Abstract

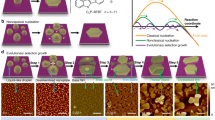

Conventional vapour deposition or epitaxial growth of two-dimensional (2D) materials and heterostructures is conducted in a large chamber in which masses transport from the source to the substrate. Here we report a chamber-free, on-chip approach for growing 2D crystalline structures directly in a nanoscale surface-confined 2D space. The method is based on the surprising discovery of the rapid, long-distance, non-Fickian transport of a uniform layer of atomically thin palladium on a monolayer crystal of tungsten ditelluride at temperatures well below the known melting points of all the materials involved. The nanoconfined growth realizes the controlled formation of a stable 2D crystalline material, Pd7WTe2, when the monolayer seed is either free-standing or fully encapsulated in a van der Waals stack. The approach is generalizable and compatible with nanodevice fabrication, promising to greatly expand the library of 2D materials and their functionalities.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data supporting the findings of this study are available in the main text. Source data are provided with this paper.

References

Geim, A. K. & Grigorieva, I. V. Van der Waals heterostructures. Nature 499, 419–425 (2013).

Novoselov, K. S., Mishchenko, A., Carvalho, A. & Castro Neto, A. H. 2D materials and van der Waals heterostructures. Science 353, aac9439 (2016).

Liu, Y., Huang, Y. & Duan, X. Van der Waals integration before and beyond two-dimensional materials. Nature 567, 323–333 (2019).

Cai, Z., Liu, B., Zou, X. & Cheng, H.-M. Chemical vapor deposition growth and applications of two-dimensional materials and their heterostructures. Chem. Rev. 118, 6091–6133 (2018).

Andrei, E. Y. et al. The marvels of moiré materials. Nat. Rev. Mater. 6, 201–206 (2021).

Zhou, J. et al. A library of atomically thin metal chalcogenides. Nature 556, 355–359 (2018).

Wu, S. et al. Vapor–solid growth of high optical quality MoS2 monolayers with near-unity valley polarization. ACS Nano 7, 2768–2772 (2013).

Huang, C. et al. Lateral heterojunctions within monolayer MoSe2–WSe2 semiconductors. Nat. Mater. 13, 1096–1101 (2014).

Mounet, N. et al. Two-dimensional materials from high-throughput computational exfoliation of experimentally known compounds. Nat. Nanotechnol. 13, 246–252 (2018).

Zavabeti, A. et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science 358, 332–335 (2017).

Zhang, P. et al. Flux-assisted growth of atomically thin materials. Nat. Synth. 1, 864–872 (2022).

Philibert, J.-M. Atom Movements—Diffusion and Mass Transport in Solids (EDP Sciences, 2012).

Endres, M. et al. Transparent Josephson junctions in higher-order topological insulator WTe2 via Pd diffusion. Phys. Rev. Mater. 6, L081201 (2022).

Ohtomo, M. et al. Josephson junctions of Weyl semimetal WTe2 induced by spontaneous nucleation of PdTe superconductor. Appl. Phys. Express 15, 075003 (2022).

Wu, Y. et al. Synthesis of superconducting two-dimensional non-layered PdTe by interfacial reactions. Nat. Synth. 1, 908–914 (2022).

Hummer, G., Rasaiah, J. C. & Noworyta, J. P. Water conduction through the hydrophobic channel of a carbon nanotube. Nature 414, 188–190 (2001).

Secchi, E. et al. Massive radius-dependent flow slippage in carbon nanotubes. Nature 537, 210–213 (2016).

Nair, R. R., Wu, H. A., Jayaram, P. N., Grigorieva, I. V. & Geim, A. K. Unimpeded permeation of water through helium-leak-tight graphene-based membranes. Science 335, 442–444 (2012).

Yang, Q. et al. Capillary condensation under atomic-scale confinement. Nature 588, 250–253 (2020).

Bocquet, L. & Charlaix, E. Nanofluidics, from bulk to interfaces. Chem. Soc. Rev. 39, 1073–1095 (2010).

You, Y. et al. Angstrofluidics: walking to the limit. Annu. Rev. Mater. Res. 52, 189–218 (2022).

Holt, J. K. et al. Fast mass transport through sub-2-nanometer carbon nanotubes. Science 312, 1034–1037 (2006).

Sengupta, S., Nichols, N. S., Del Maestro, A. & Kotov, V. N. Theory of liquid film growth and wetting instabilities on graphene. Phys. Rev. Lett. 120, 236802 (2018).

Grommet, A. B., Feller, M. & Klajn, R. Chemical reactivity under nanoconfinement. Nat. Nanotechnol. 15, 256–271 (2020).

Del Maestro, A., Wexler, C., Vanegas, J. M., Lakoba, T. & Kotov, V. N. A perspective on collective properties of atoms on 2D materials. Adv. Electron. Mater. 8, 2100607 (2022).

Ali, M. N. et al. Large, non-saturating magnetoresistance in WTe2. Nature 514, 205–208 (2014).

Wang, P. et al. Landau quantization and highly mobile fermions in an insulator. Nature 589, 225–229 (2021).

Jia, Y. et al. Evidence for a monolayer excitonic insulator. Nat. Phys. 18, 87–93 (2022).

Allen, G. L., Bayles, R. A., Gile, W. W. & Jesser, W. A. Small particle melting of pure metals. Thin Solid Films 144, 297–308 (1986).

Koma, A. Van der Waals epitaxy for highly lattice-mismatched systems. J. Cryst. Growth 201–202, 236–241 (1999).

Ali, M. N. et al. Correlation of crystal quality and extreme magnetoresistance of WTe2. Europhys. Lett. 110, 67002 (2015).

Podjaski, F. et al. Rational strain engineering in delafossite oxides for highly efficient hydrogen evolution catalysis in acidic media. Nat. Catal. 3, 55–63 (2019).

Acknowledgements

This work was mainly supported by ONR through a Young Investigator Award (N00014-21-1-2804) to S.W. STEM measurements and device fabrication were supported by NSF through a CAREER award (DMR-1942942) to S.W. and the Materials Research Science and Engineering Center (MRSEC) programme of the National Science Foundation (DMR-2011750) through support to L.M.S. and S.W. Device fabrication was partially supported by the AFOSR Young Investigator programme (FA9550-23-1-0140) to S.W. S.W. and L.M.S. acknowledge support from the Eric and Wendy Schmidt Transformative Technology Fund at Princeton. L.M.S. acknowledges support from the Gordon and Betty Moore Foundation (grant no. GBMF9064), the David and Lucile Packard Foundation and the Sloan Foundation. Y.J. acknowledges support from the Princeton Charlotte Elizabeth Procter Fellowship programme. T.S. acknowledges support from the Princeton Physics Dicke Fellowship programme. A.J.U. acknowledges support from the Rothschild Foundation and the Zuckerman Foundation. The authors acknowledge the use of Princeton’s Imaging and Analysis Center, which is partially supported by the Princeton Center for Complex Materials, a National Science Foundation MRSEC programme (DMR-2011750). K.W. and T.T. acknowledge support from the JSPS KAKENHI (grant nos. 20H00354, 21H05233 and 23H02052) and the World Premier International Research Center Initiative, MEXT, Japan.

Author information

Authors and Affiliations

Contributions

Y.J. and S.W. co-discovered the phenomena. Y.J. fabricated all the devices, performed optical and transport measurements, and analysed data, assisted by Y.T., G.Y., T.S., P.W., A.J.U.-N. and M.O. and supervised by S.W. Y.J. and F.Y. co-developed the fabrication and STEM measurement procedures, supervised by L.M.S. and S.W., in collaboration with G.C. and N.Y. R.S. and L.M.S. grew and characterized bulk WTe2 crystals. K.W. and T.T. provided hBN crystals. S.W. and Y.J. interpreted the results and wrote the paper with input from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks the anonymous reviewers for their contribution to the peer review of this work. Primary Handling Editor: Peter Seavill, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Images of devices and AFM characterization of D1 after Pd transport.

a. Optical images of Pd7WTe2 devices D1-D4 used in this study are summarized here. Schematic diagrams of the structure of each device (before growth) are sketched next to the image. b, The AFM height image, with Pd7WTe2 crystal outlined in purple. The Pd islands covered by WTe2 become narrower and thinner, while no visible change is seen for the separated Pd islands. c, A zoomed-in image of a Pd island, highlighted by the yellow dash line in b. d, Height profiles of the Pd islands along the indicated lines in b.

Extended Data Fig. 2 Optical and AFM characterizations of D2.

a, An optical image of D2 after Pd transport. b, An AFM height image of D2 with Pd7WTe2 outlined in purple dash lines. The locations of height profiles measured in c,d are indicated by solid lines. c, The height profile of monolayer WTe2 and Pd7WTe2. d, The height profile of bilayer WTe2 and bilayer-seeded Pd7WTe2. The height of the bilayer-seeded Pd7WTe2 is twice that of the monolayer-seeded Pd7WTe2.

Extended Data Fig. 3 Additional EDX analyses and elemental mappings on D4.

a,b, The HAADF STEM images and corresponding EDX elemental mappings on monolayer WTe2 and Pd7WTe2 at two additional locations on D4. The extracted atomic fractions of selected areas are summarized in the tables. The Pd:W:Te atomic ratios in Pd propagated regions are always found to be approximately 7:1:2.

Extended Data Fig. 4 Additional EDX analyses and elemental mappings on the cross-sections of D3.

a,b, The bright field images and corresponding EDX elemental mappings on another 2 locations of D3 with Pd7WTe2 synthesized from monolayer WTe2. The Pd:W:Te atomic ratio is found to be close to 7:1:2. The small deviations may be the result of insufficient signal intensity in the cross-section measurements.

Extended Data Fig. 5 Bulk Pd crystal versus the proposed crystal structure of Pd7WTe2.

a, An FCC bulk Pd crystal viewed along the [111] direction. Pd atoms from different layers are colored in different shades. The plan-view of such structure exhibits six-fold symmetry, as is shown by the simulated diffraction pattern (right panel). b, Cross-section of 7-layers of Pd atoms organized in the structure corresponding to a. c, The Pd crystal viewed along the [110] direction, which consists of alternatively stacked (A-B-A) rectangular lattices. Again, Pd atoms from different layers are shaded differently for a better visualization. The resulting plan-view lacks six-fold symmetry. The distorted hexagon is clearly seen in the simulated diffraction pattern (right panel). d, Cross-section of 7-layers of Pd atoms organized in the structure corresponding to c. e,f, The plan-view (top panel) and cross-section (bottom panel) of our proposed crystal structure for Pd7WTe2, consisting of 10 layers of hexagonal lattices, with the stacking order and atom species indicated. The half-colored atoms indicate that these sites are only filled 50 %. The simulated plan-view diffraction pattern (middle panel) captures characteristic features of experimental results.

Extended Data Fig. 6 Uniform thickness of monolayer seeded Pd7WTe2.

a, An optical image of the target region of device D2, focusing on the monolayer WTe2 and Pd7WTe2 areas. STEM measurements were performed along the cross-section cut indicated by the yellow dashed line. Spots S1, S2 and S3 are estimated locations under examination in b-e. b, A HAADF STEM image captured at spot S1, which interfaces monolayer WTe2 and Pd7WTe2. The extracted intensity along the colored line-cuts is shown in f. c, The zoomed-out STEM image at spot S1, showing the uniform thickness on the scale of ~ 100 nm. d, A HAADF STEM image acquired at the interface between monolayer Pd7WTe2 and WTe2 at spot S2. e, A HAADF STEM image obtained at spot S3. f, The extracted intensity from S1 along the line-cuts in b, indicated by the vertical lines. The signal from hBN layer structure is indicated by arrows. g, The extracted intensity from S1-S3 along line-cuts indicated by the solid lines in b, d & e. The data confirms that the thickness of Pd7WTe2 is uniform on the same monolayer seed, even the Pd comes from separate sources.

Extended Data Fig. 7 The locked orientation of Pd7WTe2 lattices and monolayer WTe2.

a, The FFT pattern and atomic-resolution image (inset) of monolayer WTe2 crystal. b, The FFT pattern and atomic-resolution image (inset) of monolayer seeded Pd7WTe2. c, An FFT pattern of the interfacing region (S1, Fig. 3b) including both monolayer WTe2 and Pd7WTe2. The resulting FFT pattern exhibits characteristic features of both materials, highlighted separately by dashed lines (red for WTe2, purple for Pd7WTe2). It is noted that their FFT patterns are aligned with specific angles and symmetric about the indicated symmetric axis. d, STEM images of another three additional spots, S2-S4, selected from three separated TEM grid holes. The locations of the three spots are indicated by white dashed boxes. e–g, The FFT patterns of S2-S4, which exhibit same orientation relation between monolayer WTe2 and Pd7WTe2 lattice. The data shows that the Pd7WTe2 lattice orientation is determined by the seed monolayer WTe2.

Extended Data Fig. 8 Pd transport on monolayer and bilayer WTe2.

a, Optical image of a WTe2 flake with both monolayer and bilayer regions. b, Optical image of device D2 as fabricated, where monolayer and bilayer WTe2 are in contact with separate Pd sources. c, Optical image of D2 after being held at 170 °C for 10 minutes, where Pd spreads widely on bilayer WTe2 while not noticeable on monolayer WTe2. d, Optical image of D2 after being held at 250 °C for 120 minutes, showing Pd transport from monolayer WTe2 to bilayer WTe2, but not vice versa.

Extended Data Fig. 9 STEM characterization of a bilayer-seeded Pd7WTe2.

a, A zoom-in optical image of device D2, focusing on the bilayer WTe2 and bilayer-seeded Pd7WTe2 areas. STEM measurements were performed along the cross-section line (yellow line) and images were obtained at estimated spots S1 and S2, as indicated. b, HAADF STEM cross-section image of bilayer WTe2 at location S1, where the vdW gap is clearly observed. c, HAADF STEM cross-section image of bilayer-seeded Pd7WTe2 at location S2. The thickness is measured to be 2.5 nm, double the thickness of monolayer-seeded Pd7WTe2 (~ 1.2 nm). d, Atomic fractions for bilayer WTe2 and bilayer-seeded Pd7WTe2 from EDX analysis. We did not obtain atomic resolution in the STEM images of the bilayer-seeded Pd7WTe2 region, which we suspect might be a result of in-plane domain inhomogeneity. Future improvements are necessary for obtaining an image with atomic resolution.

Extended Data Fig. 10 In-plane lattice structure and atomic fraction of bilayer-seeded Pd7WTe2.

a, An atomic-resolution STEM plan-view image of bilayer-seeded Pd7WTe2, which displays similar hexagonal lattice as monolayer seeded Pd7WTe2. The FFT pattern of such lattice is shown in the inset. b–d, Selected lattice structures observed in other locations of bilayer-seeded Pd7WTe2, indicating the presence of non-uniform domain structures. e, Elemental mappings and atomic fraction of bilayer-seeded Pd7WTe2.

Supplementary information

Supplementary Video 1

This video records the anomalous Pd transport on monolayer WTe2 observed in device D1, corresponding to the illustration in Fig. 1e. Pd propagation on WTe2 is indicated by the expansion of the optically darker region. Eventually, Pd covers nearly the entire WTe2 monolayer and converts the material to a new 2D crystalline structure with formula Pd7WTe2.

Source data

Source Data Fig. 1

Source data for Fig. 1e,h,i.

Source Data Fig. 2

Source data for Fig. 2c.

Source Data Fig. 3

Source data for Fig. 3f.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jia, Y., Yuan, F., Cheng, G. et al. Surface-confined two-dimensional mass transport and crystal growth on monolayer materials. Nat. Synth 3, 386–393 (2024). https://doi.org/10.1038/s44160-023-00442-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44160-023-00442-z