Abstract

Cu/Ba/bauxite possesses superior NOx storage and reduction (NSR) performances, high thermal stability, strong resistance against SO2 poisoning and outstanding regeneration ability in comparison with Pt/Ba/Al2O3. It can serve as a cheap and promising alternative for traditional Pt/Ba/Al2O3 in NOx removal from lean-burn engines.

Similar content being viewed by others

Introduction

With the rising concerns for energy crisis and global warming, lean-burn engines are widely used in vehicles to improve fuel economy and reduce greenhouse effect1. However, the conventional three-way catalysts (TWCs) are incapable of effectively removing nitrogen oxides (NOx) in lean-burn engine exhausts2. One of the most feasible and attractive solution to reduce NOx emission is to use NOx storage and reduction (NSR) catalysts, which are usually composed of precious metals, alkali or alkaline earth metals and high surface area supports3. Pt/Ba/Al2O3 has been extensively investigated as a NSR model catalyst4,5,6, but 1–2 wt% platinum loading in Pt/Ba/Al2O3 makes it quite expensive, the scarcity of platinum source in the earth also limits its further development and extensive application. Moreover, Pt/Ba/Al2O3 readily undergoes severe deactivation owing to sulfur poisoning and thermal aging, resulting in loss of catalytic activity and decline of the NOx removal efficiency6,7,8. To meet the more stringent emission limit criteria, it is of great challenge to develop a practical NSR catalyst possessing high sulfur tolerance and low dependence on precious metals without sacrificing NSR capabilities.

Great efforts have been devoted to the improvement of sulfur-resistant ability and the replacement of platinum in the NSR catalysts8. One effective strategy is to add the inexpensive transition metal oxides into Pt/Ba/Al2O39,10,11. The synergetic effect between the additives and catalysts can provide a positive structural and electrical environment for NSR. It was recently reported that the doping of CoOx or CuOx in Pt/Ba/Al2O3 increased NOx storage capacity and reduced the platinum loading10. The addition of FeOx into Pt/Ba/Al2O3 was also discovered to enhance the tolerance against sulfur poisoning11, but a strong deactivation is observed due to the interaction between Fe and Pt. Another strategy is the modification of supports. The blending of TiO2 and Al2O3 was reported to help suppress sulfur deposition and enhance NOx storage capacity of the sulfur-aged catalysts12,13. It was also observed that Ce1−xZrxO2 and Al2O3-Ce1−xZrxO2 nanopowders in the absence of platinum offered the comparable catalytic activity with Pt/Al2O3 for both NOx reduction and propane/propene oxidation14. These studies have showed that introduction of the additional components into NSR catalysts could improve thermal resistance, redox property and interaction between active components and supports. Thus, it can be speculated that the combinational use of inexpensive transition metal oxides and titanium-containing composite supports would be a promising approach for the exploration of low-cost NSR catalysts.

Bauxite is an excellent support candidate in the catalytic reactions, which possesses many advantages, such as much cheap price, ready availability, rich reserve worldwide, good pore volume and air permeability, easy treatment and modification. It is composed of Al2O3, FeOx, TiO2, CaO, SiO2 and trace of platinum (Table S1), the synergetic interactions of the components will contribute to the partial or total replacement of platinum. Moreover, Fe and Ti are beneficial for the resistance against sulfur poisoning, but the investigation of bauxite in NOx removal is still unexplored. Herein, we report a sulfur-resistant and low-cost Cu/Ba/bauxite catalyst (1 wt% Cu and 16 wt% Ba), which shows superior NSR performances over Pt/Ba/Al2O3 (1 wt% Pt and 16 wt% Ba) without the addition of the extra platinum.

Results

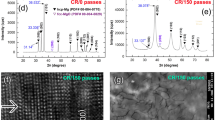

The BET surface area of natural bauxite is 8 m2/g (Table S2) and it is increased to 153 m2/g after the hydrothermal treatment, which provides a possibility to serve as a support of NSR catalysts. After impregnating Cu and Ba, the specific surface of Cu/Ba/bauxite (139 m2/g) is lower than that of Pt/Ba/Al2O3 (254 m2/g), but Cu/Ba/bauxite possesses stronger sulfur resistance than Pt/Ba/Al2O3. A decrease of ca. 10% and 24% in surface area was found when Cu/Ba/bauxite and Pt/Ba/Al2O3 were aged by SO2, respectively. XRD patterns further confirmed superior sulfur tolerance of Cu/Ba/bauxite over Pt/Ba/Al2O3. As shown in Figure S2, the XRD pattern of Pt/Ba/Al2O3–SO2 exhibited the strong reflections typical for BaSO4 at 2θ values of 26.0°, 28.7° and 42.6°, while only tiny characteristic peaks for BaSO4 were observed in Cu/Ba/bauxite-SO212.

NSR performances of Cu/Ba/bauxite were initially evaluated using the NO-to-NO2 oxidation, relative NOx storage capacity and NOx conversion. The NO-to-NO2 oxidation is known to be an important step for NOx storage since the adsorption of NO2 is more facile than that of NO in the Ba-based catalysts8. Interestingly, Cu/Ba/bauxite exhibited higher NO-to-NO2 oxidation ability than Pt/Ba/Al2O3 (Figure 1a). Moreover, along with the increment of temperature, the NO-to-NO2 conversion was enhanced and reached the maximum at 300°C, subsequent decrease was observed in all of samples. The NO-to-NO2 conversion in Cu/Ba/bauxite and Pt/Ba/Al2O3 at 300°C was 70% and 52%, respectively. As anticipated, the NO-to-NO2 conversion in Cu/Ba/bauxite-SO2 and Pt/Ba/Al2O3-SO2 was decreased in comparison with their respective fresh samples, but the NO-to-NO2 conversion in Cu/Ba/bauxite-SO2 was still comparable with that of Pt/Ba/Al2O3. As shown in Figure 1b, both Cu/Ba/bauxite and Pt/Ba/Al2O3 possess excellent NOx storage performance, their relative NOx storage capacities are more than 95% and 90% in the range of test temperatures, respectively. The presence of SO2 results in a slight decrement of NOx storage capacity in Cu/Ba/bauxite-SO2, while a sharp decrement was observed in Pt/Ba/Al2O3-SO2, which was mainly caused by the sulfation of storage component Ba, resulting in less Ba sites available to NOx storage. However, the presence of Fe, Ti and Cu in Cu/Ba/bauxite-SO2 contributes to suppress the formation of BaSO4 to a certain degree9,13. As a result, Cu/Ba/bauxite shows much higher NOx storage capacity than Pt/Ba/Al2O3 in the presence of SO2. The NOx conversion of the fresh and SO2-aged catalysts was shown in Figure 1c. Surprisingly, although no extra platinum was added in Cu/Ba/bauxite, it still exhibites higher NOx conversion than Pt/Ba/Al2O3 at test temperatures. The NOx conversion of Cu/Ba/bauxite reaches 96% at 250°C with a promotion of 20% related to Pt/Ba/Al2O3. After aged by SO2, the NOx conversion in Cu/Ba/bauxite-SO2 and Pt/Ba/Al2O3-SO2 was decreased in comparison with fresh samples.

The thermal stability of Cu/Ba/bauxite and Pt/Ba/Al2O3 was also examined. After Cu/Ba/bauxite and Pt/Ba/Al2O3 were maintained at 350°C for 200 h, an apparent thermal deactivation was observed in Pt/Ba/Al2O3 (Figure 2), the NOx conversion was decreased from 96 to 73%. However, only a 3% decrement was detected for Cu/Ba/bauxite under the same conditions, which is much lower than that in Pt/Ba/Al2O3 and the reported NOx removal catalysts15. Thermal deactivation was also shown by their BET surface area (Table S2), the surface area of Pt/Ba/Al2O3 and Cu/Ba/bauxite was decreased ca. 38% and 11%, respectively. The average pore radius of Pt/Ba/Al2O3 was increased from 2.390 to 5.886 nm, whereas no obvious change was observed in Cu/Ba/bauxite.

To further identify NSR process of Cu/Ba/bauxite, in situ DRIFTS experiments were carried out. As shown in Figure 3a, when Cu/Ba/bauxite was exposed to 500 ppm NO and 8 vol% O2 balanced by Ar at 200°C, a strong band appears around 1249 cm−1, suggesting the formation of a large number of free nitrite ions9. A small band at 964 cm−1 was also observed, which is assigned as the nitrite species. With lengthening of the exposure time, the band at 964 cm−1 was gradually weakened, while the characteristic peaks of nitrate around 1000 and 1365 cm−1 gradually become stronger, indicating the transformation of nitrite to nitrate species. The negative peaks around 1575 and 1426 cm−1 are probably due to the decomposition of carbonate9,16.

In situ DRIFTS spectra at different temperatures show the increment of temperature results in weakening of the strong band at 1245 cm−1, while the nitrate peak at 1310 cm−1 gets stronger and stronger and the peak reaches the maximum at 300°C (Figure 3b), indicating that the increasing temperature favors the activation of oxygen species and subsequent oxidation of nitrites to nitrates. Thus, the NOx storage process in Cu/Ba/bauxite should mainly proceed via nitrite route with small amount of nitrites to nitrates conversion below 300°C9,17. When the temperature was increased above 300°C, the peak at 1245 cm−1 totally disappears, implying the decomposition of nitrite species. Meanwhile, the nitrate peaks at 1310 and 1365 cm−1 were greatly decreased in intensity, indicating decomposition of nitrate species in part at high temperature. When SO2 was introduced into the system, two new peaks at 1172 and 1321 cm−1 were detected (Figure 3c), which may be assigned as the chelating bidentate S–O vibration of bulk barium sulfate and the surface sulfate, respectively. It should be mentioned that the strong peak of nitrite around 1245 cm−1 was not detected, while the peak of nitrate species around 1492 cm−1 still exists18, suggesting that NOx storage probably is mainly via nitrate route in the presence of SO2.

The XPS spectra of S2p for SO2-aged and regenerated samples are shown in Figure 4. For Pt/Ba/Al2O3-SO2, the strong peak around 169 eV indicates the formation of a large amount of sulfate species after exposure to SO2, the peak intensity was decreased after the sample was reduced using 5 vol% H2/Ar for 30 min at 400°C. However, the peak of S2p in Cu/Ba/bauxite-SO2 is much weaker than that of Pt/Ba/Al2O3-SO2, which means that the relative small amount of sulfate species was formed. Interestingly, the peak almost disappeared after Cu/Ba/bauxite-SO2 was reduced using 5 vol% H2/Ar for 30 min at 400°C. These results suggested Cu/Ba/bauxite-SO2 possesses promising sulfur tolerance and regeneration ability.

Discussion

In our work, we have showed Cu/Ba/bauxite is a cheap and readily available NSR catalyst. The catalyst shows superior NSR performances over Pt/Ba/Al2O3 without the addition of extra platinum. It possesses outstanding resistance against sulfur poisoning and thermal stability. The good thermal stability of Cu/Ba/bauxite probably results from the natural source of the bauxite. The superior oxidation performance of Cu/Ba/bauxite was mainly ascribed to the oxidation ability of Fe, Cu and trace amounts of Pt in Cu/Ba/bauxite19, meantime, the presence of trace of Pt may inhibit the negative interaction of Pt and Fe in NSR. On the other hand, the Cu-based catalysts were well known for their better resistance against SO2 deactivation than Pt-based catalysts20, the presence of Fe, Ti and Cu in Cu/Ba/bauxite-SO2 may inhibit the formation of BaSO4 to a certain degree. As a result, the synergetic effect of Cu, Fe, Ti, Ca and trace of Pt results in the promising performances of Cu/Ba/bauxite over Pt/Ba/Al2O3. The most important, the price of Cu/Ba/bauxite is much lower than that of Pt/Ba/Al2O3. The estimated starting material price of Cu/Ba/bauxite is less than 1% of Pt/Ba/Al2O3 owing to the lack of extra Pt addition. The application of Cu/Ba/bauxite will greatly cut down the catalysts cost owing to the replacement of platinum, which provides the incentive for industrial application in NOx removal of learn-burn engines.

Methods

Cu/Ba/bauxite and Pt/Ba/Al2O3 was prepared through conventional impregnation method. Natural bauxite was hydrothermally treated at 130°C for 96 h and followed by calcination at 550°C for 4 h. The Ba (16 wt%) and Cu (1 wt%) were dispersed on post-treated bauxite by the conventional impregnation method using aqueous Ba(NO3)2 and Cu(NO3)2·3H2O solution, respectively. The resulting mixture was dried at 120°C overnight, calcined at 350°C for 2 h. The obtained sample was denoted as Cu/Ba/bauxite. The alumina support was synthesized according to the literature methods. The Ba (16 wt%) and Pt (1 wt%) were loaded on alumina by the conventional impregnation method using aqueous Ba(NO3)2 and H2PtCl6·6H2O solution, respectively. The resulting mixture was dried at 120°C overnight, calcined at 350°C for 2 h. The obtained sample was denoted as Pt/Ba/Al2O3.

X-ray diffraction (XRD) patterns were recorded on a RIGAKU-Miniflex II X-ray diffractometer with Cu Kα radiation (λ = 1.5406 Å). N2 physisorption measurement was performed on an ASAP 2020 apparatus, the sample was degassed in vacuo at 180°C at least 6 h before the measurement. The Brunauer-Emmett-Teller (BET) method was utilized to calculate the specific surface area in a relative pressure range of p/p0 = 0.05−0.25. The pore size distribution was obtained from the adsorption branch using the Barrett Joyner Halenda (BJH) model. The SO2-aged samples were firstly reduced by 10 vol% H2/Ar from room temperature to 500°C and held for 2 h at 500°C, followed by the re-oxidation in 8% O2/Ar flow at 500°C for 1 h. X-ray photoelectron spectroscopy (XPS) analysis was performed on a Physical Electronics Quantum 2000 Scanning ESCA Microprobe equipped with a monochromatic Al-Kα source (Kα = 1,486.6 eV) and a charge neutralizer. The concentrations of bauxite composition were determined using a PANalytical Axios X-ray Fluorescence (XRF) spectrometer with a rhodium tube as the source of radiation. The results were analyzed by IQ+ and the concentrations were normalized to 100%. Inductively Coupled Plasma (ICP) was performed on a JY Ultima2 spectrometer.

The NSR performances of the catalysts were estimated in a quartz flow reactor (8 mm i.d) with a fixed bed. A 0.5 g sample was pretreated under N2 (30 mL/min) at 500°C for 1 h to remove surface-adsorbed species and then cooled to test temperature. The feed gas was introduced using mass-flow controllers at a total flow rate of 600 mL/min. The gas compositions are listed in Table S3. The NO-to-NO2 oxidation, relative NOx storage capacity (lean period) and NOx reduction (rich period) were evaluated after the catalysts were submitted to 10 lean/rich cycles and the catalytic system reached a steadily cyclic state. The data were obtained based on the outlet NOx concentration under lean and rich conditions. The representative examples at 350°C were provided in Figures S3-S5. The NOx concentration was measured using on-line chemiluminescence NO-NO2-NOx analyzer (model 42i-HL, Thermo Scientific). After the measurements, the catalysts were sulfated by exposing to a feed gas containing 100 ppm SO2 (Table S3), the catalysts were sulfated for 45 min each time. The sulfated Cu/Ba/bauxite and Pt/Ba/Al2O3 were denoted as Cu/Ba/bauxite-SO2 and Pt/Ba/Al2O3-SO2, respectively.

In situ DRIFTS was recorded on a Nicolet Nexus FT-IR spectrometer in the range of 650–4000 cm−1 with 32 scans at a resolution of 4 cm−1. In a DRIFTS cell, about 50 mg of powder sample was firstly pretreated with pure helium at test temperature for 30 min and then background spectrum was recorded. A mixture gas (500 ppm NO, 8 vol% O2 and balanced by Ar) was introduced to the sample cell and the spectra were immediately recorded at different exposure time up to 60 min. The DRIFTS experiments of the sulfated samples were conducted after the catalysts were exposed to NO/O2 at test temperature for 60 min, then additional 100 ppm SO2 was introduced to the sample cell and spectra were collected to follow the evolution of different surface species. The regeneration of Cu/Ba/bauxite and Pt/Ba/Al2O3 were performed with 5 vol% H2/Ar, after the samples were exposed to 100 ppm SO2 at 400°C for 60 min and then DRIFTS spectra were recorded at different time. The final differential sample spectra were calculated by the Kubelka-Munk function.

References

Forzatti, P., Lietti, L. & Nova, I. On board catalytic NOx control: mechanistic aspects of the regeneration of Lean NOx Traps with H2 . Energy Environ. Sci. 1, 236–247 (2008).

Larsson, E. M., Langhammer, C., Zoric, I. & Kasemo, B. Nanoplasmonic Probes of Catalytic Reactions. Science 326, 1091–1094 (2009).

Scholz, C. M. L., Gangwal, V. R., Hoebink, J. H. B. J. & Schouten, J. C. NOx storage/reduction over lean-burn automotive catalysts. Appl. Catal. B: Environ. 70, 226–232 (2007).

Frola, F., Manzoli, M., Prinetto, F. & Ghiotti, G. Pt-Ba/Al2O3 NSR Catalysts at Different Ba Loading: Characterization of Morphological, Structural and Surface Properties. J. Phys. Chem. C 112, 12869–12878 (2008).

Maeda, N., Urakawa, A., Sharma, R. & Baiker, A. Influence of Ba precursor on structural and catalytic properties of Pt-Ba/alumina NOx storage-reduction catalyst. Appl. Catal. B: Environ. 103, 154–162 (2011).

Dawody, J., Skoglundh, M., Olsson, L. & Fridell, E. Sulfur deactivation of Pt/SiO2, Pt/BaO/Al2O3 and BaO/Al2O3 NOx storage catalysts: Influence of SO2 exposure conditions. J. Catal. 234, 206–218 (2005).

Epling, W. S., Campbell, L. E., Yezerets, A., Currier, N. W. & Parks II, J. E. Overview of the fundamental reactions and degradation mechanisms of NOx storage/reduction catalysts. Catal. Rev. 46, 163–245 (2004).

Roy, S. & Baiker, A. NOx Storage Reduction Catalysis: From Mechanism and Materials Properties to Storage Reduction Performance. Chem. Rev. 109, 4054–4091 (2009).

Zou, Z. et al. Influence of Co or Ce addition on the NOx storage and sulfur-resistance performance of the lean-burn NOx trap catalyst Pt/K/TiO2-ZrO2 . J. Hazard. Mater. 170, 118–126 (2009).

Yamazaki, K., Suzuki, T., Takahashi, N., Yokota, K. & Sugiura, M. Effect of the addition of transition metals to Pt/Ba/Al2O3 catalyst on the NOx storage-reduction catalysis under oxidizing conditions in the presence of SO2 . Appl. Catal. B: Environ. 30, 459–468 (2001).

Le Phuc, N. et al. NOx removal efficiency and ammonia selectivity during the NOx storage-reduction process over Pt/BaO (Fe, Mn, Ce)/Al2O3 model catalysts. Part II: Influence of Ce and Mn-Ce addition. Appl. Catal. B: Environ. 102, 362–371 (2011).

Tanaka, T., Tajima, I., Kato, Y., Nishihara, Y. & Shinjoh, H. Improvement in sulfur desorption of NOx storage and reduction catalysts using a Ba-Ti composite oxide. Appl. Catal. B: Environ. 102, 620–626 (2011).

Imagawa, H., Tanaka, T., Takahashi, N. & Matsunaga, S. Titanium-doped nanocomposite of Al2O3 and ZrO2-TiO2 as a support with high sulfur durability for NOx storage-reduction catalyst. Appl. Catal. B: Environ. 86, 63–68 (2009).

Weidenhof, B. et al. High-Throughput Screening of Nanoparticle Catalysts Made by Flame Spray Pyrolysis as Hydrocarbon/NO Oxidation Catalysts. J. Am. Chem. Soc. 131, 9207–9219 (2009).

Nishihata, Y. et al. Self-regeneration of a Pd-perovskite catalyst for automotive emissions control. Nature 418, 164–167 (2002).

Xian, H. et al. Effect of the calcination conditions on the NOx storage behavior of the perovskite BaFeO3−x catalysts. Catal. Today. 158, 215–219 (2010).

Liu, Y., Meng, M., Zou, Z. Q., Li, X. G. & Zha, Y. Q. In situ DRIFTS investigation on the NOx storage mechanisms over Pt/K/TiO2-ZrO2 catalyst.Catal. Commun. 10, 173–177 (2008).

Pieta, I. S., García-Diéguez, M., Herrera, C., Larrubia, M. A. & Alemany, L. J. In situ DRIFT-TRM study of simultaneous NOx and soot removal over Pt-Ba and Pt-K NSR catalysts. J. Catal. 270, 256–267 (2010).

Mou, X. et al. Rod-Shaped Fe2O3 as an Efficient Catalyst for the Selective Reduction of Nitrogen Oxide by Ammonia. Angew. Chem. Int. Ed. 51, 2989–2993 (2012).

Centi, G. et al. NOx storage-reduction catalysts based on hydrotalcite Effect of Cu in promoting resistance to deactivation. Catal. Today. 73, 287–296 (2002).

Acknowledgements

This work was financially supported by 973 Program (2011CBA00502, 2010CB933501), Major Project of Fujian Province (2012H0049) and “One Hundred Talent Project” of Chinese Academy of Sciences.

Author information

Authors and Affiliations

Contributions

X.W. and Z.C. prepared the sample; X.W., Z.C., L.J. and R.W. designed the experiments and wrote the paper. X.W., Z.C. and Y.L. performed the measurements and analyzed the data. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

SR-Supporting information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Wang, X., Chen, Z., Luo, Y. et al. Cu/Ba/bauxite: an Inexpensive and Efficient Alternative for Pt/Ba/Al2O3 in NOx Removal. Sci Rep 3, 1559 (2013). https://doi.org/10.1038/srep01559

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01559

This article is cited by

-

Nitrogen Chemistry and Coke Transformation of FCC Coked Catalyst during the Regeneration Process

Scientific Reports (2016)

-

Bauxite-supported Transition Metal Oxides: Promising Low-temperature and SO2-tolerant Catalysts for Selective Catalytic Reduction of NOx

Scientific Reports (2015)

-

Effect of Support on the Activity of Ag-based Catalysts for Formaldehyde Oxidation

Scientific Reports (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.