Abstract

While it remains debated if mineral deposits mined for phosphorus fertilizer are running out, phosphorus insecurity is an emerging global issue. We explore how it is linked to the current linear phosphorus economy (LPE) and the historic and current implications. The problems are multifold: there are geopolitical concerns over phosphorus deposits held only by a few nations, sharply rising costs of phosphorus fertilizers, heavy metal contaminants affecting soil and food, problematic phosphorus mining wastes, and the environmental degradation caused by phosphorus fertilizer inefficiencies. Here we argue that a new phosphorus economy can resolve these problems. Transitioning to sustainable use of phosphorus demands a circular phosphorus economy (CPE). A CPE supports several Sustainable Development Goals and enables greater phosphorus autonomy. We illustrate current problems with case studies and outline opportunities for change. The CPE will feature phosphorus recovery facilities, waste valorisation technologies, and improved fertilizer formulations that are customized to target crops and crop systems. We highlight examples of the rapidly advancing CPE that is essential for sustainable agriculture.

Similar content being viewed by others

Phosphorus and food, fertilizer, fertility, and future perspectives

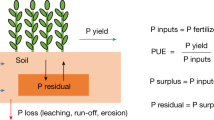

Phosphorus, a focal point of economic, agricultural, and environmental challenges, is an essential, non-substitutable element required for all life on Earth. It is a central component of biochemicals such as DNA, cell membranes and proteins, a functional element for cellular energy cycles and the structural integrity of bones, stems and root systems1. In nature, phosphorus originates from the biogeochemical breakdown of parent material (rock) to form soils and sediments. Slow phosphorus regeneration via rock weathering and nutrient cycling, together with phosphorus losses through erosion and leaching, result in infertile soils over long geological times2,3. Much of the soils’ phosphorus occurs as mineral or organic complexes with varying degrees of bioavailability4. Because phosphorus bioavailability often limits crop growth, soils must be supplemented with phosphorus. Conventional high-production farming mostly uses mineral phosphorus-fertilizers (we use the term ‘chemical’ to distinguish other phosphorus forms). The most common chemical phosphorus-fertilizers consist of immediately bioavailable formulations derived from phosphorus-rich mineral deposits which undergo physical and chemical processing. The efficiency of these chemical fertilizers is however low. It is estimated that approximately 70% of the 45 million tonnes of phosphorus fertilizer applied to soils annually are not used by crops5,6. Fertilizer is converted into largely inaccessible ‘legacy phosphorus’ in agricultural soils or lost from soil, polluting the hydrosphere. Thus, from mining and agriculture to human consumption, it is estimated that in total 95% of phosphorus is lost to inefficient utilization, epitomizing the current Linear Phosphorus Economy (LPE)7.

The inefficiencies associated with chemical phosphorus-fertilizers come at a cost. They have caused (i) global biogeochemical flows of phosphorus to push beyond the safe planetary boundaries8 and (ii) the circulation and accumulation of heavy metals (cadmium, uranium, lead, mercury) in agricultural soils and food9. Furthermore, they have caused imbalances that contribute to soil degradation and acidification10. Despite these profound consequences, a lack of reform prevails regarding mineral deposits and phosphorus-fertilizer industries, which are characterized by monopolized markets, commodity exploitation and lower food production capacity in vulnerable nations11,12,13. Furthermore, achieving the Sustainable Development Goals (SDG) in developing economies through adopting an LPE framework places greater pressures on an already fragile system14 and a heavy price on planetary boundaries15.

Phosphorus is an integral component in achieving many of the 17 SDGs aligned with agriculture, food security and environmental integrity16,17. However, it has highlighted how difficult it will be to achieve these SDGs by 2030 with current strategies18,19,20,21 while maintaining favorable economic (affordable food production), environmental (preservation and restoration), and social (access to a variety of safe foods) symbiosis22. To achieve SDG targets, “urgent” and “bold” interventions are required23. In recent years, an increase in political conflicts, climate change and the Covid-19 pandemic have led to stagnation and, in some cases, to regression of SDG advancements and phosphorus accessibility16,24,25. Extreme poverty has increased for the first time in two decades26, with almost 1 billion people going hungry and the cost of phosphorus fertilizers and food have rapidly risen since 202027,28. Only one-quarter of countries are on track to meet their 2030 child malnutrition targets29, while 17% of global food is wasted30. Furthermore, the expansion of croplands, which cover 12–14% of the world’s ice-free surface, is forecast to further exacerbate biodiversity loss31,32 although can be mitigated through adopting greater phosphorus efficiency strategies33. Compounding the hurdles to achieving the SDG targets, 2020 saw the stagnation or decline in foreign aid targeted at agriculture production in South & Central Asia, South America, and Africa34 and future investments for developing economies are expected to fall sharply35. Together, these problems point to the urgent need for the current LPE to pivot into a framework of circularity and sustainability.

Drawing on historic and current circumstances, we explore the implications of the current LPE and possible strategies to transition into a circular phosphorus economy (CPE). With principal themes of foreign market dependency, environmental degradation, and human health, we aim to illustrate these themes with case studies at country or region level. We address the SDGs with the four pillars of sustainable systems - governance, social, environment and economy - as a foundation for the CPE. Further, we outline the challenges and opportunities associated with a CPE to overcome initial investment limitations, support domestic nutrient autarky, optimise agricultural autonomy, and promote environmental integrity relative to SDG targets. Lastly, with recent and emerging threats to phosphorus sovereignty and accessibility, such as the ongoing war in eastern Europe36, we summarise the challenges and opportunities associated with the successful adoption of a CPE. This paper contributes to the evolving effort to provide safer and efficient fertilizers while reducing the impacts of agriculture to the environment. With the SDG framework adopted by global communities, this paper attempts to offer insight into the complexity of phosphorus as a commodity and fertilizer shaped by the unique challenges presented on a domestic, national and international level.

Foreign market dependency – scarcity or insecurity?

Largely defined by improvements to crop genetics, crop management and the widespread adoption of chemical fertilizers, the Green Revolution commencing in the 1950s represented an inflection point for the rapid increase of agricultural productivity. Unlike synthetic nitrogen fertilizers that are generated by converting atmospheric di-nitrogen gas, chemical phosphorus-fertilizers are manufactured by extracting and processing a finite supply of rock phosphate. Some estimates have stated rock phosphate deposits could last global demands for the next 350 years, although these models place a great emphasis on industry innovation and escalating market prices enabling for profitable extraction and processing of the 90% total global deposits currently inaccessible due to technological or economic limitations37,38. Current exploitable phosphorus deposits (reserves), determined by their accessibility and economic feasibility, are becoming increasingly monopolized and depleted6,39,40. The last decade has a seen a string of national strategies to increase phosphorus security including China’s withdrawal of phosphorus exports41, the United States diversifying its rock phosphate imports from exclusively Morocco in 2009, to mostly Peru (95%) by 202236, and Europe, especially the Baltic nations, continued investment and commitment to phosphorus recycling and valorisation technologies42,43.

Since the Green Revolution, food insecurity has largely affected developing economies, but the rapidly increasing human population, climate change and depleting resources, including declining availability of fertile land, has provoked global food insecurity44,45,46. Sustaining food production demands phosphorus fertilizers to replenish the phosphorus removed during harvest, and some scholars consider the monopolisation of the world’s sporadically distributed phosphorus reserves as one of the greatest challenges facing humanity today39,40,47,48. A priority concern is the geopolitical positioning and trade agreements which have centralized control over domestic and international phosphorus trade and will likely intensify in the future40. In recent events, such as the period between 2007-08, revealed how the LPE influenced price hikes and capitalised on global supply shortages. This caused a decline in phosphorus fertilizer use49, a rise in global food prices28, and sadly, tragic increases in farmer suicides in highly impacted regions50.

For “those who cannot remember the past are condemned to repeat it”51, the story of Nauru may serve as a warning. Nauru, a once pristine Pacific island that gained colonial attention in 1905 due to its vast deposits of phosphorus-rich seabird guano. Subsequent extensive guano mining stripped off over 83% of Nauru’s land surface with catastrophic environmental consequences that have left much of is island degraded and devoid of vegetation52,53. Guano and its volatile market trading prices and bottlenecks, controlled and manipulated by a monopolized industry54, eventually caused an abrupt market shortage and a decline in market share55. Once deemed the nation with the highest GDP per capita in the world, the economy of Nauru collapsed following the exhaustion of guano deposits in 200456.

While Nauru mirrors the fate of other Pacific islands and the Meso-American West Coast, where seabird-deposited guano has long been mined for fertilizer, most phosphorus-fertilizer originates from rock phosphate50. Leading up to the 2008 global financial crisis, the cost of rock phosphate and fertilizer commodities abruptly rose by approximately 800% (Fig. 1). This coincided with a 25% Real Food Price Index increase during the same period28. Although this phenomenon has yet to be “completely understood”57, it is likely a compounding combination of global factors that include a steady growth in East Asian middle-class and associated demand for resource-intensive foods58, India’s import policy in 2007 encouraging the import and use of fertilizer57, the USA’s renewable energy production and consumption policy stimulating plant-based biofuel production59, record oil prices in 2007 increasing phosphorus fertilizer production and transportation costs60, China’s response to global market disarray by imposing a 135% tariff on fertilizer exports61, and the aforementioned factors heightening market speculation and manipulation (i.e., commodity hoarding). This 2007-08 episode has stressed the inability of rigid markets to adapt and meet higher demands while simultaneously profiting on the very shortfalls it created.

The sharp price hike in 2007-08 was only mitigated shortly after the Global Financial Crisis. Prices of phosphorus commodies are yet to fall back and stabilise to pre 2007-08 price hike prices. Commodites since the Global Financial Crisis are in a constant state of flux causing much unpredictability. Prices sharply rose beginning July 2020 and began to decline for triple superphosphate, diammonium phosphate and petroleum by May 2022. Rock phosphate prices have continued on an upward trend.

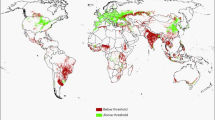

The United States Geological Survey36 details the monopoly of global national rock phosphate reserve ownership and rock phosphate mine production (Fig. 2). The reserve quantity of the top holding entities, Morocco and Western Sahara, Egypt, and Tunisia, account for over 77% of the global reserves, and 73% of total global production is generated by China, Morocco and Western Sahara, and the United States. In 2023, records show Tunisia has become the second largest rock phosphate reserve holder after making its first and only revision with an 185% increased adjustment alongside China reducing their reserve estimations by 45%36. Within Europe, only Finland and Russia have notable reserves (1.4 and 0.8%, respectively) and constitute a small fraction of global mine production (0.4 and 6.2%, respectively). The rest of the EU and Britain are reliant on importing phosphorus-fertilizers or rock phosphate for their domestic fertilizer production industry62.

In the USA, rock phosphate deposits represent 1.4% of global reserves and account for 9.6% of total global output36, although their reserves are expected to become depleted within the upcoming decades63. Florida’s ore grade, the USA’s major rock phosphate-producing state, has been declining since the exhaustion of higher grade northern deposits and supplanted by the lower grade southern deposits64,65. The USA’s declining presence and contribution to the global markets (rock phosphate and phosphorus-fertilizers) has increased their import demand (Fig. 3a, b)66 to supplement national phosphorus-fertilizer use (Fig. 3c)49. Declining phosphorus fertilizer exports from the USA and concomitant increase in imports may further monopolise producers such as China and Morocco, thus exacerbating geopolitical leveraging and commodity supply chain instabilities.

a The USA’s rock phosphate industry concerning domestic production (yellow), apparent consumption (maroon), exports (green), and imports (orange) from 1920–2019; b The USA’s phosphorus-fertilizer industry concerning production, apparent consumption, exports, and imports from 1960–2019; c The average phosphorus-fertilizer use of Europe (green), USA (gray), Africa (blue) and China (purple) from 1960–201949,66,260.

A recognized problem is that the rock phosphate industry has a long history of providing incomplete datasets55 and often overestimating reserve data63,67. The lack of transparency concerning reserves, resources and ore grades prevents a holistic understanding of the LPE and subsequently reduces our ability to accurately plan for the future50,55,68. Shortly after ‘The story of phosphorus: global food security and food for thought’50 was published, Morocco and Western Sahara revaluated and increased their reserve estimations by 777% from 5700 to 50,000 million tonnes69. These estimations did not comply with standardized geological reporting used by the geoscience governing bodies of the United Nations70, USA66, Australia71 and Britain72, drawing criticism over its legitimacy73. Rather than fostering transparency, reserve data and information disclosed by the Moroccan rock phosphate industry remains, however, ambiguous.

Moroccan deposits and mine production are solely owned and operated by the Office Chérifien des Phosphates, which itself is owned by the Moroccan government (95%) and the Banque Populaire du Maroc (5%)74. Unlike publicly listed companies that disclose deposit grades and quantities to attract investment, shareholders, and trade alliances, or adhere to international standards and public disclosure policies, the Office Chérifien des Phosphates is not obliged to provide such information. Tunisia and Morocco have made one and two (respectively) amendments to their reserve estimations since 1994 (Fig. 4)36, which is substantially less compared to that of other major reserve holders such as Australia, China, USA and Jordan (9, 8, 7 and 7 amendments, respectively). A portion of Morocco’s reserves reside in the geographically contested region at the Western Sahara border75. The region was annexed by Morocco in 1975 and de-escalated 16-years later through a UN-brokered truce promising regional independence76. International discussions, however, continue debating the ethics of extracting rock phosphate in mines located in the contested region of Boucraa77,78. In 2017, two Moroccan cargo ships containing rock phosphate mined at this location were stopped and detained on route by South Africa and Panama on the grounds of cargo illegalities79. In December 2020, the Trump Administration’s decision to recognise Morocco’s claim over the region was widely criticized and was met with considerable resistance from the African Union, neighboring Algeria and Sahrawians80.

The above examples illustrate the evolution of issues relating to the reporting, exploitation, and trading of phosphorus reserves and fertilizers over time. We conclude that the monopolisation of mining and reserves has, and currently is, causing food insecurity. The transition from one dominating global actor such as China, to another, such as Morocco, will likely lead to a similar set of problems into the future. Furthermore, the lack of industry transparency, the hazards of deposits residing in disputed territories, the exacerbation of monopolized markets and their evident fragility illustrates and undermines phosphorus security for many nations reliant on imports worldwide.

Soil degradation and phosphorus management

There is global consensus on recognizing the fundamental role of soil in safeguarding sustainable food production and environmental integrity81. Considered a non-renewable resource due to slow regenerative processes82, soil preservation and integrity must become an essential component of circular agriculture frameworks. Currently, poor land use management and unsustainable agricultural practises are causing soil degradation and decrease our ability to produce food14,83. Following aridity, soil erosion is the single greatest factor responsible for soil degradation in agricultural land14 and a primary cause of phosphorus flows into waterways. Intensive agriculture can cause soils to erode at a rate up to 1000-times that of natural rates82 and, as a consequence, a global average of 5.9 kg of phosphorus per hectare is lost to the hydrosphere every year84. Tillage, a major contributor to erosion, is the process of mechanical manipulation to a soil surface which leads to the degradation of the soil’s physical and chemical integrity85. In combination with defective nutrient stoichiometric imbalances and crop harvesting, these anthropogenic features are accelerating soil erosion and therefore phosphorus losses86. In Europe alone, harvesting crops causes 14.7 million tonnes of soil loss every year87.

Soil and nutrient loss from agricultural land and inadequate sewage treatment are primary factors for the disruption of marine nutrient cycles88,89. The impact of phosphorus pollution in marine systems manifests in many regions, including freshwater streams, lakes, estuaries, and coastal regions90. Examples are the infestations of coral-predating Crown of Thorns starfish in Australia’s Great Barrier Reef and toxic algal red tides along Florida’s coastline, killing marine life and causing other detrimental effects91. In the Baltic Sea, partial or complete cessation of phosphorus and other nutrient inputs are predicted to take centuries before pre-anthropogenic conditions are reached92. Anthropogenically-induced eutrophication is responsible for coastal ecological degradation and is considered as one of the greatest threats to marine ecosystems worldwide89, thus demanding the strict management of nutrient inputs and the development of water quality strategies to mitigate the rapid deterioration of coral reefs88,93,94. The projected increase in global demands for food, energy, clean water and waste will, however, exacerbate anthropogenic pollution and place even greater stress on fragile aquatic ecosystems15,95.

Algal blooms (i.e., green tides, red tides, phototropic blooms) are the result of nutrient enrichment caused by agricultural run-off, municipal and industrial waste, aquaculture and biogenic recycling (Fig. 5)96. Correlating with the initiation of intense farming and the use of chemical fertilizers, the first recorded instances of anthropogenic eutrophication in the Baltic Sea commenced in the 1950s97. Today approximately 18,800 tonnes of phosphorus flow into the Baltic Sea annually98. Although localized eutrophication management commenced in the 1980s, the low burial and high remobilization potential of deep biogeochemical phosphorus sediments are largely responsible for reoccurring green tide cycles99,100. The biochemical breakdown of algae during nightfall causes a reduction in dissolved oxygen creating hypoxic conditions (i.e., dead zones). Dead zones in the Baltic Sea are estimated to impact an area of similar size to that of Ireland101. If nutrient reduction is met according to the Baltic Sea Action Plan102, most of its oceanic basins are forecast to become clean from eutrophication in 180 years103.

The accumulation of reactive phosphorus in the biosphere is a global problem and is likely to magnify considering world fertilizer trends (phosphorus, nitrogen, potassium) experienced a 33% increase from 141.7 to 188.5 Mt between 2002 and 201949 in parallel to rising food demands. The European Commission’s strategy to combat nutrient loading will require the reduction of fertilizer use by 20% by 2030104. Achieving this through preventing phosphorus fertilizer inefficiencies and avoiding losses from agricultural soils requires innovative strategies, some of which we outline in later sections.

Heavy metal contaminants in phosphorus deposits and fertilizers

Sedimentary rock phosphate, geologically distinctive from its counterpart igneous rock phosphate, constitutes the major deposits in China, Morocco and the USA66. Sedimentary rock phosphate contains varying levels of toxic heavy metals including cadmium, uranium, mercury and lead105. The production of phosphoric acid, the chemical precursor for commercial triple superphosphate fertilizer and other phosphorus fertilizer blends, is produced through the physical and chemical treatment of rock phosphate to remove constituent undesirable minerals106. The process of removing predominant constituent minerals, notably different from extracting phosphorus as a pure element, causes associated heavy metal contaminants to remain within the fertilizers. The concentrations of these contaminants vary depending on the parent ore and fertilizer manufacturing processes107,108. There are currently no economically viable methods or technologies to remove these heavy metals from the ore and consequently up to 80% supersedes into the phosphoric acid109. Contaminants such as cadmium and uranium are considered to have the most detrimental effects for toxicity, accumulation in soils, plant bioavailability and leaching potential110. Here, we focus on cadmium due to its recognized consequences for public health.

Cadmium is considered a non-threshold toxin which can induce negative health effects at low concentrations111,112. Exposure can have grave effects including kidney disease, cancer and, in some cases, death113,114. The extent of cadmium exposure is largely determined by an individual’s smoking status, dietary habits and consumption of foods produced in proximity to cadmium pollution115,116. In Europe, approximately 45–60% of soil cadmium derives from phosphorus-fertilizers and 55% of human cadmium exposure originates from consuming contaminated foods117,118.

Although native geogenic concentrations of cadmium in soils vary, its presence in soils and water is largely associated with soil applications including chemical phosphorus-fertilizer and wastewater, and also atmospheric deposition from industrial processing9,119. With a high solubility and desorption potential, cadmium is one of the most mobile heavy metals in soils, a primary reason for its high bioavailability to plants and fast migration into groundwater9,120. Promisingly, cadmium concentrations in the upper layers of European soils may be decreasing as less phosphorus-fertilizer is applied (Fig. 3c) and regulations on industry emissions have tightened, although clear trends are still difficult to establish due to variable data117. However, since cadmium bioavailability increases with soil acidity49,121, and agricultural soils acidify with unsustainable practices122, formerly inaccessible cadmium in soils may become bioavailable (Fig. 6), stressing the importance of comprehensive risk mitigation strategies. A comparison between Europe and the USA illustrates the complexity of the problem. While the average application of phosphorus-fertilizer by farmers in the USA and the cadmium exposure levels of the residing populace has remained relatively consistent since the 1970s (Fig. 2c)113,123, while phosphorus-fertilizer inputs have substantially declined in Europe since the early 1990s49 and cadmium levels via aerosols in Europe have reduced four-fold since the 1960s124. Thus, the combined impact of decreased input from aerosols and phosphorus-fertilizers over several decades would be anticipated to lead to an apparent decrease in cadmium concentrations in European topsoils and exoposure levels. However, no clear decrease in cadmium is apparent.

The dotted lines represent a delay in the biogeochemical cycle. The solid line represents the potential hastening of cadmium’s biogeochemical cycling agriculture. The arrow direction represents the feedback direction. Inputs into the cadmium pool include phosphorus-fertilizers, industry and municipal aerosols and waste, natural geogenic deposits, and irrigation using contaminated water. The primary contributing factors of cadmium bioavailability influenced by anthropogenic farming is soil carbon, pH, and inputs.

The risks associated with dietary cadmium exposure is amplified for individuals in developing economies, especially in women and children111,123. Largely determined by lower iron reserves, gastrointestinal absorption of cadmium is twice as high for women than men (10% and 5% absorption rates, respectively), and up to 15% for anemic individuals111,115,125. In global regions such as Africa, over 30% of women suffer from anemia due to dietary limitations126. Therefore, using phosphorus-fertilizers that are contaminated with cadmium will likely increase the rate of exposure and further exacerbate health complications in compromised populations. However, it needs to be re-iterated that cadmium exposure is not limited to developing economies. Although data of increasing levels of cadmium exposure over time in Europe are still largely inconclusive127, a recent analysis found cadmium levels in French citizens are still above national health recommendations in almost half the population128.

Since 2015, China has pursued a ‘Zero Increase of Fertilizer Use’ strategy to flatline the extremely high use of chemical fertilizers and reduce the environmental and health consequences of over-fertilization129. Cadmium is considered China’s most abundant inorganic soil pollutant130 with 10–50% higher average concentrations than native geogenic levels since analyses began in 1986131. Cadmium analysis in North China soils identified phosphorus-fertilization as the primary factor to the 41–62% increase in cadmium concentrations from 1989 to 2009132. On a national level, phosphorus-fertilizers are recognized as a primary cause of cadmium contamination of China’s soil120, which correlates with the steady and comparatively steep rise in the average use from 41 to 95 kg ha−1 over the same time period (Fig. 3c)49.

Due to the known consequences of contaminated phosphorus-fertilizers, the European Commission has proposed a universal limit on cadmium concentrations to 60 mg Cd/kg P2O5, with a tiered reduction to a maximum of 20 mg Cd/kg P2O5 by 2032118. The proposal has been met with some resistance by the fertilizer industry stating the reduction plan is “impossible”133. A review conducted by Bloem et al. (2017)134 found average cadmium concentrations in mineral phosphorus-fertilizers sold in Europe ranging from 32–348 mg Cd/kg P2O5. Furthermore, other OECD countries have been slow to adopt similar regulations. California, the USA’s most regulated state for phosphorus-fertilizer contamination, has set its limit to 400 mg Cd/kg P2O5135, and Australian states and territories have adopted a voluntary limit of 644 mg Cd/kg P2O5136. Considering these vastly different standards and practices, and keeping in mind the significant health hazard posed by cadmium, it is now imperative that a global approach is developed to minimize heavy metal contaminants in phosphorus-fertilizers.

Wastes from phosphorus fertilizer production

Current technologies to process rock phosphate for the manufacture of chemical phosphorus-fertilizers are plagued by inefficiencies and waste production. Depending on the ore grade and processing technology, phosphorus recovery from rock phosphate ranges from approximately 70–90%137,138. However, while some technologies can increase phosphorus recovery to more than 95%139,140,141, implementing them on an industrial scale presents theoretical and practical challenges139. Industry standards generally require the beneficiation of low to medium grade ores to improve phosphorus concentrations, which inevitably increases production costs, energy demand and associated waste142.

The process of manufacturing chemical phosphorus-fertilizers involves mixing of crushed rock phosphate with sulfuric acid to produce phosphoric acid, the base ingredient required for phosphorus-fertilizers such as superphosphates, mono- and di-ammonium-phosphate. During the process of phosphoric acid production, the potentially hazardous waste by-product phosphogypsum, hydrated calcium sulfate, is produced at a quantity 5-times that of phosphoric acid110,143. In Europe and the USA, the disposal of phosphogypsum into waterways has been outlawed due to the associated environmental impacts144. In 2010, the European Commission sent Spain a warning concerning Rio Tinto’s illegal stockpiling of 120 million tonnes of phosphogypsum into a local waterbody145. It is reported that a portion of Morocco’s operations still disposes their phosphogypsum into the Atlantic Ocean110. Globally, approximately 10% of phosphogypsum is dumped into marine environments146 which equates to 16 million tonnes per year147.

Phosphogypsum has minimal recycling utility due to its contaminants including cadmium, uranium, and other radionuclides. The USA’s phosphogypsum waste is held in over 70 mountainous ‘stacks’ up to 3.2 km long and 60 m high148. In 2005, Florida, the USA’s primary rock phosphate mining and fertilizer-producing state, had 1.1 billion tonnes of phosphogypsum spread over 36 km2 110. The solubility of phosphogypsum and constituent contaminants, its leaching potential, acidity, combined with its poor management by the industry has caused numerous environmental disasters149. Since 1994, leaching, sink holes, stack breakages and overflows have caused water contamination and polluted drinking reservoirs, aquifers and waterways110. In 2015, the EPA and Florida’s environmental agencies successfully sued the largest operating company, Mosaic, for US$1.8 billion for law violations, clean-up costs and future mitigation strategies150. In 2021, the Governor of Florida declared a State of Emergency and evacuated local residents when a fragile phosphogypsum stack holding 2.3 billion liters of fluid was on the verge of collapse151,152.

In most cases phosphogypsum stacks do not pose an immediate threat to the environment and best management practises continue to develop153. Geotechnical advancements aim to reduce the risk of a stack wall collapse, and leaching mitigation strategies include collecting and treating edge flows and/or covering stacks with an impermeable barrier have been advised154,155. Although the use of phosphogypsum is the best case scenario for reducing the risk of environmental impacts and achieving greater circularity, its use is limited by its radioactivity and the presence of other trace elements153,156. It is estimated only 15% of the phosphogypsum is used for secondary commercial purposes and the common applications can include its use in cement production, building materials (e.g., bricks and plasterboard), and in agriculture and soil remediation157. Phosphogypsum has also been identified as a potential source of rare earth elements, and improved extraction methods are being investigated which include organic-solvent leaching, and flotation and magnetic separation158.

The ongoing legacy of mining waste that is disposed into waterbodies or stored over large areas of land is clearly of concern. Where regulators can instigate and enforce change, marine pollution through the dumping of phosphogypsum can be prevented, although storage on land, as the Florida example shows, is not an adequate alternative. The cost of such waste disposal practices should be considered as part of the negative externalities of the LPE.

Reimagining phosphorus in a circular phosphorus economy

Orchestrating a phosphorus framework which sustains humanity throughout the 21st century and beyond will require the transition into a CPE. This must be achieved through greater agricultural efficiencies, soil management strategies and adoption of circular phosphorus technologies10,33,37,159,160,161,162,163. It will take careful deliberation how best to achieve an intersect between high agricultural demand and output through a circular framework while maintaining environmental integrity and economic feasibility33,164,165,166,167. This must, however, be a priority for global objectives to reduce the ongoing cropland expansion into natural ecosystems, which target fertile lands in critical areas hosting concentrated levels of clean water, biodiversity and carbon stocks168.

The continued use of chemical phosphorus-fertilizers combined with the likelihood of increasing extreme weather events caused by climate change has strong potential to lead to even higher rates of phosphorus losses from soil due to intensified erosion169, and exacerbate the degradation of marine ecosystems and the loss of biodiversity170,171. Therefore, improving phosphorus efficiency in agriculture must be a central consideration for all societies and nations.

Advancing the CPE requires innovative measures to successfully implement a framework required for achieving circularity. A proposed strategy to alleviate foreign market dependency, environmental degradation and public health deterioration can be achieved through adopting such a framework (Fig. 7). This interconnected system aims to achieve three primary goals, (i) Food Sovereignty, (ii) Phosphorus Autonomy and (iii) Ecosystem Preservation, which are facilitated by three principal levers: (a) Nutrient Recovery Facilities, (b) Valorisation Technologies and (c) Sustainable Agriculture and Soil Management strategies. A CPE will support several SDGs, i.e., Zero Hunger (2), Clean Water and Sanitation (6), Decent Work and Economic Growth (8), Life Below Water (14) and Partnerships for the Goals (17). Furthermore, the CPE contributes to achieving No Poverty (1), Good Health and Well-Being (3), Industry, Innovation, and Infrastructure (9), Sustainable Cities and Communities (11), Responsible Consumption and Production (12) and Life on Land (15) (see Supplementary Information 1). The successful transition into a CPE will, however, require the addressing of existing endemic economic, technological, and agronomic constraints. Below, we elaborate on the three principal levers.

Circular Phosphorus Economy: Goals Food Sovereignty (i), Ecosystem Preservation (ii), Phosphorus Autonomy (iii) can be achieved through Levers Nutrient Recovery Facilities (a), Valorisation Technology (b), and Sustainable Agricultural and Soil Management strategies (c), respectively. SDGs No Poverty (1), Zero Hunger (2), Good Health and Well-Being (3), Clean Water and Sanitation (6), Decent Work and Economic Growth (8), Industry, Innovation, and Infrastructure (9), Sustainable Cities and Communities (11), Responsible Consumption and Production (12), Life Below Water (14), Life on Land (15), and Partnerships for the Goals (17) are position respective to the Levers in which they are accomplished. Underlined SDG numbers represent immediate SDG targets met through a circular phosphorus economy (see Supplementary Information 1); non-underlined SDG numbers represent circular phosphorus economy Levers which contribute to achieving SDGs targets.

Partial adoption of CPE aspects can be seen in motion across the developed world. Europe’s Green New Deal aims to reduce soil nutrient losses by 50% and thereby reducing fertilizer application by 20%172, while a new European Union regulation provides greater permeability for international trade for safer recycled phosphorus materials across Europe173 and, in instances for some of these materials, their use for organic farming174. China has recently updated their Green Development Plan to include a greater focus on nutrient recycling technologies175. The United States has announced $19.5 billion in funding for precision agriculture and nutrient management, and $500 million for fertilizer production innovation176. The consequences of an abrupt shift in government policy, which can be exemplified by Sri Lanka’s recent food shortages caused by a ban on synthetic fertilizers, may serve as an example of implementing sustainable-orientated action without innovated measures to compensate pre-existing technological and agronomic conditions177,178. The successful transition into a CPE must therefore coincide with economically, social, and environmentally working alternatives.

Nutrient recovery and valorisation technologies

Resource accessibility and security is fundamental for eradicating poverty and transitioning nations into a circular economy46. Government legislation plays a central role in catalyzing innovation and initiation. However, many governments have historically been hesitant to introduce legislation that demands greater resource security46. This is notable considering that adoption of waste treatment technologies by the industry is largely compelled by legislative compliance, not economic incentives179,180. Therefore, the adoption of nutrient recovery and valorisation technology requires policy-driven support and economic incentives to alleviate high upfront capital and ongoing costs181. Examples of this can be seen in Europe, where ongoing projects facilitate (i) collaborative partnerships between governments, academic institutions and industry182, but also (ii) assess recycled materials (such as struvite and ashes) as fertilizers and soil conditioning agents174,183.

Governments must factor in the environmental and public health consequences associated with an LPE into their broader socio-economic analyses. When considering public health116,184, the potential for resource recovery185, the UN Impact Categories of ‘terrestrial acidification potential’ and the ‘freshwater eutrophication potential’179,186, moving beyond current chemical phosphorus-fertilizers and phosphorus recovery from waste streams can become economically beneficial. Conventional waste management and valorisation technologies for phosphorus-wastes include (i) enhanced biological phosphorus removal, (ii) chemical precipitation, (iii) thermal- or wet-chemical treatment, (iv) mono-incineration and (v) thermo-chemical treatment146,187. Techno-economic advantages and disadvantages are dependent on relevant processes, which include phosphorus recovery efficacy, upfront and upkeep costs, and additives (such as chemicals) required for recovery and valorisation188. Many of these technologies have yet to reach techno-socio-ecological maturity189,190 with continuous improvements including (i) greater extraction and resource recovery efficiencies, (ii) smaller scale operations which can be established at a closer proximity to phosphorus-waste feedstocks, (iii) lower upfront capital investments, and (iv) desired properties of the final product191,192.

Valorisation technologies can remove harmful pollutants from feedstocks while concentrating phosphorus in the final product193,194. Mono-incineration of biowastes destroy heat sensitive bioactives including human diseases, pharmaceuticals, pathogens, and PFAS195,196, while thermo-chemical treatment can remove undesired heavy metals to produce a pollutant free phosphorus-fertilizer197. This supports the aim of achieving a negative soil-cadmium mass balance which requires cadmium concentrations in fertilizers to be limited to below 20 mg cadmium kg−1 phosphorus117. Heavy metal removal technologies to produce low contaminant phosphorus-fertilizers from wastes form an essential component of the CPE by reducing the current and ongoing input of heavy metals into agricultural soils.

Improving phosphorus use efficiency in agriculture

The Green Revolution launched the widespread use of chemical nitrogen-phosphorus-potassium (NPK) fertilizers and related technological innovations. Input of such concentrated and immediately crop-available nutrients left soil health and biology largely ignored86. Soils are complex systems governed by a multitude of interconnected biogeochemical characteristics influenced by soil type, climate, vegetation and, in the case of agricultural systems, management. Chemical fertilizers lack carbon (unlike manures and other organic materials such as composts), which can cause biogeochemical stoichiometric imbalances and a series of undesirable soil and agronomic consequences198,199. Organic carbon has a key function for soil structural integrity200, soil fertility201, water retention and availability202, soil biological health86,203, reducing uptake of contaminants (e.g., cadmium) by crops204,205 and pH-neutralising effects in acidic soils132. Thus, carbon and the other crop essential nutrients must be part of the solutions aimed at achieving greater phosphorus efficiency in agriculture206,207.

To address the problem of exceeded planetary boundaries, global phosphorus use efficiency (PUE) in croplands must increase to 68–81%208. PUE in plants is a complex phenomenon with diverse evolutionary adaptations guided by and attuned to different soil and climatic conditions209. Identifying desirable traits in crop genotypes that underlie PUE is becoming a key component in crop selection and breeding programs which its research being relatively novel and understanding still developing210. PUE is defined by two primary mechanisms: external efficiency that is largely determined by a plant’s competency to acquire phosphorus from soil, and internal efficiency, defined by a plant’s ability to maximise phosphorus related biochemical processes. External PUE includes (i) proficient root exudation profiles, (ii) amplified microbial-root interactions, and (iii) beneficial root physiology, morphology and architecture211. Multi-trait mapping has identified quantitative trait loci associated with root morphology (specifically total root surface area) that have a high correlation with grain yield under phosphorus limiting conditions212. Root architecture is an important trait for accessing phosphorus in soil, including legacy phosphorus, that increases efficiency to sustain yield in low phosphorus-fertilized soils213,214. Microbially mediated processes can liberate legacy phosphorus for plant uptake215,216, and genotypes with greater root colonization of arbuscular mycorrhizal fungi have higher yields and greater grain phosphorus concentrations217. Identified internal efficiencies include (i) the effective remobilization of phosphorus from older tissues, (ii) substitution of the phosphorus component for non-phosphorus elements in phospholipids, (iii) using alternative ATP-independent pathways, and (iv) lower phosphorus concentrations in leaves without compromised photosynthetic productivity that enables greater distribution of phosphorus to other components of the plant218,219,220.

The magnitude of crop PUE importance is illustrated by the 33 million tonnes of legacy phosphorus that has accumulated in Brazilian cropland soils during the last half-century, and how exploiting this phosphorus source could save Brazilian farmers USD$20.8 billion over the coming decades221. Alongside identifying and selecting preferable crop traits associated with efficiently accessing legacy phosphorus from soil, crop breeding programs should endeavor pairing favorable traits with recycled phosphorus materials214,218. The lower solubility that characterizes many recyclates can be addressed by breeding crops with (i) thicker roots that exude greater quantities of carboxylates and phosphatases than crops with thinner roots222, and (ii) seeds with higher phosphorus content for more prolific initial growth and root establishment211. Interestingly, recycled materials can increase PUE as the proportion of other essential nutrients in many recycled materials, such as nitrogen, magnesium, zinc, and iron, can positively correlate with crop phosphorus uptake208,223,224.

The need to consider PUE as integral component of the CPE is evident considering that many of the phosphorus recovery technologies are primarily focused on the extraction of nutrients in the most efficient and economically viable manner with desirable agronomic characteristics receiving secondary consideration12. The agronomic efficacy of valorised phosphorus materials are largely influenced by their respective chemical and physical characteristics225 and respective relationships to soil properties226. For example, the agronomic performance of the precipitant struvite (magnesium-ammonium-phosphate), a by-product of phosphorus-rich effluent treatment which removes phosphorus and nitrogen, is largely influenced by its particle size225 and soil pH227,228. Raniro, et al.229 found that the solubility of the valorised phosphorus materials struvite, AshDec© (thermo-chemical product) and hazenite (chemically precipitated phosphorus salt) was largely influenced by soil pH and exposure to different solvents. Therefore, enhancing the agronomic efficacy of valorised phosphorus-materials requires tailoring their physiochemical properties to complement soil conditions and the crop’s phosphorus-mobilization efficiency230,231. Improving phosphorus fertilizer formulations thus requires empirical research and modelling to design crop-system targeted phosphorus-fertilizers232,233.

The improvement of phosphorus bioavailability of recycled materials can also be achieved in situ without prior processing. For example, improving phosphorus bioavailability from organic wastes such as manures can be achieved through the use of phosphate-liberating enzymes (e.g., purple acid phosphatases or organophosphate-degrading enzymes)234,235 deployed, for instance, on nanoclays236,237. The availability of inorganic phosphate, such as chemical precipitates and ash, can also be potentially improved with phosphorus-solubilizing microbes that excrete particular organic acids238.

Realising a circular phosphorus economy in the developing economies – example Africa

The CPE is relevant for all nations aiming to enhance their phosphorus sovereignty, as the Covid-19 pandemic highlighted that communities with food insecurity live at the mercy of foreign markets239. This was especially prevalent in Africa, where many countries rely on imports for their staple food supply240, which we highlight as a case scenario here. In 2020, Africa saw 800 million people suffer from moderate to severe food insecurity, with one in five persons undernourished, and one third of children have stunted growth due to malnutrition241. To further compound this issue, the true socio-economic consequences of heightening resource insecurity and the subsequent repercussions on food production may have been underestimated by previous reports46. Furthermore, the increasing adoption of an LPE framework is likely to generate a spectrum of contemporary complications observed across the developed world.

The challenges and respective antidotes facing the developed world are fundamentally different when compared to developing economies such as those experienced in Africa. While there is a universal desire for food security, high yields and economic affluency enables the developed world to focus its efforts on mitigating the environmental degradation caused by an LPE, while developing economies delay environmental concerns in favor of achieving socio-economic objectives detailed in the SDGs. Dissimilar to developed nations, achieving a CPE within Africa is not a process of retrofitting pre-existing infrastructure or implementing novel technologies, but a process of introducing the systems, technologies and frameworks required for fertilizer production, application, and management. This process is necessary to address the primary limitations associated with food production and insecurity caused by the lack of access to fertilizers necessary to produce and sustain high yields.

Nutrient recovery and valorisation technologies

For Africa, it is estimated that adequate wastewater management systems could save 325,000 lives annually through reducing the spread of diseases, while a reduction of nutrient loading into waterways could mitigate a further 613,000 annual deaths caused by poor quality drinking water and insufficient sanitation242. However, the development of efficient wastewater management systems and the provision of basic sanitation facilities poses a great logistical and economic challenge243, especially when considering the requirements necessary for establishing infrastructure in areas with pre-existing municipal buildings in high-density areas. Currently, much of the sewage produced in African cities ends up in local waterways due to the lack of wastewater management facilities244 leaving this potential nutrient resource largely unexploited. The direct reuse of humanure does, however, offer a low economic and technological solution with a potentially high return on investment245. In contrast, technological and infrastructure requirements for rural African communities present unique challenges due to low density and sporadic populations246. Feedstocks excluding wastewater management can be sourced from a variety of other phosphorus-rich biowastes other than humanure, including livestock manure and bones, composts, food waste and digestates247,248. However, consideration must be given to such resources as they may already serve a secondary purpose such as use for shelter building or livestock feed.

Sustainable agriculture and soil management

Agricultural run-off is considered a primary contributing factor of Africa’s declining water quality184 and thus demands improved agricultural and soil management strategies. Reaching high agricultural output without mirroring the chemical phosphorus-fertilizer inputs seen in the developed world (Fig. 3c) will require great agricultural methodological and industrial innovations. The development of localized management strategies should include the recruitment of local farmers to ensure integration of indigenous knowledge which can help mitigate biodiversity loss249 and identify localized best management practises250. Through education, access to technological resources that promote soil management schemes, and nutrient biofortification targeting phosphorus-deficient soils, the loss of biodiversity to agricultural expansion can be eliminated in sub-Saharan Africa33. However, due to the complexity of phosphorus in soils, previous analyses may have underestimated the quantity of phosphorus required to meet the agricultural demands in this region251. The high variability in soil characteristics and environmental conditions across Africa requires an advanced approach to articulate a farmer’s unique fertilizer requirements, especially when considering that conventional methods, such as single point soil analyses, are highly variable and largely inaccurate252,253. Providing advanced resources such as spatial data (e.g., Africa Soil Information Service) can be used to help calculate the required quantities of phosphorus-fertilizer254. Other immediate and low-barriers to adoption solutions which can conserve soil phosphorus and moderate nutrient loading into waterways are linked to regenerative agricultural techniques that include (i) cover cropping, (ii) conservation tillage and (iii) precision fertilizer management strategies255,256,257,258.

Final remarks

The LPE continues to undermine food security, public health, and environmental integrity across the globe. Adopting an LPE framework to accomplish SDGs will encounter contemporary global challenges while exacerbating the shortfalls of an already fragile system. Continued monopolisation and resource nationalism, increasing demands from emerging economies, and the USA withdrawing from the global market will likely further undermine supply security and exacerbate phosphorus access inequality. Furthermore, without advancing phosphorus management in agro-ecosystems, reducing heavy metal contamination and limiting the continued loss of biodiversity through agricultural land expansion and eutrophication, these issues will likely intensify in the future. By harnessing phosphorus in waste streams that currently contribute to environmental degradation, the successful pivot into a CPE based on nutrient recovery and valorisation technologies can promote phosphorus autarky and, therefore, agricultural autonomy. Policy and financial support from governments and cooperative partnerships must be the backbone behind CPE innovation and implementation.

Change history

09 October 2023

A wrong Supplementary file was originally published with this article; it has now been removed.

References

Plaxton, W. & Lambers, H. Annual plant reviews, phosphorus metabolism in plants. Vol. 48 (John Wiley & Sons, 2015).

Lizcano-Toledo, R., Reyes-Martín, M. P., Celi, L. & Fernández-Ondoño, E. Phosphorus Dynamics in the Soil–Plant–Environment Relationship in Cropping Systems: A Review. Appl. Sci. 11, 11133 (2021).

Addiscott, T. & Thomas, D. Tillage, mineralization and leaching: phosphate. Soil Tillage Res. 53, 255–273 (2000).

Menezes-Blackburn, D. et al. Opportunities for mobilizing recalcitrant phosphorus from agricultural soils: a review. Plant Soil 427, 5–16 (2018).

FAO. Inorganic fertilizers 1961–2019. Anal. Brief Ser. 27, 2–3 (2021).

Brownlie, W. J. et al. Global actions for a sustainable phosphorus future. Nature Food 2, 71–74 (2021).

Geissler, B., Hermann, L., Mew, M. C. & Steiner, G. Striving toward a circular economy for phosphorus: The role of phosphate rock mining. Minerals 8, 395 (2018).

Steffen, W. et al. Planetary boundaries: Guiding human development on a changing planet. Science 347, 1259855 (2015).

Kubier, A., Wilkin, R. T. & Pichler, T. Cadmium in soils and groundwater: a review. Appl. Geochem. 108, 104388 (2019).

Lal, R. Restoring soil quality to mitigate soil degradation. Sustainability 7, 5875–5895 (2015).

Ekardt, F., Garske, B., Stubenrauch, J. & Wieding, J. Governance Instruments for Phosphorus Supply Security. In: Phosphorus in Agriculture: 100% Zero. Vol. 1, pp. 331–347 (Springer, 2016).

Mayer, B. K. et al. Total value of phosphorus recovery. Environ. Sci. Technol. 50, 6606–6620 (2016).

Cordell, D., Dominish, E., Esham, M., Jacobs, B. & Nanda, M. Adapting food systems to the twin challenges of phosphorus and climate vulnerability: the case of Sri Lanka. Food Security 13, 477–492 (2021).

Prăvălie, R. et al. Arable lands under the pressure of multiple land degradation processes. A global perspective. Environ. Res. 194, 110697 (2021).

Randers, J. et al. Achieving the 17 Sustainable Development Goals within 9 planetary boundaries. Global Sustain. 2, E24 (2019).

El Wali, M., Golroudbary, S. R. & Kraslawski, A. Circular economy for phosphorus supply chain and its impact on social sustainable development goals. Sci. Total Environ. 777, 146060 (2021).

Brooks, J. Food security and the Sustainable Development Goals. In: Debate the Issues: New Approaches to Economic Challenges. OECD Publishing, Paris. 143–146 (2016).

Leal Filho, W. et al. Reinvigorating the sustainable development research agenda: the role of the sustainable development goals (SDG). Int. J. Sustain. Dev. World Ecol. 25, 131–142 (2018).

Kruk, M. E. et al. High-quality health systems in the Sustainable Development Goals era: time for a revolution. Lancet Global Health 6, e1196–e1252 (2018).

Salvia, A. L., Leal Filho, W., Brandli, L. L. & Griebeler, J. S. Assessing research trends related to Sustainable Development Goals: Local and global issues. J. Cleaner Prod. 208, 841–849 (2019).

Sachs, J. et al. Six transformations to achieve the sustainable development goals. Nature Sustain. 2, 805–814 (2019).

Ibeh, C. & Walmsley, B. The role of impact assessment in achieving the sustainable development goals in Africa. In: IAIA21 Smartening Impact Assessment in Challenging Times. International Association for Impact Assessment, 1–15 (Fargo, ND, 2021).

United Nations. The Sustainable Development Goals Report 2019. (New York, 2019).

Sachs, J., Kroll, C., Lafortune, G., Fuller, G. & Woelm, F. Sustainable Development Report 2021. (2021).

Kuokkanen, A. The next-generation of sustainable fertilisers: a win-win solution. (European Commission, Petten, 2022).

World Bank. Poverty and Shared Prosperity 2020: Reversals of Fortune. (The World Bank, 2020).

Laganda, G. 2021 is going to be a bad year for world hunger, https://www.un.org/en/food-systems-summit/news/2021-going-be-bad-year-world-hunger (2021).

FAO. FAO Food Price Index, http://www.fao.org/worldfoodsituation/foodpricesindex/en/ (2021).

WHO. Levels and trends in child malnutrition: UNICEF/WHO/The World Bank Group joint child malnutrition estimates: key findings of the 2021 edition. (World Health Organization, 2021).

UNEP. Food Waste Index Report 2021. (United Nations, Nairobi, 2021).

IPCC. Climate Change and Land: an IPCC special report on climate change, desertification, land degradation, sustainable land management, food security, and greenhouse gas fluxes in terrestrial ecosystems. (2019).

Zabel, F. et al. Global impacts of future cropland expansion and intensification on agricultural markets and biodiversity. Nat. Commun. 10, 1–10 (2019).

Mogollón, J. M. et al. More efficient phosphorus use can avoid cropland expansion. Nature Food 2(7), 509–18 (2021).

OECD. Geographical Distribution of Financial Flows to Developing Countries 2022: Disbursements, Commitments, Country Indicators. OECD Publishing (2022).

Giroud, A. & Ivarsson, I. World Investment Report 2020: International production beyond the pandemic. (2020).

U.S. Geological Survey. Mineral commodity summaries 2023. (U.S. Geological Survey, 2023).

Köhn, J., Zimmer, D. & Leinweber, P. Is phosphorus really a scarce resource? Int. J. Environ. Technol. Manag. 21, 373–395 (2018).

IFA & Argus Media Group. Phosphate Rock - Resources & Reserves. Int. Fertil. Assoc. 1, 11–45 (2023).

Cordell, D. Peak phosphorus and the role of P recovery in achieving food security. In: Source Separation and Decentralization for Wastewater Management. IWA Publishing, 29–44 (London, 2013).

Nassar, N. T. et al. Evaluating the mineral commodity supply risk of the US manufacturing sector. Sci. Adv. 6, eaay8647 (2020).

U.S. Department of Agriculture. Impacts and Repercussions of Price Increases on the Global Fertilizer Market, https://www.fas.usda.gov/data/impacts-and-repercussions-price-increases-global-fertilizer-market (2022).

HELCOM. Overview of nutrient recycling in the Baltic Sea countries. (Baltic Marine Environment Protection Commission, Helsinki, 2018).

ESPP. ESPP - DPP - NNP nutrient recovery technology catalogue, https://phosphorusplatform.eu/catalogue (2023).

Hayes, S. M. & McCullough, E. A. Critical minerals: A review of elemental trends in comprehensive criticality studies. Res. Policy 59, 192–199 (2018).

European Commission. Critical Raw Materials for Strategic Technologies and Sectors in the EU - A Foresight Study. (European Commission, 2020).

Wackernagel, M. et al. The importance of resource security for poverty eradication. Nat. Sustain. 4, 731–738 (2021).

Cordell, D. & White, S. Life’s bottleneck: sustaining the world’s phosphorus for a food secure future. Ann. Rev. Environ. Res. 39, 161–188 (2014).

Reijnders, L. Phosphorus resources, their depletion and conservation, a review. Res. Conserv. Recycling 93, 32–49 (2014).

FAOSTAT. Fertilizer by Product and Nutrient, http://www.fao.org/faostat/en/#data/EF (2023).

Cordell, D., Drangert, J.-O. & White, S. The story of phosphorus: global food security and food for thought. Global Environ. Change 19, 292–305 (2009).

Santayana, G. Reason in common sense. Vol. 1 (Constable, 1910).

Komar Kawatra, S. & Carlson, J. Beneficiation of phosphate ore. (Society for Mining, Metallurgy, and Exploration, 2013).

Gale, S. J. The mined-out phosphate lands of Nauru, equatorial western Pacific. Australian J. Earth Sci. 63, 333–347 (2016).

Australian Parliament. Pricing and supply arrangement in the Australian and global fertiliser market. (Parliment of Australia, 2009).

Ulrich, A. E. & Frossard, E. On the history of a reoccurring concept: phosphorus scarcity. Sci. Total Environ. 490, 694–707 (2014).

Fenner, D. in World Seas: an Environmental Evaluation (Second Edition) (ed Charles Sheppard) 793-805 (Academic Press, 2019).

Khabarov, N. & Obersteiner, M. Global phosphorus fertilizer market and national policies: a case study revisiting the 2008 price peak. Front. Nutrition 4, 22 (2017).

Heffer, P. & Prud’homme, M. World agriculture and fertilizer demand, global fertilizer supply and trade in 2007-2008 - Summary report. (International Fertilizer Association, 2008).

Sissine, F. Energy Independence and Security Act of 2007: a summary of major provisions. (Library of Congress Washington DC Congressional Research Service, 2007).

Hamilton, J. D. Causes and Consequences of the Oil Shock of 2007-08. (National Bureau of Economic Research, 2009).

Cordell, D., Turner, A. & Chong, J. The hidden cost of phosphate fertilizers: mapping multi-stakeholder supply chain risks and impacts from mine to fork. Global Change, Peace Security 27, 323–343 (2015).

Geissler, B., Mew, M. C. & Steiner, G. Phosphate supply security for importing countries: Developments and the current situation. Sci.Total Environ. 677, 511–523 (2019).

Geissler, B., Mew, M. C., Weber, O. & Steiner, G. Efficiency performance of the world’s leading corporations in phosphate rock mining. Res. Conserv. Recycling 105, 246–258 (2015).

Steiner, G., Geissler, B., Watson, I. & Mew, M. C. Efficiency developments in phosphate rock mining over the last three decades. Res. Conserv. Recycling 105, 235–245 (2015).

Samreen, S. & Kausar, S. Phosphorus Fertilizer: The original and commercial sources. In: Phosphorus Recovery and Recycling, (IntechOpen, 2019).

U.S. Geological Survey. Mineral Commodity Summaries 2022. (U.S. Department of the Interior, Virginia, 2022).

Cordell, D. & Neset, T.-S. Phosphorus vulnerability: a qualitative framework for assessing the vulnerability of national and regional food systems to the multi-dimensional stressors of phosphorus scarcity. Global Environ. Change 24, 108–122 (2014).

De Ridder, M., De Jong, S., Polchar, J. & Lingemann, S. Risks and opportunities in the global phosphate rock market: Robust strategies in times of uncertainty. (Hague Centre for Strategic Studies, 2012).

U.S. Geological Survey. Mineral Commodity Summaries 2011. (U.S. Department of the Interior, 2011).

European Commission. Study of the EU’s list of Critical Raw Materials - Final Report (2020). (Luxembourg, 2020).

JORC. Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves. (Joint Ore Reserves Committee of The Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia (JORC), 2012).

British Geological Survey. British Geological Survey: Risk list 2015. (2015).

Edixhoven, J., Gupta, J. & Savenije, H. Recent revisions of phosphate rock reserves and resources: a critique. Earth System Dyn. 5, 491–507 (2014).

OCP. Our History, https://www.ocpgroup.ma/history (2021).

Allan, J. & Ojeda-García, R. Natural resource exploitation in Western Sahara: new research directions. J. North African Studies 27, 1107–1136 (2021).

United Nations. Guterres ‘remains committed’ to maintaining 1991 ceasefire in Western Sahara, https://news.un.org/en/story/2020/11/1077672 (2020).

Kutz, W. Between dependency and engagement: Centring subaltern geopolitics in multiperspectival border studies. Lessons from the Western Sahara. Political Geography 89, 102431 (2021).

Irwin, R. L. Terrains of legality and sovereignty: adjudicating the ownership of Western Sahara’s phosphate in South Africa. J. North African Studies 27, 1137–1159 (2021).

Ruys, T. The role of state immunity and act of state in the NM Cherry Blossom case and the Western Sahara dispute. Inte. Comparative Law Quarterly 68, 67–90 (2019).

U.S. Embassy & Consulates in Morocco. Proclamation on Recognizing The Sovereignty Of The Kingdom Of Morocco Over The Western Sahara, https://ma.usembassy.gov/proclamation-on-recognizing-the-sovereignty-of-the-kingdom-of-morocco-over-the-western-sahara/ (2020).

FAO, ITPS, GSBI, SCBD & EC. State of knowledge of soil biodiversity - Status, challenges and potentialities. Report No. 9251335826, (FAO, Rome, 2020).

FAO. Status of the World’s Soil Resources: Technical Summary. (FAO, Rome, Italy, 2015).

FAO. The state of the world’s land and water resources for food and agriculture (SOLAW) - Managing systems at risk. Report No. 1849713278, (Food and Agriculture Organization of the United Nations, Rome and Earthscan, London, 2011).

Alewell, C. et al. Global phosphorus shortage will be aggravated by soil erosion. Nat. Commun. 11, 1–12 (2020).

Busari, M. A., Kukal, S. S., Kaur, A., Bhatt, R. & Dulazi, A. A. Conservation tillage impacts on soil, crop and the environment. Int. Soil Water Conserv. Res. 3, 119–129 (2015).

Lehman, R. M. et al. Understanding and enhancing soil biological health: the solution for reversing soil degradation. Sustainability 7, 988–1027 (2015).

Panagos, P., Borrelli, P. & Poesen, J. Soil loss due to crop harvesting in the European Union: A first estimation of an underrated geomorphic process. Sci.Total Environ. 664, 487–498 (2019).

Withers, P. J. et al. A global perspective on integrated strategies to manage soil phosphorus status for eutrophication control without limiting land productivity. J. Environ. Quality 48, 1234–1246 (2019).

Malone, T. C. & Newton, A. The globalization of cultural eutrophication in the coastal ocean: causes and consequences. Front. Marine Sci. 7, 670 (2020).

Wurtsbaugh, W. A., Paerl, H. W. & Dodds, W. K. Nutrients, eutrophication and harmful algal blooms along the freshwater to marine continuum. WIREs Water 6, e1373 (2019).

Brodie, J., Devlin, M. & Lewis, S. Potential enhanced survivorship of crown of thorns starfish larvae due to near-annual nutrient enrichment during secondary outbreaks on the central mid-shelf of the Great Barrier Reef, Australia. Diversity 9, 17 (2017).

McCrackin, M. L., Jones, H. P., Jones, P. C. & Moreno‐Mateos, D. Recovery of lakes and coastal marine ecosystems from eutrophication: A global meta‐analysis. Limnology Oceanogr. 62, 507–518 (2017).

Chazottes, V., Hutchings, P. & Osorno, A. Impact of an experimental eutrophication on the processes of bioerosion on the reef: One Tree Island, Great Barrier Reef, Australia. Marine Pollut. Bulletin 118, 125–130 (2017).

Wooldridge, S. A. Excess seawater nutrients, enlarged algal symbiont densities and bleaching sensitive reef locations: 1. Identifying thresholds of concern for the Great Barrier Reef, Australia. Marine Pollut. Bulletin 152, 107667 (2020).

Glibert, P. M. Harmful algae at the complex nexus of eutrophication and climate change. Harmful Algae 91, 101583 (2020).

Gladyshev, M. & Gubelit, Y. I. Green tides: new consequences of the eutrophication of natural waters (invited review). Contemporary Prob. Ecol. 12, 109–125 (2019).

Andersen, J. H. et al. Long‐term temporal and spatial trends in eutrophication status of the Baltic Sea. Biol. Rev. 92, 135–149 (2017).

Svendsen, L. M. & Gustafsson, B. Waterborne nitrogen and phosphorus inputs and water flow to the Baltic Sea 1995–2019. HELCOM, 2–12 (2020).

Savchuk, O. P. Large-scale nutrient dynamics in the Baltic Sea, 1970–2016. Front. Marine Sci. 5, 95 (2018).

Kuliński, K. et al. Baltic Earth Assessment Report on the biogeochemistry of the Baltic Sea. Earth Sys. Dyn. Discuss. 1–93 (2021).

Meier, H. et al. Disentangling the impact of nutrient load and climate changes on Baltic Sea hypoxia and eutrophication since 1850. Climate Dyn. 53, 1145–1166 (2019).

HELCOM. HELCOM Baltic Sea action plan. 2007 (HELCOM Ministerial Meeting, Poland, 2007).

Murray, C. J. et al. Past, present and future eutrophication status of the Baltic Sea. Front. Marine Sci. 6, 2 (2019).

European Commission. Biodiversity Strategy for 2030 Bringing nature back into our lives COM/2020/380 final. (European Commission, 2020).

De Boer, M. A., Wolzak, L. & Slootweg, J. C. In Phosphorus Recovery and Recycling 75-100 (Springer, 2019).

Revuelta, M. B. Mineral Processing. Mineral Res. 1, 423–530 (2018).

Gray, C., McLaren, R., Roberts, A. & Condron, L. The effect of long-term phosphatic fertiliser applications on the amounts and forms of cadmium in soils under pasture in New Zealand. Nutrient Cycling Agroecosys. 54, 267–277 (1999).

Kratz, S., Schick, J. & Schnug, E. Trace elements in rock phosphates and P containing mineral and organo-mineral fertilizers sold in Germany. Scie. Total Environ. 542, 1013–1019 (2016).

Kouzbour, S. et al. Comparative analysis of industrial processes for cadmium removal from phosphoric acid: A review. Hydrometallurgy 188, 222–247 (2019).

Taylor, M. et al. Trace element contaminants and radioactivity from phosphate fertiliser. Phosphorus in Agriculture: 100% Zero, 231–266 (2016).

Centers for Disease Control and Prevention. Biomonitoring Summary, https://www.cdc.gov/biomonitoring/Cadmium_BiomonitoringSummary.html (2017).

Rahman, Z. & Singh, V. P. The relative impact of toxic heavy metals (THMs)(arsenic (As), cadmium (Cd), chromium (Cr)(VI), mercury (Hg), and lead (Pb)) on the total environment: an overview. Environ. Monitoring Assessment 191, 1–21 (2019).

Adams, S. V. & Newcomb, P. A. Cadmium blood and urine concentrations as measures of exposure: NHANES 1999–2010. J. Exposure Sci. Environ. Epidemiol. 24, 163–170 (2014).

WHO. Preventing disease through healthy environments: exposure to highly hazardous pesticides: a major public health concern. Report No. WHO/CED/PHE/EPE/19.4.2, (World Health Organization, 2019).

WHO. Air quality guidelines for Europe. Report No. 9289013583, (WHO Regional Office for Europe, 2000).

Pizzol, M., Smart, J. C. & Thomsen, M. External costs of cadmium emissions to soil: a drawback of phosphorus fertilizers. J. Cleaner Prod. 84, 475–483 (2014).

Smolders, E. Scientific aspects underlying the regulatory framework in the area of fertilisers–state of play and future reforms. (European Union, 2017).

Ulrich, A. E. Cadmium governance in Europe’s phosphate fertilizers: Not so fast? Sci. Total Environ. 650, 541–545 (2019).

Hou, D. et al. Metal contamination and bioremediation of agricultural soils for food safety and sustainability. Nat. Rev. Earth Environ. 1, 366–381 (2020).

Nino-Savala, A. G. et al. Cadmium pollution from phosphate fertilizers in arable soils and crops: an overview. Front. Agr. Sci. Eng. 6, 419–430 (2019).

Shahid, M., Dumat, C., Khalid, S., Niazi, N. K. & Antunes, P. M. Cadmium bioavailability, uptake, toxicity and detoxification in soil-plant system. Rev. Environ. Contam. Toxicol. 241, 73–137 (2016).

Tkaczyk, P. et al. The mineral fertilizer-dependent chemical parameters of soil acidification under field conditions. Sustainability 12, 7165 (2020).

Kowal, N., Johnson, D., Kraemer, D. & Pahren, H. Normal levels of cadmium in diet, urine, blood, and tissues of inhabitants of the United States. J.Toxicol. Environ. Health, Part A Current Issues 5, 995–1014 (1979).

Smolders, E. & Six, L. Revisiting and updating the effect of phosphate fertilizers to cadmium accumulation in European agricultural soils. (Division of Soil and Water Management, Belgium, 2013).

Nordberg, G. F. Cadmium and health in the 21st century–historical remarks and trends for the future. Biometals 17, 485–489 (2004).

FAO, IFAD, UNICEF, WFP & WHO. The State of Food Security and Nutrition in the World 2021. Transforming food systems for food security, improved nutrition and affordable healthy diets for all. Vol. 2021 (FAO, 2021).

Lundh, T., Axmon, A., Skerfving, S. & Broberg, K. Cadmium and mercury exposure over time in Swedish children. Environ. Res. 150, 600–605 (2016).

Oleko A. et al. Imprégnation de la population française par le cadmium. Programme national de biosurveillance, Esteban 2014–2016. 43 (2021).

Ji, Y., Liu, H. & Shi, Y. Will China’s fertilizer use continue to decline? Evidence from LMDI analysis based on crops, regions and fertilizer types. Plos one 15, e0237234 (2020).

MLR & MEP. MEP and MLR announce the report on national general survey on soil contamination, http://english.www.gov.cn/policies/latest_releases/2014/08/23/content_281474983026954.htm (2014).

Wang, L. et al. A review of soil cadmium contamination in China including a health risk assessment. Environ. Sci. Pollut. Res. 22, 16441–16452 (2015).

Qi, F. et al. Cadmium solubility and bioavailability in soils amended with acidic and neutral biochar. Sci. Total Environ. 610, 1457–1466 (2018).

Fertilizers Europe. The European Parliament goes down a wrong path, https://www.fertilizerseurope.com/news/the-european-parliament-goes-down-a-wrong-path/ (2017).

Bloem, E. et al. Contamination of organic nutrient sources with potentially toxic elements, antibiotics and pathogen microorganisms in relation to P fertilizer potential and treatment options for the production of sustainable fertilizers: a review. Sci. Total Environ. 607, 225–242 (2017).

California Department of Food and Agriculture. Food and agricultural code, Division 7, Agricultural chemicals, livestock remedies, and commerical feeds, Chapter 5. Fertilizing materials [14501-14682]. (California Department of Food and Agriculture, 2020).

Warne, M. et al. Final Report of the National Cadmium Management Committee (NCMC). (National Cadmium Committee, 2007).

Ruan, Y., He, D. & Chi, R. Review on beneficiation techniques and reagents used for phosphate ores. Minerals 9, 253 (2019).

Abouzeid, A.-Z. M. Physical and thermal treatment of phosphate ores—An overview. Int. J. Mineral Process. 85, 59–84 (2008).

Wingate, E. & Kohmuench, J. An optimized approach to phosphate recovery. (Society for Mining, Metallurgy & Exploration, 2016).

Günther, S., Grunert, M. & Müller, S. Overview of recent advances in phosphorus recovery for fertilizer production. Eng. Life Sci. 18, 434–439 (2018).

Hobert, A., Dohm, E., Tallarico, F. & Dedé, C. Improved Flotation Recovery and Selectivity of an Ultra-Fine Brazilian Phosphate Ore Using Eriez’ Column Flotation Technology. SYMPHOS - 5th International Symposium on Innocation & Technology in the Phosphate Industry (2020).

Steen, I. Phosphorus availability in the 21st century: management of a non-renewable resource. Phosphorus Potassium 217, 25–31 (1998).

Macías, F., Pérez-López, R., Cánovas, C. R., Carrero, S. & Cruz-Hernandez, P. Environmental Assessment and Management of Phosphogypsum According to European and United States of America Regulations. Proc. Earth Planetary Sci. 17, 666–669 (2017).

Environmental Protection Agency. Title 40: Protection of Environment. Part 61-National Emission Standards for Hazardous Air Pollutants. (2021).

European Commission. Spain: Commission sends warning over industrial waste case. (Brussels, 2009).

Jupp, A. R., Beijer, S., Narain, G. C., Schipper, W. & Slootweg, J. C. Phosphorus recovery and recycling–closing the loop. Chem. Society Rev. (2021).

Rashad, A. M. Phosphogypsum as a construction material. J. Cleaner Prod. 166, 732–743 (2017).

EPA. TENORM: Fertilizer and Fertilizer Production Wastes, https://www.epa.gov/radiation/tenorm-fertilizer-and-fertilizer-production-wastes#tab-2 (2021).

Burnett, W. C. & Elzerman, A. W. Nuclide migration and the environmental radiochemistry of Florida phosphogypsum. J. Environ. Radioa. 54, 27–51 (2001).

EPA. Mosaic Fertilizer, LLC Settlement, https://www.epa.gov/enforcement/mosaic-fertilizer-llc-settlement (2015).

Center for Biological Diversity. Imminent Failure of Phosphogypsum Stack in Tampa Bay Exposes Phosphate Industry Risks Catastrophic Wastewater Release Highlights Need for Federal Action. 1 (Center for Biological Diversity, Florida, 2021).

Florida Department of Environmental Protection. Piney Point - Frequenty Asked Questions. (Florida, 2021).

Bilal, E. et al. Phosphogypsum circular economy considerations: A critical review from more than 65 storage sites worldwide. J.Cleaner Prod. 414, 137561 (2023).

Pérez-López, R., Nieto, J. M., de la Rosa, J. D. & Bolívar, J. P. Environmental tracers for elucidating the weathering process in a phosphogypsum disposal site: Implications for restoration. J. Hydrol. 529, 1313–1323 (2015).

Husein Malkawi, D. A., Husein Malkawi, A. I. & Bani-Hani, K. A. Slope Stability Analysis for the Phosphogypsum Stockpiles: A Case Study for the Sustainable Management of the Phosphogypsum Stacks in Aqaba Jordan. Sustainability 14, 15763 (2022).

Bouargane, B., Laaboubi, K., Biyoune, M. G., Bakiz, B. & Atbir, A. Effective and innovative procedures to use phosphogypsum waste in different application domains: review of the environmental, economic challenges and life cycle assessment. J. Mater. Cycles Waste Manag. 25, 1288–1308 (2023).

Pliaka, M. & Gaidajis, G. Potential uses of phosphogypsum: A review. J. Environ. Sci. Health, Part A 57, 746–763 (2022).

Yang, X., Salvador, D., Makkonen, H. T. & Pakkanen, L. Phosphogypsum Processing for Rare Earths Recovery¡ªA Review. Nat. Res. 10, 12 (2019).