Abstract

Solar thermal energy-assisted direct air capture (DAC) is widely considered as a novel carbon-negative technical route, innovatively enabling an effective removal of CO2 directly from ambient air. Here, we introduce an advanced concept that involves the conversion of CO2 captured by the solar thermal energy-assisted DAC into liquid methanol, simultaneously mitigating climate change and supplying green chemicals. This concept revolves around a well-considered integration of existing systems, and we emphasize key technologies for capturing, separating, and utilizing CO2 in this integrated system. Advances in Metal-Organic Frameworks (MOFs) based-DAC are reviewed, while the utilization of solar thermal energy further ensures the carbon-negative nature of DAC. Upcycling CO2 captured by DAC into value-added methanol adds both environmental benefits and economic feasibilities, which is also beneficial to achievinga circular carbon economy. The current status, ongoing developments, and anticipated future trends in this technology integration are timely addressed, the considerable application potential of integrated system is also comprehensively discussed.

Similar content being viewed by others

Introduction

In recent years, there has been significant attention towards the technology advances of direct air capture (DAC), which is developed for managing atmospheric CO2 levels and limiting global warming to 1.5 °C target1,2,3. Among all DAC technologies, solid sorbent-based DAC has undergone rapid development4. The main principle of the solid sorbent-based DAC approach involves selective CO2 adsorption from the air using solid capture media, followed by sorbent regeneration driven by a low-temperature (80–120 °C) heat source4,5. Therefore, the primary focus of research in this domain revolves around the enhancement of high-performance sorbents and the supply of low-temperature thermal energy.

Metal-organic frameworks (MOFs), an emerging class of gas sorbents, are regarded as one of the most promising materials in the field of DAC2,6. A key distinguishing feature of MOFs is their ability to be directionally designed and optimized in terms of framework structures, driving extensive research for achieving high-performance CO2 capture. MOFs boast the advantages of requiring low energy consumption for running CO2 adsorption-desorption cycles, simultaneously applicable for low-temperature heat source range operation. Moreover, integrating solar thermal energy with DAC is considered as one emerging solution to further reduce the total cost, due to the sustainable and environmentally friendly nature of solar thermal energy. The large-scale deployment of solar thermal collectors and existing cases of solar thermal energy-assisted DAC demonstrate high-feasibility commercial applications of this integrated technology7.

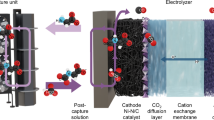

As depicted in Fig. 1, solar thermal energy-assisted DAC is proposed to be integrated with direct CO2 hydrogenation, aiming to establish a closed carbon cycle and mitigate or even eliminate the impact of anthropogenic’ CO2 emissions on the atmospheric environment. Among various syntheses of carbon-containing fuels (i.e., methanol, dimethyl ether, and methane), methanol production has the lowest costs and highest chemical conversion efficiency8. Moreover, Nobel laureate George Olah and his colleagues have championed methanol as a viable alternative basic chemical and fuel source, while also advocating for the establishment of a ‘methanol economy’9. Therefore, in this work, methanol is selected as an important carbon-based fuel to be one promising alternative to traditional fossil fuels. The captured CO2 is used as a carbon precursor for direct CO2 hydrogenation, where CO2 and H2 are catalytically transformed into methanol10. Hydrogen production and catalytic CO2 hydrogenation are both energy-consuming processes, including water electrolysis and essential steps (i.e., compression). These energy demands could be fully supplied from the well-established solar photovoltaic systems11. This sustainable and environmentally friendly methanol is widely investigated as a critical alternative to conventional fossil fuels. However, the integration of solar thermal energy-assisted DAC technology for transforming CO2 into green methanol is still rarely reported.

The benefits of utilizing the technical characteristics of specific technologies in integrated systems also need to be investigated. Thus, we explore the potential of technological integration by critically reviewing research advances and existing challenges and addressing future perspectives for each subsystem considered in this integrated system. Sustainable valorization of CO2 captured by solar thermal energy-assisted DAC into green methanol aims to mitigate climate change and solidify energy security, simultaneously, which is also beneficial to achieving some of UN Sustainable Development Goals (i.e., Goals 7 and 13) and a circular carbon economy.

Evaluating integrated technologies’ environmental impact across their entire life-cycle supplements the constraints posed by current production costs of green methanol. In a development context fueled by the demand for environmentally friendly technology, this integration may become a viable choice. The discussion regarding the development for specific technologies within the subsystems delves into the corresponding challenges and opportunities inherent to their specific technical characteristics. This approach makes technology integration a feasible possibility.

Reducing additional carbon emissions in DAC process

The substantial energy consumption occurred in the DAC process results in additional carbon emissions, and raises concerns regarding the technology’s carbon-negative attributes. Integrating renewable energy sources as a driving force strongly ensures the ultimate carbon-negative characteristics of the final CO2 product12. The application of concentrated solar technologies for thermal energy supply has been widely investigated since the 1970s13. The concept of solar thermal energy-assisted carbon capture has been proposed and extensively discussed in the last decade, wherein the heat supplied by solar energy is utilized for sorbent regeneration and has been proven to reduce the efficiency penalty14. This concept was initially introduced in 2010, focusing on the development of an amine-based solar thermal energy-assisted carbon capture system that utilized solar energy for solvent regeneration7. Subsequently, two types of solar thermal energy-assisted systems have been further introduced, classified as indirect and direct solar thermal energy-assisted, based on the integration approaches of solar thermal energy15. In this work, primary consideration is placed on the direct solar thermal energy-assisted approach, wherein solar thermal energy is directly employed to drive carbon capture systems.

The reliable and stable operation of the carbon capture system, which relies on solar thermal energy as its heat source, is of paramount importance. This has been demonstrated through a comparison with a conventional system integrated with steam bleed (steam is used for thermal regeneration of sorbents to achieve CO2 enrichment)14. Typically, the regeneration heat required for the carbon capture system is obtained from steam bleed in the integration system. However, when addressing emissions from coal-fired power plants, the need for steam bleed results in a high efficiency penalty (~ 10% or even higher)16. The integration of solar energy into the carbon capture system reduces the net electric efficiency penalty to 6.93%, with only minimal modifications to the steam cycle14. Furthermore, the feasibility of this integration system is significantly influenced by the types of solar thermal collectors used. Two types of solar collectors, namely vacuum tube and parabolic trough collectors, have been subjected to comparative analysis within a solar thermal energy-assisted carbon capture system17. Carbon capture system assisted by vacuum tube collectors achieves lower levelized costs of electricity and lower costs for CO2 removal compared to systems assisted by parabolic trough collectors.

Solar thermal energy utilization

The impact of solar heat flux and available active control strategies should be important considerations within the integration system. A solar thermal energy-assisted 5-step temperature-vacuum swing adsorption (TVSA) carbon capture system has been investigated for the treatment of emissions from cement plants18. The annual-scale analysis of the integration system was conducted using a dynamic simulation model. Weather data, including ambient temperature and mean irradiance in Tianjin City, China, were utilized as input features. The energy collected from the solar radiation by thermal collectors was used to meet the energy requirements for the integration system. The concept of the ‘solar stripper’ was proposed to combine solar thermal utilization with the regeneration process of the desorption unit19. Given that the conventional desorption unit in the carbon capture system was replaced by the innovative solar stripper, an effective process control strategy is essential to operate this system, ensuring that the solvent is synchronized with the dynamic solar heat flux. The characteristics of dynamic heat sources need to be well-considered when assessing the performance of the integration system, moreover, the characteristics of solar thermal energy are regarded as even more critical factors for designing this kind of system.

Integrated into direct air capture technology

To delve deeper, air contains a relatively low concentration of CO2, necessitating the use of specialized strong alkaline solution sorbents (i.e., NaOH, KOH) or porous materials (i.e., zeolites or MOFs) to enrich and separate CO2 effectively. A TVSA system for DAC has been studied for integration with solar energy and air conditioning systems20. This research also considered representative weather conditions, incorporating essential data (i.e., monthly direct normal irradiation, average sunshine hours, and average ambient temperature in Guangzhou, China), to calculate the thermal energy supplied by the solar thermal collectors. The proposed best system configuration demonstrates significant potential for integration between solar thermal energy supply systems and DAC systems, showcasing the feasibility of this approach. In addition, a preliminary techno-economic assessment (TEA) of the integrated system has been conducted in this work, resembling the methodology used for assessing solar thermal energy-assisted industrial post-combustion carbon capture system13. However, it is crucial to acknowledge the uniqueness of DAC technology, which requires specialized considerations in integration efforts.

In conclusion, this integrated system, an efficient combination of solar thermal utilization and carbon capture technology, holds the potential for energy savings, owing to that renewable energy is serving as the primary energy input for reducing additional carbon emissions from DAC. In specific research endeavors, the dynamic characteristics of solar thermal energy and key components of the integrated system (i.e., solar collectors and heat exchangers) are the central areas of investigation. Concerning carbon capture technology, current research predominantly centers on post-combustion carbon capture technology. However, when it comes to DAC technology, there remain unresolved issues, with a key focus for future research likely to revolve around enhancing system performance and conducting comprehensive assessments.

Matching solar thermal range with novel materials

Applying adsorption technology to separate CO2 from air is one promising and practical choice for the most advanced DAC projects.21. The abundant pores and special surface structures of solid porous materials enable them to directly interact with CO2 in the air for achieving high-performance CO2 capture. Among them, MOFs have gained widespread attentions in recent years and have shown significant feasibility in DAC technologies. Such novel materials have well-developed porous structures with large specific surface areas through the selection of metal ions and organic ligands, which is beneficial to achieving high-performance CO2 adsorption separation22. The excellent performance of these advanced materials makes them have tremendous potential in DAC technologies. Although MOFs still have a relatively high cost, it is expected that their costs decrease to a socially acceptable value in the future with further development and large-scale deployment.

Sample-scale performance characterizations

Sample development is mainly focusing on MOFs, and sample-scale characterizations determines the CO2 adsorption capacity of novel samples under the application scenario of DAC conditions. General characterizations are carried out under atmospheric temperature and CO2 partial pressure conditions, while the regeneration conditions primarily focus on the thermal regeneration temperature. Specifically, it is feasible to capture CO2 from the air using chemisorption, but the chemical reaction must be reversible in order to regenerate adsorbents. Owing to that the CO2 adsorption uptake of the adsorbent is temperature-sensitive, increasing the operating temperature directly leads to CO2 desorption from adsorbents, ultimately achieving the regeneration of the adsorbents.

Typical investigations on novel MOFs based DAC are summarized in Table 11,23,24,25,26,27. MOFs are suitable for directly adsorbing and separating CO2 from air levels at atmospheric temperature even though CO2 concentration is only around 400 ppm. Sample-scale performance characterizations could not entirely correspond to the practical performance of the samples in commercial-scale applications, however, current research still focuses on the cross-comparison of performance indicators such as equilibrium adsorption uptake (listed in Table 1), to predict their performance in a practical cycle. It must be emphasized that in future developments, more experimental data from large-scale experiments need to be considered to accurately assess practical performance.

Thermal regeneration is applicable to these MOFs, and a regeneration temperature (≤110 °C) well matches the working ranges of solar thermal energy-assisted processes. As depicted in Fig. 2, the temperature range of solar thermal energy sources well matches the temperature range of MOFs thermal regeneration22,28,29,30,31,32,33,34,35,36,37.

Reactor-scale practical applications

In addition to the sample development investigations, additional work is required to ensure the use of materials in practical air contactors, bridging the gaps between the sample-scale to reactor-scale research. The sample-scale research generally includes the preparation and characterization of the samples, while reactor-scale work involves the application of samples in an actual reactor and also performance testing. A spherical core-shell pellet (cs-pellet) has been designed with one MOF in the core surrounded by another MOF in the shell38. As aforementioned, commonly used MOFs often exhibit competitive adsorption between H2O and CO2, and they may even degrade under humid conditions, so in the cs-pellet design, the MOF in the shell can protect the core MOF from H2O, making it more suitable for the DAC setting. Similar core-shell structures have been experimentally measured and studied through both theoretical and multiscale simulations39. Starting with two basic MOF structures, MOFs-UiO-66 and UiO-67, they were augmented to create 30 possible variations with different functional groups. Among a total of 1,740 core-shell structures designed, 10 cs-pellets were selected and confirmed to exhibit better DAC performance compared to individual MOFs. A rational shaping of MOFs in a scalable architecture of fiber sorbent has been reported with the application potential in DAC condition40, the module packaged with the scalable MOFs can be easily utilized in the operating procedure, proving that developing MOFs as monoliths is also an option for the reactor-scale applications.

In addition to both sample- and reactor-scale investigations, more practical scenarios need to be considered in the system-scale investigation, where indicators such as energy consumption and total investment can be studied. A 5-step TVSA process has been proposed for DAC use, in which two MOFs, MIL-101(Cr)-PEI-800 and mmen-Mg2(dobpdc), were studied as the CO2 adsorbent41. The modeling study and economic assessment of this DAC were performed, and necessary performance indicators including minimum energy requirements and cost have been estimated in the practical application scenario. However, the results of the TEA are still insufficient to demonstrate the comprehensive performance evaluation of MOFs-based DAC process. Introducing a life-cycle assessment (LCA) and obtaining environmental impacts for the system-scale perspective achieve a more comprehensive evaluation. Currently, LCA on the practical applications of MOFs in DAC is primarily limited to the sample-scale studies, with a greater focus on the environmental impacts during sample preparation processes42,43, the work from the system-scale perspective is still urgently required.

In summary, the application of MOFs-based DAC is being explored from various perspectives. These materials exhibit excellent CO2 adsorption capabilities, and the regeneration temperature range of which can be well-matched with the temperature range of solar thermal heat sources, making them a promising technology for use in solar thermal energy-assisted DAC systems. The competitive adsorption characteristics of these materials for CO2 and H2O have also received widespread attention, which is a challenge that must be addressed in DAC applications. Moreover, further research still needs to be investigated from the reactor- and system-scale perspectives.

Producing value-added products for a closed carbon cycle

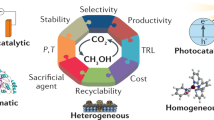

The production of renewable methanol, also known as electro-methanol, through the hydrogenation of CO2 has emerged as a promising approach for CO2 utilization. This approach not only addresses CO2 reduction but also reduces our reliance on conventional fossil fuels. Methanol stands out as an eco-friendly fuel, as it produces no harmful by-products when burned, making it a sustainable and practical option for transportation. However, at the current stage, 90% of methanol production still relies on natural gas, which is one typical non-renewable source due to that combustion of natural gas results in positive greenhouse gas emissions44. In the CO2 hydrogenation into electro-methanol, catalysts are employed to facilitate the reaction between captured CO2 and H2 (commonly derived from water electrolysis, i.e., green hydrogen, when powered by renewable energy). This catalytic transformation serves as the supporting technology for the CO2 product in the solar thermal energy-assisted DAC system, enabling the effective utilization of captured CO2.

Typical research of electro-methanol production can be found in Table 245,46,47,48,49,50,51,52,53, in which the most used catalysts in electro-methanol production processes can also be found. Current industrial production processes still mainly rely on traditional Cu/Zn/Al and CuO/ZnO/Al2O3 catalysts. The specific implementation of the process relies on the use of these efficient catalysts, which is currently a major focus of research. When considering electro-methanol as a potential low-impact energy carrier in terms of its climate impact, both the source of electricity and the origin of CO2 need to be essentially considered. While the utilization of renewable electricity (i.e., solar photovoltaic power) has been extensively investigated, the sourcing of all the necessary CO2 for electro-methanol synthesis has also been thoroughly examined using DAC technology in detailed case studies54. In this context, it has been demonstrated that the negative carbon footprint associated with fuel production can be effectively mitigated. It suggests that the integration of renewable energy sources into DAC technology, much like the solar thermal energy-assisted approach explored in this study, further enhances its overall negative carbon characteristics.

In addition, substantial attention has been given to the TEA of DAC-based CO2 methanolization53,55. The primary emphasis has been on the cost associated with the production of electro-methanol, as this factor ultimately dictates its potential to substitute traditional natural gas-based methanol. Discussions regarding integration strategies have revealed that economically viable methanol production can be achieved by incorporating a central low-temperature DAC unit that supplies waste heat to the downstream processes55. Nevertheless, a sensitivity analysis concerning the cost of CO2 and its influence on the cost of electro-methanol production has been carried out. The comparison results have demonstrated that DAC cannot economically compete with the MEA washing CO2 capture method, although the net production costs of electro-methanol obtained is still more than 2.5 times the current fossil-based methanol in the market53. However, these challenges can be solved by using solar thermal energy-assisted DAC technologies. The use of DAC technology is not contingent upon emission point sources, providing greater flexibility in deployment and significant potential for large-scale applications. The utilization of renewable energy will also further reduce costs. Therefore, solar thermal energy-assisted DAC technology offers distinct advantages in addressing these economic challenges. Nevertheless, in practical applications, supplementary policies such as carbon taxes still play a significant role in providing economic support during the initial stages of technology adoption56.

The conclusions drawn from these TEA primarily focus on unit methanol production. The potential for utilizing electro-methanol and the feasibility of replacing natural gas-based methanol is discussed solely in terms of methanol prices, with little consideration for their environmental impact. From a life-cycle perspective, although the production cost of electro-methanol may be higher, the environmental benefits stemming from the use of CO2 as a feedstock during the manufacturing process, which can offset greenhouse gas emissions during utilization, must be considered. Preliminary tests of advanced technologies are commonly conducted at bench-scale investigation, and while commercial-scale assessments are carried out from the life-cycle perspective, more actual experimental data from commercial-scale operations are still required.

The environmental friendliness of electro-methanol has been validated by performing comprehensive LCA57,58, at this point, the research focus has transitioned to evaluating the global warming potential (GWP) linked to the production of each unit mass of methanol. The contribution of renewable energy inputs to the reduction of GWP is reflected in two aspects. The use of renewable energy in the production of methanol has been a topic of interest. By replacing grid mix input with wind power in the hydrogen production process, the GWP can be reduced from 8.53 t CO2/t methanol to 13.10 t CO2/t methanol. Furthermore, substituting wind power for grid mix input in the methanol production process can further reduce the electrical consumption to 0.86 t CO2/t methanol59. The electricity usage considered in large-scale production still differs significantly from the sample-scale experimental data provided in Table 2. Typically, scale-up modeling and simulation need to be considered. Moreover, it is the contribution of introducing renewable energy into the production of CO2 feedstock, as proposed in this work. Without considering emissions from feedstock, the emission value for producing electro-methanol is only approximately 0.0068 t CO2/t methanol58. At this point, when using CO2 obtained from solar thermal-assisted DAC as a feedstock (the GWP of producing CO2 in DAC processes using renewable energy is approximately −0.75 t CO2/t CO2 captured21), it is evidently possible to further reduce the GWP of electro-methanol production. The results will be significantly lower than the GWP of current fossil-based methanol (around 0.60 t CO2/t methanol60). As a result, while the high production cost remains a hurdle for green methanol generation, it’s worth noting that each ton of electro-methanol can lead to a substantial reduction in CO2 emissions. If the carbon tax were to reach $200 per ton of CO2, this could potentially establish the economic feasibility of electro-methanol production. At the same time, the production of carbon-neutral or carbon-negative fuels is significant in meeting the greenhouse gas reduction demands outlined by organizations such as the International Maritime Organization (IMO) and the International Energy Agency (IEA)61. The applications in these scenarios also rely on an accurate assessment of the GWP of green methanol production from the full life-cycle perspective.

Consequently, from the standpoint of environmental sustainability, incorporating the CO2 captured by solar thermal energy-assisted DAC technology as a feedstock for electro-methanol production results in a further reduction in the GWP of the entire process. For further LCA, the system boundaries should be determined as shown in Fig. 3, this also suggests that, even though complete technical integration has not yet been realized, drawing from the existing research findings, we preliminarily gauge the environmental friendliness of the integrated system outlined in this study. More details and results regarding the LCA of electro-methanol production can be considered to enhance the accuracy of research conclusions44,54. Additionally, future trends brought about by technological advancements and developments should also be considered in subsequent research.

The necessary carbon emissions in adsorbent preparation must be considered together with solar thermal energy providing the energy consumption for the DAC unit, i.e., to drive the regeneration of adsorbents. Throughout the entire process, the CO2 captured is used as the raw material for methanol production. The H2 used for methanol production is derived from water electrolysis, and the electricity required is sourced entirely from photovoltaic power generation. When considering the entire system within this system boundary, total environmental impacts of the integrated system transforming CO2 into methanol can be analyzed.

Conclusions

In this work, the carbon-negative attributes of solar thermal energy-assisted DAC technologies, followed by the utilization of captured CO2 as a raw material for producing green electro-methanol, are concurrently addressed, resulting in a reduction in process carbon footprint and the replacement of traditional fossil fuels. The integrated system proposed in this work, drawing upon existing research, is anticipated to possess environmentally friendly characteristics. A more comprehensive analysis of the advantages of the integrated system is facilitated from a life-cycle perspective.

Solar thermal utilization provides a sustainable heat source for running DAC, significantly enhancing the system’s carbon-negative effect. The application of novel MOFs-based DAC technology further improves system cyclic performance, reduces unit capture energy consumption. Building upon existing electro-methanol production processes, providing raw CO2 materials through solar thermal energy-assisted DAC technology further reduces the GWP per unit of methanol production, making it more advantageous and sustainable compared to traditional fossil fuels.

References

Ji, Y., Yong, J., Liu, W., Zhang, X. & Jiang, L. Thermodynamic analysis on direct air capture for building air condition system: balance between adsorbent and refrigerant. Energy Built Environ. 4, 399–407 (2023).

Zhang X. et al. Direct air capture of CO2 in designed metal-organic frameworks at lab and pilot scale. Carbon Capture Sci. Technol. 9, 100145 (2023).

Li S. et al. Critical review on mobile direct air capture: Concept expansion, characteristic description, and performance evaluation. Matter. 7, 889–933 (2024).

Erans, M. et al. Direct air capture: process technology, techno-economic and socio-political challenges. Energy Environ. Sci. 15, 1360–1405 (2022).

Sanz-Perez, E. S., Murdock, C. R., Didas, S. A. & Jones, C. W. Direct capture of CO2 from Ambient air. Chem. Rev. 116, 11840–11876 (2016).

Caskey, S. R., Wong-Foy, A. G. & Matzger, A. J. Dramatic tuning of carbon dioxide uptake via metal substitution in a coordination polymer with cylindrical pores. J. Am. Chem. Soc. 130, 10870–10871 (2008).

Madhu, K., Pauliuk, S., Dhathri, S. & Creutzig, F. Understanding environmental trade-offs and resource demand of direct air capture technologies through comparative life-cycle assessment. Nat. Energy 6, 1035–1044 (2021).

Ishaq, H. & Crawford, C. CO2‑based alternative fuel production to support development of CO2 capture, utilization and storage. Fuel 331, 125684 (2023).

Olah, G. A. Beyond oil and gas: the methanol economy. Angewandte Chem. Int. Edn. 44, 2636–2639 (2005).

Bongartz, D. et al. Comparison of light-duty transportation fuels produced from renewable hydrogen and green carbon dioxide. Appl. Energy 231, 757–767 (2018).

Maimaiti, S., Gu, Y., Chen, Q. & Tang, Z. Prospective life cycle environmental impact assessment of renewable energy-based methanol production system: a case study in China. J. Clean. Prod. 425, 139002 (2023).

Okonkwo, E. C., AlNouss, A., Shahbaz, M. & Al-Ansari, T. Developing integrated direct air capture and bioenergy with carbon capture and storage systems: progress towards 2 ° C and 1.5 °C climate goals. Energy Conversion Manag. 296, 117687 (2023).

Shirmohammadi, R., Aslani, A., Ghasempour, R., Romeo, L. M. & Petrakopoulou, F. Techno-economic assessment and optimization of a solar-assisted industrial post-combustion CO2 capture and utilization plant. Energy Rep. 7, 7390–7404 (2021).

Wu, Y., Dai, Y., Xie, W., Chen, H. & Zhu, Y. Performance analysis for post-combustion CO2 capture in coal-fired power plants by integration with solar energy. Energy 261, 125239 (2022).

Saghafifar, M. & Gabra, S. A critical overview of solar assisted carbon capture systems: is solar always the solution? Int. J. Greenhouse Gas Control 92, 102852 (2020).

Goto, K., Yogo, K. & Higashii, T. A review of efficiency penalty in a coal-fired power plant with post-combustion CO2 capture. Appl. Energy 111, 710–720 (2013).

Wang, J., Liu, L., Zeng, X. & Li, K. Solar-assisted CO2 capture with amine and ammonia-based chemical absorption: a comparative study. Thermal Sci. 25, 717–732 (2021).

Chen, B. et al. Performance analysis of solar-assisted CO2 adsorption capture system based on dynamic simulation. Solar Energy 209, 628–645 (2020).

Milani, D., Luu, M. T., Nelson, S. & Abbas, A. Process control strategies for solar-powered carbon capture under transient solar conditions. Energy 239, 122382 (2022).

Ji, Y., Liu, W., Yong, J., Zhang, X. & Jiang, L. Solar-assisted temperature vacuum swing adsorption for direct air capture: Effect of relative humidity. Appl. Energy 348, 121493 (2023).

Deutz, S. & Bardow, A. Life-cycle assessment of an industrial direct air capture process based on temperature–vacuum swing adsorption. Nat. Energy 6, 203–213 (2021).

Madden, D. G. et al. Flue-gas and direct-air capture of CO2 by porous metal–organic materials. Philos. Transact. R. Soc. A: Mathe. Phys. Eng. Sci. 375, 20160025 (2017).

Liu, W. et al. Thermodynamic study on two adsorption working cycles for direct air capture. Appl. Thermal Eng. 214, 118920 (2022).

Sadiq, M. M. et al. A pilot‐scale demonstration of mobile direct air capture using metal‐organic frameworks. Adv. Sustain. Syst. 4, 2000101 (2020).

Kulkarni, V. & Singh, S. K. Direct CO2 capture from simulated and ambient air over silica-rich MIL-101 (Cr). Reaction Chem. Eng. 8, 3185–3195 (2023).

Bose, S. et al. Suitability of a diamine functionalized metal–organic framework for direct air capture. Chem. Sci. 14, 9380–9388 (2023).

Darunte, L. A., Oetomo, A. D., Walton, K. S., Sholl, D. S. & Jones, C. W. Direct air capture of CO2 using amine functionalized MIL-101 (Cr). ACS Sustain. Chem. Eng. 4, 5761–5768 (2016).

Qiu, L. et al. Harnessing the hybridization of a metal‐organic framework and superbase‐derived ionic liquid for high‐performance direct air capture of CO2. Small 19, 2302708 (2023).

Kumar, A. et al. Direct air capture of CO2 by physisorbent materials. Angewandte Chemie Int. Edition 54, 14372–14377 (2015).

Shekhah, O. et al. Made-to-order metal-organic frameworks for trace carbon dioxide removal and air capture. Nat. Commun. 5, 4228 (2014).

Bhatt, P. M. et al. A fine-tuned fluorinated MOF addresses the needs for trace CO2 removal and air capture using physisorption. J. Am. Chem. Soc. 138, 9301–9307 (2016).

Bien, C. E. et al. Bioinspired metal–organic framework for trace CO2 capture. J. Am. Chem. Soc. 140, 12662–12666 (2018).

Cai, Z., Bien, C. E., Liu, Q. & Wade, C. R. Insights into CO2 adsorption in M–OH functionalized MOFs. Chem. Mater. 32, 4257–4264 (2020).

Choi, S., Watanabe, T., Bae, T.-H., Sholl, D. S. & Jones, C. W. Modification of the Mg/DOBDC MOF with amines to enhance CO2 adsorption from ultradilute gases. J. Phys. Chem. Lett. 3, 1136–1141 (2012).

Lee, W. R. et al. Diamine-functionalized metal–organic framework: exceptionally high CO2 capacities from ambient air and flue gas, ultrafast CO2 uptake rate, and adsorption mechanism. Energy Environ. Sci. 7, 744–751 (2014).

McDonald, T. M. et al. Capture of carbon dioxide from air and flue gas in the alkylamine-appended metal–organic framework mmen-Mg2 (dobpdc). J. Am. Chem. Soc. 134, 7056–7065 (2012).

Guo, M. et al. A highly efficient and stable composite of polyacrylate and metal–organic framework prepared by interface engineering for direct air capture. ACS Appl. Mater. Interfaces 13, 21775–21785 (2021).

Lieber, A. R. et al. Parametric simulations of hierarchical core–shell MOF materials for direct air capture. Sep. Purifi. Technol. 322, 124180 (2023).

Boone, P. et al. Designing optimal core–shell MOFs for direct air capture. Nanoscale 14, 16085–16096 (2022).

Lee, Y. H. et al. Controlled synthesis of metal–organic frameworks in scalable open-porous contactor for maximizing carbon capture efficiency. JACS Au 1, 1198–1207 (2021).

Sinha, A., Darunte, L. A., Jones, C. W., Realff, M. J. & Kawajiri, Y. Systems design and economic analysis of direct air capture of CO2 through temperature vacuum swing adsorption using MIL-101 (Cr)-PEI-800 and mmen-Mg2 (dobpdc) MOF adsorbents. Ind. Eng. Chem. Res. 56, 750–764 (2017).

Escobar-Hernandez, H. U., Quan, Y., Papadaki, M. I. & Wang, Q. Life cycle assessment of metal–organic frameworks: sustainability study of zeolitic imidazolate framework-67. ACS Sustain. Chem. Eng. 11, 4219–4225 (2023).

Ntouros, V., Kousis, I., Papadaki, D., Pisello, A. L. & Assimakopoulos, M. N. Life cycle assessment on different synthetic routes of ZIF-8 nanomaterials. Energies 14, 4998 (2021).

Abbas, A. et al. Process development and policy implications for large scale deployment of solar-driven electrolysis-based renewable methanol production. Green Chem. 24, 7630–7643 (2022).

Vaquerizo, L. & Kiss, A. A. Thermally self-sufficient process for cleaner production of e-methanol by CO2 hydrogenation. J. Clean. Prod. 433, 139845 (2023).

Kiss, A. A., Pragt, J., Vos, H., Bargeman, G. & De Groot, M. Novel efficient process for methanol synthesis by CO2 hydrogenation. Chem. Eng. J. 284, 260–269 (2016).

GhasemiKafrudi, E., Samiee, L., Mansourpour, Z. & Rostami, T. Optimization of methanol production process from carbon dioxide hydrogenation in order to reduce recycle flow and energy consumption. J. Clean. Prod. 376, 134184 (2022).

Meunier, N., Chauvy, R., Mouhoubi, S., Thomas, D. & De Weireld, G. Alternative production of methanol from industrial CO2. Renew. Energy 146, 1192–1203 (2020).

Pérez-Fortes, M., Schöneberger, J. C., Boulamanti, A. & Tzimas, E. Methanol synthesis using captured CO2 as raw material: techno-economic and environmental assessment. Appl. Energy 161, 718–732 (2016).

Wang, D. et al. A near-zero carbon emission methanol production through CO2 hydrogenation integrated with renewable hydrogen: Process analysis, modification and evaluation. J. Clean. Prod. 412, 137388 (2023).

Sollai, S., Porcu, A., Tola, V., Ferrara, F. & Pettinau, A. Renewable methanol production from green hydrogen and captured CO2: a techno-economic assessment. J. CO2 Utiliz. 68, 102345 (2023).

Prachumsai, W. et al. Carbon dioxide reduction to synthetic fuel on zirconia supported copper-based catalysts and gibbs free energy minimization: methanol and dimethyl ether synthesis. J. Environ. Chem. Eng. 9, 104979 (2021).

Rahmat, Y. et al. Techno-economic and exergy analysis of e-methanol production under fixed operating conditions in Germany. Appl. Energy 351, 121738 (2023).

Kanchiralla, F. M., Brynolf, S., Malmgren, E., Hansson, J. & Grahn, M. Life-cycle assessment and costing of fuels and propulsion systems in future fossil-free shipping. Environ. Sci. Technol. 56, 12517–12531 (2022).

Prats-Salvado, E., Monnerie, N. & Sattler, C. Techno-economic assessment of the integration of direct air capture and the production of solar fuels. Energies 15, 5017 (2022).

Li, J. et al. Comparative well-to-pump assessment of fueling pathways for zero-carbon transportation in China: Hydrogen economy or methanol economy? Renew. Sustain. Energy Rev. 169, 112935 (2022).

Galusnyak, S. C., Petrescu, L. & Cormos, C.-C. Classical vs. reactive distillation technologies for biodiesel production: an environmental comparison using LCA methodology. Renew. Energy 192, 289–299 (2022).

Yusuf, N. & Almomani, F. Highly effective hydrogenation of CO2 to methanol over Cu/ZnO/Al2O3 catalyst: a process economy & environmental aspects. Fuel 332, 126027 (2023).

Galusnyak, S. C., Petrescu, L., Chisalita, D. A. & Cormos, C.-C. Life cycle assessment of methanol production and conversion into various chemical intermediates and products. Energy 259, 124784 (2022).

Wernet, G. et al. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230 (2016).

International Renewable Energy Agency (IRENA). A pathways to decarbonise the shipping sector by 2050 Presenter. (2022), [cited12 March, 2024]. Available from: https://www.irena.org/Publications/2021/Oct/A-Pathway-to-Decarbonise-the-Shipping-Sector-by-2050

Acknowledgements

This work was supported by the Start-up Research Fund of Southeast University (RF1028623274), China. This work was also supported by the Youth Program of National Natural Science Foundation of China (No. 72104257), the Key Project of Natural Science Funds of Tianjin City (No. 22JCZDJC00540), and the Guangzhou Basic and Applied Basic Research Foundation (No. SL2023A04J00924).

Author information

Authors and Affiliations

Contributions

Proposal, writing-review & editing, supervision, Xiangzhou Yuan; conceptualization, Junyao Wang, Shuai Deng, and Huiyuan Zhang.; original draft, Shuangjun Li and Runkai Chen; writing-review & editing, Mengxiang Fang and Hui Zhou.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, S., Chen, R., Wang, J. et al. Solar thermal energy-assisted direct capture of CO2 from ambient air for methanol synthesis. npj Mater. Sustain. 2, 11 (2024). https://doi.org/10.1038/s44296-024-00014-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44296-024-00014-y