhang et al. High-temperature sensor using a Fabry-Perot interferometer based on solid-core photonic crystal fiber. Chin. Opt. Lett. 10, 70607 (2012).

Li et al. Watt-level Yb-doped silica glass fiber laser with a core made by sol-gel method. Chin. Opt. Lett. 11, 91601 (2013).

Burshtein, Z. et al. Impurity local phonon nonradiative quenching of Yb3+ fluorescence in ytterbium-doped silicate glasses. IEEE J. Quantum Elect. 36, 1000 (2000).

Wang et al. Spectroscopic properties of thulium ions in bismuth silicate glass. Chin. Opt. Lett. 10, 101601 (2012).

Li, L. et al. Short cladding-pumped Er/Yb phosphate fiber laser with 1.5 W output power. Appl. Phys. Lett. 85, 2721 (2004).

Li, L. et al. Ultracompact cladding-pumped 35-mm-short fiber laser with 4.7-W single-mode output power. Appl. Phys. Lett. 88, 161106 (2006).

Dauliat et al. Inner cladding microstructuration based on symmetry reduction for improvement of singlemode robustness in VLMA fiber. Opt. Express 21, 18927 (2013).

Coscelli, E. et al. Thermally resilient Tm-doped large mode area photonic crystal fiber with symmetry-free cladding. Opt. Express 22, 9707 (2014).

Acknowledgements

This research was supported by the Chinese National Natural Science Foundation (No. 51272262).

Author information

Authors and Affiliations

Contributions

L.W. wrote the main manuscript text, co-authors D.C., J.Q. and L.H. checked the paper and D.H., S.F. and C.Y. are responsible for the experiment. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Wang, L., He, D., Feng, S. et al. Yb/Er co-doped phosphate all-solid single-mode photonic crystal fiber. Sci Rep 4, 6139 (2014). https://doi.org/10.1038/srep06139

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep06139

This article is cited by

-

Yb–Er doped composite fiber with silicate clad and phosphate core prepared by stack-and-draw method

Optical and Quantum Electronics (2017)

-

Large-mode-area single-mode-output Neodymium-doped silicate glass all-solid photonic crystal fiber

Scientific Reports (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.