Abstract

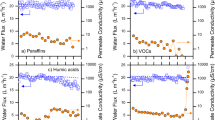

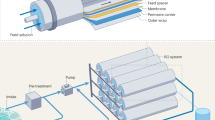

Membrane distillation (MD), an emerging thermal desalination technology for more than five decades, has not been widely commercialized largely due to the use of hydrophobic membranes. Here we introduce fabric distillation (FD), a novel membraneless thermal desalination technology, as a transformative alternative to MD. FD shares similar working principles with MD but distinguishes itself by employing hydrophilic fabrics instead of hydrophobic membranes for vapour–water separation. We outline the requirements of a desirable fabric for FD and show that common hydrophilic cotton and linen are applicable. Subsequently, we propose feasible FD configurations with experimental demonstrations. Through rigorous module-scale analysis, we reveal that FD outperforms MD in thermal desalination performance. Additionally, we elucidate the interaction of the membrane or fabric with ubiquitous substances in saline brines and experimentally demonstrate the promise of FD for practical applications. We conclude by highlighting the advantages of FD over MD, casting doubts on the rationale of MD for desalination.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$99.00 per year

only $8.25 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with the paper. Source data for figures are in Excel format (.xlsx) and also available publicly via https://doi.org/10.6084/m9.figshare.24511759.

Code availability

The codes for modelling MD and FD in different configurations are available publicly via https://github.com/selinacyml/NATWATER-23-0679.

References

Mekonnen, M. M. & Hoekstra, A. Y. Four billion people facing severe water scarcity. Sci. Adv. 2, 2 (2016).

Greve, P. et al. Global assessment of water challenges under uncertainty in water scarcity projections. Nat. Sustain. 1, 486–494 (2018).

Grant, S. B. et al. Taking the ‘waste’ out of ‘wastewater’ for human water security and ecosystem sustainability. Science 337, 681–686 (2012).

Chen, X. & Yip, N. Y. Unlocking high-salinity desalination with cascading osmotically mediated reverse osmosis: energy and operating pressure analysis. Environ. Sci. Technol. 52, 2242–2250 (2018).

Tong, T. & Elimelech, M. The global rise of zero liquid discharge for wastewater management: drivers, technologies, and future directions. Environ. Sci. Technol. 50, 6846–6855 (2016).

Shaffer, D. L. et al. Desalination and reuse of high-salinity shale gas produced water: drivers, technologies, and future directions. Environ. Sci. Technol. 47, 9569–9583 (2013).

Deshmukh, A. et al. Membrane distillation at the water–energy nexus: limits, opportunities, and challenges. Energy Environ. Sci. 11, 1177–1196 (2018).

Kang-Jia Lu, T.-S. C. Membrane Distillation: Membranes, Hybrid Systems, and Pilot Studies, 1st edn (CRC Press, 2019).

Wang, Z. et al. Pathways and challenges for efficient solar-thermal desalination. Sci. Adv. 5, eaax0763 (2019).

Dongare, P. D. et al. Nanophotonics-enabled solar membrane distillation for off-grid water purification. Proc. Natl Acad. Sci. USA 114, 6936–6941 (2017).

Lin, S. Energy efficiency of desalination: fundamental insights from intuitive interpretation. Environ. Sci. Technol. 54, 76–84 (2020).

Gingerich, D. B. & Mauter, M. S. Quantity, quality, and availability of waste heat from United States thermal power generation. Environ. Sci. Technol. 49, 8297–8306 (2015).

Wang, W. et al. Integrated solar-driven PV cooling and seawater desalination with zero liquid discharge. Joule 5, 1873–1887 (2021).

Lawson, K. W. & Lloyd, D. R. Membrane distillation. J. Membr. Sci. 124, 1–25 (1997).

Wang, P. & Chung, T.-S. Recent advances in membrane distillation processes: membrane development, configuration design and application exploring. J. Membr. Sci. 474, 39–56 (2015).

Shabani, Z., Mohammadi, T., Kasiri, N. & Sahebi, S. Development of high-performance thin-film composite FO membrane by tailoring co-deposition of dopamine and m-phenylenediamine for the Caspian seawater desalination. Desalination 527, 115577 (2022).

Alkhudhiri, A., Darwish, N. & Hilal, N. Membrane distillation: a comprehensive review. Desalination 287, 2–18 (2012).

Horseman, T. et al. Wetting, scaling, and fouling in membrane distillation: state-of-the-art insights on fundamental mechanisms and mitigation strategies. ACS ES&T Eng. 1, 117–140 (2021).

Wang, W. et al. Trade-off in membrane distillation with monolithic omniphobic membranes. Nat. Commun. 10, 3220 (2019).

Li, M., Cao, Y. & Zhang, X. Hierarchically structured nanoparticle-free omniphobic membrane for high-performance membrane distillation. Environ. Sci. Technol. 57, 5841–5851 (2023).

Gong, W. et al. Wicking-polarization-induced water cluster size effect on triboelectric evaporation textiles. Adv. Mater. 33, e2007352 (2021).

Miao, D., Huang, Z., Wang, X., Yu, J. & Ding, B. Continuous, spontaneous, and directional water transport in the trilayered fibrous membranes for functional moisture wicking textiles. Small 14, 1801527 (2018).

Wang, J. et al. Pistia-inspired photothermal fabric based on waste carbon fiber for low-cost vapor generation: an industrialization route. Adv. Funct. Mater. 32, 2201922 (2022).

Das, S. S., Pedireddi, V. M., Bandopadhyay, A., Saha, P. & Chakraborty, S. Electrical power generation from wet textile mediated by spontaneous nanoscale evaporation. Nano Lett. 19, 7191–7200 (2019).

Wu, Y. et al. Long-term antibacterial protected cotton fabric coating by controlled release of chlorhexidine gluconate from halloysite nanotubes. RSC Adv. 7, 18917–18925 (2017).

Fan, X. et al. A siphon-based spatial evaporation device for efficient salt-free interfacial steam generation. Desalination 552, 116442 (2023).

Wu, S. et al. Spill-SOS: self-pumping siphon-capillary oil recovery. ACS Nano 13, 13027–13036 (2019).

Schellbach, S. L., Monteiro, S. N. & Drelich, J. W. A novel method for contact angle measurements on natural fibers. Mater. Lett. 164, 599–604 (2016).

Zhu, G., Fang, Y., Zhao, L., Wang, J. & Chen, W. Prediction of structural parameters and air permeability of cotton woven fabric. Text. Res. J. 88, 1650–1659 (2018).

Li, C. et al. Bioinspired inner microstructured tube controlled capillary rise. Proc. Natl Acad. Sci. USA 116, 12704–12709 (2019).

Dong, G., Cha-Umpong, W., Hou, J., Ji, C. & Chen, V. Open-source industrial-scale module simulation: paving the way towards the right configuration choice for membrane distillation. Desalination 464, 48–62 (2019).

Yu, H., Yang, X., Wang, R. & Fane, A. G. Numerical simulation of heat and mass transfer in direct membrane distillation in a hollow fiber module with laminar flow. J. Membr. Sci. 384, 107–116 (2011).

Khalifa, A. E. Water and air gap membrane distillation for water desalination—an experimental comparative study. Sep. Purif. Technol. 141, 276–284 (2015).

Alkhudhiri, A., Darwish, N. & Hilal, N. Produced water treatment: application of air gap membrane distillation. Desalination 309, 46–51 (2013).

Alklaibi, A. M. & Lior, N. Transport analysis of air-gap membrane distillation. J. Membr. Sci. 255, 239–253 (2005).

Ansari, A. et al. Downstream variations of air-gap membrane distillation and comparative study with direct contact membrane distillation: a modelling approach. Desalination 526, 115539 (2022).

Hitsov, I., De Sitter, K., Dotremont, C., Cauwenberg, P. & Nopens, I. Full-scale validated air gap membrane distillation (AGMD) model without calibration parameters. J. Membr. Sci. 533, 309–320 (2017).

Kalla, S., Upadhyaya, S. & Singh, K. Principles and advancements of air gap membrane distillation. Rev. Chem. Eng. 35, 817–859 (2019).

Xu, S. et al. Air-gap diffusion distillation: theory and experiment. Desalination 467, 64–78 (2019).

Alsaadi, A. S. et al. Modeling of air-gap membrane distillation process: a theoretical and experimental study. J. Membr. Sci. 445, 53–65 (2013).

Swaminathan, J. & Lienhard V, J. H. Energy efficiency of sweeping gas membrane distillation desalination cycles. Proceedings of the 22nd National and 11th International ISHMT-ASME Heat and Mass Transfer Conference https://web.mit.edu/lienhard/www/papers/conf/SWAMINATHAN_ISHMT_2013.pdf (2013).

Chen, Y., Feng, D., Lin, S. & Wang, Z. Quantifying the benefits of membranes with ultrahigh vapor permeability for membrane distillation. ACS ES&T Eng. https://doi.org/10.1021/acsestengg.3c00010 (2023).

Noamani, S., Niroomand, S., Rastgar, M., Azhdarzadeh, M. & Sadrzadeh, M. Modeling of air-gap membrane distillation and comparative study with direct contact membrane distillation. Ind. Eng. Chem. Res. 59, 21930–21947 (2020).

Kalla, S., Upadhyaya, S., Singh, K. & Baghel, R. Experimental and mathematical study of air gap membrane distillation for aqueous HCl azeotropic separation. J. Chem. Technol. Biotechnol. 94, 63–78 (2019).

Said, I. A., Chomiak, T., Floyd, J. & Li, Q. Sweeping gas membrane distillation (SGMD) for wastewater treatment, concentration, and desalination: a comprehensive review. Chem. Eng. Process. Process Intensif. 153, 107960 (2020).

Abu-Zeid, M. A. E.-R. et al. A comprehensive review of vacuum membrane distillation technique. Desalination 356, 1–14 (2015).

Lu, K. J., Zuo, J., Chang, J., Kuan, H. N. & Chung, T. S. Omniphobic hollow-fiber membranes for vacuum membrane distillation. Environ. Sci. Technol. 52, 4472–4480 (2018).

Banat, F., Al-Rub, F. A. & Bani-Melhem, K. Desalination by vacuum membrane distillation: sensitivity analysis. Sep. Purif. Technol. 33, 75–87 (2003).

Alklaibi, A. M. & Lior, N. Heat and mass transfer resistance analysis of membrane distillation. J. Membr. Sci. 282, 362–369 (2006).

Rivier, C. A., Garcı́a-Payo, M. C., Marison, I. W. & von Stockar, U. Separation of binary mixtures by thermostatic sweeping gas membrane distillation: I. theory and simulations. J. Membr. Sci. 201, 1–16 (2002).

Tomaszewska, M. in Encyclopedia of Membranes (eds Drioli, E. & Giorno, L.) 33–34 (Springer Berlin Heidelberg, 2016).

Lee, S. & Straub, A. P. Analysis of volatile and semivolatile organic compound transport in membrane distillation modules. ACS ES&T Eng. 2, 1188–1199 (2022).

Rezaei, M. et al. Wetting phenomena in membrane distillation: mechanisms, reversal, and prevention. Water Res. 139, 329–352 (2018).

Li, C. et al. Elucidating the trade-off between membrane wetting resistance and water vapor flux in membrane distillation. Environ. Sci. Technol. 54, 10333–10341 (2020).

Wang, Z., Chen, Y., Sun, X., Duddu, R. & Lin, S. Mechanism of pore wetting in membrane distillation with alcohol vs. surfactant. J. Membr. Sci. 559, 183–195 (2018).

Lu, K.-J., Chen, Y. & Chung, T.-S. Design of omniphobic interfaces for membrane distillation—a review. Water Res. 162, 64–77 (2019).

Tijing, L. D. et al. Fouling and its control in membrane distillation—a review. J. Membr. Sci. 475, 215–244 (2015).

Xu, L.-P. et al. Capillary-driven spontaneous oil/water separation by superwettable twines. Nanoscale 7, 13164–13167 (2015).

Wang, Y. et al. Mussel-inspired design of a self-adhesive agent for durable moisture management and bacterial inhibition on PET fabric. Adv. Mater. 33, 2100140 (2021).

Chen, S., Li, L., Zhao, C. & Zheng, J. Surface hydration: principles and applications toward low-fouling/nonfouling biomaterials. Polymer 51, 5283–5293 (2010).

Ye, Y. et al. Microbubble aeration enhances performance of vacuum membrane distillation desalination by alleviating membrane scaling. Water Res. 149, 588–595 (2019).

Warsinger, D. M. et al. Scaling and fouling in membrane distillation for desalination applications: a review. Desalination 356, 294–313 (2015).

Christie, K. S. S., Yin, Y., Lin, S. & Tong, T. Distinct behaviors between gypsum and silica scaling in membrane distillation. Environ. Sci. Technol. 54, 568–576 (2020).

Tong, T., Wallace, A. F., Zhao, S. & Wang, Z. Mineral scaling in membrane desalination: mechanisms, mitigation strategies, and feasibility of scaling-resistant membranes. J. Membr. Sci. 579, 52–69 (2019).

Su, C. et al. Robust superhydrophobic membrane for membrane distillation with excellent scaling resistance. Environ. Sci. Technol. 53, 11801–11809 (2019).

McBride, S. A., Girard, H.-L. & Varanasi, K. K. Crystal critters: self-ejection of crystals from heated, superhydrophobic surfaces. Sci. Adv. 7, eabe6960 (2021).

Pan, Y. et al. Simple design of a porous solar evaporator for salt-free desalination and rapid evaporation. Environ. Sci. Technol. 56, 11818–11826 (2022).

Karanikola, V., Boo, C., Rolf, J. & Elimelech, M. Engineered slippery surface to mitigate gypsum scaling in membrane distillation for treatment of hypersaline industrial wastewaters. Environ. Sci. Technol. 52, 14362–14370 (2018).

Chen, Y., Lu, K.-J. & Chung, T.-S. An omniphobic slippery membrane with simultaneous anti-wetting and anti-scaling properties for robust membrane distillation. J. Membr. Sci. 595, 117572 (2020).

Bico, J. & Quere, D. Rise of liquids and bubbles in angular capillary tubes. J. Colloid Interface Sci. 247, 162–166 (2002).

Acknowledgements

We thank the financial support from National Key Research Development Program of China (2021YFC3201404).

Author information

Authors and Affiliations

Contributions

Y.C. performed the modelling of MD and FD and wrote the draft. Z.W. and Y.C. designed the experiment. S.Y. carried out the experiments. Z.W. and M.E. conceived the idea, supervised the research and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Water thanks Tiezheng Tong and Xuan Zhang for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–11, Text 1–6 and Tables 1 and 2.

Supplementary Data 1

Data for Supplementary Figs. 3–5.

Source data

Source Data Fig. 1

Data for Figs. 3–5 in the main text.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Yang, S., Wang, Z. et al. Transforming membrane distillation to a membraneless fabric distillation for desalination. Nat Water 2, 52–61 (2024). https://doi.org/10.1038/s44221-023-00174-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44221-023-00174-6