Abstract

Stable white-emitting down-converted LEDs are straightforwardly prepared by bulk polymerization of an organic dye doped polymethyl-methacrylate (PMMA) shell directly on top of a highly efficient commercial blue-emitting InGaN LED. Our optimized polymerization procedure allows for extending the form factor of achievable luminescence converter (LUCO) material beyond the conventional thin film form and to directly produce devices with light bulb design. The selected organic dyes, the blue-emitting Coumarin 30 and a red-emitting diketopyrrolopyrrole derivative, exhibit high compatibility with the free radical polymerization reaction of the PMMA matrix and ensure high stability of the final hybrid device. The control of both the thickness of the PMMA shell and the concentration of the dopant dyes allow for fine tuning of the emission color of the LUCO LED and to obtain white light with CIE chromatic coordinates x = 0.32 and y = 0.33, with rendering index as high as 80. This simple and versatile procedure is not dye-exclusive and is therefore extendable to other molecular systems for color-tunable efficient solid-state lighting sources.

Similar content being viewed by others

Introduction

The achievement of alternative lighting sources to incandescent or fluorescent lamps is a technological priority in view of a reduction of the global energy consumption. In this regard, over the last years, a massive effort has been devoted to the development of solid-state lighting devices and, in particular, white light-emitting diodes (LEDs)1,2. To date, commercially available white LEDs are fabricated using inorganic semiconductors. Despite the tremendous advancement of this technology over the years, inorganic LEDs are still expensive and limited in terms of color tunability, in the case of monochromatic LEDs and color rendering index in the case of white-emitting devices. This is due to the fact that white light is obtained by combining narrow emission spectra which leave entire portions of the visible spectrum essentially uncovered, or through inorganic down-converters with relatively poor emission in the green and red spectral regions resulting in typically low rendering of saturated colors3. In contrast, organic light-emitting diodes (OLEDs) feature high color tunability (both in terms of color coordinates and rendering index)4, high brightness and fast response time5,6. Furthermore, organic materials are amenable to solution-based fabrication methods and are compatible with flexible substrates7,8,9. However, the intrinsic low electrical and chemical stability of organic dyes strongly limits the lifetime of OLEDs and imposes the use of expensive preparation and encapsulation procedures that significantly raise their cost of light. The use of an efficient blue-emitting inorganic LED in combination to one or more organic luminescent converters (usually referred to as LUCO dyes) can in principle provide the best trade-off between the two technologies10. In a LUCO LED, an inorganic LED performs the electroluminescence function, whilst the color correction necessary to achieve aesthetically pleasing white light is provided by organic down-converter materials featuring a high luminescence efficiency and broad emission spectra11,12,13,14. Such hybrid strategy recently gained attention thanks to the availability of group III nitride-based LEDs that provide the blue or UV excitation source necessary to drive the white emission15. Ideal organic LUCO dyes should exhibit strong absorption in the UV/blue spectral region, high luminescence efficiency and broad emission covering the whole visible spectrum. Furthermore, for the color characteristics of a LUCO LED to be stable over the whole device lifetime, it is necessary that the photochemical stability of LUCO dyes is comparable to the operational lifetime of the pump LED. Finally, LUCO dyes should be easily dispersed in high optical quality polymeric matrixes without the occurrence of segregation processes. So far, both epoxy resins and PMMA have been used as matrixes in combination with a variety of highly fluorescent dyes16,17. In particular, PMMA features good optical properties and reduced permeability to oxygen and moisture, which suppresses oxidation of the dopant dyes and other quenching processes18.

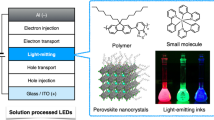

In this work we show that the combination of an optimized bulk polymerization procedure of PMMA and the selection of suitable fluorescent dyes - Coumarin 30 and diketopyrrolopyrrole (DPPth) shown in Fig. 1 - enable the fabrication of efficient and stable white LUCO LEDs. The described strategy is of particular practical appeal as it yields white-emitting LEDs directly in the shape of a light bulb through a fabrication protocol that can be readily scaled up to industrial mass production. This is achieved through a simple and fast immersion procedure of a commercial LED in a mold containing a partially pre-polymerized viscous mixture of MMA and fluorescent dyes. Provided that the proper mold is selected, white LEDs of any shape can be directly and cost-effectively prepared.

Results and Discussion

The main interest in the development of LUCO LEDs regards the capability to fabricate white emitters in a simple yet reliable way. In addition, this strategy offers the possibility to fine tune the emission color and rendering characteristics of an LED by controlling the thickness of the doped polymeric composite and the concentration of the LUCO dyes. We decided to operate with a three-component system: a commercial UV InGaN LED (emission at 405 nm) combined with two LUCO dyes. Both the employed chromophores are photo- and chemically stable and compatible with the radical polymerization process of the PMMA matrix.

As blue-emitting dye, we selected Coumarin 30 which is a well-known organic emitter19. As the red-emitting component, we choose the DPPth derivative shown in Fig. 1 that was prepared on purpose for this study. DPP derivatives are well known stable organic pigments and dyes and are gaining growing attention as high performance chromophores. Furthermore, DPP dyes are characterized by a charge transfer behavior that results in their typically large Stokes Shift20. This is a favorable feature as it minimizes re-absorption of emitted light that could affect the emission efficiency and color quality of the LUCO LED. For the preparation of DPPth, we followed the procedure reported in the literature20. With respect to this protocol, we took particular care in performing chromatographic purification, since impurities and side products, having similar retention factors as the target compound, are often overlooked. We selected DPPth because of its broad emission spectrum in the yellow-red spectral region. Finally, DPPth is freely soluble in MMA, showing no sign of phase segregation even during the polymerization process.

PMMA is among the most commonly used polymers in applications requiring excellent optical quality and good mechanical, thermal and chemical stability. The preparation of bulk PMMA with high optical quality is usually performed through a bulk polymerization procedure, as this method does not require the evaporation of the polymerization solvent. Fabrication procedure of our LUCO LED is explained in details in the experimental section.

Optical characterization of our materials was performed by absorption and photoluminescence (PL) experiments. PL spectra of Coumarin 30 and DPPth are shown in Fig. 1, both in solution and after incorporation in PMMA. All details of the optical measurements are reported in the experimental section, while the main findings are summarized in Table 1.

Coumarin 30 shows a featureless low energy absorption band at 410 nm and a broad PL spectrum peaked at 470 nm21. The absorption band of DPPth shows a well-defined vibronic progression with main maxima at 505 nm and 550 nm. Its PL is the mirror image of the absorption spectrum with peaks at 570 nm, 610 nm and 680 nm20. The absorption and emission spectra of Coumarin 30 and DPPth show no change upon incorporation in PMMA, except for a negligible broadening typically observed in solid-state samples. In the case of DPPth, we note a small redistribution of the PL intensity among the vibronic replica in favor of the higher order peaks, which suggests that DPPth conformation is more strongly distorted in solid PMMA than in solution.

A key feature of lighting sources is the emission efficiency, which, in the case of LUCO LEDs, is a direct consequence of the PL quantum yield (QY) of the LUCO dyes. Typical PL QYs for Coumarin 30 and DPPth in solution are around 55% and 74%, respectively19,20. Importantly for our purpose, nonradiative recombination channels associated to conformational mobility typically affect molecules with many vibrational and rotational degrees of freedom, such our dyes of choice. In these cases, incorporation in a solid matrix stiffens the molecular structure and results in significant increase of the PL efficiency. Indeed, for both dyes, we observe a significant increase of the PL lifetimes from solution to the solid state (see Table 1), indicating the effective suppression of nonradiative decay channels. As a consequence, the measured QYs of Coumarin 30 and DPPth in PMMA are as high as 92% and 100%, respectively.

For the realization of a LUCO LED, we should consider that Coumarin 30 is directly excited by the employed pump LED at 405 nm. On the contrary, DPPth is nearly transparent at 405 nm and it must be indirectly excited by Coumarin 30 through two different mechanisms: (i) absorption of Coumarin 30 fluorescence, which depends on both the DPPth molar concentration and the thickness of the doped PMMA capsule and (ii) Förster resonant energy transfer (FRET), which depends exclusively on the concentration of DPPth22. The schematic representation of the LUCO LED is reported in Fig. 2a showing the InGaN LED embedded in the doped PMMA capsule and the excitation/emission mechanisms of the dyes.

Optical properties of LUCO LEDs.

(a) Schematic representation of the LUCO LED showing the InGaN LED embedded in the PMMA capsule doped with Coumarin 30 (blue) and DPPth (red). (b) Simulated PL spectra of a LUCO LED as a function of the thickness of the doped down-converting PMMA capsule. Upon increasing the capsule thickness, the emission color changes from blue of pure Coumarin 30 to red of DPPth excited via FRET (grey arrow) and by reabsorption of Coumarin 30 luminescence (blue arrow). (c) CIE chromaticity plot showing the calculated color trajectory (black line) corresponding to the spectra in ‘b’. Points A and B indicate the chromatic coordinates of the PL of pure DPPth and Coumarin 30, respectively. The color coordinates of representative LUCO LEDs with increasing capsule thickness (T = 1.3, 2.6, 4.6, 6.3 and 8.2 mm) are reported in circles. (d) Emission spectra of representative LUCO LEDs corresponding to the color coordinates in ‘c’. (e) Color rendering index radial plot of a LUCO LED with capsule thickness T = 4.6 mm. The color scheme is the same throughout the figure.

The color tuning of the LUCO LED requires a proper balance of the contributions of the two dyes to the total emission spectrum. However, the control of dye concentration is not straightforward in bulk. Indeed, during the polymerization and the subsequent thermal annealing at high temperature, a fraction of the dye molecules undergoes degradation. The process is sizeable only in the co-presence of high temperature, residual monomer and oxygen, in agreement with what has already been observed for PMMA-based luminescent solar concentrators23. We did not detect any further degradation after complete polymerization and high temperature degassing (see below). However, this degradation process prevents the fine optimization of the FRET efficiency. Therefore, we preferred to use a DPPth concentration low enough to minimize FRET and to obtain the desired emission color by varying the thickness of the PMMA capsule. The Förster radius (R0) has been calculated from the overlap between the absorption and PL spectra of the dyes in diluted solution, where the respective concentrations can be precisely determined. We obtained a Förster radius of 45.1 Å, which reflects the large superposition between Coumarin 30 emission and DPPth absorption spectra and corresponds to a FRET efficiency in PMMA of 19% for a DPPth concentration of 5·10−4 M (see supplementary information for details).

The effective FRET efficiency, evaluated from the comparison of the PL lifetime of Coumarin 30 in PMMA with and without DPPth, is lower than expected (in the range 0.04–0.10, considering the accuracy of the measurements). This can be explained by a small difference between the nominal and the real molecular concentrations in PMMA. Accordingly, the integrated area of the DPPth absorption band in solution is larger than that in PMMA (Fig. 1b), despite the nominal concentrations are the same. As expected, this energy-transfer rate is not sufficient to obtain white emission exclusively by FRET, allowing for further fine tuning of the emission color by varying the thickness of the PMMA capsule.

DPPth emission has CIE (Commission Internationale de l'Éclairage) chromaticity coordinates: x = 0.56 and y = 0.43 (see point “A” in Fig. 2a) and Coumarin 30 PL spectrum corresponds to x = 0.16 and y = 0.32 (point “B” in Fig. 2a). By mixing the two dyes, different colors can be obtained, including white light. Given the overlap between the absorption spectrum of DPPth and the emission spectrum of Coumarin 30, even at fixed dye concentration, the emission spectrum of Coumarin 30 varies with the thickness of the PMMA composite. The color trajectory achievable with our material system was calculated using the equation reported in Monguzzi et al.24, adapted for taking into account the collection geometry. Figure 2b shows the simulated emission spectra of PMMA composites with increasing thickness. The resulting color trajectory, shown in Fig. 2c, is not a straight line and crosses the pure white region (chromatic coordinates: x = 0.32, y = 0.33) for a capsule thickness of 4.60 mm (crosses in Fig. 2a). Experimental PL spectra for LUCO LEDs with different thickness are shown in Fig. 2d. As a function of the capsule thickness, the chromatic coordinates span from the green/blue to the yellow/red region of the chromaticity space, in good agreement with the theoretical predictions. Only for small thicknesses we observe a minor deviation from the expected values due to the presence of residual pump light at 405 nm.

In addition to the CIE coordinates, other parameters must be taken into account for a comprehensive qualification of a lighting source: the correlated color temperature (CCT) and the color rendering index (CRI). The color temperature of artificial white light is largely a matter of personal taste and is typically associated with the requirements of specific settings. The general trend in western countries is to use cold whites for business and medical locations (e.g. offices, factories, clinics) and warm tones of white for social ambiences that prefer a comforting atmosphere, such as hotels and houses. The CCT of our devices was evaluated by using the McCamy's approximation algorithm25, obtaining CCT = 5980 K, corresponding to cold white light. The effect on illuminated objects with this device is the enhancement of the blues and the flattening of the reds, as required, for instance, in medical environments such as hospitals. The corresponding CRI is 80 (see supplementary information), which is an accepted standard requirement for indoor lighting sources (Fig. 2e). Only for R8 (corresponding to color test TCS08 “light reddish purple”), R3 (TCS03 “strong yellow green”) and R4 (TCS04 “moderate yellowish green”) the rendering is not perfect, due to the relatively low emission intensity in the region centered at about 520 nm and in the deep-red tail of the visible spectrum (λ > 635 nm).

Finally we measured the emission efficiency and operational stability of a prototypical LUCO LED. The PL QY of the down-converter material was measured using 405 nm excitation in an integrating sphere and was found to be remarkably high, with a value of 92%, which reflects the near unity PL quantum yield of our LUCO dyes in the solid PMMA matrix. With this material we realized shells for both high- and low-power commercial UV LEDs. As expected, the obtained emission spectra are essentially independent on the employed UV LED and on the driving current (see Supplementary Fig. S1). On the contrary, the output power of the pump diode determines the luminous flux of the LUCO LED that ranges from fractions of Lumen, when the converting capsule is coupled to a LE-0503-03UV (JKL Components Corporation) LED, up to 11 Lumen when the pump is a high-power Ledengin LZ4-00UA00 LED (see Supplementary Fig. S1).

In order to evaluate the stability of our devices, we collected the PL spectrum of a LUCO LED, excited with the JKL Components Corp pump, every hour for a total of 72 hours of continuous operation. As shown on Fig. 3, only a negligible drop of the emission is observed. This confirms the short-term stability of the dyes after the mass polymerization process of the PMMA matrix and the subsequent thermal annealing. Long-term stability has not been tested here, but probably requires the inclusion in the PMMA matrix of proper additives as usual to avoid the degradation of all UV-exposed plastic materials.

In summary, we designed and realized a hybrid white-emitting LUCO LED with high color rendering index and efficiency of over 90%. This was achieved through rational combination of an inorganic InGaN LED with two organic dyes (Coumarin 30 and DPPth) embedded in mass polymerized PMMA. Incorporation in PMMA increases both the photostability and the efficiency of parental molecules. Aging tests confirm the operational stability of both efficiency and color purity of the device over several days of operation. Our organic LUCO materials, obtained through a new fabrication protocol that can be readily scaled up to industrial quantities, could replace conventional phosphors-based down-converters used in white LEDs, thus opening the way to better performing white solid-state lighting sources.

Experimental section

Measurements were performed on dyes, both in diluted solution (Coumarin 30 in hexane and DPPth in dichloromethane) and embedded in PMMA. Coumarin 30 was purchased by Sigma Aldrich (546127-100MG), while DPPth was synthesized on purpose for this study, following reference 20.

For device fabrication, we employed a two-step polymerization protocol that involves first, the formation of a viscous solution of PMMA in monomer MMA. Such solution (usually referred to as ‘syrup’) is mixed with the fluorescent dyes and casted in the mold having the required shape, where it is finally completely polymerized to give bulk PMMA26. The nominal concentrations of the dyes in the polymeric matrix are 5·10−3 M for Coumarin 30 and 5·10−4 M for DPPth. In a typical procedure, 100 mg of 2,2′-Azobis(2-methylpropionitrile) (AIBN) were dissolved in 100 ml of freshly distilled MMA. Solutions were placed in beakers and slowly heated until the temperature of 80°C was reached. This temperature was maintained for 2 minutes, during which the viscosity increased substantially. The solution was immediately transferred in an ice bath and cooled to 20°C. A solution of Coumarin 30 (7.00 mg, 0.02 mmol), DPPth (10.80 mg, 0.02 mmol) in freshly distilled MMA (60 ml) was added along with 150 mg of lauryl peroxide. One ml of the viscous syrup thus obtained was poured in semispherical molds (1 cm diameter) and a 405 nm emitting commercial LED (model LE-0503-03UV by JKL Components Corporation andLZ4-00UA00 by Ledengin) was immersed directly in the mold without removing its protective epoxy capping. The molds were sealed and immersed in a water bath at 65°C for 24 h. At the end of the thermal treatment, the syrup turns into solid PMMA blocks embedding the LEDs. The devices are then removed from the mold and further cured at 75°C for 4 h. In the end of the process, devices are still perfectly functional.

A VARIAN Cary 50 UV-Visible spectrometer was used for optical absorption measurements. Steady-state photoluminescence measurements were carried out with a home-made setup, collecting the light emitted by the LUCO LEDs with a CCD coupled to a spectrometer. For time-resolved PL measurements, samples were excited at 405 nm using a pulsed diode laser (pulse duration = 40 ps) and the signal was detected by a photomultiplier tube coupled to a monochromator (time resolution better than 0.5 ns). All measurements were performed at room temperature. QYs were measured using an integrating sphere coupled to a calibrated spectrometer following the procedure reported in ref. 27 in order to take into account the re-absorption effects. With the same set-up we evaluated also the external emission efficiency of the LUCO LEDs. A series of automatically collected PL spectra (1 per hour for a total of 72 hours of continuous current operation of our fabricated LED) were analyzed for aging tests.

References

Schubert, E. F. & Kim, J. K. Solid-state light sources getting smart. Science 308, 1274–1278, 10.1126/science.1108712 (2005).

Basic Research Needs for Solid-State Lighting, Report of the Basic Energy Sciences Workshop on Solid-State Lighting. (May 22–24, 2006), U.S. Department of Energy http://science.energy.gov/~/media/bes/pdf/reports/files/ssl_rpt.pdf.

Smet, P. F., Parmentier, A. B. & Poelman, D. Selecting Conversion Phosphors for White Light-Emitting Diodes. J. Electrochem. Soc. 158, R37–R54, 10.1149/1.3568524 (2011).

Brovelli, S. et al. Emission Color Trajectory and White Electroluminescence Through Supramolecular Control of Energy Transfer and Exciplex Formation in Binary Blends of Conjugated Polyrotaxanes. Adv. Funct. Mater. 22, 4284–4291, 10.1002/adfm.201200786 (2012).

Farinola, G. M. & Ragni, R. Electroluminescent materials for white organic light emitting diodes. Chem. Soc. Rev. 40, 3467–3482, 10.1039/c0cs00204f (2011).

Reineke, S. et al. White organic light-emitting diodes with fluorescent tube efficiency. Nature 459, 234–U116, 10.1038/nature08003 (2009).

Han, T. H. et al. Extremely efficient flexible organic light-emitting diodes with modified graphene anode. Nature Photon. 6, 105–110, 10.1038/nphoton.2011.318 (2012).

Wang, Z. B. et al. Unlocking the full potential of organic light-emitting diodes on flexible plastic. Nature Photon. 5, 753–757, 10.1038/nphoton.2011.259 (2011).

Capelli, R. et al. Organic light-emitting transistors with an efficiency that outperforms the equivalent light-emitting diodes. Nature Mater. 9, 496–503, 10.1038/nmat2751 (2010).

Hide, F., Kozodoy, P., DenBaars, S. P. & Heeger, A. J. White light from InGaN/conjugated polymer hybrid light-emitting diodes. Appl. Phys. Lett. 70, 2664–2666, 10.1063/1.118989 (1997).

Narukawa, Y. et al. Phosphor-conversion white light emitting diode using InGaN near-ultraviolet chip. Jpn. J. Appl. Phys. Part 2 - Lett. 41, L371–L373, 10.1143/jjap.41.l371 (2002).

Schlotter, P., Schmidt, R. & Schneider, J. Luminescence conversion of blue light emitting diodes. Appl. Phys. A-Mater. Sci. Process. 64, 417–418, 10.1007/s003390050498 (1997).

Xiang, H. F., Yu, S. C., Che, C. M. & Lai, P. T. Efficient white and red light emission from GaN/tris-(8-hydroxyquinolato) aluminum/platinum(II) meso-tetrakis(pentafluorophenyl) porphyrin hybrid light-emitting diodes. Appl. Phys. Lett. 83, 1518–1520, 10.1063/1.1604192 (2003).

Ermakov, O. N. et al. Hybrid organic-inorganic light-emitting diodes. Microelectron. Eng. 69, 208–212, 10.1016/s0167-9317(03)00298-3 (2003).

Belton, C. R. et al. New light from hybrid inorganic-organic emitters. J. Phys. D-Appl. Phys. 41, 094006/10.1088/0022-3727/41/9/094006 (2008).

Zhang, L., Li, B., Lei, B., Hong, Z. & Li, W. A triphenylamine derivative as an efficient organic light color-conversion material for white LEDs. J. Lumines. 128, 67–73, 10.1016/j.jlumin.2007.05.009 (2008).

Youn-Sik, L., Hyun-Jeong, K., Ji-Young, J., Sang-Hee, L. & Chang-Hee, H. An efficient luminescence conversion LED for white light emission, fabricated using a commercial InGaN LED and a 1,8-naphthalimide derivative. Chem. Phys. Lett. 431, 341–345, 10.1016/j.cplett.2006.09.090 (2006).

Kinderman, R. et al. I-V performance and stability study of dyes for luminescent plate concentrators. J. Sol. Energy Eng. Trans.-ASME 129, 277–282, 10.1115/1.2737469 (2007).

Senthilkumar, S., Nath, S. & Pal, H. Photophysical Properties of Coumarin-30 Dye in Aprotic and Protic Solvents of Varying Polarities. Photochem. and Photobio. 80, 104–111 (2004).

Burckstummer, H., Weissenstein, A., Bialas, D. & Wurthner, F. Synthesis and Characterization of Optical and Redox Properties of Bithiophene-Functionalized Diketopyrrolopyrrole Chromophores. J. Org. Chem. 76, 2426–2432, 10.1021/jo2003117 (2011).

Jones, G., Jackson, W. R., Choi, C. & Bergmark, W. R. Solvent effects on emission yield and lifetime for coumarin laser-dyes - Requirements for a rotatory decay mechanism. J. Phys. Chem. 89, 294–300, 10.1021/j100248a024 (1985).

Lakowicz, J. R. Principle of Fluorescence Spectroscopy (Springer, 2006).

Baumberg, I. et al. Effect of polymer matrix on photo-stability of photo-luminescent dyes in multi-layer polymeric structures. Polym. Degrad. Stabil. 73, 403–410, 10.1016/s0141-3910(01)00119-7 (2001).

Monguzzi, A., Riva, F., Tubino, R. & Meinardi, F. White light generation by sensitized photon up-conversion. Chem. Phys. Lett. 521, 17–19, 10.1016/j.cplett.2011.11.037 (2012).

McCamy, C. S. Correlated color temperature as an explicit function of chromaticity coordinates. Color Res. Appl. 17, 142–144, 10.1002/col.5080170211 (1992).

Heitner, B. J. E. I. Du Pont de Nemours and Co. Process for preparing acrylic polymer sheets using a dual peroxide initiator system. United States Patent US 4,588,798.1986 May 13.

de Mello, J. C., Wittmann, H. F. & Friend, R. H. An improved experimental determination of external photoluminescence quantum efficiency. Advanced Materials 9, 230–232 (1997).

Acknowledgements

Financial support of the regional programme IndOLED (POR FESR 2007–2013, Regione Lombardia) is gratefully acknowledged. D.D. and S.B. thank Cariplo Foundation (under project numbers 2010-0564 and 2012-0844) for financial support. S.B. wishes to thank the European Community's Seventh Framework Programme (FP7/2007-2013) under grant agreement N. 324603. We thank A. Monguzzi and G. Vaccaro for valuable discussion.

Author information

Authors and Affiliations

Contributions

D.D., L.B., F.M. and R.T. conceived the idea of direct radical polymerization of doped PMMA on InGaN LEDs. L.B. and M.S. synthesized the materials. D.D., F.M. and S.B. performed the optical experiments. D.D., F.M. and S.B. analyzed the results and wrote the manuscript in consultation with all authors.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Di Martino, D., Beverina, L., Sassi, M. et al. Straightforward fabrication of stable white LEDs by embedding of inorganic UV-LEDs into bulk polymerized polymethyl-methacrylate doped with organic dyes. Sci Rep 4, 4400 (2014). https://doi.org/10.1038/srep04400

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04400

This article is cited by

-

Application of an orange–yellow emitting cationic iridium(III) complex in GaN-based warm white light-emitting diodes

Journal of Materials Science: Materials in Electronics (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.