Abstract

Ion implantation is a promising technique for fabricating high density bit patterned media (BPM) as it may eliminate the requirement of disk planarization. However, there has not been any notable study on the impact of implantation on BPM fabrication of FePt, particularly at nano-scale, where the lateral straggle of implanted ions may become comparable to the feature size. In this work, implantation of antimony ions in patterned and unpatterned L10-FePt thin films has been investigated. Unpatterned films implanted with high fluence of antimony exhibited reduced out-of-plane coercivity and change of magnetic anisotropy from perpendicular direction to film-plane. Interestingly, for samples implanted through patterned masks, the perpendicular anisotropy in the unimplanted region was also lost. This noteworthy observation can be attributed to the displacement of Fe and Pt atoms from the implantation sites to the unimplanted areas, thereby causing a phase disorder transformation from L10 to A1 FePt.

Similar content being viewed by others

Introduction

Current hard disk drives use perpendicular recording media based on CoCrPt alloys with oxide grain boundary material. Such media have been projected to face media trilemma challenges at areal densities higher than one tera bits per square inch (Tb/in2). Bit patterned media (BPM) technology, where magnetic islands separated by nonmagnetic material act as bits, is considered as a potential future candidate. Areal density achievable by BPM using a Co/Pd multi-layered structure as a recording layer has been demonstrated1 to provide 1 Tb/in2. It has been reported2 that such multi-layered structure has the potential up to 5 Tb/in2. Hence, in order to achieve areal density beyond 5 Tb/in2, it is essential to have recording media based on high anisotropy materials such as FePt in combination with BPM3,4,5,6. Out of several other high anisotropy materials such as SmCo, NdFeB and CoPt, the superiority of FePt lies in an optimal combination of corrosion resistance, higher saturation magnetization and substrate temperature. In the current technological scenario, heat-assisted magnetic recording (HAMR) is favoured as the next generation technology. However, even if HAMR were adapted, patterned media technology needs to be combined with HAMR in order to achieve areal densities above 5 Tb/in2. At such high densities, it is essential to use high anisotropy materials such as L10-FePt-based patterned media7.

Various experimental works have been carried out on FePt-based BPM for high areal densities8,9,10. In all these reports, BPM was fabricated based on lithography followed by physical etching of the FePt recording layer. When such a method is used, the lithographically modified surface has to be flattened or planarized later in order to meet the high areal density requirements from the tribological perspective. However, planarization over the entire disk that meets the demanding requirements of magnetic spacing is a highly challenging task11,12.

Ion implantation has been used as an alternative method to form patterned media. In this method, the use of energetic ion irradiation results in the formation of magnetic islands without any significant depletion or modification of topography13. Various research studies have been done to fabricate BPM, but the recording layers have either been based on conventional CoCrPt or Co/Pd multilayers14,15,16,17,18. Nevertheless, only a few works have been undertaken on ion implantation in disordered FePt and FePd phases; L10-FePt-based patterned media have seldom been investigated using ion implantation19,20,21. In particular, though Terris et al. have carried out implantation work on FePt patterned structures, their work is carried out at micrometer scale and hence does not discuss the important effects that we have observed at nanometer scale in this paper21.

In this work, therefore, the effects of implantation of ion species were investigated on the magnetic and structural properties of the L10-FePt media. An interesting observation of this study is that the lateral diffusion of species may change the ordered L10-FePt material to disordered FePt, even in regions that were not implanted. As this diffusion results in magnetic islands with a weaker magnetic anisotropy, the study highlights a significant challenge in using the ion implantation method for fabricating high-density patterned FePt media.

Results

FePt magnetic media were prepared by magnetron sputtering and the media stack is shown in Fig. 1(a). A 20 nm Cr90Ru10 underlayer was deposited at 200 W and 400°C on the glass substrate to provide a (001) texture for the FePt film. Cr90Ru10 was followed by a MgO buffer layer of about 3 nm, deposited at 150 W and 400°C, in order to reduce the Cr diffusion into the L10-FePt. A Fe60Pt40 layer of 10 nm was deposited on the MgO underlayer at 100 W and 600°C to obtain the L10 phase. Experimentally, it has been found that even though the ordering parameter (S), is unity for Fe50Pt50, the magnetocrystalline anisotropy is maximum when the Fe content is increased slightly above the equiatomic compositions of Fe and Pt. Hence, a non equiatomic composition of FePt was chosen for this study. XPS depth profile measurements showed the composition to be Fe60Pt4022. The Ar pressures during the deposition of FePt, MgO and CrRu, were 3, 1.5 and 1.5 mTorr, respectively. The topmost layer of 2 nm Si was deposited at room temperature as a protective layer against corrosion of the FePt film.

The FePt media structure was further deposited with 20 nm tantalum (Ta) to form a hard mask for ion implantation, as shown in Fig. 1(a). Ta-coated samples were spin-coated with STU (Simultaneous Thermal and UV) resist. The spin-coated resist samples were then used in nanoimprint lithography (NIL). For NIL, a silicon master mold, which had cylindrical pillars of 30 nm diameter and 80 nm pitches, was used. Combined thermal and UV NIL was used to increase the lifetime of the master mold through a two-step process. Using thermal imprinting under the optimized imprinting conditions, the master mold was first replicated on an intermediate polymer stamp (IPS). The daughter mold, IPS, thus formed was used to imprint the UV-curable STU resist at a much lower temperature. Such a technique solves the problem related to thermal expansion and provides highly uniform and thin residual layers23. A 10 nm residual layer was observed, which was later removed by means of oxygen plasma for nine seconds at 120 mTorr and 50 W RF bias in 30 sccm of oxygen.

To transfer the patterns to Ta, the samples were further etched by means of reactive ion etching-inductively coupled plasma (RIE-ICP) in a CF4 environment. Cross-sectional SEM of the patterns showed that a ~20 nm pillar height of Ta was obtained for 90 secs of etching in a CF4 environment as shown in Fig. 1(b). The FePt media samples (both patterned and unpatterned) were subsequently implanted homogeneously with Sb+ with energy of 9 keV. For unpatterned films, the implantation fluences chosen were 1015, 5 × 1015, 1016 and 5 × 1016 ions/cm2.

Effect of ion implantation on unpatterned samples

The magnetization loop and θ–2θ plot obtained from the as-deposited samples in Fig. 1(c, d) show the easy axis to be along the out-of-plane (001) direction. Fig. 1(c) shows an out-of-plane coercivity of 13.55 kOe and in-plane coercivity of 7.82 kOe, respectively, for the as-deposited L10-FePt (fct) sample. The saturation magnetization (Ms) of the FePt media was found to be 1200 emu/cc. Fig. 1(d) showed the existence of FePt (001), FePt (002), MgO (002) and CrRu (002) peaks. This indicated the heteroepitaxial growth of a CrRu(001)[110]||MgO (001)[100]||FePt(001)[100] in the media. The relatively weak MgO (002) peak was attributed to the small thickness of the MgO layer.

Fig. 2(a) shows the hysteresis loop in the out-of-plane direction and Fig. 2(b) shows the in-plane loops for samples implanted with Sb+ with various ion fluences without any Ta mask. The magnetization loops showed a change in the easy axis direction from the out-of-plane to in-plane direction at 1015 ions/cm2. This was further evidenced by a square loop along the in-plane and a slope in the out-of-plane direction. A similar change in the easy axis direction from perpendicular to in-plane has previously been reported in the Co/Pd and Co/Pt multilayers after implantation with ions such as Ar+ and He+24,25,26. The change in anisotropy was explained based on the irradiation-induced rearrangement of the atoms in the superlattice structure to form a mixed-interface state. As a result, the anisotropy arising from the interface vanished due to a mixing induced by the implantation. However, in the case of FePt media, the interface anisotropy does not play a major role as the high anisotropy in FePt is associated with the chemically ordered ferromagnetic L10 phase. Therefore, it was speculated that the ion implantation with Sb+ ions may cause phase transformation from the chemically ordered ferromagnetic L10 phase to a disordered A1 (fcc) phase due to the lateral diffusion of Fe and Pt atoms. As the disordered A1 phase has a lower magnetic anisotropy, the perpendicular anisotropy vanished. We carried out further experimental and simulation studies to investigate this possibility.

Fig. 3(a, b) shows the change of coercivity and the saturation magnetization as a function of fluence. The change of coercivity, Hc, was significant even for smaller fluences as shown in Fig. 3(a). The coercivity showed a further decrease with the increase in the implantation fluence. The arrows in Fig. 2(a) show the corresponding anisotropy field for a particular fluence. Similar to coercivity, the value of anisotropy field, Hk, was also observed to reduce from 10 kOe to 5 kOe with increasing implantation fluence till 1016 ions/cm2. As this value of Hk appears to be equal to 4.pi.Ms, this is another indication of loss of perpendicular anisotropy. For unimplanted samples, the Hk (measured by the meeting field of in-plane and perpendicular loops) was more than 70 kOe. Saturation magnetization, Ms, also reduced with increasing fluence. However, in contrast to the reduction in coercivity, Ms reduced at a much slower rate from 1200 emu/cc in unimplanted sample to 1000 emu/cc in sample implanted with lower dose, 1015 ion/cm2 as seen in Fig. 3(b). The normalized values of Hc and Ms (with respect to the unimplanted samples) are plotted in Fig. 3(c) in order to highlight the relative changes. It should be mentioned that the Hc decreased sharply even at a low fluence of 5 × 1015 ion/cm2, indicating a phase transformation in such films.

The reduction of Ms with fluence is essential for patterned media application so as to produce non-magnetic material in the implanted region. Hence, the highest fluence of 5 × 1016 ion/cm2 was further used for subsequent patterned media fabrication. Our previous studies on Sb+ implantation have indicated that a fluence of 2 × 1016 ions/cm2 is sufficient to reduce magnetization to zero in Co-based alloys27. Because the saturation magnetization in FePt is larger than that of Co-based alloy, a slightly higher implantation fluence was necessary in this study to ensure that the magnetization could be reduced to zero.

Effect of ion implantation on patterned sample

The patterned sample, as shown in Fig. 1(a), was subsequently implanted with antimony (Sb+) at 5 × 1016 ions/cm2 so as to ensure that the magnetization is reduced close to zero in the implanted regions. Fig. 4(a) shows the out-of-plane hysteresis loops of the patterned sample. It is surprising to note that the patterned sample did not show the hysteresis loop corresponding to an out-of-plane anisotropy even though the masked regions should have their magnetic properties unchanged. The coercivity and the remanent magnetization values were much reduced in comparison to the unpatterned and unimplanted sample. The hysteresis loop of the unpatterned film, which was implanted at the same fluence, is also shown for comparison. It can be observed that the magnetization of the patterned sample dropped by about 75%, when compared with the unimplanted sample. For the same fluence, the unpatterned sample showed a decline in Ms close to zero (Fig. 4(a)). Surprisingly, a perpendicular hysteresis loop expected from the masked region was not observed. Implantation studies so far have reported a change in anisotropy or magnetization mainly in the implanted region. However, a change in anisotropy in the unimplanted region was an unexpected observation. The in-plane hysteresis loop measurements (Fig. 4(b)) also confirmed that the perpendicular anisotropy was reduced significantly, resulting in an observation of in-plane magnetization after implantation.

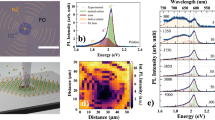

Magnetic force microscopy (MFM) studies were further carried out on the patterned samples after implantation to check if magnetic patterns were visible. Fig. 5 shows the atomic force microscopy (AFM) and MFM images of the FePt samples before and after implantation (fluence of 5 × 1016 ions/cm2). Before implantation, the nanoimprinted Ta patterns on the media were very clearly visible (Fig. 5(a)). Also, a maze like domain structure, typical representation for material with a perpendicular magnetic anisotropy, was noticeable in the FePt media (Fig. 5(b)). However, after implantation, both the physical patterns and magnetic patterns were observed to be changed (Fig. 5(c, d)). The change of physical patterns could be due to the partial sputter etching of the metal mask due to ion-beam current. The damage in magnetic domain structure as a result of implantation through Ta masks could be due to lateral displacement of Fe and Pt atoms beneath the mask thereby distorting the ordered fct FePt structure. The MFM pattern of implanted sample does not show the characteristics of films with perpendicular magnetic anisotropy, which usually show strong signals from up and down domains.

In order to confirm whether such a phase change had occurred and the fct-FePt structure is vanished, XRD measurements were carried out on the unpatterned samples and the results are shown in Fig. 6. It can be observed that the L10-fct (001) peak vanished even for the lowest fluence of implantation. This supports our observation of in-plane anisotropy even for the lowest fluence in this study. The fcc/fct (002) peak of FePt (~48°) shifted left towards 47° progressively as a function of fluence. This suggests the dominance of the fcc (200) phase over the fct (002) L10 phase in the XRD or a mixing of Sb in FePt resulting in a change of lattice constant. However, as the L10 phase is diminished (as seen from (001) peak), fct (002) is not expected. Also, it was seen that MgO (002) and CrRu (002) peaks are vanished as a result of ion implantation. This might be due to damage in MgO and CrRu lattices or interface diffusion of materials. These results support our earlier observations and discussions.

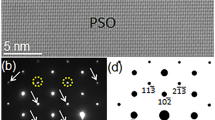

To observe the changes in microstructure, TEM was carried out. The plan-view TEM images of as-deposited (Fig. 7(a)) and high fluence (5 × 1016 ions/cm2) implanted sample (Fig. 7(b)) displayed an increase in grain size, thus, correlating well with the explanation of increase in displacement of ions with implantation leading to increase in grain size and exchange interaction as previously observed. Fig. 7(c) and Fig. 7(d) show the corresponding selected area electron diffraction (SAED) rings obtained from a single grain in the TEM images of the as-deposited FePt sample and sample implanted with 5 × 1016 ions/cm2. From the radii of the SAED rings of the as-deposited sample, one can observe the MgO (200) and fct-FePt (200) ring (Fig. 7(c)). Implanted sample just showed MgO (200) and no fct-FePt ring was visible (Fig. 7(d)). Infact, a different ring was visible with lattice constant lower than 0.386 nm. Such absence of diffraction ring corresponding to fct (001) phase of FePt confirmed the order-disorder phase transformation. Similar to the inference extracted from the XRD plot, indexing of diffraction rings in SAED images also revealed the existence of a heteroepitaxial relationship between unimplanted L10-FePt and the underlying layer (Fig. 7(c)).

Discussion

The results described above can be explained by considering the displacement or lateral straggle of atoms in the course of ion implantation. During the implantation, the implanted ions interact with the host lattice. As a result, the host atoms may be displaced when the mass of the implanted atom is much higher than that of the host. This damage can be seen from the TRIM (Transport of Ions in Matter) simulations. It can be seen that Sb+ implantation leads to maximum damage in the FePt layer of the media with a number of atoms getting displaced from their positions creating large vacancies (Fig. 8(a)). This simulation also provided calculations on lateral straggle, which was found to be about 2–3 nm (Fig. 8(b)). On the other hand, a lighter ion such as He+ does not cause much displacement as Sb+, but it straggles significantly (4 times larger). These results indicate that the implantation of lighter atoms and heavier atoms could have different implications in the properties of the obtained magnetic nanostructures.

In our recent study, we have reported through first-order reversal curves of magnetization that a heavy ion such as Sb+ can dislodge the atoms from the host lattice, resulting in a lateral diffusion of host atoms27. This effect is not very severe in alloyed films such as hcp-CoPt, where the lateral diffusion of Co and Pt is only changing the composition. Therefore, the pre-implantation composition can be tailored to achieve the desired anisotropy after implantation. However, the lateral displacement of host atoms is a significant cause of concern in L10-FePt-based patterned media of high areal densities. In these media, the initial (pre-implantation) state is an ordered structure (L10) that gives rise to the high-anisotropic properties of FePt. However, post-implantation, it was quite likely that the lateral displacement of Fe and Pt atoms caused not only a change of composition, but also a damage of an ordered L10-FePt phase as seen in XRD and SAED results. Consequently, the high magnetic anisotropy was lost as evidenced from the hysteresis loops and MFM images. Such a diffusion-induced phase change was more evident at densities of 100 Gb/in2 and above, where the lateral movement of the host atoms was comparable to the dot spacing as in this paper.

Implantation through a mask of 30 nm diameter dots at 80 nm pitch ideally should give 89% non-magnetic (unmasked, implanted region) and 11% of magnetic (unimplanted region, below the mask) regions. Hence, the magnetization reduction should be about 89% of the saturation magnetization of the unimplanted FePt sample. Such a result was expected as the implantation had been designed to occur only in selected (unmasked) areas. However, the magnetization reduction by about 75% of the unimplanted FePt sample showed some diffusion or the lateral movement of ions beneath the mask. It may also be argued that the shadowing of implanted areas could be a cause of the observed difference in magnetization reduction. However, our arguments above do not consider straggle of Sb+ ions. In reality, Sb+ ions will also straggle about 3 nm (based on TRIM simulations) and the result is an opposite effect of shadowing, which minimizes the Sb+ implanted region. This diffusion of lateral movement of ions further induced phase change as discussed earlier leading to loss of perpendicular anisotropy as observed before. This effect would not be observed at low densities, where the dot spacing is much larger compared to the displacement of Fe and Pt atoms. FePt-based BPM fabricated by means of ion implantation through 1 μm holes spaced at 2 μm pitch did not show such an effect21.

To illustrate our discussions further, Fig. 8 shows the damage profile and lateral straggle of a light ion (He+) and heavy ion (Sb+) in FePt media based on TRIM simulations. It must be noted that the y scales of the damage profile (Fig. 8(a, c)) and lateral distribution (Fig. 8(b, d)) plots of helium and antimony are different. It can be seen that less vacancies were created with helium implantation (Fig. 8(c)) compared to antimony (Fig. 8(a)). This would lead to less damage in magnetic properties of FePt sample implanted with helium compared to antimony. Comparing the lateral distribution profile of both the ions, it can be seen that helium being a lighter ion showed higher lateral straggle (Fig. 8(d)) compared to that with antimony (Fig. 8(b)). On the other hand, the larger displacement associated with Sb+ will cause more damage to the perpendicular magnetic anisotropy in the unimplanted region.

Although we have not succeeded in the fabrication of FePt-patterned media using ion implantation, these results forecast a major bottleneck in the ion implantation-assisted fabrication of patterned media for 10 Tb/in2. At 10 Tb/in2, the spacing between two magnetic islands is only 4 nm for a bit aspect ratio (BAR) of one28. If light ions are used for implantation, the lateral straggle of the implanted ions is high enough to negate the benefits of ion implantation. To prevent such a lateral straggle, there is a need to use heavy ions26. However, with heavier ions, we observed a disordered FePt (with low magnetic anisotropy) in the masked region. It may be argued that the ordered state could be retrieved by carrying out post-annealing after implantation. It is foreseeable, however, that post-annealing may cause diffusion of atoms and coarsening of FePt grains, resulting in the loss of periodicity of the nanostructures29. Nevertheless, this is an interesting topic for further study. Study of materials such as Cr+, which have a lighter mass but more effective in reducing the magnetization may be attempted in future.

Methods

Magnetic media fabrication and ion implantation

FePt media samples were grown in a dc magnetron sputtering system with the base pressure lower than 5 × 10−8 Torr. The size of all the media samples was 1 cm × 1 cm. The reported thickness of all the layers was nominal, based on the deposition rate as calibrated by atomic force microscopy (AFM). The alloy composition of the deposited FePt film was confirmed by the X-ray photoelectron spectroscopy (XPS) depth profile.

The FePt media samples (both patterned and unpatterned) were implanted homogeneously with Sb+ over the whole media surface by means of ion beam scanning. The ion source for the implantation was SbO3 (solid). Ion implantation was carried out in the recording layer such that the maximum peak of the implantation profile was in the middle of the recording layer. This was done while keeping in mind the application for patterned media. To obtain the required profile, TRIM calculation was made to obtain the energies of implantation, 15 keV for 121 Sb+ ions.

Hard mask fabrication

A Combined thermal and UV Nanoimprint lithography (NIL) system from Obducat was used to fabricate/imprint the patterns over an area of 3 mm × 3 mm. Obducat proprietary STU (Simultaneous Thermal and UV) resist diluted with methiopropamine (MPA) at a ratio of 2:3 was used for the studies. Before NIL, the resist was first spin-coated on the samples at 5000 rpm for 45 seconds and baked at 100°C for 3 minutes, resulting in an organic layer of ~50 nm thickness. Post NIL, ozone plasma was used to etch some residual resist. Further, reactive ion etching-inductively coupled plasma (RIE-ICP) was used to etch through deposited Ta to fabricate hard mask. The etching was carried out in 90 sccm of CF4 at a pressure of 150 mTorr and at a RF and ICP power of 50 and 200 W, respectively.

Characterization of magnetic media

Due to large pattern area (9 mm2), hysteresis loop measurements could be carried out using alternating gradient force magnetometer (AGFM) to observe the effect of ion implantation on coercivity and average magnetization. A vibrating sample magnetometer (VSM) system with maximum field strength of 90 kOe was used to measure the hysteresis loop for the as-deposited FePt sample which had coercivity as high as 15 kOe. X-ray Diffraction (XRD) was used to characterize the deposited films for their orientation. In addition to characterization of crystal orientation using selected area electron diffraction (SAED) patterns, transmission electron microscopy (TEM) was also used to examine any change in microstructure.

References

Hellwig, O. et al. Bit patterned media based on block copolymer directed assembly with narrow magnetic switching field distribution. Appl. Phys. Lett. 96, 052511–052513 (2010).

Sbiaa, R., Aung, K. O., Piramanayagam, S. N., Tan, E.-L. & Law, R. Patterned media with composite structure for writability at high areal recording density. J. Appl. Phys. 105, 073904–073907 (2009).

Coffey, K. R., Parker, M. A. & Howard, J. K. High anisotropy L10 thin films for longitudinal recording. IEEE Trans. Magn. 31, 2737–2739 (1995).

Shibata, K. FePt magnetic recording media: Problems and possibilities for practical use. Mater. Trans. 44, 1542–1545 (2003).

Pandey, K. K. M., Chen, J. S., Lim, B. C. & Chow, G. M. Effects of Ru underlayer on microstructures and magnetic properties of Co72Pt28 thin films. J. Appl. Phys. 104, 073904–073911 (2008).

Velu, E. M. T. & Lambeth, D. N. CoSm-based high-coercivity thin films for longitudinal recording. J. Appl. Phys. 69, 5175–5177 (1991).

Sbiaa, R., Tan, E.-L., Aung, K. O., Wong, S. K., Srinivasan, K. & Piramanayagam, S. N. Material and layer design to overcome writing challenges in bit-patterned media. IEEE Trans. Magn. 45, 828–832 (2009).

Thiele, J. U., Folks, L., Toney, M. F. & Weller, D. K. Perpendicular magnetic anisotropy and magnetic domain structure in sputtered epitaxial FePt (001) L10 films. J. Appl. Phys. 84, 5686–5692 (1998).

Weller, D. et al. High Ku materials approach to 100 Gbits/in2. IEEE Trans. Magn. 36, 10–15 (2000).

Kurth, F. et al. Finite-size effects in highly ordered ultrathin FePt films. Phys. Rev. B 82, 184404–184411 (2010).

Piramanayagam, S. N. et al. Planarization of patterned recording media. IEEE Trans. Magn. 46, 759–763 (2010).

Poh, A. W. C. et al. Novel planarizing scheme for patterned media. J. Vac. Sci. Technol. B 28, 806–809 (2010).

Chappert, C. et al. Planar patterned magnetic media obtained by ion irradiation. Science 280, 1919–1922 (1998).

Sato, K. et al. Magnetization suppression in Co/Pd and CoCrPt by nitrogen ion implantation for bit patterned media fabrication. J. Appl. Phys. 107, 123910–123913 (2010).

Hinoue, T., Ito, K., Hirayama, Y. & Hosoe, Y. Effects of lateral straggling of ions on patterned media fabricated by nitrogen ion implantation. J. Appl. Phys. 111, 07B912–07B914 (2012).

Hinoue, T., Ito, K., Hirayama, Y., Ono, T. & Inaba, H. Magnetic properties and recording performances of patterned media fabricated by nitrogen ion implantation. J. Appl. Phys. 109, 07B907–07B909 (2011).

Gaur, N. et al. Ion implantation induced modification of structural and magnetic properties of perpendicular media. J. Phys. D: Appl. Phys. 44, 365001–1–9 (2011).

Gaur, N. et al. Magnetic and structural properties of CoCrPt–SiO2-based graded media prepared by ion implantation. J. Appl. Phys. 110, 083917–083921 (2011).

Aoyama, T., Sato, I., Ito, H. & Ishi, S. B ion implantation effects on L10 chemical ordering of FePt thin films. J. Mag. Mag. Mater. 287, 209–213 (2005).

Revelsona, D. et al. Chemical ordering at low temperatures in FePd films. J. Appl. Phys. 91, 8082–8084 (2002).

Terris, B. D. et al. Patterning magnetic films by ion beam irradiation. J. Appl. Phys. 87, 7004–7006 (2000).

Barmak, K. et al. Stoichiometry–anisotropy connections in epitaxial L10 FePt (001) films. J. Appl. Phys. 95, 7501–7503 (2004).

Tan, E. L. et al. Nanoimprint mold fabrication and duplication for embedded servo and discrete track recording media. J. Vac. Sci. Technol. B 27, 2259–2263 (2009).

Ferré, J. et al. Irradiation induced effects on magnetic properties of Pt/Co/Pt ultrathin films. J. Mag. Mag. Mater. 198, 191–193(1999).

Rettner, C. T., Anders, S. J., Baglin, E. E., Thomson, T. & Terris, B. D. Characterization of the magnetic modification of Co/Pt multilayer films by He+, Ar+ and Ga+ ion irradiation. Appl. Phys. Lett. 80, 279–281 (2002).

McCord, J., Mönch, I., Fassbender, J., Gerber, A. & Quandt, E. Local setting of magnetic anisotropy in amorphous films by Co ion implantation. J. Phys. D: Appl. Phys. 42, 055006–1–6 (2009).

Gaur, N. et al. First-Order Reversal Curve Investigations on the Effects of Ion Implantation in Magnetic Media. IEEE Trans. Magn. 48, 2753–2756 (2012).

Chong, T. C., Piramanayagam, S. N. & Sbiaa, R. Perspectives for 10 terabits/in2 magnetic recording. J. Nanosci. Nanotechnol. 11, 2704–2709 (2011).

Klemmer, T. J. et al. Combined reactions associated with L10 ordering. J. Mag. Mag. Mater. 266, 79–87 (2003).

Acknowledgements

This work is partially supported by Singapore NRF under CRP Award No. NRF-CRP 4-2008-06. The work has been done under the NUS and IBM joint study agreement #W0853529. The authors thank A. W. C. Poh and M. Ranjbar for their assistance.

Author information

Authors and Affiliations

Contributions

N.G., S.N.P. and C.S.B. designed experiments. N.G., S.K., S.L.M., S.E.S., H.K.T. and S.K.W. performed experiments. N.G., S.N.P., H.Y. and C.S.B. analyzed the data. N.G. and S.N.P. wrote the main manuscript text and prepared figures. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Gaur, N., Kundu, S., Piramanayagam, S. et al. Lateral displacement induced disorder in L10-FePt nanostructures by ion-implantation. Sci Rep 3, 1907 (2013). https://doi.org/10.1038/srep01907

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01907

This article is cited by

-

Role of patterning induced defect on the switching field in magnetic nanostructure

Applied Physics A (2016)

-

Probing the Role of an Atomically Thin SiNx Interlayer on the Structure of Ultrathin Carbon Films

Scientific Reports (2014)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.